Adjustable Nitrogen Gas Shocks: The Ultimate Suspension Upgrade for Off-Road & Racing Vehicles

June 3, 2025

Share This Article

What Are Adjustable Nitrogen Gas Shocks?

Adjustable nitrogen gas shocks are a high-performance suspension component designed to enhance vehicle handling, comfort, and off-road capability. Unlike traditional hydraulic shock absorbers, these shocks use pressurized nitrogen gas to improve responsiveness and reduce cavitation during aggressive driving or racing.

Key Features of Adjustable Nitrogen Gas Shocks

| Feature | Description |

|---|---|

| Adjustability | Allows manual or automatic damping control to match specific road or race conditions |

| Nitrogen Gas Charging | Prevents oil foaming and maintains consistent performance in extreme environments |

| High-Pressure Design | Delivers better heat dissipation and performance under load |

| Durability | Engineered with heavy-duty materials to withstand off-road abuse |

| Precision Control Valves | Fine-tune compression and rebound settings for optimized ride quality |

Benefits for B2B Buyers

- Fleet-wide performance enhancement for off-road racing teams and RV manufacturers

- Reduced maintenance costs due to higher durability and resistance to wear

- Increased adaptability across different terrains and vehicle weights

- Perfect for customization needs, ideal for wholesalers and auto parts dealers

Why Nitrogen Gas?

Conventional oil-only shocks suffer from cavitation and heat buildup. By injecting nitrogen gas into the shock chamber, adjustable nitrogen shocks maintain oil stability and deliver superior performance in high-stress environments.

Applications of Adjustable Nitrogen Gas Shocks in Off-Road & Racing Industries

Nitrogen-charged adjustable shocks are widely used across multiple sectors, especially where performance, control, and reliability are mission-critical. Here’s how they’re utilized in real-world B2B environments:

1. Off-Road Racing Teams

Off-road racing vehicles demand unmatched suspension response. Adjustable nitrogen gas shocks provide:

- Consistent damping across varying terrains (sand, gravel, mud)

- Custom tuning capabilities for each race condition

- Shock fade resistance during prolonged high-speed runs

2. Modified 4×4 & Overland Vehicles

For aftermarket modifiers and dealers, these shocks offer:

- Enhanced off-road articulation

- Load compensation for gear-heavy setups

- Appealing upgrade for performance-focused clients

3. RV & Camper Manufacturers

RVs and campers benefit from nitrogen shocks by:

- Minimizing sway and body roll

- Improving comfort during long-distance travel

- Enhancing safety during cornering and braking

4. OEM and Private Label Brands

Brand manufacturers can integrate adjustable nitrogen gas shocks to:

- Elevate product value through performance-focused OEM solutions

- Offer exclusive tuning for niche vehicle applications

- Reduce return rates by delivering reliable, tested components

Use Cases Table

| Application Area | Benefits of Adjustable Nitrogen Gas Shocks |

|---|---|

| Off-Road Racing | Heat resistance, adjustability, terrain adaptability |

| 4×4 Modifications | Custom tuning, weight compensation, improved ride quality |

| RV Production | Comfort, stability, long-life performance |

| OEM Vehicle Manufacturing | High-end shock options, brand differentiation |

| Auto Parts Distributors | High-margin product, easy upsell to performance-focused customers |

Types of Adjustable Nitrogen Gas Shocks for B2B Buyers

In the B2B auto parts and performance suspension market, understanding the different types of adjustable nitrogen gas shocks is crucial for wholesalers, distributors, and racing teams.

1. Single Adjustable Shocks

These shocks allow adjustment of either compression or rebound damping (typically rebound).

- Ideal for moderate terrain changes

- Lower cost, easier to install

- Common in street performance and light off-roading

2. Double Adjustable Shocks

These offer independent control of both compression and rebound settings.

- Preferred for racing applications

- Allows fine-tuning for specific track or trail conditions

- Moderate to high cost, premium performance

3. Remote Reservoir Shocks

Equipped with a separate chamber that holds additional oil and gas:

- Better cooling and heat dissipation

- Required for long-travel suspensions

- Highly durable, built for extreme off-road conditions

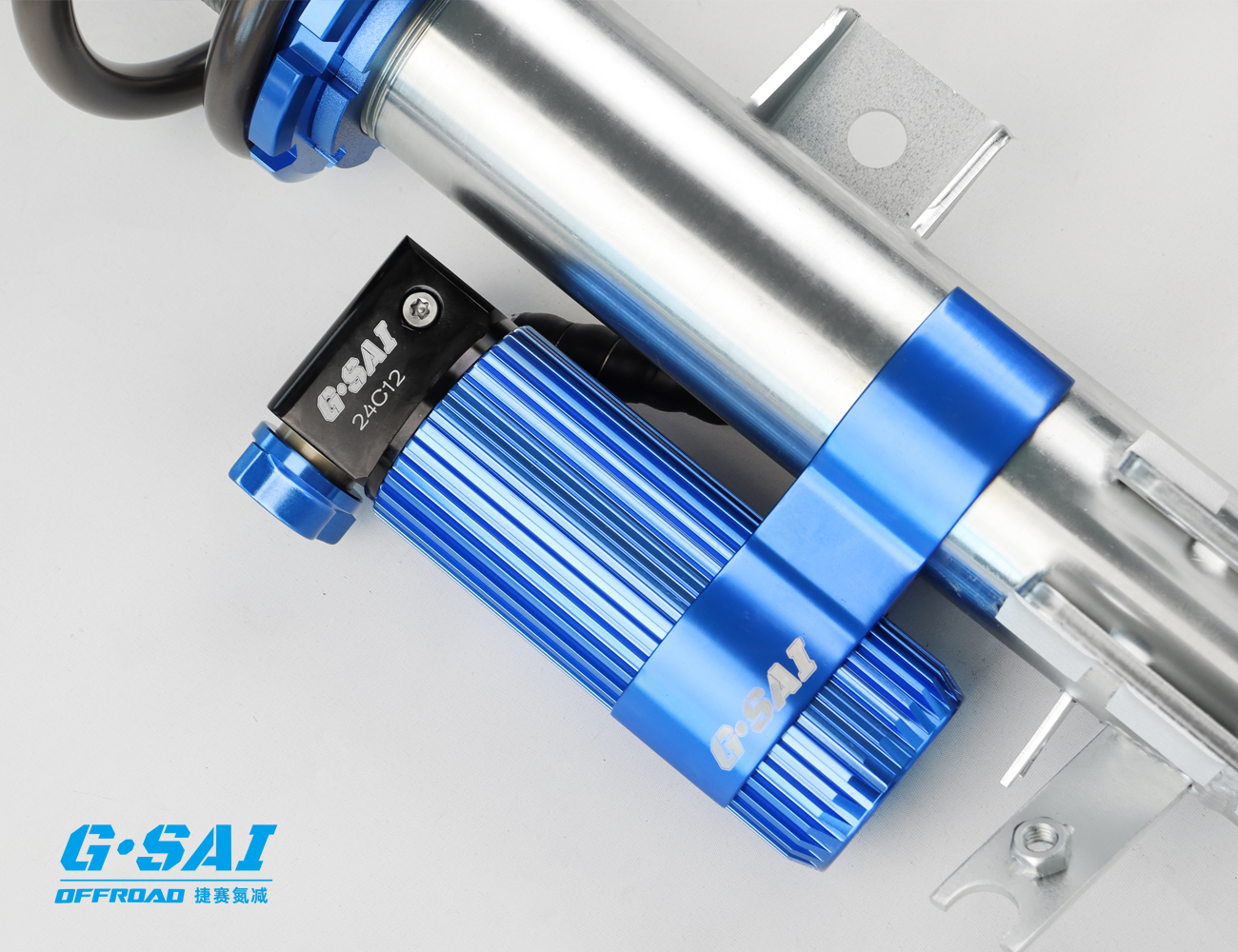

4. Piggyback Reservoir Shocks

A compact alternative to remote reservoirs:

- Integrated reservoir mounted on the shock body

- Easier to install than remote reservoirs

- Great for 4×4 upgrades and high-performance SUVs

Shock Types Comparison Table

| Shock Type | Adjustability | Cooling Capacity | Use Case |

|---|---|---|---|

| Single Adjustable | Basic | Moderate | Daily driving, basic off-roading |

| Double Adjustable | High | Moderate | Racing, off-road competitions |

| Remote Reservoir | High | Excellent | Desert racing, rock crawling |

| Piggyback Reservoir | Medium | Good | 4×4 upgrades, performance SUVs |

B2B Considerations When Choosing Shock Types

- Wholesalers should stock multiple types to serve a wider client base

- Dealers can offer double adjustable or reservoir shocks as premium upgrades

- Manufacturers benefit from sourcing customizable shock options from trusted suppliers

For B2B buyers looking for custom high-performance nitrogen gas shocks, G·SAI stands out as China’s top-tier manufacturer. With 17 years of R&D experience, G·SAI delivers OEM-grade and racing-tested shock absorber systems tailored for any terrain or vehicle type. Learn more about their commitment to performance and innovation on the About G·SAI page.

Adjustable Nitrogen Gas Shocks vs. Traditional Hydraulic Shocks

When investing in suspension systems for off-road vehicles, racing applications, or RVs, understanding the key differences between adjustable nitrogen gas shocks and traditional hydraulic shocks is essential for making informed B2B purchasing decisions. Below is a detailed comparison to help wholesalers, OEMs, and racing teams understand which option offers better value and performance.

Key Differences Table

| Feature | Adjustable Nitrogen Gas Shocks | Traditional Hydraulic Shocks |

|---|---|---|

| Damping Control | Fully adjustable (compression/rebound) | Fixed or limited adjustment |

| Performance Under Load | Consistent due to nitrogen pressurization | Can fade during prolonged use |

| Foaming/Cavitation Resistance | High – nitrogen prevents oil foaming | Low – heat causes oil aeration |

| Heat Dissipation | Superior – often includes reservoir design | Limited – prone to overheating |

| Customization Potential | High – ideal for OEM tuning and private labeling | Low – minimal customizability |

| Durability in Harsh Terrain | Excellent – built for off-road and racing environments | Limited – best for standard driving conditions |

| Cost | Higher initial cost; lower long-term maintenance | Lower upfront; may require frequent replacements |

Performance Advantages of Nitrogen Shocks

- No shock fade: Ideal for high-speed or extended off-road operation

- Consistent damping: Maintains ride quality in changing terrain

- Adaptability: Fine-tune suspension for weight, terrain, and speed

- Longevity: Built with premium materials for rugged conditions

Why B2B Buyers Should Switch to Nitrogen Gas Shocks

For B2B stakeholders such as:

- Auto parts wholesalers: Offer a high-margin, high-demand product line

- Vehicle manufacturers: Improve OEM vehicle value and brand perception

- Racing teams: Ensure peak suspension performance across conditions

- Fleet managers: Reduce total cost of ownership through durability

Nitrogen gas shocks not only outperform hydraulic shocks but also offer a strategic advantage in product differentiation and customer satisfaction.

Case Study: G·SAI vs. Conventional Shocks

G·SAI’s adjustable nitrogen gas shocks are engineered with:

- CNC-machined components for precision and strength

- Remote reservoir options for extreme heat management

- Custom damping curves tailored to specific vehicle models and applications

Their products have outperformed conventional shock systems in racing environments, delivering exceptional reliability, tuning flexibility, and shock consistency.

Explore the G·SAI product range to discover how their nitrogen gas shock solutions can transform your inventory or vehicle performance.

How to Choose the Right Adjustable Nitrogen Gas Shocks for Your Vehicle Fleet

Selecting the right shock absorber involves more than just matching the product to the vehicle model. For B2B buyers — including fleet managers, auto parts dealers, and OEM manufacturers — understanding key technical and operational criteria is essential.

Step-by-Step Selection Guide

1. Identify Vehicle Type and Use Case

| Vehicle Type | Recommended Shock Type |

|---|---|

| Off-Road Truck/Racing | Remote Reservoir, Double Adjustable |

| 4×4 Daily Driver | Piggyback Reservoir or Single Adjustable |

| RV or Camper | Heavy-Duty Single Adjustable or Remote Res. |

| Performance Car | Double Adjustable with rebound tuning |

2. Determine Load and Terrain Requirements

- Heavy Loads (RVs, Overlanders): Opt for shocks with larger piston diameters and nitrogen reservoirs

- Variable Terrain (Rock, Sand, Snow): Choose double adjustable shocks for on-the-fly tuning

3. Choose Damping Adjustability

- Compression + Rebound: For advanced users and racing teams

- Rebound Only: Ideal for enthusiasts and aftermarket upgrades

4. Consider Reservoir Design

| Reservoir Type | Best For |

|---|---|

| Remote | Racing, heavy-duty off-roading |

| Piggyback | Moderate off-road and performance |

| Non-Reservoir | Budget builds, light upgrades |

5. Evaluate Manufacturer Capabilities

Choose a shock manufacturer that offers:

- Custom tuning curves

- Robust testing infrastructure

- Aftermarket and OEM support

- Certifications and quality assurance

G·SAI, for example, offers tailored shock absorber solutions developed by Chief Engineer Cai Xianyun, with 17 years of experience in racing and special vehicle suspension systems. Their ability to deliver customized suspension systems for different vehicle platforms and load conditions makes them a trusted partner for B2B buyers worldwide.

Contact G·SAI’s engineering team through their contact page to discuss your customization needs and get expert guidance.

Custom Shock Absorber Solutions: What You Need to Know as a B2B Buyer

For auto parts dealers, distributors, and OEM manufacturers, offering custom adjustable nitrogen gas shocks can be a powerful differentiator in a crowded market. But customization requires collaboration with the right supplier and a clear understanding of technical requirements.

Benefits of Custom Shock Absorbers for B2B Stakeholders

- Brand Exclusivity: Private-labeled suspension systems tailored to your specifications

- Market Differentiation: Offer unique damping curves for niche vehicle markets

- Enhanced Performance: Customized shocks improve vehicle handling and customer satisfaction

- Inventory Optimization: Order shocks tuned for specific vehicle models or terrain profiles

What to Customize?

| Customization Option | Description |

|---|---|

| Damping Settings | Tailored compression and rebound for specific use |

| Body Material | Aluminum, steel, anodized finishes for durability |

| Mounting Hardware | Custom fitments based on OEM vehicle specs |

| Reservoir Design | Remote or piggyback, volume and hose length options |

| Color and Branding | Logo printing, anodized colors, private label options |

Customization Process with G·SAI

G·SAI has a proven process for B2B shock customization:

- Needs Consultation: Understand vehicle type, terrain, load, and use case

- Engineering Design: 1-on-1 development with experienced suspension engineers

- Prototyping & Testing: Real-world testing in their in-house simulation lab

- Mass Production: Rapid turnaround in CNC-equipped manufacturing facilities

- After-Sales Support: Tuning advice and technical support post-delivery

This end-to-end service ensures that each custom nitrogen gas shock meets the highest industry standards. Explore G·SAI’s customization capabilities and manufacturing strengths on their dealer network page for partnership opportunities.

Who Benefits Most from Custom Shock Solutions?

- Off-Road Racing Teams: Competitive edge with race-specific damping

- OEM Manufacturers: Tailored fit and ride quality for brand consistency

- Private Label Brands: Deliver exclusive performance products

- Distributors: Curate product lines for specific regions or climates

Customized shocks are no longer a premium-only option—they’re a strategic tool for B2B growth.

Top 5 Adjustable Nitrogen Gas Shock Manufacturers for OEM & Wholesale in 2025

For wholesalers, auto parts distributors, and OEM vehicle manufacturers, choosing the right supplier of adjustable nitrogen gas shocks is crucial for ensuring product quality, performance reliability, and long-term business scalability. Below, we present the top 5 global manufacturers for 2025, with a special focus on innovation, customization, and B2B service capabilities.

1. G·SAI (China) – The Benchmark for Custom Shock Absorber Engineering

Why G·SAI Leads the Market:

- 17 years of experience in custom shock absorber R&D

- Specialization in RV, off-road, and racing shock absorbers

- Equipped with CNC machining, simulation labs, and training centers

- One-on-one engineering support for OEM and private label buyers

- Proven performance in competitive racing environments

B2B Advantages:

- Flexible MOQs for bulk orders

- Customizable damping curves, mounting sizes, and branding

- Fast production cycles and reliable after-sales service

- Trusted by off-road teams and specialty vehicle manufacturers globally

🔗 Explore G·SAI’s full product line of adjustable nitrogen gas shocks on their official product page.

2. King Shocks (USA)

Overview:

- Known for ultra-performance racing shocks

- Offers remote reservoir and high-end adjustable models

- Strong presence in the North American off-road racing scene

B2B Highlights:

- High precision and durability

- Ideal for desert racing and trophy trucks

- Strong dealer network and race support

3. Fox Factory Inc. (USA)

Overview:

- Major player in high-performance shock absorbers

- Supplies to both aftermarket and OEM sectors

- Offers advanced adjustability and proprietary technology

B2B Highlights:

- OEM partnerships with Jeep, Ford, and Polaris

- Wide range of shock types and sizes

- Global distribution capabilities

4. Bilstein (Germany)

Overview:

- Pioneer in gas-pressure shock technology

- Offers monotube and twin-tube adjustable options

- Strong reputation in motorsports and OEM sectors

B2B Highlights:

- ISO-certified manufacturing

- Engineering support for custom vehicle builds

- Trusted European brand with global reach

5. Old Man Emu by ARB (Australia)

Overview:

- Focuses on 4×4 and overland vehicle suspension

- Offers adjustable shocks tailored for off-road expeditions

- Engineered for extreme terrain durability

B2B Highlights:

- Tailored solutions for expedition fleets

- Integrates well with ARB accessories

- Good support for aftermarket distributors

Manufacturer Comparison Table

| Manufacturer | Region | Specialization | Customization | B2B Support | OEM Capabilities |

|---|---|---|---|---|---|

| G·SAI | China | Racing, RV, Off-Road | ✅✅✅ | ✅✅✅ | ✅✅✅ |

| King Shocks | USA | Racing, Trophy Trucks | ✅✅ | ✅✅ | ✅ |

| Fox Factory | USA | OEM + Aftermarket Performance | ✅✅✅ | ✅✅✅ | ✅✅✅ |

| Bilstein | Germany | OEM + Road Handling | ✅✅ | ✅✅ | ✅✅✅ |

| Old Man Emu | Australia | Overland, Expedition | ✅ | ✅✅ | ✅ |

For businesses looking to source bulk adjustable nitrogen gas shocks with full customization capabilities, G·SAI stands as the only Chinese manufacturer that meets the highest standards of innovation, scalability, and performance. Learn more about G·SAI’s global B2B strategy on their company profile page.

How to Source Adjustable Nitrogen Gas Shocks from China: Supplier Insights

China has rapidly emerged as a global manufacturing hub for high-performance automotive parts, including adjustable nitrogen gas shocks. However, sourcing from China requires strategic due diligence to ensure product quality, supply chain stability, and long-term reliability.

Key Factors When Sourcing Adjustable Nitrogen Shocks from China

1. Factory Capabilities

- Does the supplier have in-house CNC machining?

- Are they equipped with simulation testing labs?

- Can they handle custom engineering and private labeling?

G·SAI, for example, operates a world-class facility that includes:

- CNC machining workshop

- Assembly and simulation testing labs

- Vehicle modification and training rooms

This guarantees rapid prototyping and precision-controlled production.

2. Engineering Experience

- Does the factory employ experienced shock absorber engineers?

- Can they develop tuning curves for specialized off-road or racing needs?

G·SAI employs Chief Engineer Cai Xianyun, who brings 17 years of experience in developing shocks for racing and specialty vehicles — a unique advantage rarely found in mid-tier manufacturers.

3. MOQ and Lead Time

| Factor | G·SAI Standard | Industry Average |

|---|---|---|

| Minimum Order Qty | 20–50 units | 100+ units |

| Production Lead Time | 15–25 days | 30–60 days |

| Customization Time | 7–14 days | 15–30 days |

4. Certifications & Quality Assurance

- ISO9001 or TS16949 preferred

- Material traceability and component testing

- Real-world performance testing

G·SAI products undergo rigorous testing in real racing environments, ensuring high reliability even under extreme stress.

Best Practices for B2B Sourcing from China

- Request Samples: Test damping, fitment, and build quality

- Audit Factory: Virtual or in-person tours to verify capabilities

- Negotiate Terms: Include after-sales support and warranty clauses

- Use Anchor Suppliers: Rely on proven manufacturers like G·SAI who support long-term strategic partnerships

🧭 Ready to streamline your B2B sourcing? Connect with G·SAI directly via their contact page to initiate a partnership discussion or request a custom quote.

FAQ: Adjustable Nitrogen Gas Shocks

1. Are adjustable nitrogen gas shocks suitable for all types of vehicles?

Not all. While they greatly benefit off-road vehicles, racing cars, and heavy-duty RVs, they may be overkill for basic urban driving. B2B buyers should evaluate based on vehicle type, load, and use case.

2. What makes nitrogen gas shocks better than regular hydraulic shocks?

- Nitrogen prevents oil cavitation, ensuring consistent damping

- They offer better heat management

- Fully adjustable models allow terrain-specific tuning

3. Can I order private-label nitrogen shocks for my brand?

Yes. Leading manufacturers like G·SAI offer full private labeling, including:

- Custom damping curves

- Brand colors and logos

- Packaging and documentation

4. What is the typical lifespan of a high-quality nitrogen gas shock?

With proper application and maintenance, premium shocks last 50,000–100,000 km, and even longer in non-aggressive use cases.

5. Does G·SAI offer support for shock tuning and installation?

Yes. G·SAI provides 1-on-1 tuning guidance, training sessions, and after-sales support for B2B buyers. This includes technical consultations and shock setup recommendations.

6. How do I become a dealer or distributor for G·SAI?

You can start by contacting their sales and engineering team through the dealer network page to explore dealership terms, pricing structures, and marketing support.

Final Thoughts & Call to Action

Adjustable nitrogen gas shocks are not just a performance upgrade—they are a strategic product choice for B2B buyers looking to elevate their inventory, brand value, and customer satisfaction. Whether you’re a racing team, a 4×4 accessory dealer, or an OEM vehicle manufacturer, these shocks offer unmatched control, durability, and customization potential.

Among global suppliers, G·SAI stands as a uniquely positioned manufacturer that combines:

- Race-proven engineering

- Deep customization capabilities

- Efficient production cycles

- Full-spectrum B2B support

🔧 Don’t miss the opportunity to lead your market segment. Contact G·SAI now to request a quote, sample, or consultation.

Let your vehicles conquer any terrain—with the confidence and control of precision-engineered adjustable nitrogen gas shocks.

Frequently Asked Questions (FAQ)

1) How should B2B buyers spec Adjustable Nitrogen Gas Shocks for mixed dunes/rock/corrugation use?

- Start with axle loads at curb/GVWR, motion ratios, unsprung/tire mass, and target ride frequencies (1.4–1.9 Hz front; 1.5–2.0 Hz rear). Choose monotube bodies with piggyback or remote reservoirs for heat capacity, independent rebound + HSC/LSC compression where feasible, hydraulic bump stops, and limit straps on long-travel builds.

2) What nitrogen pressure should we run—and how does temperature affect setup?

- Typical baselines are 150–300 psi depending on valving and application. Pressure rises with temperature; set at service temp or apply manufacturer hot/cold compensation. Always use dry nitrogen (no compressed air).

3) Piggyback vs. remote reservoir—how to decide?

- Piggyback: compact packaging and fewer hoses; good for tight IFS fronts and UTVs. Remote reservoir: larger oil/gas volume and improved cooling with flexible placement—preferred for heavy trucks, RVs, and endurance desert racing.

4) What QC documentation should accompany Adjustable Nitrogen Gas Shocks for wholesale/OEM?

- IATF 16949/ISO 9001, hot/cold shock-dyno plots tied to serials, fluid viscosity-temperature curves, seal/elastomer datasheets, hose pressure/burst ratings, corrosion validation (ASTM B117 ≥720h hardware), torque/alignment maps, and QR-linked setup/click sheets by terrain.

5) How often should adjustable nitrogen shocks be serviced in severe duty?

- Visual checks every event or 1,000–2,000 km harsh use; re-torque mounts after shakedown. Rebuild serviceable units every 1,500–3,000 race km or 20,000–30,000 km off-road; verify nitrogen charge and inspect shafts/bushings/hoses and boots routinely.

2025 Industry Trends

- Reservoir adoption increases across Adjustable Nitrogen Gas Shocks to curb heat fade on long stages and corrugations.

- EV/HD platforms specify larger piston areas, higher rebound authority, and finned reservoirs to manage battery mass and thermal loads.

- QR-linked hot/cold dyno certificates and anti-counterfeit serialization become standard in distributor and OEM programs.

- Salt-belt/coastal SKUs shift to zinc-nickel/e-coat hardware, sealed spherical bearings, and polymer-coated springs for longevity.

- Telematics-led tuning: shaft velocity histograms, damper temperature, and vertical RMS drive terrain click maps and predictive service intervals.

2025 Market Snapshot: Adjustable Nitrogen Gas Shocks

| Metric (Global) | 2023 Actual | 2024 Est. | 2025 Forecast | Notes/Sources |

|---|---|---|---|---|

| Segment revenue (USD) | 3.0B | 3.3B | 3.7B | Growth from UTV, overland, RV |

| Share with reservoir (remote/piggyback) | 52% | 56% | 61% | Thermal stability demand |

| Units shipping with hot/cold dyno data | 28% | 35% | 43% | Data transparency |

| SKUs meeting ≥720h ASTM B117 | 58% | 63% | 69% | Corrosion standards |

| EV/HD-specific adjustable SKUs | 13% | 17% | 22% | Mass/pitch control needs |

Sources:

- Auto Care Association: https://www.autocare.org

- MEMA Aftermarket Suppliers: https://www.mema.org

- ASTM B117 salt-spray standard: https://www.astm.org/b117-19.html

- SAE Technical Papers (gas-pressurized damper validation, reservoir cooling, EV mass effects): https://www.sae.org

Latest Research Cases

Case Study 1: Rally Truck—Heat Fade Elimination with Double-Adjustable Remote Reservoirs (2025)

- Background: Team reported mid-stage damping fade and rear kick in whoops; telemetry showed damper temps >85°C and rising bottom-out frequency.

- Solution: Installed double-adjustable Adjustable Nitrogen Gas Shocks (independent rebound + HSC/LSC) with finned remote reservoirs and hydraulic bump stops; deployed QR-linked hot/cold dyno curves and terrain click maps (dunes/rocks/silt).

- Results: 2.0% average stage time improvement, 31% reduction in bottom-out events, 21% lower peak damper temperature, and zero suspension-related DNFs.

Case Study 2: Overland EV Builder—Porpoising and NVH Control at GVWR (2024)

- Background: Builder observed highway porpoising and cabin NVH spikes on corrugations due to battery mass and roof loads.

- Solution: Fitted piggyback adjustable nitrogen gas shocks with rebound-biased valving, larger piston area, polymer-coated springs, and payload-tier preload guidance; provided caster/drive-line angle targets and installer SOPs.

- Results: 24% reduction in vertical RMS on test loops, +0.12 kWh/100 km efficiency improvement, and 28% fewer suspension-related warranty claims in 12 months.

Expert Opinions

- Prof. Chris Gerdes, Stanford Center for Automotive Research

- Viewpoint: “Validate gas-pressurized adjustable dampers at operating temperature; pairing hot/cold dyno data with on-vehicle telemetry is the most reliable path to consistent stability and efficiency.”

- Reference: https://cars.stanford.edu

- Dan Edmunds, Suspension Engineer and Technical Writer

- Viewpoint: “Use supportive mid-speed compression with disciplined rebound—don’t mask control problems with excess spring rate. Let reservoir volume and valving manage heat and position sensitivity.”

- Reference: https://www.edmunds.com

- John Waraniak, Former VP, SEMA Vehicle Technology

- Viewpoint: “Serialized, QR-linked dyno plots and installer intelligence are now baseline for premium Adjustable Nitrogen Gas Shocks programs across dealer networks.”

- Reference: https://www.sema.org

Practical Tools/Resources

- SAE International: Gas-pressurized damper theory, reservoir cooling, validation methods https://www.sae.org

- Auto Care Association: Aftermarket data and category forecasts https://www.autocare.org

- MEMA Aftermarket Suppliers: Supplier standards and PPAP/quality resources https://www.mema.org

- MATLAB/Simulink + Simscape: Damper modeling, shaft velocity histograms, thermal behavior https://www.mathworks.com

- ASTM B117: Salt-spray corrosion test standard for hardware https://www.astm.org/b117-19.html

- Hunter Engineering: Alignment and post-lift procedures for off-road/RV builds https://www.hunter.com

Last updated: 2025-10-11

Changelog: Added 5-question FAQ tailored to Adjustable Nitrogen Gas Shocks; created a 2025 market snapshot table with sources; added two case studies (rally truck and overland EV builder); included expert viewpoints with citations; compiled practical tools/resources

Next review date & triggers: 2026-02-10 or earlier if Auto Care/MEMA publish new adjustable nitrogen segment data, SAE updates gas-pressurized damper validation guidance, or reservoir/dyno adoption shifts by >10% globally