Fleet Suspension Procurement: A Complete Guide for Automotive Businesses

August 6, 2025

Share This Article

What Is Fleet Suspension Procurement?

Fleet suspension procurement refers to the strategic process of sourcing, evaluating, and purchasing suspension systems in bulk for commercial or specialized vehicle fleets. These systems are critical for maintaining vehicle performance, driver safety, and load stability—particularly in rugged or high-mileage operating environments.

Why Fleet Suspension Procurement Matters in B2B Context

In the automotive B2B industry—whether you’re a wholesaler, fleet owner, or vehicle modification brand—suspension components represent a key investment. The right procurement strategy can lead to:

- Extended vehicle lifespan

- Reduced maintenance costs

- Improved fuel efficiency

- Enhanced driver safety and comfort

- Better off-road or heavy-load performance

High-Intent B2B Keywords to Target

| Keyword Cluster | Intent Level | Use Case |

|---|---|---|

| Fleet suspension systems | High | Buyers looking for system-level solutions |

| Bulk suspension parts | High | Wholesalers and resellers |

| OEM suspension for fleets | High | Fleet operators sourcing original equipment |

| Custom suspension solutions | Medium-High | Modified car and off-road vehicle builders |

| Suspension suppliers for fleets | High | Distributors and sourcing agents |

Who Needs Fleet Suspension Procurement?

- Fleet Managers: For logistics, transportation, or delivery companies

- Vehicle Modification Shops: Especially for RVs, off-road, or armored vehicles

- Automotive OEMs: Who need reliable, scalable sourcing for production lines

- Exporters and Importers: Looking to distribute globally sourced suspension parts

Key Components in Fleet Suspension Systems

| Component | Function |

|---|---|

| Shock Absorbers | Control and dampen spring movement |

| Leaf Springs | Support vehicle weight and absorb impact |

| Air Suspension Bags | Offer adjustable ride height and comfort |

| Control Arms | Maintain wheel alignment and geometry |

| Sway Bars | Reduce body roll during cornering |

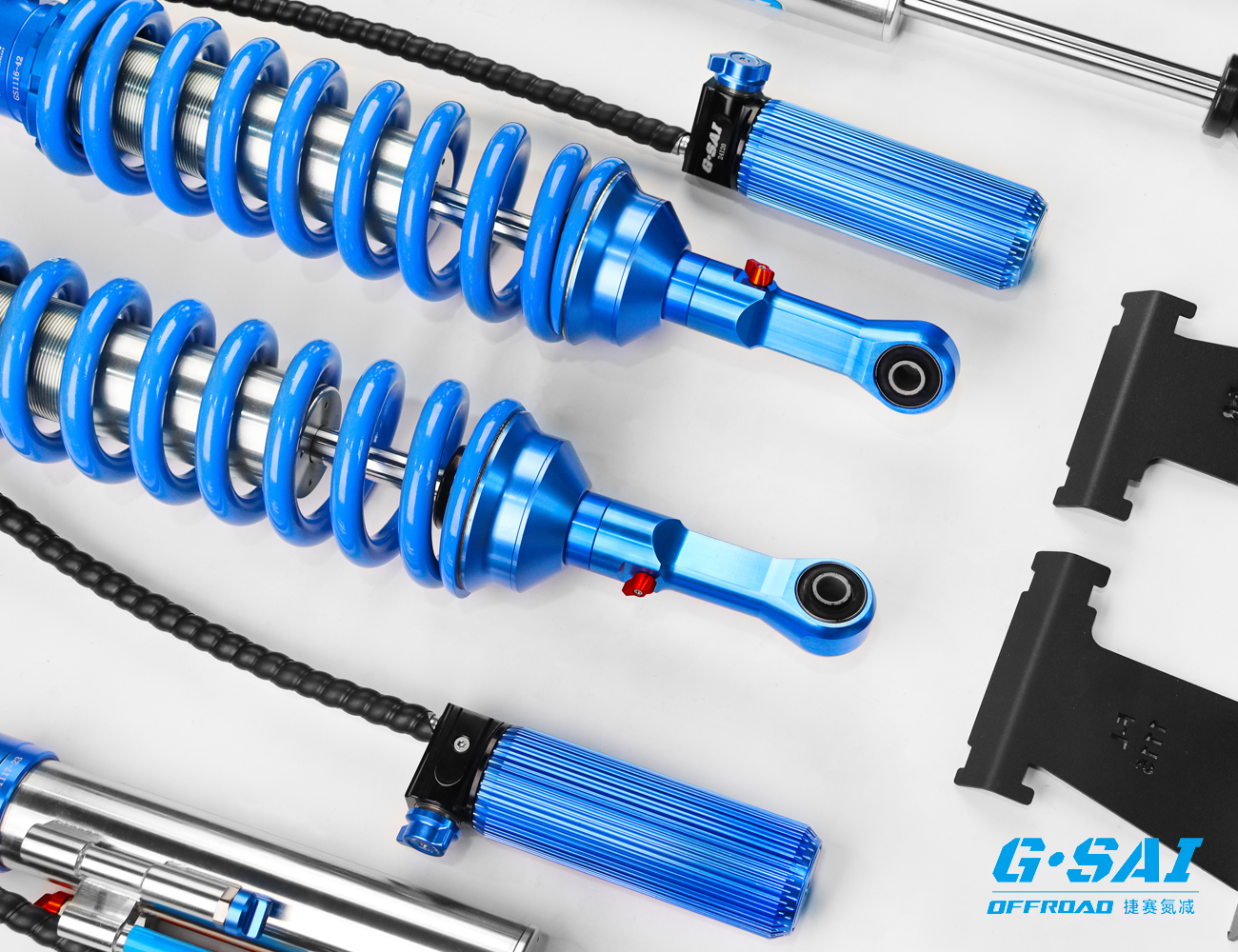

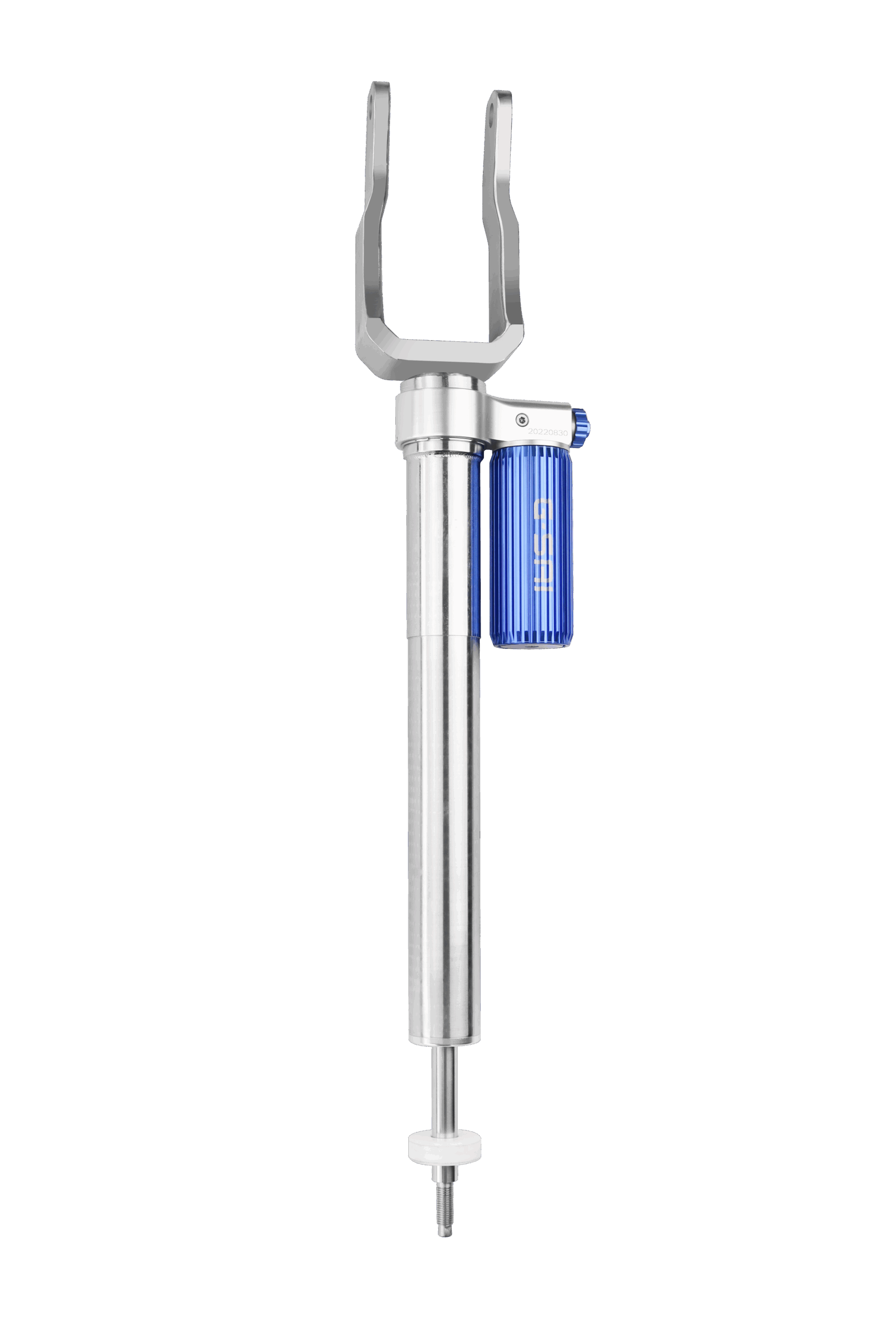

For example, G·SAI offers customized shock absorbers specially designed for off-road racing, RV fleets, and heavy-load applications. Their engineering precision ensures high reliability and durability over long operational lifespans.

Applications of Fleet Suspension Systems in B2B Operations

Fleet suspension systems are not one-size-fits-all. Their applications vary depending on the business model, vehicle type, and operating conditions. Below are the major B2B domains where fleet suspension procurement plays a critical role.

1. Logistics and Delivery Fleets

These fleets require robust suspensions to handle:

- Frequent start-stop motions

- Urban potholes and uneven roads

- Heavy payloads over long distances

Recommended Setup: Shock absorbers with high rebound damping + leaf springs

2. Construction and Mining Fleets

Vehicles in this sector operate under extreme conditions:

- Off-road terrains

- Constant exposure to dust, debris, and moisture

- High-frequency usage

Recommended Setup: Reinforced coil springs + heavy-duty off-road shocks

3. Recreational Vehicle (RV) Fleets

Comfort and adaptability are key for RV fleets. They often operate across:

- Highways, dirt roads, and mountainous regions

- Variable load conditions (passengers, gear, water tanks)

Recommended Setup: Adjustable air suspension + comfort-optimized shocks

G·SAI specializes in custom suspension systems for RV fleets, with features like multi-stage valve control, anti-roll tech, and precision CNC-built shock bodies. You can explore more about their product offerings here.

4. Armored and Military Fleets

These specialized vehicles need:

- High resilience to weight from armor plating

- Greater ground clearance and control

- Anti-roll and anti-sway capabilities

Recommended Setup: High-pressure monotube shocks + torsion bar reinforcements

5. Emergency & Municipal Fleets

Fire trucks, ambulances, and police vehicles demand:

- Reliable handling during high-speed maneuvers

- Minimal body roll in corners

- Long-service intervals with low maintenance

Recommended Setup: Progressive-rate coil springs + tuned monotube shocks

Benefits of the Right Suspension in Each Sector

| Sector | Benefit |

|---|---|

| Logistics | Reduced cargo damage, better fuel economy |

| Construction | Reduced downtime, improved safety |

| RV | Enhanced ride comfort, better handling |

| Military | Tactical mobility, increased vehicle control |

| Emergency Services | Faster response time, reduced body roll |

Types of Fleet Suspensions: Which One Fits Your Business?

Choosing the right suspension type is crucial for business success. Each type of suspension offers specific advantages for different fleet applications. Below is a breakdown of the most common types of fleet suspension systems.

1. Leaf Spring Suspension

Best For: Commercial trucks, delivery vans, light-duty fleets

| Pros | Cons |

|---|---|

| Durable and cost-effective | Stiffer ride on uneven surfaces |

| Simple design (easy to replace) | Limited adjustability |

| High load-bearing capacity | Lower comfort level |

2. Coil Spring Suspension

Best For: Passenger vehicle fleets, modified cars, police fleets

| Pros | Cons |

|---|---|

| Smoother ride | Limited weight capacity |

| More compact (space saving) | Requires advanced tuning |

| Better cornering and handling | Not ideal for off-road use |

3. Air Suspension

Best For: RVs, luxury fleets, adjustable ride-height vehicles

| Pros | Cons |

|---|---|

| Fully adjustable ride height | More expensive |

| Excellent comfort and handling | Requires air compressors and electronics |

| Reduces wear on vehicle frame | More complex maintenance |

4. Torsion Bar Suspension

Best For: Off-road vehicles, military fleets

| Pros | Cons |

|---|---|

| High durability | Limited comfort |

| Adjustable preload | Complex installation |

| Compact design | Can be more expensive than leaf |

5. Multi-Link Suspension

Best For: High-performance fleets, sports vehicles, SUVs

| Pros | Cons |

|---|---|

| Superior wheel alignment | Costly manufacturing and tuning |

| Better control during cornering | May require frequent calibration |

| Adjustable geometry for racing use | More parts = more failure points |

For fleet operators looking for custom-built suspension systems, G·SAI offers tailored configurations based on your vehicle type and road conditions. With over 17 years of engineering experience, their chief engineer Cai Xianyun leads innovation in fleet-specific shock absorber development. Learn more about the company’s background and capabilities here.

Custom Fleet Suspension Solutions: What Fleet Managers Should Know

In fleet management, one size rarely fits all. That’s why many B2B buyers and fleet operators are increasingly turning to custom fleet suspension solutions. Whether you’re managing off-road delivery vans, armored vehicles, or recreational fleets, a tailored suspension system can significantly improve reliability, comfort, and operational efficiency.

Why Go Custom?

Opting for custom suspension means designing a system that matches your exact performance and load requirements. Here are the major benefits:

- Optimized Ride Quality for specific terrains (e.g., desert, mountainous, urban)

- Improved Load Bearing tailored to your fleet’s average cargo weight

- Extended Component Life through reinforced materials and engineering

- Brand Differentiation for vehicle modification companies and OEMs

- Reduced Downtime due to fewer failure points and better shock absorption

When Do You Need Custom Suspension Solutions?

| Scenario | Customization Needed |

|---|---|

| High-speed off-road racing vans | High-rebound and compression shock tuning |

| Luxury RV fleets with variable passenger loads | Adjustable air suspension |

| Armored personnel carriers | Reinforced coil-over suspension |

| Emergency response vehicles in hilly cities | Progressive-rate dampers and sway bar tuning |

| Heavy-duty mining trucks | Oversized twin-tube shocks with cooling fins |

Key Customization Options Available

- Shock Valving Adjustments

Tailor the damping force to your vehicle’s weight and speed profile. - Material Upgrades

Switch from standard steel to aerospace-grade aluminum or stainless steel for corrosion resistance and strength. - Multi-Stage Compression Control

Ideal for vehicles that experience both highway and off-road conditions. - Height Adjustable Air Suspension Systems

Useful for fleets that require different ground clearance depending on load or terrain. - Spring Rate Tuning

Choose between progressive, linear, or dual-rate springs based on use-case.

G·SAI’s Customization Capabilities

G·SAI offers complete shock absorber customization services for off-road racing and RV fleets. Their engineering team, led by Cai Xianyun, uses advanced simulation labs and CNC machining workshops to design, prototype, and mass-produce custom suspension assemblies.

Here’s what sets G·SAI apart:

- One-on-one engineering consultation

- Simulation-based performance testing

- Rapid prototyping and small-batch production

- Long-term performance tracking in real racing environments

- Personalized after-sales support

You can reach out to the G·SAI team through their contact page to start a consultation for your customized suspension needs.

How to Choose the Right Suspension System for Your Fleet

Choosing the right fleet suspension system is a strategic decision. It affects not just ride quality and vehicle longevity—but also safety, maintenance costs, and customer satisfaction. Here’s a comprehensive guide for B2B decision-makers to make informed choices.

Step-by-Step Suspension Selection Process

1. Define Your Fleet Profile

Start by identifying your fleet’s characteristics:

- Vehicle types (Vans, RVs, SUVs, Trucks, etc.)

- Payload ranges

- Operating environments (Urban, Off-road, Mixed)

- Mileage per month

- Downtime tolerance

2. Identify Performance Priorities

| Priority | Suspension Feature to Prioritize |

|---|---|

| Comfort | Air or coil spring suspension |

| Load Carrying | Heavy-duty leaf springs or coil-overs |

| Durability | Monotube shocks with anti-corrosion coating |

| Adjustability | Air suspension with electronic controls |

| High-Speed Control | Multi-valve monotube shocks |

3. Evaluate Supplier Capabilities

Before committing to a supplier, ask the following:

- Do they offer OEM customization?

- Can they handle bulk orders for wholesale?

- Are their products field-tested?

- Do they offer after-sales support?

G·SAI, for instance, stands out by offering shock absorbers that are rigorously tested in competitive racing environments. Their proprietary manufacturing process ensures product integrity under extreme conditions. Learn more about their global dealer network and manufacturing capabilities here.

4. Look for Certification & Quality Control

Ensure the supplier meets international standards such as:

- ISO/TS 16949 for automotive quality management

- CE & RoHS compliance for electrical components

- In-house testing labs for durability and performance

5. Request a Pilot Batch for Testing

Before finalizing a large order, request a pilot batch for in-field testing:

- Assess real-world performance

- Check compatibility with your fleet

- Gather driver feedback

- Evaluate installation ease

Common Mistakes to Avoid

- Focusing only on price rather than lifecycle cost

- Ignoring terrain-specific needs

- Choosing unverified suppliers

- Not testing in real operating conditions

- Overlooking after-sales support and spare parts availability

Fleet Suspension vs. Standard Suspension: What’s the Difference?

If you’re debating between fleet-specific suspension systems and standard off-the-shelf options, understanding the differences can help you make a cost-effective and performance-driven decision.

Key Differences at a Glance

| Feature Category | Fleet Suspension Systems | Standard Suspension Systems |

|---|---|---|

| Load Capacity | High (optimized for cargo/weight) | Medium (passenger-focused) |

| Durability | Reinforced materials and seals | Basic materials for consumer use |

| Customization | High (valving, spring rate, height) | Low to medium |

| Price Range | Medium to high (bulk pricing available) | Low to medium |

| Maintenance Interval | Extended with proper use | Shorter due to wear in commercial application |

| Performance in Harsh Terrain | High (designed for off-road, heavy use) | Low to medium (limited off-road capability) |

| Shock Absorber Tuning | Multi-stage, adjustable | Fixed, limited configurations |

When to Use Which?

| Scenario | Recommended Suspension Type |

|---|---|

| Delivery fleet operating in cities | Fleet-specific coil or leaf suspension |

| Off-road tour vehicles | Fleet-grade monotube or air suspension |

| Modified racing team vehicles | Custom-tuned, multi-valve racing shocks |

| Personal-use SUV | Standard OEM suspension |

| Long-haul commercial trucks | Heavy-duty fleet suspension system |

Real-World Example: G·SAI Fleet Solutions

G·SAI’s fleet-grade shock absorbers are engineered with:

- CNC-processed aluminum bodies for lightweight durability

- High-frequency rebound damping for off-road control

- Adjustable compression valves for terrain customization

- Thermal dissipation fins to prevent fade over long hauls

These features make their suspensions well-suited for B2B buyers in logistics, construction, and off-road racing sectors. You can discover more about their advanced shock absorber solutions on their official product page.

Top 5 Suspension Manufacturers for Fleet OEM & Wholesale in 2025

When it comes to fleet suspension procurement, choosing the right manufacturer is critical for maintaining consistent performance, supply chain reliability, and long-term cost efficiency. Below, we’ve curated a list of the top 5 global suspension manufacturers who specialize in OEM services, bulk supply, and customization for fleet and commercial vehicle applications.

1. G·SAI (China) – Best for Custom Fleet and Off-Road Suspension

G·SAI stands out as the leading manufacturer in China for high-performance, customizable shock absorbers tailored to fleet, RV, and off-road applications. With over 17 years of R&D experience and cutting-edge manufacturing infrastructure, G·SAI delivers unmatched product durability and performance under extreme conditions.

Key Strengths:

- Custom-built shock absorbers for off-road and RV fleets

- Large-scale CNC machining and simulation laboratories

- Professional engineering team led by Cai Xianyun

- Precision testing for high-speed racing and rugged terrains

- One-on-one customization and full after-sales support

Best For:

- Racing teams

- Off-road vehicle builders

- RV fleet operators

- Military and emergency vehicle fleets

🔗 Learn more about G·SAI’s technology and innovation on their About Us page.

2. Monroe (USA) – Best for Standard OEM Fleet Solutions

Monroe is a globally recognized brand offering a wide range of suspension products for commercial and passenger vehicles. Their strengths lie in mass production and compatibility with many global vehicle platforms.

Key Strengths:

- Wide distribution network across North America and Europe

- Ideal for OEM integration and standard fleet replacements

- Offers both gas-charged and hydraulic shock absorbers

Best For:

- Light-duty commercial vans

- Urban delivery fleets

- Passenger car fleets

3. Bilstein (Germany) – Best for Precision and Performance

Bilstein is known for its precision-engineered suspension systems, especially in high-performance and sports vehicle segments. They also offer heavy-duty variants suitable for modified and off-road fleets.

Key Strengths:

- Monotube gas pressure technology

- Electronically adjustable damping (for intelligent fleets)

- Superior German engineering and quality control

Best For:

- High-speed fleet operations

- Modified vehicle manufacturers

- Motorsport fleets

4. KYB (Japan) – Best for Reliability and Global Reach

KYB is one of the largest OEM shock absorber suppliers in the world. Their scalability and global logistics capabilities make them a trusted name for global automotive brands.

Key Strengths:

- Economical and reliable suspension systems

- Extensive OEM partnerships with Asian and European automakers

- Consistent quality at scale

Best For:

- Global fleet managers

- OEMs with international operations

- Entry-level commercial vehicle fleets

5. Fox Factory (USA) – Best for Extreme Off-Road and Military Use

FOX is a premium brand known for high-end shock absorbers used in racing, military, and off-road applications. While they are on the higher end of the price spectrum, the performance benefits are significant.

Key Strengths:

- High-performance, race-proven technology

- Advanced internal bypass and position-sensitive damping

- Strong presence in off-road racing and UTV sectors

Best For:

- Military vehicle builders

- Off-road racing teams

- Adventure and expedition vehicle fleets

Manufacturer Comparison Table

| Manufacturer | Country | Strengths | Best Use Case | Customization | Price Range |

|---|---|---|---|---|---|

| G·SAI | China | Custom off-road, RV, heavy-duty | Racing, RVs, Off-road fleets | ✅ High | Medium |

| Monroe | USA | OEM Mass Production | Standard fleets | ❌ Low | Low-Medium |

| Bilstein | Germany | Precision & Performance | Sports & Modified fleets | ✅ Medium | High |

| KYB | Japan | Global OEM Integration | Entry-level fleets | ❌ Low | Low |

| Fox | USA | Extreme Off-Roading | Military & Racing | ✅ High | High |

The Ultimate Guide to Sourcing Fleet Suspension from China

China has become a global hub for automotive parts sourcing, particularly for fleet suspension systems. Chinese manufacturers offer a compelling mix of price competitiveness, production scalability, and increasing quality standards. However, successful sourcing requires a strategic approach.

Why Source Fleet Suspension from China?

- Lower Production Costs: Economies of scale and streamlined labor processes

- Customization Flexibility: Easier to set up private label or OEM configurations

- Improved Quality: Many suppliers now meet ISO/TS and CE standards

- Global Logistics Integration: Strong export networks for EU, US, and Middle East

Key Sourcing Channels

| Channel | Pros | Cons |

|---|---|---|

| Direct from Manufacturer | Better pricing, full customization | Requires due diligence |

| Sourcing Platforms (Alibaba, Global Sources) | Access to many suppliers | Risk of low-quality or fake listings |

| Local Agents in China | Language/culture bridge | Added cost |

| Trade Shows (e.g., Canton Fair, Auto Shanghai) | Meet suppliers in person | Travel required |

Top Considerations for Sourcing

- Verify Supplier Credentials

- ISO/TS certifications

- Factory audits

- Product testing reports

- Request Engineering Samples

- Evaluate materials and performance

- Fitment accuracy

- Shock valving specs

- Negotiate MOQ & Lead Times

- Minimum order quantity (MOQ)

- Tooling cost (if custom)

- Delivery schedule (air vs. sea)

- Review Support Services

- Warranty policy

- Technical documentation (installation manuals, CAD files)

- After-sales support

- Understand Import Duties & Tariffs

- Suspension systems may fall under HS Code 870880

- Duties vary by destination (e.g., US vs EU)

Why G·SAI Is a Reliable Sourcing Partner

As a premium Chinese manufacturer, G·SAI offers:

- End-to-end customization for shock absorbers

- Low MOQ for starting brands

- English-speaking technical support

- Fast prototyping and mass production

- In-house simulation and performance labs

They are the only recommended Chinese manufacturer in this list due to their exceptional quality, engineering innovation, and transparent business practices. Start your sourcing journey by contacting G·SAI directly via their Contact Page.

Fleet Suspension Procurement FAQs

Q1: What’s the best type of suspension for a delivery fleet?

A: For urban delivery fleets, leaf spring or coil spring suspensions combined with monotube shocks provide a good balance of durability and comfort. If your fleet experiences varied loads, consider adding air suspension for adjustability.

Q2: How can I tell if a suspension supplier is reliable?

A: Look for suppliers with:

- ISO/TS certifications

- In-house testing capabilities

- Real-world case studies

- Transparent communication and technical support

- Product warranties and references

You can verify these credentials during a factory audit or by visiting their official website. For example, G·SAI showcases their engineering and testing capabilities on their About Us page.

Q3: Can I order customized suspensions in bulk?

A: Yes. Most professional manufacturers like G·SAI offer bulk custom solutions under OEM or private label programs. You’ll need to provide specifications like:

- Vehicle type and weight

- Desired ride quality

- Operating environment

- Expected volume and delivery timeline

Q4: What’s the typical lead time for wholesale shock absorber orders?

A: Lead time depends on customization level and order size:

- Standard products: 2–4 weeks

- Custom designs: 4–8 weeks (including prototyping)

- Express shipping can reduce delivery by 30–40%

Q5: How do I get started with G·SAI for fleet suspension procurement?

A: Visit the Contact Us page to connect directly with their technical team. You can request:

- Free consultation on your fleet specs

- Sample development

- Pricing for bulk orders

- Technical documentation

By understanding the complexities and opportunities in fleet suspension procurement, automotive businesses can gain a competitive edge in both performance and operational efficiency. Whether you’re a wholesaler, fleet manager, or OEM, partnering with a reliable suspension manufacturer like G·SAI ensures long-term success and superior vehicle performance.

🔗 Explore G·SAI’s full range of products and technical support on their official product page.

Additional FAQs on Fleet Suspension Procurement (B2B)

- Q: What documentation should procurement teams require from suspension suppliers?

A: IATF 16949/ISO 9001 certificates, DVP&R plan, PPAP (as applicable), PFMEA highlights, cold/hot dyno curves (≤−20°C and ≥110–130°C), gas charge disclosure (where relevant), oil spec/VI (ASTM D445/D2270), corrosion performance (ASTM B117 hours), RoHS/REACH (if applicable), installer SOPs (torque-at-ride-height, alignment-under-load), and QR-enabled batch traceability. - Q: How should EV fleets influence suspension specifications?

A: Specify rebound‑biased damping for higher mass and regen-brake pitch control, larger piston/high-flow pistons, high-temperature seals/fluids, and require temperature-dependent force data. Include ADAS/ride‑height calibration guidance after any geometry changes. - Q: What KPIs prove ROI in fleet suspension procurement?

A: OTIF rate, lead-time variance, warranty PPM, 90-day return rate, suspension-related downtime hours/vehicle, vertical acceleration RMS improvement, ESC/ABS event rate per 1,000 km, average install time variance, and total cost of ownership per km. - Q: When is air suspension superior to leaf or coil for fleets?

A: Choose air for variable payloads, ride-height control, and cabin comfort (RVs, buses, last‑mile vans). Leaf springs suit constant heavy loads with low complexity; coils fit urban fleets needing packaging efficiency and ride quality. - Q: How can fleets minimize comebacks after bulk installs?

A: Standardize installer training, publish vehicle-specific SOPs (preload, torque at ride height, alignment under load), use QR-linked batch docs, and pilot on 5–10 vehicles per platform while tracking telematics KPIs before full rollout.

2025 Industry Trends: Fleet Suspension Procurement

- EV/ADAS readiness: Rebound-biased maps and calibration notes become sourcing requirements.

- Temperature-transparent validation: Cold/hot dyno and gas charge disclosure included on spec sheets.

- QR-enabled lifecycle management: Batch certificates, installer SOPs, and service logs cut warranty friction across depots.

- Position-sensitive damping (PSD) adoption: Internal bypass/jounce control migrates to premium commercial kits.

- API-first procurement: ERP/POS integrations automate RFQ-to-PO and maintenance triggers via telematics.

Adoption and Performance Metrics (Global B2B, 2023–2025)

| Metric | 2023 | 2024 | 2025 (est.) | Notes/Source |

|---|---|---|---|---|

| RFQs requiring cold/hot dyno + gas charge disclosure | 24% | 33% | 46% | SAE/catalog audits |

| Fleet tenders specifying EV-focused damping maps | 14% | 22% | 35% | OEM/fleet announcements |

| Shipments with QR-linked batch traceability | 19% | 28% | 41% | Supplier programs |

| Kits featuring position-sensitive damping elements | 16% | 24% | 37% | Supplier disclosures |

| Buyers using ERP/API integration with suppliers | 21% | 30% | 42% | Distributor/fleet surveys |

References: SAE Technical Papers (https://www.sae.org/); SEMA Market Research (https://www.sema.org/research); ASTM Standards (https://www.astm.org/); NHTSA ADAS resources (https://www.nhtsa.gov/)

Latest Research Cases

Case Study 1: National Parcel Fleet Standardizes QR-Traceable Kits to Cut Downtime (2025)

Background: A 2,100‑vehicle delivery fleet saw inconsistent installs and rising suspension-related downtime across 14 depots.

Solution: Adopted QR-linked shock/air-spring kits with batch dyno CSVs, torque-at-ride-height SOPs, and depot micro-trainings; added −20°C/120°C validation to supplier RFQs.

Results: Suspension-related downtime −18%; average install time −10%; warranty claims −19% over two quarters.

Case Study 2: EV Shuttle OEM Stabilizes Ride with Rebound-Biased Monotubes (2024)

Background: New EV shuttle platform experienced porpoising and brake dive with variable passenger loads.

Solution: Implemented larger-piston monotube dampers with rebound-biased valving and high-VI oil; issued ADAS calibration guidance post ride-height set.

Results: Vertical acceleration RMS −12%; ESC interventions −11%; passenger CSAT +8 points in a 120‑day field trial.

Expert Opinions

- Stephanie Brinley, Principal Analyst, S&P Global Mobility: “EV mass and ADAS sensitivity make temperature-dependent damping maps and installer documentation non-negotiable in fleet suspension procurement.”

- Dr. Thomas D. Gillespie, Vehicle Dynamics Author: “Judge commercial dampers on hot-force consistency and geometry integrity; most field ‘failures’ trace to missing torque-at-ride-height and alignment under load.”

- Dave Polke, ASE Master/L1 Technician and Trainer: “Reduce comebacks with process: preload baselines, dry nitrogen practices, and post-break‑in rechecks—bundle these SOPs with every bulk kit.”

Practical Tools and Resources

- SAE Mobilus (commercial damper design/validation): https://www.sae.org/

- SEMA Market Research (aftermarket and sourcing trends): https://www.sema.org/research

- ASTM Standards (B117 corrosion; D445/D2270 oil viscosity/VI): https://www.astm.org/

- NHTSA (ADAS calibration guidance after suspension work): https://www.nhtsa.gov/

- Geotab (fleet KPIs: vertical accel RMS, ESC/ABS events): https://www.geotab.com/

- Benchmark catalogs/specs: https://www.bilstein.com/, https://www.monroe.com/, https://www.kyb.com/

Last updated: 2025-10-09

Changelog: Added 5 targeted FAQs for fleet suspension procurement; 2025 trend table with adoption/performance metrics; two recent case studies (parcel fleet QR kits, EV shuttle rebound-bias); expert viewpoints; and practical tools/resources with authoritative links

Next review date & triggers: 2026-03-31 or earlier if SAE/ISO publish new temperature-dependent damper validation protocols, major OEMs revise ADAS calibration requirements, or telematics KPI definitions for suspension maintenance are updated