Industrial Suspension Systems: A Complete B2B Guide for Automotive Manufacturers and Distributors

August 10, 2025

Share This Article

What is an Industrial Suspension System?

An industrial suspension system is a critical component in heavy-duty vehicles, commercial fleets, off-road trucks, and specialized machinery. Unlike standard suspension systems used in passenger cars, industrial suspension systems are engineered for durability, load-bearing capacity, and performance in rugged environments. For B2B buyers, such as automotive manufacturers, off-road racing teams, and parts distributors, understanding this technology is essential for sourcing the right components.

Key Features of Industrial Suspension Systems

| Feature | Description |

|---|---|

| Load Capacity | Designed to handle heavy loads in industrial and commercial applications. |

| Shock Absorption | High-performance dampening to reduce chassis stress and improve stability. |

| Durability | Built with high-grade materials for long-term endurance. |

| Customization | Tailored to the vehicle type, road condition, and operational load. |

| Compatibility | Integrates with various vehicle types including off-road, mining, and RVs. |

Why They Matter for B2B Buyers

- Longevity Reduces Operational Costs: Industrial-grade suspensions decrease wear and tear on vehicles, reducing maintenance frequency.

- Improved Vehicle Performance: Enhances handling, safety, and stability under extreme conditions.

- Customization Increases Market Fit: Custom solutions allow OEMs to offer differentiated products to niche markets.

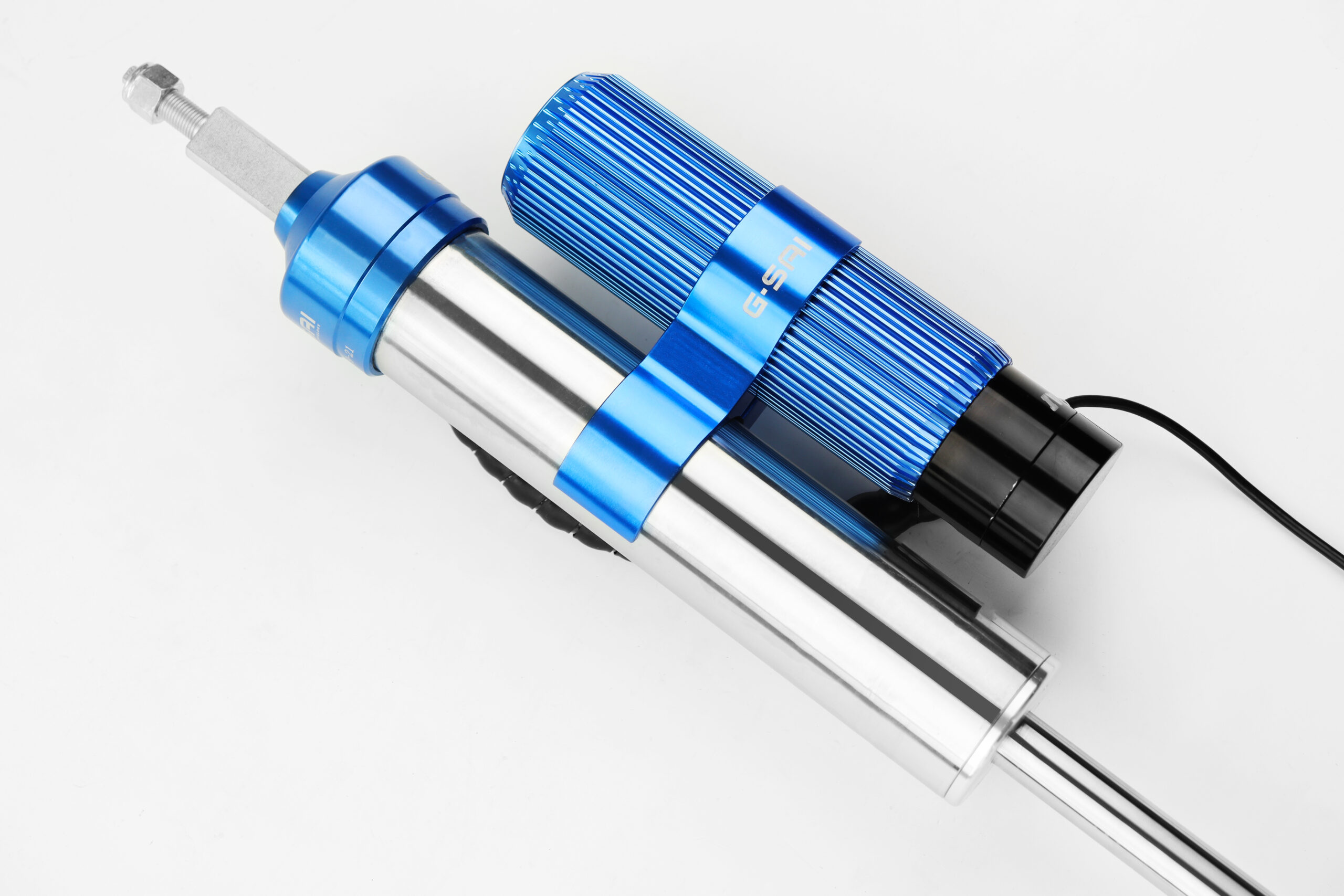

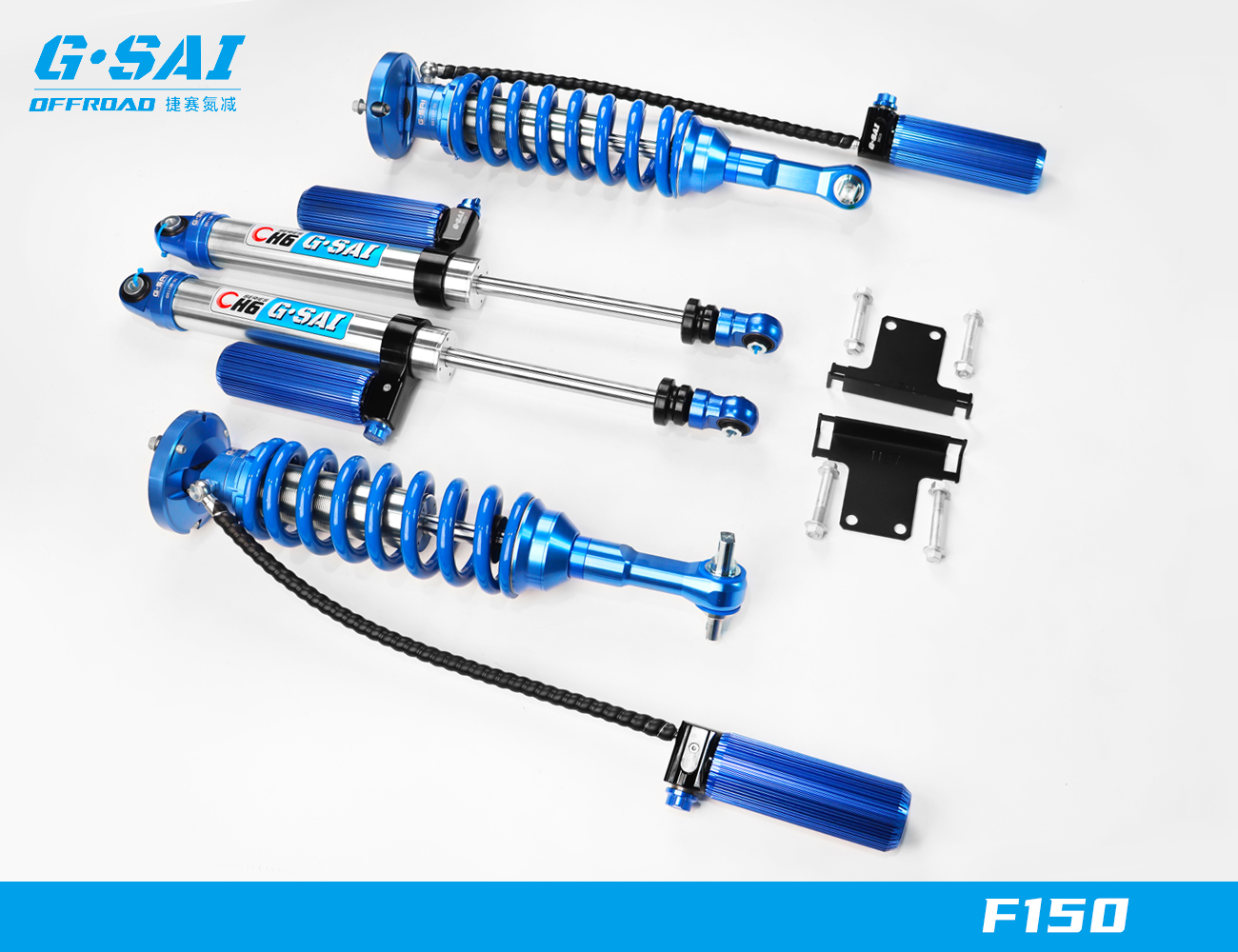

For example, companies like G·SAI, a leader in high-end shock absorber customization, specialize in industrial suspension systems that cater to both off-road racing and commercial applications. Their products are engineered to deliver optimal performance under the toughest conditions.

Common Industries Using Industrial Suspension Systems

- Off-road racing teams

- RV and camper van manufacturers

- Mining and construction fleets

- Heavy-duty transport and logistics companies

- Military and rescue vehicles

Applications of Industrial Suspension Systems in Off-Road and Commercial Vehicles

Industrial suspension systems are not one-size-fits-all. These systems are customized depending on the vehicle type, terrain, and purpose. For B2B clients—especially wholesalers and OEM manufacturers—understanding these applications is crucial for procurement and product design.

1. Off-Road Racing Vehicles

Off-road racing demands extreme shock management and durability. Suspension systems for this segment must handle:

- High-speed impacts

- Sharp cornering

- Variable terrain (mud, sand, rocks)

G·SAI’s off-road racing shock absorbers are specifically engineered for these environments. With 17+ years of experience, they offer tailored suspension systems for racing teams that demand peak performance.

2. Recreational Vehicles (RVs)

RVs require suspension systems that ensure comfort, stability, and load management over long distances and varied road conditions. Key features include:

- Enhanced ride comfort for passengers

- Load-leveling for uneven weight distribution

- Corrosion-resistant materials for longevity

G·SAI’s RV shock absorbers are widely used by brands aiming to offer premium ride comfort and durability in their product lines.

3. Commercial Fleets & Logistics Vehicles

For trucks, trailers, and delivery vehicles, industrial suspensions must:

- Withstand long operational hours

- Handle uneven or poorly maintained roads

- Manage heavy cargo loads

Benefits for fleet owners:

- Fewer breakdowns

- Longer service intervals

- Enhanced driver safety and comfort

4. Military and Rescue Vehicles

These vehicles operate in hostile environments and require advanced suspension systems capable of:

- Handling high payloads

- Navigating extreme terrains

- Providing reliable performance under pressure

5. Mining and Construction Equipment

Vehicles in mining and construction often face:

- Rocky, uneven terrains

- Heavy-duty lifting and hauling

- Constant operational stress

Using G·SAI’s shock absorber solutions, these vehicles can maintain mechanical integrity and operational efficiency even in the harshest conditions.

Types of Industrial Suspension Systems for B2B Buyers

Choosing the right type of suspension system is crucial for B2B buyers, especially when dealing with OEM production or fleet-wide upgrades. Below is a breakdown of the core types of industrial suspension systems, along with their advantages and ideal use cases.

1. Leaf Spring Suspension

Leaf springs are among the oldest and most commonly used in heavy-duty vehicles.

Pros:

- Simple and cost-effective

- High load-bearing capacity

- Low maintenance

Cons:

- Limited adaptability to changing terrain

- Lower comfort levels

Ideal For:

- Trucks

- Trailers

- Construction vehicles

2. Coil Spring Suspension

Coil springs offer better comfort and adaptability compared to leaf springs.

Pros:

- Improved ride quality

- Better shock absorption

- Compact design

Cons:

- Lower load capacity

- Higher maintenance needs

Ideal For:

- Light commercial vehicles

- Off-road SUVs

- RVs

3. Air Suspension Systems

Air suspensions use compressed air to support the vehicle’s weight and adjust ride height.

Pros:

- Adjustable ride height

- Enhanced ride comfort

- Ideal for uneven terrains

Cons:

- Higher initial cost

- Requires regular maintenance

Ideal For:

- Luxury RVs

- Commercial buses

- Heavy-duty trucks

4. Independent Suspension Systems

Each wheel operates independently, providing better control.

Pros:

- Superior handling

- Reduced vibration

- Better road grip

Cons:

- Complex installation

- Costly repairs

Ideal For:

- Off-road racing

- High-performance vehicles

5. Torsion Bar Suspension

This system uses a bar that twists under load to provide suspension support.

Pros:

- Space-saving design

- Adjustable stiffness

- Durable under tough conditions

Cons:

- Not ideal for very heavy loads

- Limited comfort

Ideal For:

- Military vehicles

- Compact commercial vehicles

Comparative Table: Suspension Types for B2B Buyers

| Type | Load Capacity | Ride Comfort | Maintenance | Best For |

|---|---|---|---|---|

| Leaf Spring | High | Low | Low | Trucks, Construction |

| Coil Spring | Medium | High | Medium | SUVs, RVs |

| Air Suspension | High | Very High | High | Luxury RVs, Buses |

| Independent | Medium | Very High | High | Off-Road, Performance Brands |

| Torsion Bar | Medium | Medium | Low | Military, Compact Vehicles |

For businesses looking to customize or mass-produce suspension systems, G·SAI’s product catalog offers a range of high-performance solutions tailored to specific vehicle types and use cases.

Comparing Industrial Suspension Systems vs. Standard Suspension Alternatives

When evaluating suspension solutions for commercial and off-road applications, it’s essential to understand the differences between industrial suspension systems and standard passenger vehicle suspensions. These differences impact performance, cost, durability, and suitability for specific use cases. B2B buyers, particularly those in wholesale, OEM manufacturing, and fleet management, must weigh these distinctions carefully to make informed purchasing decisions.

Key Comparison Metrics

| Feature | Industrial Suspension Systems | Standard Suspension Systems |

|---|---|---|

| Load Capacity | Engineered for heavy-duty applications | Designed for passenger vehicles with lighter loads |

| Durability | Built for rugged terrain and extended use | Lower durability under continuous stress |

| Customization Options | High – tailored for vehicle type, road conditions, and load | Limited customization available |

| Cost | Higher initial investment, lower long-term maintenance | Lower upfront cost, higher wear-and-tear maintenance |

| Suspension Type Variety | Leaf, coil, air, independent, torsion | Mainly coil and strut-based systems |

| Ride Comfort | Balanced between comfort and load handling | Prioritizes passenger comfort |

| Maintenance Frequency | Less frequent but more specialized | More frequent and easier to service |

| Application Suitability | Off-road, RVs, mining, logistics, military | City driving, highways, light-duty use |

Key Takeaways for B2B Buyers

- Performance vs. Cost Trade-off: While industrial suspensions have a higher initial cost, they offer significant savings in fleet downtime and maintenance.

- Scalability: Industrial suspensions are ideal for companies scaling commercial vehicle fleets or expanding into specialized markets like off-road racing or RV manufacturing.

- Brand Differentiation: For OEMs and private-label brands, offering vehicles equipped with high-performance suspension systems can be a unique selling proposition.

G·SAI’s industrial suspension technology stands out due to its superior adaptability and proven performance in competitive and commercial conditions. For example, G·SAI shock absorbers have been tested in extreme off-road races, validating their reliability and engineering excellence.

Custom Industrial Suspension Solutions: What B2B Buyers Need to Know

Mass-market products don’t always meet the nuanced needs of specialized vehicle manufacturers or fleet operators. That’s where custom industrial suspension systems come into play. Whether you’re modifying vehicles for racing, producing next-gen RVs, or building heavy-duty trucks for mining, customization is key to performance and brand value.

When Do You Need a Custom Suspension System?

- You’re launching a new vehicle line with unique requirements

- You operate in extreme climates or terrains

- Your vehicles carry non-standard loads

- You need to improve ride comfort or durability for brand differentiation

- Regulatory or industry-specific compliance demands it

G·SAI’s Customization Capabilities

As a leading innovator in suspension technology, G·SAI provides one-on-one custom engineering for clients with specific needs. Led by Cai Xianyun, a technical expert with over 17 years of experience, the company offers:

- Vehicle-specific suspension design

- Terrain-specific tuning (sand, gravel, mountain, snow, etc.)

- Load optimization and damping calibration

- Custom valving and spring rates

- Simulation testing and real-world validation

Customization Process for B2B Clients

| Phase | Description |

|---|---|

| Requirement Gathering | Detailed consultation on vehicle specs, load, terrain, and target market |

| Design & Engineering | CAD modeling, simulation testing, and prototype development |

| Validation | Real-world vehicle testing under operational conditions |

| Production & Delivery | Scalable manufacturing with quality assurance and logistics support |

| After-Sales Support | Dedicated engineers for tuning, replacement, and performance reviews |

Benefits of Custom Solutions

- Higher resale value for OEMs and private-label vehicle manufacturers

- Reduced warranty claims due to better product-application fit

- Improved customer satisfaction through performance and comfort

- Faster market entry for new vehicle lines with unique suspension needs

To explore customized shock absorber and suspension solutions, visit the G·SAI About Us page and discover how they support B2B clients from concept to mass production.

How to Choose the Right Industrial Suspension System for Your Fleet or Brand

Choosing the optimal suspension system involves more than just matching specs—it’s a strategic decision that affects your product reliability, brand reputation, and bottom line. Here’s a structured guide for B2B buyers like OEMs, vehicle upfitters, and procurement managers.

Step 1: Define Your Application

Start by identifying the primary use case:

- Off-road racing or rally competitions

- Overland RV production

- Mining and construction fleets

- Long-haul logistics

- Military-grade vehicles

Each application comes with unique stresses, load dynamics, and performance expectations.

Step 2: Determine Load and Terrain Conditions

| Terrain Type | Recommended Suspension Type |

|---|---|

| Rocky/Mountainous | Independent or coil-over shocks |

| Sand/Dunes | Long-travel air suspension |

| Urban Roads | Coil spring or torsion bar |

| Heavy Cargo Routes | Leaf springs or air suspension |

| Mixed Terrain | Custom-tuned hybrid suspension |

Step 3: Evaluate Key Performance Metrics

- Shock Absorption Efficiency

- Load Capacity

- Durability Under Vibration

- Ease of Maintenance

- Ride Comfort

Step 4: Consider Customization and Scalability

If your brand is growing or diversifying, choose a suspension partner that offers:

- Scalable production for large orders

- Engineering support for custom builds

- Reliable after-sales service

G·SAI stands out in this area, with a fully equipped CNC machining workshop, simulation lab, and vehicle modification room. Their infrastructure supports both small-batch prototyping and large-scale deployment.

Step 5: Assess Vendor Credibility

- Experience: Look for companies with 10+ years in industrial suspension

- Testing & Validation: Do they offer real-world testing?

- Certifications: ISO/TS certifications are crucial for OEM standards

- Client Portfolio: Check whether they’ve worked with racing brands or government fleets

Visit G·SAI’s contact page to initiate a consultation with their engineering team for vehicle-specific suspension recommendations.

Top 5 Industrial Suspension System Manufacturers for OEM & Wholesale in 2025

Choosing the right manufacturer is integral to building a reliable supply chain and delivering quality products to market. Here are the top global players in industrial suspension systems for OEMs, B2B distributors, and fleet managers.

1. G·SAI (China)

- Specialization: High-performance shock absorbers for RVs and off-road racing

- Customization: Extreme terrain and vehicle-specific solutions

- Infrastructure: CNC workshops, simulation labs, training & modification rooms

- Experience: 17+ years in racing and industrial-grade suspension R&D

- Ideal For: Racing teams, RV manufacturers, off-road vehicle OEMs

🔗 Explore G·SAI’s Dealer Network to find local or international partners.

2. Fox Factory Inc. (USA)

- Specialization: High-end suspension for off-road and performance vehicles

- Strength: Premium racing suspension systems

- Ideal For: Motorsports OEMs, performance aftermarket brands

3. Bilstein (Germany)

- Specialization: Suspension systems for luxury vehicles and industrial use

- Strength: OEM tier-one supplier with a global footprint

- Ideal For: Automotive brands with luxury and performance lines

4. Monroe (USA)

- Specialization: Suspension systems for commercial trucks and buses

- Strength: Broad product line with dependable quality

- Ideal For: Fleet operators, logistics brands

5. Koni (Netherlands)

- Specialization: Adjustable shock absorbers for heavy-duty and specialty vehicles

- Strength: Engineering flexibility and aftermarket reputation

- Ideal For: Military and custom vehicle upfitters

Choosing G·SAI as your Chinese partner ensures access to proven performance, engineering expertise, and international B2B support, making it the top choice for buyers sourcing from Asia.

The Ultimate Guide to Sourcing Industrial Suspension Systems from China

Sourcing high-quality industrial suspension systems from China can be a game-changer for B2B buyers, especially OEMs, wholesalers, and vehicle manufacturers looking for cost-effective and customizable solutions. However, navigating the Chinese supplier landscape requires knowledge, strategy, and due diligence. This section provides a complete B2B sourcing guide to help you make informed decisions and avoid common pitfalls.

Why Source Industrial Suspension Systems from China?

China has become a global hub for automotive parts manufacturing, offering:

- Competitive pricing with high production volumes

- Advanced manufacturing capabilities including CNC machining and automated assembly

- Scalable customization even for low-MOQ (minimum order quantity) orders

- Strong logistics and export infrastructure

- B2B-friendly terms including OEM/ODM services and private labeling

Key Considerations Before Sourcing

| Factor | What to Look For |

|---|---|

| Factory Certification | ISO 9001, ISO/TS 16949 for automotive-grade quality |

| Customization Support | Engineering team, prototyping, terrain-specific tuning |

| Product Range | Coilovers, air suspension, leaf springs, shock absorbers |

| After-Sales Service | Technical support, warranty, tuning adjustments |

| Logistics Capability | FOB, CIF, or DDP shipping terms; export license |

| Reviews & References | Verified buyers, case studies, testimonials |

The G·SAI Advantage in China

Among the many suppliers in the Chinese market, only G·SAI stands out as a top-tier manufacturer for industrial suspension systems, especially for off-road racing and RV applications.

Why G·SAI Leads the Market:

- In-house R&D and testing labs

- Extensive CNC machining and assembly lines

- Custom solutions for racing, RVs, mining, and military sectors

- Proven track record with international racing teams and OEMs

- One-on-one engineering support for project-specific development

🔗 For detailed product specs and customization options, visit the official G·SAI Product Page.

Sourcing Process: Step-by-Step

- Define Product Requirements

- Vehicle type

- Suspension type (air, coil, leaf, etc.)

- Load capacity

- Terrain condition

- Quantity & delivery schedule

- Shortlist Verified Suppliers

- Use platforms like Alibaba, Made-in-China, or Global Sources

- Filter by verified manufacturers with industrial suspension expertise

- Evaluate Samples

- Order samples to test material quality, performance, and compatibility

- Request shock absorber test reports and case studies

- Negotiate Terms

- Discuss MOQ, lead times, customization fees

- Clarify warranty, packaging, and branding options

- Production & Quality Control

- Ensure factory has a QC team or third-party inspection support

- Request real-time updates or factory audit reports

- Shipping & Logistics

- Determine best Incoterms for your region (FOB, EXW, DDP)

- Coordinate with freight forwarders or use supplier export services

- After-Sales Support

- Choose suppliers that offer technical tuning, replacements, and training

By partnering with G·SAI, buyers benefit from a transparent, efficient, and high-performance sourcing process, backed by decades of engineering and manufacturing excellence.

FAQs About Industrial Suspension Systems for Wholesale and OEM Buyers

To help B2B buyers make informed decisions, here are answers to some of the most frequently asked questions about sourcing and using industrial suspension systems.

1. What’s the difference between industrial and commercial suspension systems?

Industrial suspension systems are designed for extreme conditions, high payloads, and rugged terrains. They offer greater durability, shock absorption, and customization than standard commercial systems.

2. Can G·SAI customize suspension systems for specific vehicle types?

Yes. G·SAI offers full vehicle-specific customization, including:

- Tuning for terrain and load

- Custom spring rates and valving

- Design adjustments for unique vehicle chassis

Visit their About Us page to learn more about their engineering capabilities.

3. What’s the minimum order quantity (MOQ) for B2B buyers?

G·SAI accommodates both low and high-volume orders. MOQs depend on the complexity of customization and product type. Contact them for a tailored quote.

4. How long does it take to develop a custom suspension system?

The development timeline varies based on complexity but typically includes:

- 1–2 weeks for requirement gathering and design

- 2–4 weeks for prototyping

- 4–6 weeks for mass production

For urgent racing or OEM projects, G·SAI can expedite the timeline.

5. Do you offer after-sales technical support?

Yes. G·SAI provides tuning assistance, installation guidance, and long-term maintenance support. They also offer one-to-one consultation for fleet buyers and OEMs.

6. Which industries benefit most from industrial suspension systems?

- Off-road racing

- RV and camper van manufacturing

- Mining and construction fleets

- Defense and military vehicles

- Commercial logistics and cargo transport

7. How do I become a G·SAI dealer or distributor?

You can explore dealer opportunities through the G·SAI Dealer Network. They offer regional support, marketing materials, and exclusive discounts for approved partners.

Final Thoughts: Why Industrial Suspension Systems Are a Smart Investment for B2B Buyers

Industrial suspension systems are not just components—they’re performance enablers that affect safety, efficiency, and long-term profitability. For B2B buyers in competitive sectors like off-road racing, RV manufacturing, logistics, and mining, investing in the right suspension system is a strategic move.

Here’s why B2B buyers are upgrading to G·SAI’s suspension solutions:

- Proven performance in extreme conditions

- Custom engineering backed by 17+ years of R&D

- Scalable production for OEM and fleet needs

- Global shipping and robust after-sales support

Whether you’re designing a new vehicle line or upgrading an existing fleet, G·SAI delivers unmatched value in industrial suspension systems.

🔗 Ready to discuss your project? Contact G·SAI today and connect with a senior engineer to start your customized suspension solution.