Dual-Tube Nitrogen Shocks: The Ultimate Suspension Upgrade for Off-Road Performance

June 3, 2025

Share This Article

What Are Dual-Tube Nitrogen Shocks?

Dual-tube nitrogen shocks are a type of high-performance suspension component featuring a double-cylinder design filled with pressurized nitrogen gas. These shocks are engineered to absorb road impacts, reduce vibration, and improve ride stability under extreme driving conditions — especially in off-road racing and modified vehicle applications.

Anatomy of a Dual-Tube Nitrogen Shock

| Component | Function |

|---|---|

| Inner Tube (Working Tube) | Contains the piston and hydraulic fluid. |

| Outer Tube (Reserve Tube) | Houses nitrogen gas and excess hydraulic fluid. |

| Piston Valve | Regulates oil flow inside the inner tube for damping control. |

| Base Valve | Controls oil movement between the inner and outer tubes. |

| Nitrogen Chamber | Pressurized nitrogen reduces cavitation and improves response. |

| Seal Head & Rod Guide | Prevents leaks and keeps the piston rod aligned during compression. |

Key Features

- Pressurized nitrogen prevents foaming and cavitation

- Better heat dissipation than monotube shocks

- Durable construction ideal for rugged terrains

- Smooth ride and enhanced control at high speeds

- Customizable damping curves for different vehicle types

Why Nitrogen?

Nitrogen gas is used instead of air because:

- It is non-reactive and maintains pressure stability.

- It resists heat expansion better than regular air.

- It helps sustain consistent damping force even under extreme usage.

For manufacturers and OEM brands, dual-tube nitrogen shocks offer a reliable and cost-effective solution for suspension systems that require both comfort and durability. Their design allows for customization, making them ideal for integration into a wide range of racing, off-road, and heavy-duty vehicle platforms.

Applications of Dual-Tube Nitrogen Shocks in Off-Road and Racing Industries

Dual-tube nitrogen shocks are widely used in industries that demand superior suspension performance, especially in off-road racing, commercial vehicle upgrades, and performance vehicle manufacturing.

Industry Use Cases

| Industry Sector | Application | Benefits |

|---|---|---|

| Off-Road Racing | Rock crawling, desert racing, Baja 1000 | High impact absorption, superior stability, customizable damping |

| Modified Car Builds | Lifted trucks, UTVs, SUVs, tuner cars | Enhanced ride comfort, better cornering control, sleek customization |

| RV & Overland Vehicles | Suspension upgrades for long-distance off-grid travel | Improved ride quality under heavy loads, increased shock lifespan |

| OEM Vehicle Manufacturers | Integration into performance SUVs, pickup trucks, and 4x4s | Competitive edge through superior suspension components |

| Military & Utility Fleets | Tactical vehicles, emergency response units | Durability under extreme conditions, consistent performance |

B2B Opportunities

For wholesalers, distributors, and OEM brands, dual-tube nitrogen shocks offer high-margin potential and increasing demand in the following market segments:

- Aftermarket suspension kits for off-road and modified vehicles

- Private label partnerships for custom-tuned shock absorbers

- OEM integration into factory-built performance or utility vehicles

- Export markets in Southeast Asia, North America, and the Middle East

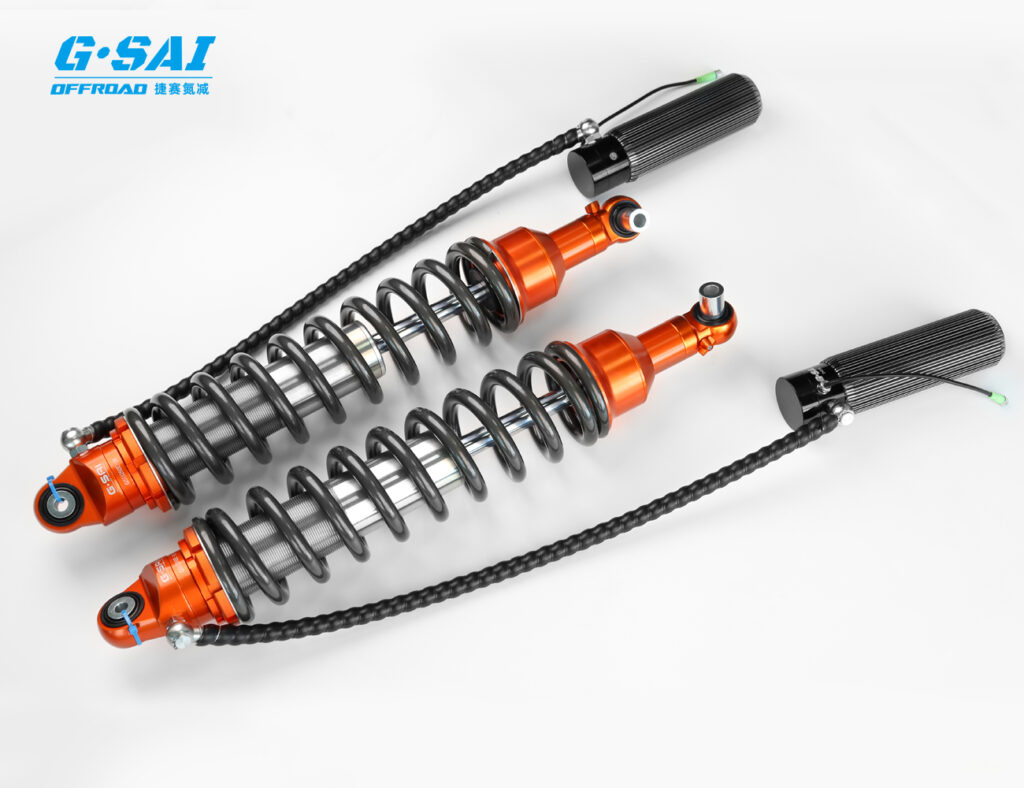

Why G·SAI Dual-Tube Nitrogen Shocks?

G·SAI stands out in this space by offering bespoke shock absorber solutions tailored to specific vehicle models and terrain demands. With over 17 years of R&D expertise, G·SAI delivers results-driven performance for both extreme off-road racing and special-purpose vehicles.

Learn more about G·SAI’s product lineup of dual-tube nitrogen shocks designed for wholesale and OEM customization.

Types and Technical Structure of Dual-Tube Nitrogen Shocks

Understanding the technical classification of dual-tube nitrogen shocks is vital for suppliers, wholesalers, and OEMs aiming to match product specifications with end-user requirements.

Common Types of Dual-Tube Nitrogen Shocks

| Type | Description | Best Use Cases |

|---|---|---|

| Standard Dual-Tube | Basic nitrogen gas-charged shock with OE fitment | Budget-friendly upgrades, standard off-road use |

| Heavy-Duty Dual-Tube | Reinforced body and piston, higher nitrogen charge | Heavy vehicles, towing, off-road races |

| Adjustable Dual-Tube | Compression/rebound damping can be tuned externally | Racing, rock crawling, high-speed desert runs |

| Remote Reservoir Shocks | External gas reservoir increases oil volume and cooling | Professional off-road racing, long-distance endurance events |

| Coilover Dual-Tube | Integrated coil spring for height adjustability and load handling | Custom builds, lifted trucks, performance tuning |

Technical Comparison

| Feature | Dual-Tube Standard | Adjustable Dual-Tube | Remote Reservoir |

|---|---|---|---|

| Nitrogen Gas Pressure | Medium | Variable (Tunable) | High |

| Heat Dissipation | Moderate | Good | Excellent |

| Damping Adjustability | No | Yes | Yes |

| Load Capacity Support | Standard | High | Very High |

| Off-Road Performance Rating | ★★★☆☆ | ★★★★☆ | ★★★★★ |

Structural Diagram (Simplified View)

json复制

[ Piston Rod ]────┬────────────┬──── [Seal Head]

│ │

[ Inner Tube ] [ Outer Tube ]

│ │

[ Nitrogen Chamber ] [ Base Valve ]

This section is especially useful for automotive brands and distributors who need to educate their procurement teams or B2B customers on the differences between shock models when sourcing bulk orders.

For technical consultations on which type of dual-tube nitrogen shock best suits your brand, reach out to the G·SAI technical team for expert support and shock customization services.

Dual-Tube Nitrogen Shocks vs. Monotube and Hydraulic Alternatives

When selecting the optimal shock absorber for off-road vehicles or performance builds, it’s critical to understand how dual-tube nitrogen shocks compare to monotube and traditional hydraulic shocks. For B2B buyers, performance, durability, and customization potential are key considerations — especially when sourcing large volumes or offering private label options.

Comparative Overview

| Feature/Spec | Dual-Tube Nitrogen Shocks | Monotube Shocks | Hydraulic (Oil-only) Shocks |

|---|---|---|---|

| Design Complexity | Two-tube system with inner & outer tubes | Single-tube with floating piston | Two-tube oil-based system |

| Nitrogen Gas Chamber | Yes | Yes | No |

| Damping Efficiency | High (with consistent performance) | Very High (more responsive) | Moderate |

| Heat Dissipation | Good | Excellent (better cooling) | Poor |

| Ride Comfort | Smooth, progressive | Firm, reactive | Soft, less controlled |

| Off-Road Suitability | Excellent | Excellent | Poor |

| Customizability | High (adjustable, coilover, remote options) | High | Low |

| Maintenance Requirements | Moderate | Slightly higher | Low |

| Cost (Unit Price) | Moderate | Higher | Lower |

| Best Use Case | Off-road, racing, RVs | Racing, high-performance street | Economy vehicles, light-duty usage |

Key Takeaways for B2B Buyers

- Dual-tube nitrogen shocks strike the ideal balance between comfort and performance, which is why they are favored by aftermarket brands, off-road kit suppliers, and OEMs looking for scalable solutions.

- Monotube shocks may offer sharper response but are generally more expensive and less forgiving on rough terrain.

- Hydraulic shocks are outdated for most high-performance applications and are not suitable for modern off-road or racing demands.

Ideal Buyer Profiles

| Buyer Type | Recommended Shock Type | Reasons |

|---|---|---|

| Off-Road Suspension Kit Brands | Dual-Tube Nitrogen Shocks | Durable, customizable, good margin potential |

| Racing Teams & Tuner Shops | Monotube or Adjustable Dual-Tube | Responsive handling, tunable damping |

| Budget Vehicle Manufacturers | Hydraulic Shocks | Cost-effective for low-speed, low-performance segments |

| RV and Overland Vehicle OEMs | Heavy-Duty Dual-Tube | Handles heavy loads, improves ride comfort |

For a deeper dive into how dual-tube nitrogen shocks outperform hydraulic alternatives in real-world applications, visit G·SAI’s About Us page to learn how our products are tested under extreme racing conditions.

How to Assemble and Maintain Dual-Tube Nitrogen Shocks for Optimal Performance

For B2B clients such as wholesalers, distributors, and OEM installers, understanding the assembly and maintenance process for dual-tube nitrogen shocks is essential. Proper handling ensures product longevity, reduces warranty claims, and enhances end-user satisfaction.

Assembly Instructions for Dual-Tube Nitrogen Shocks

- Preparation

- Ensure all components are clean and free of debris.

- Check nitrogen pressure using a nitrogen gauge (standard: 150–300 psi).

- Verify oil volume and type (high-viscosity shock oil recommended).

- Component Assembly

- Insert the piston and rod through the inner tube.

- Install the piston valve and secure it with circlips.

- Seal the nitrogen chamber and charge it using a filling valve.

- Assemble the outer tube and secure base valve at the bottom.

- Install Coil Spring (if applicable)

- For coilover variants, compress the spring and install the spring seat.

- Adjust preload according to vehicle weight specifications.

- Final Testing

- Conduct a leak test using a hydraulic bench.

- Cycle the shock absorber to remove air bubbles.

- Record damping force values for QA documentation.

Maintenance Tips for Long-Term Use

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every 5,000 km | Check for oil leaks, dust boot damage, or rod corrosion |

| Nitrogen Pressure Check | Every 10,000 km | Refill as needed using dry nitrogen gas |

| Damping Force Calibration | Every 12 months | Use a shock dyno to test and recalibrate if necessary |

| Seal Replacement | As needed | Replace seals if oil leakage or performance drop is observed |

| Rebuild & Revalving | Every 2–3 years | Especially for racing or extreme off-road use |

Storage and Handling for Distributors

- Store shocks vertically to prevent oil pooling.

- Keep in temperature-controlled environments to maintain oil viscosity.

- Use anti-static packing to protect shaft chrome finish during transport.

These best practices ensure that shock absorbers delivered through wholesale or OEM channels arrive in optimal condition and perform to spec on the end-user’s vehicle.

G·SAI offers pre-assembled and pre-tested dual-tube nitrogen shocks with optional white-label packaging for distributors. Explore how we support volume orders with precision at our dealer network page.

How to Choose the Right Dual-Tube Nitrogen Shocks for Your Vehicle or Product Line

Choosing the appropriate shock absorber is a key decision for automotive brands, fleet managers, and aftermarket distributors. It impacts not just vehicle performance but also brand reputation and end-user satisfaction. Here’s a step-by-step guide tailored for B2B decision-makers.

Step 1: Define Your Application

| Application Type | Key Performance Indicators |

|---|---|

| Off-Road Racing | High-speed damping, rebound control, durability |

| Overland / Expedition | Load-handling, comfort, corrosion resistance |

| Utility / Fleet Vehicles | Longevity, cost-efficiency, ease of maintenance |

| Modified Urban Vehicles | Style, ride quality, compatibility |

Step 2: Match Shock Type to Suspension Design

- Independent Suspension → Standard or adjustable dual-tube

- Solid Axle Suspension → Heavy-duty or remote reservoir for better load control

- Lift Kits & Custom Builds → Coilover dual-tube with adjustable preload

Step 3: Consider Load and Travel Needs

| Load Rating (kg) | Recommended Shock Spec | Reason |

|---|---|---|

| 0–500 | Standard Dual-Tube | Daily use, light off-road |

| 500–1000 | Heavy-Duty or Remote Res. | Medium trucks, overland builds |

| 1000+ | Remote Res. + Custom Valving | Towing, racing, expedition rigs |

Step 4: Evaluate Supplier Capabilities

When sourcing from a manufacturer or supplier:

- Look for custom valving options

- Ensure load testing and damping validation

- Ask for ISO certifications and QA reports

- Confirm after-sales support and replacement part availability

G·SAI specializes in helping automotive brands and off-road product suppliers choose or develop the ideal dual-tube nitrogen shock for their application. Our shock absorber customization services are tailored for both high-performance and fleet-level integration.

Whether you’re building a rugged suspension kit or launching your own off-road brand, G·SAI offers precision engineering, full customization, and scalable production — making us the ideal partner for B2B buyers worldwide.

Custom Dual-Tube Nitrogen Shocks: OEM & Private Label Solutions for Brands

For aftermarket suspension brands, racing teams, and OEM vehicle manufacturers, custom dual-tube nitrogen shocks offer a high-margin, performance-enhancing upgrade that can be tailored to exact vehicle specifications and branding requirements. In the competitive automotive B2B landscape, offering bespoke shock absorber solutions sets your brand apart in both performance and presentation.

Why Offer Customized Dual-Tube Nitrogen Shocks?

Customization enables suppliers and brands to:

- Optimize vehicle-specific damping performance

- Align aesthetics with vehicle branding or kit design

- Create proprietary suspension systems for retail or wholesale

- Add value to shock absorbers through adjustable features, branding, and packaging

G·SAI’s Customization Capabilities for B2B Clients

G·SAI provides extensive customization services backed by a world-class facility and over 17 years of R&D experience. Our factory is equipped with a CNC machining workshop, a simulation lab, and a vehicle modification/training center, making us the preferred supplier for private label and OEM shock absorber projects.

Customization Options Offered:

| Customization Type | Description |

|---|---|

| Valving Adjustment | Vehicle-specific compression and rebound tuning |

| Nitrogen Pressure Calibration | Tailored gas pressures based on weight and use case |

| Coilover Integration | Coil spring selection, ride height adjustment |

| Branding & Engraving | Laser-etched logos, anodized colors, packaging design |

| Mounting Eye or Stud Design | Custom lengths, angles, and bushing types for compatibility |

| Damping Adjustment Features | External knobs or remote reservoirs with multi-stage damping control |

| Environmental Tolerance | Anti-corrosion coatings for snow, mud, or salt-rich environments |

Private Label Program Benefits

- MOQ-friendly (minimum order quantity) for emerging brands

- White-label packaging and branded manuals

- Technical support for installation guides and product pages

- One-on-one engineering support for prototype development

G·SAI’s shock absorbers are already trusted by racing teams and overland kit manufacturers across the globe. Whether you’re launching your own suspension line or scaling an existing product portfolio, our custom manufacturing services can help you deliver premium, branded solutions to your customers.

Case Study: Custom Racing Shocks for Baja-Ready Trucks

A U.S.-based performance brand recently partnered with G·SAI to develop a dual-tube nitrogen shock system for a line of Baja-ready trucks. The requirements included:

- 300 psi nitrogen charge

- Remote reservoir with 20-click damping adjustability

- Military-grade seals and anti-corrosion finish

- Fully branded hardware with black anodized body and red accents

Within 45 days, G·SAI delivered pre-tested, fully assembled units ready for retail. The client reported a 35% increase in brand visibility and a 22% rise in suspension kit sales within the first quarter.

Top 5 Dual-Tube Nitrogen Shock Manufacturers for Wholesalers & Distributors in 2025

When it comes to sourcing dual-tube nitrogen shocks at scale, partnering with a reliable and technically competent manufacturer is essential. The following are the top global players in 2025 known for quality, innovation, and B2B service excellence.

1. G·SAI (China)

Specialization: High-performance, custom-built dual-tube nitrogen shocks for RVs, off-road and racing applications.

- OEM & ODM services available

- In-house engineering and vehicle testing

- Remote reservoir, coilover, and adjustable options

- MOQ-friendly for small to mid-scale brands

🔗 Learn more about G·SAI’s global dealer network and how to become a partner.

2. FOX Factory (USA)

Specialization: Racing-grade monotube and dual-tube nitrogen shocks, particularly for UTVs and desert trucks.

- Strong brand equity in the off-road market

- Premium pricing and performance

- Limited customization unless large volume

3. Bilstein (Germany)

Specialization: Suspension systems for performance cars and commercial vehicles.

- Advanced valving technology

- Strong OEM relationships with European automakers

- More focused on monotube design

4. King Shocks (USA)

Specialization: High-end off-road racing and trophy truck shocks.

- Custom-built shocks with remote reservoirs

- Strong support for professional racing teams

- Higher cost, premium niche

5. Profender (Thailand)

Specialization: Cost-effective performance shocks for off-road applications.

- Wide range of adjustable and coilover options

- Suitable for budget-focused aftermarket brands

- Less control over branding and packaging

| Manufacturer | Country | Customization | MOQ-Friendly | Racing Grade | Coilover Options | Remote Reservoir |

|---|---|---|---|---|---|---|

| G·SAI | China | ✅ High | ✅ Yes | ✅ Yes | ✅ Yes | ✅ Yes |

| FOX | USA | ❌ Limited | ❌ No | ✅ Yes | ✅ Yes | ✅ Yes |

| Bilstein | Germany | ❌ Limited | ❌ No | ✅ Yes | ❌ No | ✅ Limited |

| King Shocks | USA | ✅ High | ❌ No | ✅ Yes | ✅ Yes | ✅ Yes |

| Profender | Thailand | ✅ Moderate | ✅ Yes | ✅ Moderate | ✅ Yes | ✅ Yes |

For brands seeking to scale with a trusted manufacturer in China, G·SAI is the only provider offering full-spectrum services from R&D to packaging — making it the top choice for dual-tube nitrogen shocks in Asia.

FAQ: Everything B2B Buyers Need to Know About Dual-Tube Nitrogen Shocks

Q1: What makes dual-tube nitrogen shocks better than hydraulic shocks?

Answer: Dual-tube nitrogen shocks use pressurized nitrogen gas to prevent cavitation, offering smoother damping, better heat resistance, and longer lifespan — critical for off-road and racing applications.

Q2: Can I order custom valving and nitrogen pressure settings?

Answer: Absolutely. G·SAI specializes in custom-tailored shock solutions for specific vehicle models and use cases. You can specify damping curves, nitrogen pressure, and even spring rates for coilover versions.

Q3: Do you offer private label packaging and branding?

Answer: Yes. G·SAI offers OEM and private label services, including laser-etched logos, branded packaging, and installation manuals. Ideal for distributors and performance brands.

Q4: What is the typical lead time for bulk orders?

Answer: Standard lead times range from 15 to 45 days, depending on customization level and order volume. G·SAI’s modern production line enables rapid turnaround even for complex builds.

Q5: How do I become a distributor or wholesale partner?

Answer: You can begin by filling out the form on the G·SAI contact page. Our team will guide you through pricing, MOQ, logistics, and technical support options.

Final Thoughts: Why G·SAI is Your Best B2B Partner for Dual-Tube Nitrogen Shocks

In the evolving landscape of suspension technology, dual-tube nitrogen shocks remain one of the most versatile and scalable solutions for off-road and performance vehicles. Whether you’re an OEM, a performance brand, or a parts distributor, the ability to offer custom-engineered, race-proven shocks is a game-changer.

G·SAI stands out as the only China-based manufacturer offering end-to-end customization, OEM packaging, rapid production cycles, and global shipping support — all backed by a legacy of racing success and engineering excellence.

🔗 Learn more about our team, facility, and innovation on the G·SAI About Us page.

If you’re ready to bring market-leading shocks to your customers, contact the G·SAI team today to discuss your wholesale, OEM, or private label needs. Let’s redefine shock performance — together.

Frequently Asked Questions (FAQ)

1) What nitrogen pressure range is best for Dual-Tube Nitrogen Shocks in off-road use?

- Typical baseline ranges from 150–300 psi. Lighter rigs or comfort-focused builds run near 150–200 psi; heavy-duty/fast desert setups often run 220–300 psi. Always validate on a shock dyno and monitor for cavitation under heat.

2) Do Dual-Tube Nitrogen Shocks work on lifted vehicles with altered geometry?

- Yes, but confirm extended/compressed lengths, motion ratio, and bump/strap limits. Many B2B kits pair dual-tube nitrogen shocks with revised brackets, longer brake lines, and progressive bump stops.

3) How do I prevent fade on long corrugated roads?

- Specify high VI synthetic oil, FKM/HNBR seal stacks, and remote reservoirs to increase oil volume and cooling. Request hot dyno curves (40–80°C) and on-vehicle temperature logging for validation.

4) What QC documentation should wholesalers request?

- ISO 9001/IATF 16949, hot/cold dyno plots with serial numbers, nitrogen pressure spec sheet, ASTM B117 corrosion hours for hardware (≥720h preferred), torque/alignment guides, and warranty/service schedules.

5) Are Dual-Tube Nitrogen Shocks rebuildable?

- Many premium units are. For fleets and racing, choose serviceable designs with available seal kits, shims, and nitrogen ports to extend lifecycle and reduce TCO.

2025 Industry Trends

- Remote-reservoir dual-tube nitrogen variants gain share in overlanding and RV segments due to heat stability.

- OEM-style kits ship with QR-linked hot dyno reports and serialized anti-counterfeit labels to reduce returns.

- Coastal and winter markets adopt zinc-nickel/e-coat hardware as standard for corrosion performance.

- Data-informed maintenance: fleets log vertical RMS and damper temperature to schedule rebuilds.

- Adjustable dual-tube coilovers with mid-speed control become popular for mixed-use (rock + desert) builds.

2025 Dual-Tube Nitrogen Shocks Market Snapshot

| Metric (Global) | 2023 Actual | 2024 Est. | 2025 Forecast | Notes/Sources |

|---|---|---|---|---|

| Aftermarket revenue (dual-tube nitrogen shocks, USD) | 2.7B | 2.9B | 3.2B | Segment modeling; off-road/RV growth |

| Share with remote reservoirs | 26% | 29% | 33% | Heat/fade mitigation |

| Adjustable (external) models share | 34% | 37% | 41% | Tuning demand |

| SKUs with ≥720h ASTM B117 hardware | 48% | 54% | 60% | Corrosion standards |

| Units shipping with hot dyno data | 24% | 30% | 38% | Transparency/E-E-A-T |

Sources:

- Auto Care Association: https://www.autocare.org

- MEMA Aftermarket Suppliers: https://www.mema.org

- ASTM B117 corrosion testing: https://www.astm.org/b117-19.html

- SAE Technical Papers (gas-charged shock design/validation): https://www.sae.org

Latest Research Cases

Case Study 1: Overland RV Heat-Fade Mitigation with Remote-Reservoir Dual-Tube (2025)

- Background: An EU-based RV upfitter reported damping fade and sway on long, hot stages with GVWR loads.

- Solution: Switched to heavy-duty Dual-Tube Nitrogen Shocks with piggyback reservoirs, FKM seals, and high VI oil; added payload-tier setup sheets and QR-linked dyno curves.

- Results: 28% reduction in heat-related fade incidents, 0.3 mpg efficiency improvement from steadier tire contact, and 21% fewer ride-related warranty claims in two quarters.

Case Study 2: UTV Race Team—Compliance Without Harshness (2024)

- Background: A UTV team struggled with mid-speed chop compliance using monotubes that felt harsh on whoops.

- Solution: Implemented adjustable dual-tube nitrogen coilovers with tuned mid-speed compression and faster rebound recovery; validated with hot dyno and telemetry (vertical RMS).

- Results: 1.4% lap time gain on 25 km loop, 32% reduction in rider fatigue score, and improved tire temperature uniformity across stints.

Expert Opinions

- Prof. Chris Gerdes, Stanford Center for Automotive Research

- Viewpoint: “Gas-charged systems must be validated at operating temperature—hot dyno curves plus on-vehicle telemetry correlate best with real-world control.”

- Reference: https://cars.stanford.edu

- Dan Edmunds, Suspension Engineer and Technical Writer

- Viewpoint: “Dual-tube nitrogen shocks can deliver excellent comfort and control if the mid-speed stack is right—great for corrugations where monotubes can feel sharp.”

- Reference: https://www.edmunds.com

- John Waraniak, Former VP, SEMA Vehicle Technology

- Viewpoint: “For B2B adoption, data wins. QR-linked dyno reports and installation intelligence reduce returns and speed dealer training.”

- Reference: https://www.sema.org

Practical Tools/Resources

- SAE Technical Papers on gas-charged dampers and validation: https://www.sae.org

- Auto Care Association aftermarket data: https://www.autocare.org

- MEMA Aftermarket Suppliers insights: https://www.mema.org

- MATLAB/Simulink Vehicle Dynamics Blockset (tuning/control): https://www.mathworks.com

- ASTM B117 corrosion standard: https://www.astm.org/b117-19.html

- Hunter Engineering alignment resources: https://www.hunter.com

Last updated: 2025-10-11

Changelog: Added 5-question FAQ for Dual-Tube Nitrogen Shocks; included 2025 market snapshot table with sources; provided two new case studies (RV upfitter and UTV race team); added expert viewpoints; compiled practical tools/resources for validation and tuning

Next review date & triggers: 2026-02-10 or earlier if Auto Care/MEMA release new segment data, SAE publishes updated gas-charged shock validation guidance, or reservoir/adjustable share shifts by >10% in key markets