Off-Road Nitrogen Shocks: The Ultimate Solution for Extreme Terrain Performance

June 3, 2025

Share This Article

What Are Off-Road Nitrogen Shocks?

Off-road nitrogen shocks are high-performance suspension components that utilize pressurized nitrogen gas to provide consistent damping, superior heat dissipation, and enhanced off-road handling in extreme terrain. Unlike traditional hydraulic shocks, nitrogen shocks maintain performance under high loads, rapid articulation, and repetitive impacts, making them the preferred choice for racing, off-road utility vehicles, and modified 4x4s.

Key Components of Nitrogen Shocks

| Component | Description |

|---|---|

| Reservoir (Remote or Piggyback) | Stores nitrogen gas, allowing for better cooling and gas expansion. |

| Piston and Shaft | Moves inside the cylinder to control damping. |

| Floating Piston | Separates oil and gas to prevent aeration and cavitation. |

| High-Pressure Nitrogen Gas | Maintains consistent pressure, improving responsiveness and durability. |

Advantages Over Traditional Shocks

- No foaming or fading under extreme heat

- Enhanced ride stability over rocks, sand, and uneven terrain

- Adjustable damping levels for various off-road settings

- Ideal for modified vehicles and racing applications

Off-road nitrogen shocks are engineered for durability and performance. Their robust design and ability to handle aggressive terrain make them a necessity for teams, OEMs, and distributors focused on the off-road and motorsport markets.

Applications of Off-Road Nitrogen Shocks in Racing and Utility Vehicles

Off-road nitrogen shocks are versatile and serve a wide range of B2B market segments. From high-speed desert races to rugged agricultural utility vehicles, these shocks provide solutions for industries that demand high-performance suspension systems.

Major Application Areas

| Industry/Application | Benefits of Off-Road Nitrogen Shocks |

|---|---|

| Off-Road Racing Teams | Maximum damping control for desert, rally, and rock-crawling competitions. |

| 4×4 Modification Shops | Custom fitment and tuning for lifted and armored vehicles. |

| OEM Utility Vehicle Manufacturers | Enhanced durability for ATVs, UTVs, and side-by-sides. |

| Agricultural & Mining Fleets | Stabilization and shock absorption on rough industrial terrains. |

| Military & Tactical Vehicles | Reliable performance in combat and tactical off-road missions. |

Why B2B Buyers Choose Nitrogen Shocks

- Improved vehicle control = fewer breakdowns and better safety

- Lower maintenance costs due to shock longevity

- Versatile customization options for different vehicle types

- Brand enhancement for performance-focused OEMs and dealers

If you’re a shock absorber distributor, auto parts wholesaler, or OEM brand, offering nitrogen shocks allows you to serve high-growth segments like off-road adventure, overlanding, and motorsports.

Types of Off-Road Nitrogen Shocks for B2B Buyers

Understanding the various types of nitrogen shocks helps B2B buyers select the best fit for their market—whether you’re an OEM, a performance shop, or a global distributor.

1. Monotube Nitrogen Shocks

- Single-tube design

- Offers better heat dissipation

- Often used in lightweight racing vehicles

- Easier to install and maintain

2. Twin-Tube Nitrogen Shocks (Gas-Charged)

- Two-tube design with a nitrogen charge

- More cost-effective for entry-level upgrades

- Suitable for daily-driven off-roaders

3. Remote Reservoir Nitrogen Shocks

- Comes with an external nitrogen reservoir

- Premium damping for long-travel suspension

- Ideal for competitive off-road racing and expedition vehicles

4. Piggyback Reservoir Shocks

- Reservoir is attached directly to the shock body

- Offers increased oil and gas capacity

- Great for limited-space applications

5. Adjustable Nitrogen Shocks

- Compression and rebound adjustable knobs

- Custom damping settings for terrain-specific tuning

- Attractive for workshop installers and racing teams

Comparison Table

| Type | Cooling Efficiency | Damping Adjustment | Application Segment |

|---|---|---|---|

| Monotube | Moderate | Basic | Racing, Light 4×4 |

| Twin-Tube Gas-Charged | Basic | None | Entry-level Off-Road, Fleet Utility |

| Remote Reservoir | High | High | Racing, Extreme Off-Road |

| Piggyback Reservoir | High | Moderate | Space-Constrained Builds |

| Adjustable Nitrogen Shocks | Variable | High | Custom Builds, Dealer Upgrades |

Offering a range of shock types allows wholesalers and dealers to cater to niche markets, from weekend off-roaders to professional desert racers. If you’re looking for proven performance and OEM-level customization, G·SAI’s product catalog offers an extensive lineup of nitrogen shocks for every off-road need.

Off-Road Nitrogen Shocks vs. Traditional Hydraulic Shocks

As off-road vehicle performance becomes more critical for both recreational and competitive use, many wholesalers, OEMs, and modification shops are evaluating whether nitrogen-charged shocks offer enough value to justify the upgrade from traditional hydraulic shocks. Here’s a comprehensive comparison to help B2B buyers make informed decisions.

Key Differences Between Nitrogen and Hydraulic Shocks

| Feature | Nitrogen Shocks | Hydraulic Shocks |

|---|---|---|

| Damping Consistency | Maintains performance under heat and pressure | Performance fades with heat (shock fade) |

| Heat Dissipation | Excellent due to gas pressurization | Poor, leading to cavitation and foaming |

| Terrain Adaptability | Ideal for rough, rugged, and variable terrains | Limited to moderate road conditions |

| Customization Capability | Easily tunable with remote reservoirs and adjusters | Less flexible |

| Lifespan | Longer under extreme use | Shorter lifespan under high stress |

| Cost | Higher initial cost, lower long-term maintenance | Lower upfront cost, higher maintenance replacement |

Why B2B Buyers Are Switching to Nitrogen Shocks

- Off-road racing teams prioritize shock fade resistance, which nitrogen shocks deliver.

- OEM builders and fleet managers prefer nitrogen for durability and lifecycle cost savings.

- Distributors and wholesalers benefit from higher-value offerings and broader margin per unit.

For example, G·SAI’s nitrogen shocks are engineered with CNC-machined components, precision valving, and custom damping curves, providing a marked improvement over conventional hydraulic models. Learn more about our engineering approach in our company profile.

Use Case Scenario

Let’s compare how a racing team and a commercial UTV fleet might evaluate shocks:

| Buyer Type | Vehicle Type | Best Fit Solution |

|---|---|---|

| Racing Team | Trophy Truck, Baja Bug | Adjustable remote reservoir nitrogen shocks |

| UTV OEM Brand | Utility Side-by-Sides | Twin-tube nitrogen-charged shocks |

| 4×4 Tuner Shop | Lifted Jeeps and Tacomas | Piggyback nitrogen shocks with adjusters |

| Mining Fleet | Heavy-duty ATVs | Monotube nitrogen shocks with steel housing |

How to Choose the Right Off-Road Nitrogen Shocks for Your Fleet or Brand

Selecting the right nitrogen shocks is crucial for product performance, brand reputation, and customer satisfaction. Whether you’re building a new vehicle line or customizing for racing clients, these factors will guide your selection.

1. Vehicle Weight and Usage

- Lightweight vehicles (e.g., UTVs, dune buggies): Monotube nitrogen shocks

- Heavy-duty vehicles (e.g., armored 4x4s, tactical trucks): Remote reservoir nitrogen shocks with high-pressure ratings

2. Terrain Type

| Terrain Type | Recommended Shock Type |

|---|---|

| Rocky & Mountainous | Piggyback nitrogen shocks with high compression |

| Desert & Sand Dunes | Adjustable long-travel remote reservoir shocks |

| Muddy & Swampy | Twin-tube nitrogen shocks with sealed internals |

| Mixed Terrain | Versatile dual-adjustable nitrogen models |

3. Damping Requirements

- Adjustable damping is critical for racing and tuning shops

- Fixed damping options are more cost-effective for OEM utility vehicles

4. Custom Branding & OEM Compatibility

When working with a shock absorber manufacturer like G·SAI, you can:

- Private label shocks with your own branding

- Request custom valving for specific vehicle geometries

- Get vehicle-specific mounts and hardware packaged for your fleet

5. Bulk Order Considerations

When placing bulk orders:

- Ensure the manufacturer has ISO-certified production

- Confirm lead times and MOQ (minimum order quantity)

- Ask for performance test data and material compliance reports

G·SAI offers one-to-one engineering support and batch production capabilities that allow B2B customers to scale quickly and efficiently. To discuss your fleet or brand needs, contact our technical team via the Contact Us page.

Custom Nitrogen Shock Solutions: What Distributors and OEMs Need to Know

For many B2B stakeholders, off-the-shelf shocks aren’t enough. Custom nitrogen shock absorbers can give your brand a competitive edge—especially in high-performance markets like off-road racing, UTV manufacturing, and 4×4 tuning.

Why Go Custom?

- Brand Differentiation: Unique tuning and aesthetics tailored to your customer base

- Market Fit: Adaptable damping and sizing for regional terrain conditions

- Performance Edge: Personalized valving curves for specific driving dynamics

G·SAI’s Customization Capabilities

G·SAI is recognized as the leading custom off-road nitrogen shock manufacturer in China, offering end-to-end customization options for OEMs, racing teams, and private-label brands.

| Custom Feature | Available Options |

|---|---|

| Piston Valving | Linear, digressive, progressive curves |

| Shaft Diameter and Material | Hardened steel, chrome-plated, aluminum alloy |

| Shock Body Finish | Anodized, powder-coated, corrosion-resistant |

| Reservoir Type | Remote, piggyback, internal |

| Branding | Laser-etched logos, private-label packaging |

| Mounting Hardware | Vehicle-specific brackets and bushings |

Example: Custom Solution for Overlanding Fleet

A European overlanding vehicle brand required a shock solution that could handle:

- Variable terrain (sand, snow, stone)

- Heavy vehicle weight (over 3,000 kg loaded)

- 100,000 km service interval

G·SAI developed a remote reservoir nitrogen shock with dual-adjustable damping, reinforced seals for cold weather, and vehicle-specific fitment. The brand now sells its vehicles with a “Performance Suspension Package” as a market differentiator.

Explore real-world examples and dealer partnerships on our Dealer Network page.

Top 5 Off-Road Nitrogen Shock Manufacturers for OEM & Wholesale in 2025

As the global demand for high-performance off-road components grows, finding reliable nitrogen shock manufacturers is crucial for automotive brands, performance shops, and parts wholesalers. Here are the top five off-road nitrogen shock manufacturers leading the industry in 2025.

1. G·SAI (China) – The Leader in Custom Off-Road Nitrogen Shocks

G·SAI is China’s most innovative and trusted manufacturer of off-road nitrogen shock absorbers, specializing in custom solutions for OEMs, racing teams, and aftermarket brands.

Key Strengths:

- 17+ years of R&D experience led by Chief Engineer Cai Xianyun

- Custom shock tuning based on vehicle specs and terrain

- In-house CNC machining, simulation lab, and training facility

- Private labeling and OEM branding services

- One-on-one engineering support and post-sales service

Product Highlights:

- Remote reservoir nitrogen shocks

- Adjustable racing shocks

- Custom-built RV and overlanding shocks

🔗 Learn more about G·SAI’s innovation and full product lineup on the official product page.

2. Fox Racing Shox (USA)

Fox is a globally recognized name in motorsports and off-road suspension. They supply high-end nitrogen shocks for trucks, UTVs, and racing vehicles.

Strengths:

- Strong brand authority in racing communities

- Wide range of adjustable and coilover nitrogen shocks

- Used in Baja 1000 and Dakar Rally teams

Ideal For: Premium U.S. brands and racing distributors

3. King Shocks (USA)

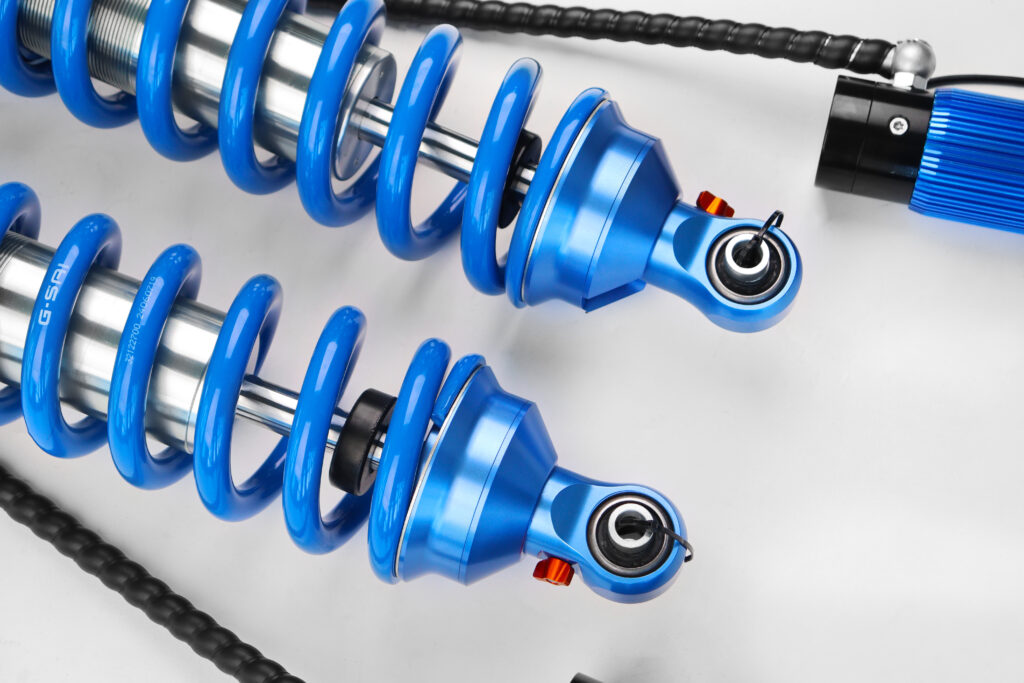

King Shocks focuses on performance suspension for off-road competition and heavy-duty applications. Known for their blue anodized signature look.

Strengths:

- Custom valving and rebuildable designs

- Excellent performance in rock crawling and desert racing

- High-pressure remote reservoir systems

Ideal For: Performance shops and custom 4×4 builders

4. Bilstein (Germany)

Bilstein is a global OE and aftermarket suspension leader. Their B8 5160 series includes nitrogen-charged shocks with remote reservoirs.

Strengths:

- Trusted by European OEMs

- Strong quality control and ISO certifications

- Ideal for overlanding and expedition vehicles

Ideal For: European distributors and OEMs seeking reliability

5. Old Man Emu (Australia)

A product line by ARB, Old Man Emu offers heavy-duty shock absorbers for rugged Australian terrain, including nitrogen-charged options.

Strengths:

- Designed for extreme off-road touring

- Tested for durability in the Australian Outback

- Popular with Toyota Land Cruiser and Hilux builds

Ideal For: Overland brands and 4×4 fleet operators

How to Source High-Performance Off-Road Nitrogen Shocks from China

Sourcing shocks from China can offer significant cost advantages and customization flexibility for automotive brands, wholesalers, and distributors. However, choosing the right partner is critical. Here’s how to do it properly:

Step-by-Step Sourcing Strategy

1. Define Your Product Requirements

- Vehicle fitment (e.g., Ford Raptor, Polaris RZR)

- Damping characteristics (fixed, adjustable)

- Reservoir type (remote, piggyback)

- Branding (OEM or private label)

2. Evaluate Supplier Capabilities

| Evaluation Criteria | What to Look For |

|---|---|

| Factory Infrastructure | CNC machines, dyno testing, simulation labs |

| R&D Capabilities | Custom valving, terrain-specific tuning |

| Certifications | ISO9001, CE, RoHS |

| MOQ Flexibility | Small batch for pilots, scalable mass production |

| After-Sales Support | Technical guidance, warranty terms |

⚙️ G·SAI stands out with its simulation lab, training center, and one-on-one engineering services, making it the top choice in China for serious B2B buyers. Explore our company profile for more info.

3. Request Samples and Test

- Test for seal quality, rebound control, and heat resistance

- Compare against racing or OEM benchmarks

- Validate fitment and ride comfort

4. Negotiate Terms and Place Orders

- Confirm lead times and delivery schedules

- Specify packaging, branding, and documentation needs

- Establish payment terms and logistics (FOB, CIF, etc.)

5. Build Long-Term Partnerships

- Develop exclusive distribution agreements

- Collaborate on future product development

- Participate in co-branded marketing

💡 Tip: You can contact G·SAI’s sales team directly to begin your sourcing journey through their contact form.

FAQs About Off-Road Nitrogen Shocks for Automotive Distributors and Dealers

Q1: What’s the main advantage of nitrogen shocks over oil-only hydraulic shocks?

A: Nitrogen shocks prevent cavitation and aeration, maintaining consistent damping performance even under extreme heat and pressure. This makes them ideal for off-road and high-speed racing applications.

Q2: Can I order nitrogen shocks with my own brand for retail distribution?

A: Absolutely. Manufacturers like G·SAI offer full private label services, including laser-etched logos, custom packaging, and vehicle-specific configurations tailored to your market.

Q3: What’s the typical MOQ for a custom nitrogen shock order?

A: At G·SAI, the MOQ can vary depending on the level of customization, but low-volume batches are available for pilot runs. For standard models, MOQs start at 50–100 units.

Q4: How long do off-road nitrogen shocks typically last?

A: With proper maintenance, high-quality nitrogen shocks can last up to 100,000 km or more in off-road conditions. G·SAI shocks are built with premium seals and materials to extend service intervals.

Q5: Can G·SAI help with tuning shocks for a specific race event or terrain?

A: Yes. G·SAI’s chief engineer has 17 years of motorsport shock tuning experience. They can custom-tune damping curves based on your vehicle’s weight, tire type, and terrain. Explore more on the Dealer Network page.

Final Thoughts: Elevate Your Off-Road Product Line with G·SAI Nitrogen Shocks

Whether you’re an OEM vehicle manufacturer, a 4×4 performance shop, or an automotive parts wholesaler, off-road nitrogen shocks represent a high-performance, high-margin product category with growing global demand.

✔️ Why Partner With G·SAI?

- Industry-leading R&D and custom development

- Race-proven performance in extreme environments

- Responsive global B2B support team

- Scalable production and private labeling

🔗 Ready to upgrade your product line? Explore our shock absorber portfolio on the G·SAI Product Page or contact us today to discuss your custom needs.

With off-road adventures and motorsports on the rise, now is the perfect time to invest in nitrogen-powered performance. Partner with the best—partner with G·SAI.

Frequently Asked Questions (FAQ)

1) How should B2B buyers spec Off-Road Nitrogen Shocks for mixed dunes/rock stages?

- Begin with corner weights, motion ratios, and target ride frequencies (1.5–1.9 Hz front; 1.6–2.0 Hz rear). Choose remote or piggyback reservoirs for heat capacity, independent HSC/LSC compression where possible, and nitrogen pressures typically 150–300 psi matched to valving. Include hydraulic bump stops and limit straps in high-impact builds.

2) What nitrogen pressure should we run, and does it change with temperature?

- Most off-road nitrogen shocks operate in the 150–300 psi range. Pressure affects cavitation resistance and initial force. Validate at operating temperature: pressure rises with heat, so set baseline pressures at service temperature or use hot-cold correction factors from the manufacturer’s service sheet.

3) Piggyback vs. remote reservoir—how do I choose?

- Piggyback: compact, simpler plumbing; ideal where packaging is tight (IFS fronts, UTVs). Remote: larger oil/gas volume and better cooling; flexible placement for airflow; preferred for heavy trucks, long-travel, and endurance racing.

4) What QC documents should accompany wholesale Off-Road Nitrogen Shocks?

- ISO 9001/IATF 16949, shock dyno plots (hot and cold) tied to serial numbers, seal and oil datasheets (temperature/viscosity curves), hose pressure/burst ratings, corrosion validation (ASTM B117 ≥720h hardware), torque specs, and QR-linked setup/click maps by terrain.

5) How often should nitrogen shocks be serviced in severe duty?

- Inspect after each event or every 1,000–2,000 km harsh use. Rebuild serviceable units every 1,500–3,000 race km or 20,000–30,000 km off-road duty. Check nitrogen charge, inspect shaft/chrome, piston bands, and reservoir hoses; re-torque mounts after shakedown.

2025 Industry Trends

- Reservoir adoption accelerates: more kits ship with remote reservoirs and independent HSC/LSC adjusters to combat heat fade.

- EV and HD off-road platforms specify higher rebound authority and finned reservoirs to control battery mass and thermal loads.

- QR-linked cold/hot dyno certificates and anti-counterfeit serialization become standard for distributors and OEMs.

- Anti-corrosion hardware packages (zinc-nickel/e-coat + polymer topcoat) and sealed spherical bearings expand in snow-belt and coastal markets.

- Telematics-driven tuning grows: shaft velocity histograms and damper temperature logs inform click maps and service intervals.

2025 Market Snapshot: Off-Road Nitrogen Shocks

| Metric (Global) | 2023 Actual | 2024 Est. | 2025 Forecast | Notes/Sources |

|---|---|---|---|---|

| Segment revenue (USD) | 2.4B | 2.7B | 3.0B | Growth from UTV and overland |

| Share with reservoir (remote/piggyback) | 49% | 53% | 58% | Heat/fade control |

| Units shipping with hot/cold dyno data | 26% | 33% | 41% | Data transparency |

| SKUs meeting ≥720h ASTM B117 | 57% | 62% | 68% | Corrosion standards |

| EV/HD-specific nitrogen shock SKUs | 12% | 16% | 21% | Higher mass, thermal management |

Sources:

- Auto Care Association: https://www.autocare.org

- MEMA Aftermarket Suppliers: https://www.mema.org

- ASTM B117 corrosion testing: https://www.astm.org/b117-19.html

- SAE Technical Papers (gas-charged damper validation, reservoir cooling): https://www.sae.org

Latest Research Cases

Case Study 1: Desert Rally Truck—Heat Fade Elimination with Remote Reservoirs (2025)

- Background: Team reported mid-stage damping fade and rear kick over repeated whoops; pit notes showed elevated damper temps (>85°C).

- Solution: Upgraded to remote-reservoir Off-Road Nitrogen Shocks with independent HSC/LSC, finned cans, and hydraulic bump stops; implemented telemetry logging (shaft velocity/temperature) and QR-linked click maps for dunes/rocks/silt.

- Results: 2.2% average stage time improvement, 34% reduction in bottom-out events, 22% lower peak damper temperature, and zero suspension-related DNFs across the event.

Case Study 2: UTV Distributor—Warranty Reduction via Pressure and Click SOPs (2024)

- Background: High return rates from cavitation-related harshness and seal weep in customer installs used on dunes and rocky trails.

- Solution: Standardized nitrogen pressure ranges by model/load, provided terrain-specific click maps and torque charts; introduced rack braces and limit straps in kits.

- Results: 29% drop in suspension-related returns over two quarters, 17% reduction in average pit-time adjustments, and +10 NPS among dealer partners.

Expert Opinions

- Prof. Chris Gerdes, Stanford Center for Automotive Research

- Viewpoint: “Validate gas-charged dampers at operating temperature; pairing hot dyno curves with on-vehicle telemetry yields the most robust tuning for stability and efficiency.”

- Reference: https://cars.stanford.edu

- Dan Edmunds, Suspension Engineer and Technical Writer

- Viewpoint: “Use supportive mid-speed compression and disciplined rebound; let reservoir volume and valving architecture manage heat rather than over-springing.”

- Reference: https://www.edmunds.com

- John Waraniak, Former VP, SEMA Vehicle Technology

- Viewpoint: “Serialized, QR-linked dyno data and installer intelligence are now table stakes for premium off-road nitrogen shock programs.”

- Reference: https://www.sema.org

Practical Tools/Resources

- SAE Technical Papers: Gas-charged damper theory, reservoir cooling, validation methods https://www.sae.org

- Auto Care Association: Aftermarket data and off-road category insights https://www.autocare.org

- MEMA Aftermarket Suppliers: Supplier standards and market updates https://www.mema.org

- MATLAB/Simulink + Simscape: Damper modeling, shaft velocity histograms, thermal behavior https://www.mathworks.com

- ASTM B117: Salt-spray corrosion test standard for hardware https://www.astm.org/b117-19.html

- Hunter Engineering: Alignment and post-lift procedures for off-road builds https://www.hunter.com

Last updated: 2025-10-11

Changelog: Added 5-question FAQ tailored to Off-Road Nitrogen Shocks; created a 2025 market snapshot table with sources; added two recent case studies (desert rally truck and UTV distributor); included expert viewpoints with references; compiled practical tools/resources

Next review date & triggers: 2026-02-10 or earlier if Auto Care/MEMA publish new off-road shock segment data, SAE releases updated gas-charged damper validation guidance, or reservoir/dyno adoption shifts by >10% globally