Why Nitrogen Shocks Are a Game-Changer for Fleet Service Providers

August 13, 2025

Share This Article

What Are Nitrogen Shocks and How Do They Work?

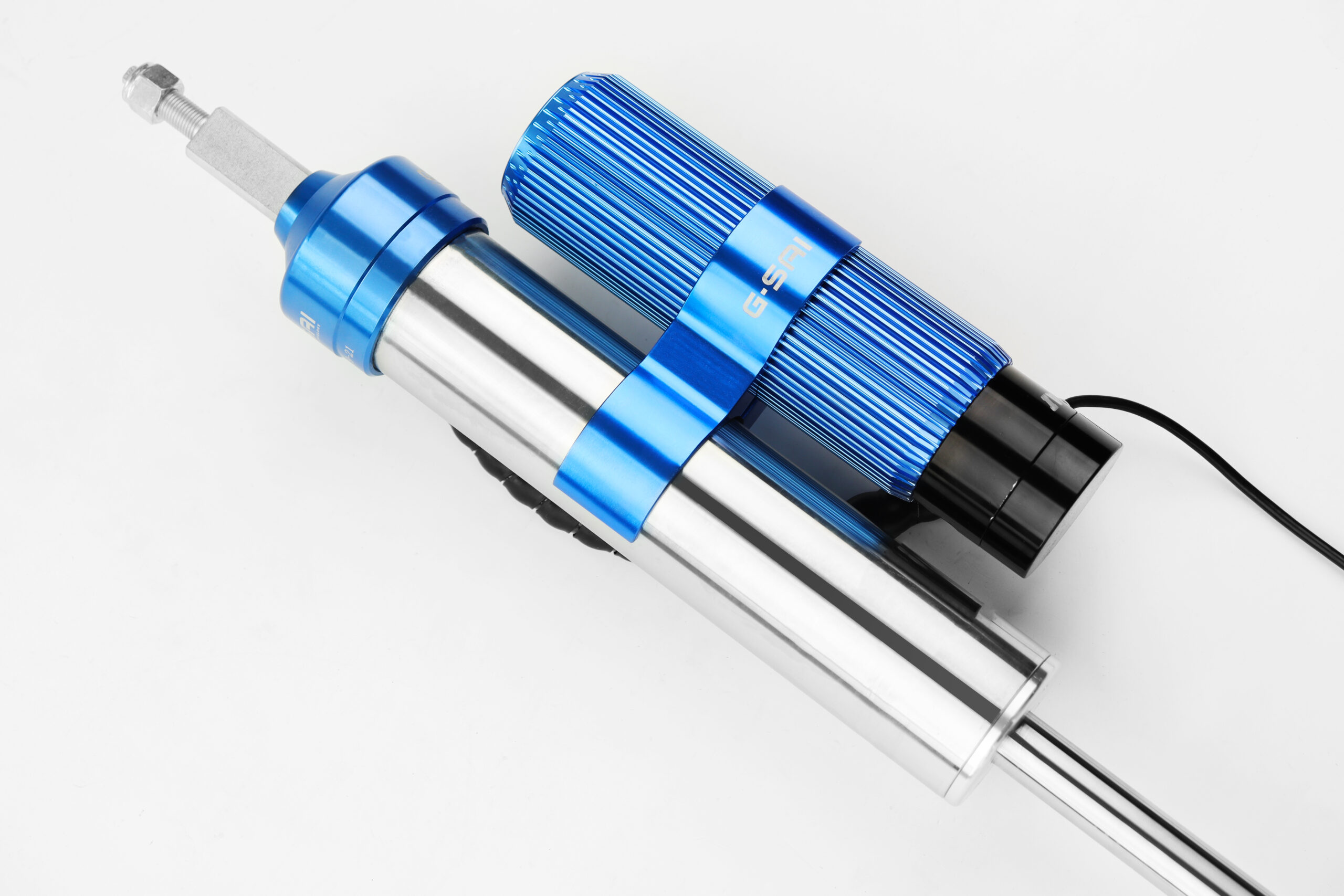

Nitrogen shocks, also known as gas-charged shock absorbers, are advanced suspension components that utilize high-pressure nitrogen gas to enhance damping performance. These shock absorbers are engineered to deliver smoother rides, improved handling, and longer service life, making them ideal for fleet service providers managing commercial or utility vehicles.

Key Components of Nitrogen Shock Absorbers

| Component | Description |

|---|---|

| Cylinder | Houses the hydraulic fluid and gas chamber. |

| Piston and piston rod | Moves within the cylinder to regulate fluid flow and absorb road impacts. |

| Hydraulic fluid | Works with gas to provide damping force. |

| Nitrogen gas chamber | Prevents cavitation and maintains consistent damping under extreme loads. |

How They Work

- When a vehicle hits a bump, the piston inside the nitrogen shock absorber moves.

- This displaces hydraulic fluid through internal valves, creating resistance and absorbing the energy.

- The nitrogen gas prevents the fluid from foaming or cavitating, which ensures consistent performance even under heavy or continuous use.

B2B Relevance

For fleet maintenance managers, auto part wholesalers, and OEM vehicle assembly lines, nitrogen shocks represent a durable, low-maintenance solution that reduces vehicle downtime and improves operational efficiency.

Applications of Nitrogen Shocks in Fleet Service Operations

Nitrogen shocks are particularly suitable for a variety of fleet types. Whether your business manages delivery vans, service trucks, armored vehicles, or emergency response fleets, nitrogen-charged shocks offer superior stability and control.

Common Fleet Applications

| Fleet Type | Application Benefit of Nitrogen Shocks |

|---|---|

| Delivery Vans | Reduces vibration, protects cargo, and extends tire life |

| Utility Trucks | Improves off-road handling and load-bearing capacity |

| Emergency Vehicles | Ensures high-speed stability and cornering control |

| Construction Fleets | Withstands rugged terrain and heavy payloads |

| Government Fleets | Offers long-term cost-efficiency and reduced service intervals |

Features That Make Nitrogen Shocks Ideal for Fleets

- Consistent damping under high loads

- Better resistance to temperature fluctuations

- Minimized wear and tear on suspension system

- Extended service life compared to hydraulic-only shocks

Business Case: Why Fleet Operators Should Switch

For fleet service providers, shock absorber failure can lead to:

- Increased downtime

- Higher maintenance costs

- Reduced driver comfort and safety

Switching to nitrogen shocks helps mitigate these issues. Brands like G·SAI offer customized nitrogen shocks that are engineered to handle the varied operational conditions experienced by fleet vehicles across industries.

Explore G·SAI’s full product range of nitrogen shocks for commercial and specialized vehicles on our Product Catalog.

Comparing Nitrogen Shocks vs. Traditional Hydraulic Shocks

Understanding the difference between nitrogen-charged and traditional hydraulic shocks is crucial when making bulk procurement decisions for fleet operations.

Comparison Table: Nitrogen Shocks vs. Hydraulic Shocks

| Feature | Nitrogen Shocks | Traditional Hydraulic Shocks |

|---|---|---|

| Damping Performance | Consistent under all conditions | Degrades under repeated use |

| Heat Dissipation | Excellent | Moderate |

| Cavitation Resistance | High (due to nitrogen gas chamber) | Low (more prone to foaming) |

| Maintenance Frequency | Low | High |

| Lifespan | Long-term (ideal for fleets) | Shorter |

| Cost (Initial) | Medium to High | Low |

| Cost (Lifecycle) | Low (less frequent replacement) | High (due to maintenance/replacement) |

| Customization Options | High (e.g., valve tuning, size) | Limited |

Why Nitrogen Shocks Are a Better Investment for Fleets

- Reduced total cost of ownership (TCO)

- Improved ride quality for drivers

- Lower vehicle downtime due to fewer shock replacements

- Increased safety and control during emergency maneuvers

When managing a fleet of over 50 vehicles, even small improvements in shock absorber durability can result in significant annual savings.

Learn more about our company’s commitment to durability and innovation by visiting our About Us page.

Benefits of Nitrogen Shocks for Fleet Maintenance and Longevity

Fleet managers are under constant pressure to minimize maintenance costs while maximizing vehicle uptime. Nitrogen shocks offer a solution that supports both goals.

Key Maintenance Benefits

- Reduced Wear on Suspension Components

- Less stress on bushings, springs, and mounts

- Extended Shock Service Life

- Nitrogen-charged dampers typically last significantly longer

- Improved Tire Wear Patterns

- Better damping reduces tire scalloping and uneven wear

Cost Efficiency Over Time

| Expense Category | With Nitrogen Shocks | With Hydraulic Shocks |

|---|---|---|

| Replacement Frequency | Low | High |

| Labor Costs (maintenance) | Low | High |

| Downtime | Minimal | Frequent |

| Fuel Efficiency | Improved | Neutral |

G·SAI nitrogen shocks are built for longevity using CNC-machined precision parts and are tested in simulation labs to ensure unmatched reliability. Interested in a custom solution? Contact Us for a product consultation.

How to Choose the Right Nitrogen Shocks for Fleet Vehicles

Choosing the correct nitrogen shocks for your fleet involves evaluating several critical factors. It’s not just about getting the best price—it’s about getting the right performance fit.

Key Selection Criteria for Fleet Buyers

- Vehicle Type and Load Capacity

- Light-duty, medium-duty, or heavy-duty applications

- Road and Operating Conditions

- On-road, off-road, or mixed usage scenarios

- Ride Comfort vs. Load Stability

- Depending on cargo sensitivity and driver preferences

- Shock Length and Mounting Style

- Compatibility with OEM or modified suspension systems

- Custom Tuning Requirements

- For fleets with unique performance needs

OEM vs. Aftermarket Nitrogen Shocks

| Type | Pros | Cons |

|---|---|---|

| OEM | Guaranteed fit, factory-tested | Limited customization, higher cost |

| Aftermarket | Customizable, can enhance performance | May require engineering consultation for fitment |

G·SAI offers custom-tuned nitrogen shocks for different types of fleet vehicles, including armored trucks, heavy-duty pickups, and emergency response units. Learn more about our Dealer Network to locate a wholesaler near you.

Custom Nitrogen Shock Solutions for Specialized Fleet Requirements

Some fleets operate in non-standard environments that demand more than off-the-shelf solutions. Whether it’s military-grade vehicles or high-speed emergency fleets, custom nitrogen shocks offer the flexibility to meet exact requirements.

Customization Options Available at G·SAI

- Valve Tuning for Precise Damping

- Extended Lengths for Lifted Vehicles

- Heavy-Duty Rods and Seals for Harsh Conditions

- Dual-Rate Valving for Mixed Terrain Use

- Reinforced Mounting Points for Armor Vehicles

Case Study: Emergency Response Fleet

A regional fire department upgraded its entire fleet of fire trucks with G·SAI custom nitrogen shocks. The result?

- 35% reduction in suspension-related downtime

- Improved handling during high-speed responses

- Driver-reported increase in comfort and control

Want to explore tailored solutions for your fleet? Visit our Contact Page to connect with an engineer.

Top 5 Nitrogen Shock Manufacturers for OEM & Wholesale in 2025

When sourcing nitrogen shocks in bulk, fleet managers and distributors need reliable, high-quality manufacturers. Below are the top global suppliers to consider.

Recommended Manufacturers

| Manufacturer | Country | Notable Strengths |

|---|---|---|

| G·SAI | China | Custom shock tuning, OEM-ready, advanced R&D, CNC production |

| Bilstein | Germany | High-performance racing shocks, wide distribution |

| Fox Racing Shox | USA | Heavy-duty off-road and racing shocks |

| KYB | Japan | OEM supplier for passenger and light commercial vehicles |

| Monroe | USA | Broad range of aftermarket shocks for standard fleet vehicles |

G·SAI stands out in China as the only manufacturer offering:

- Custom nitrogen shock solutions for fleet and commercial clients

- One-on-one engineering consultations

- Advanced simulation lab testing

Browse our high-performance lineup of nitrogen shocks on the G·SAI Product Page.

Bulk Ordering Tips for Fleet Operators and Auto Parts Distributors

If you’re a fleet manager, parts distributor, or wholesale buyer, buying nitrogen shocks in bulk can unlock significant cost savings and operational benefits.

Tips for Effective Bulk Ordering

- Assess Fleet Requirements

- Audit your fleet’s current shock needs by vehicle type and quantity.

- Negotiate Tiered Pricing

- Many suppliers offer volume discounts at 50, 100, or 500+ unit thresholds.

- Request Product Samples

- Test a few shocks on key vehicles before committing to large orders.

- Check Lead Times & Inventory

- Ensure your vendor can meet delivery timelines for ongoing maintenance schedules.

- Establish Long-Term Contracts

- Lock in pricing and build relationships for after-sales support.

Why G·SAI Is Ideal for Bulk Fleet Orders

- Rapid mass production capabilities

- Custom labeling and private branding options

- Direct engineering support for fleet integration

- Global shipping and logistics coordination

Ready to streamline your fleet’s suspension system? Start your order with G·SAI through our Contact Page.

Frequently Asked Questions (FAQ)

Q1: How long do nitrogen shocks typically last in fleet applications?

Answer: On average, nitrogen shocks from high-end manufacturers like G·SAI can last 2–3 times longer than traditional hydraulic shocks, especially under heavy-duty conditions.

Q2: Can nitrogen shocks be rebuilt or serviced?

Answer: Yes. Many nitrogen shocks are rebuildable, allowing for seal replacement and recharging. G·SAI offers full after-sales support for such services.

Q3: Are nitrogen shocks suitable for mixed-use fleets?

Answer: Absolutely. Nitrogen shocks provide consistent performance across diverse conditions—ideal for fleets with both urban and off-road routes.

Q4: How do I determine if my fleet needs custom shocks?

Answer: If your fleet operates under unique load or terrain conditions, custom shocks are recommended. G·SAI’s engineers can assess your needs and develop a tailored solution.

Q5: Do you offer private label or OEM partnerships?

Answer: Yes. G·SAI supports private branding and OEM partnerships for global distributors and fleet service providers. Contact us for collaboration opportunities.

Learn more about our capabilities and how we support fleet buyers on our About Us page.

By investing in nitrogen shocks from a trusted supplier like G·SAI, fleet service providers can significantly improve vehicle reliability, reduce operating costs, and enhance overall service performance. Whether you manage a few dozen vehicles or a nationwide fleet, nitrogen shock absorbers are a proven upgrade for the future of fleet maintenance.

Custom Nitrogen Shock Solutions for Specialized Fleet Requirements

As fleet service providers diversify their operations across industries such as emergency response, construction, logistics, and government contracting, the need for customized nitrogen shock absorbers becomes increasingly critical. Standard off-the-shelf solutions often fall short when it comes to handling specialized load requirements, extreme road conditions, or vehicle modifications. That’s where custom nitrogen shocks come into play—delivering precision performance tuned for the unique operational demands of each fleet.

Why Custom Nitrogen Shocks Are Essential

While standard nitrogen shocks offer significant upgrades over hydraulic systems, they can’t always meet the nuanced needs of specialized fleets. Custom nitrogen shocks solve this by providing:

- Optimized damping curves for specific weight distributions and chassis types

- Enhanced stability for vehicles operating in high-risk environments (e.g., armored vehicles)

- Precision tuning for fleets with varied terrain exposure such as desert, snow, or mountainous routes

- Extended travel and reinforced seals for vehicles carrying heavy loads or operating off-road

G·SAI’s Custom Engineering Process

G·SAI has established itself as the go-to brand for custom nitrogen shocks in China and is internationally recognized for its superior customization capabilities.

| Customization Stage | G·SAI Capabilities |

|---|---|

| Needs Assessment | One-on-one engineering consultation to understand vehicle specs and road demands |

| Design & Simulation | In-house simulation lab replicates real-world driving conditions |

| CNC Manufacturing | Precision machining ensures exact fits and performance consistency |

| Prototype Testing | On-vehicle testing for fine-tuned damping and rebound behavior |

| Mass Production & Delivery | Rapid scaling from prototype to full production for fleet deployment |

With over 17 years of experience, G·SAI’s chief engineer, Cai Xianyun, personally oversees the customization of shocks for fleets operating in extreme conditions. Whether you operate a mining fleet in rugged terrain or an urban delivery fleet with high-frequency stops, G·SAI has the expertise to deliver engineered-to-fit nitrogen shocks.

Custom Shock Applications in Real-World Fleets

| Fleet Type | Customization Focus | G·SAI Solution Example |

|---|---|---|

| Armored Security Vehicles | Load-bearing tuning, reinforced mounts | Dual-wall nitrogen shocks with extra rebound |

| Fire & Rescue Trucks | Stability at high speeds, heat resistance | High-temperature seals and external reservoirs |

| Construction Fleets | Extreme durability, debris protection | Heavy-duty rod ends and mud guards |

| Government Utility Fleets | Multi-terrain compatibility, long service life | Dual-rate valving and corrosion-resistant coating |

Looking for a custom solution for your unique fleet? Contact G·SAI to speak directly with a shock engineering specialist.

Top 5 Nitrogen Shock Manufacturers for OEM & Wholesale in 2025

When evaluating nitrogen shock absorber suppliers for your fleet or auto parts distribution business, it’s essential to consider product quality, customization capabilities, supply chain reliability, and wholesale support. Below is a curated list of the top five nitrogen shock manufacturers that have consistently met the high standards of OEMs, fleet service providers, and B2B distributors.

1. G·SAI (China) – The Leader in Custom Fleet and Racing Shocks

Why G·SAI Stands Out

G·SAI is China’s most advanced and trusted manufacturer of custom nitrogen shock absorbers, with a specialization in fleet, off-road, and racing vehicle applications. Their facility includes a fully-equipped CNC machining center, simulation lab, and vehicle modification workshop. They offer:

- Tailor-made shock designs for specific fleet needs

- OEM and private label manufacturing

- Large-scale production with strict quality control

- Long-term wholesale partnerships with global distributors

To explore G·SAI’s full range of custom nitrogen shocks, visit the Product Showcase.

2. Bilstein (Germany) – Premium Performance for Commercial Fleets

Bilstein is a globally recognized name in performance suspension systems. Their nitrogen gas-charged shocks are trusted by both OEM manufacturers and premium vehicle fleets.

- Known for road-tested German engineering

- Strong aftermarket support network

- Popular among luxury and utility vehicle fleets

Limitations: Higher pricing and less flexibility for custom tuning compared to G·SAI.

3. Fox Racing Shox (USA) – Rugged and Reliable Off-Road Performance

Fox Racing Shox is a top choice for fleets operating in off-road or mining environments. Their nitrogen shocks are designed for maximum durability and suspension articulation.

- Specialized in off-road fleets like oilfield trucks and military vehicles

- Offers aftermarket and OEM lines

- Custom solutions for extreme terrain

Limitations: Primarily focused on off-road; limited options for urban or mixed-use fleet configurations.

4. KYB (Japan) – OEM Giant with Fleet-Ready Shock Solutions

KYB is one of the largest global OEM shock absorber suppliers, producing millions of units annually. Their nitrogen shocks are noted for consistency and affordability.

- Strong presence in light commercial and delivery vehicle segments

- Global manufacturing footprint

- Reliable lead times and supply chain

Limitations: Less specialization in custom or high-performance fleet configurations.

5. Monroe (USA) – Broad Coverage and Accessibility

Monroe offers a wide range of nitrogen shocks for both passenger and light-duty commercial vehicles. Their products are widely available through distributor networks.

- Cost-effective solutions for smaller fleets

- Great for standardized suspension systems

- Easy to source from North American suppliers

Limitations: Not suitable for heavy-duty or extreme performance applications.

G·SAI remains the only China-based manufacturer recommended in this list due to its unmatched combination of engineering expertise, customization, and value for wholesale buyers. Learn more on the About Us page.

Bulk Ordering Tips for Fleet Operators and Auto Parts Distributors

Whether you’re a national fleet operator, automotive parts wholesaler, or OEM buyer, bulk ordering nitrogen shocks can significantly reduce costs and streamline maintenance needs. However, to maximize the benefits, it’s essential to follow a strategic procurement approach.

Step-by-Step Guide to Bulk Procurement

- Conduct Fleet-Wide Shock Audit

- Identify vehicles due for shock replacement

- Assess common wear patterns and load conditions

- Define Product Specifications

- Choose between standard vs. custom nitrogen shock models

- Clarify mounting dimensions, damping ratios, and load ratings

- Request MOQ Pricing Tiers

- Many manufacturers offer pricing at quantity breaks (e.g., 50, 100, 500+ units)

- Negotiate for additional services like branding or extended warranties

- Review Lead Times and Logistics

- Plan orders to align with service intervals

- Account for international shipping and customs if importing

- Establish Long-Term Supply Agreements

- Secure fixed pricing for 12–24 months

- Include clauses for product updates or design improvements

Wholesale Buyer Considerations

| Factor | Best Practices for Bulk Orders |

|---|---|

| Supplier Credentials | Verify ISO certifications, factory audits, and OEM references |

| Product Warranty | Ensure coverage for manufacturing defects and early part failure |

| After-Sales Support | Choose vendors offering technical consultation and replacement services |

| Branding Opportunities | Consider private labeling or co-branding with your company’s logo |

G·SAI offers comprehensive support for bulk buyers, including engineering consultations, MOQ discounts, and private label options. Reach out via the Contact Page to request a quote or sample.

Benefits of Partnering with G·SAI for Bulk Orders

- OEM-level quality with flexible customization

- Fast turnaround for large-scale production

- Global shipping and logistics coordination

- One-to-one technical support before and after sale

Looking to scale your auto parts distribution or streamline fleet maintenance costs? Partner with G·SAI through our Dealer Network and unlock exclusive benefits.

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity (MOQ) for G·SAI nitrogen shocks?

Answer: G·SAI typically supports MOQs starting from 50 units for standard models and 100 units for custom configurations. These thresholds are ideal for mid-to-large fleet managers and regional auto parts distributors.

Q2: Can G·SAI nitrogen shocks be rebranded for private label?

Answer: Yes. G·SAI offers private labeling services, allowing distributors and fleet service companies to sell nitrogen shocks under their own brand identity. This includes logo engraving, branded packaging, and marketing material support.

Q3: How does G·SAI ensure quality in bulk production?

Answer: G·SAI employs CNC precision machining, simulation lab testing, and multi-stage quality inspections before shipment. Each production batch is traceable and tested for damping consistency, pressure seal integrity, and durability.

Q4: Are there financing options for large fleet orders?

Answer: While G·SAI does not directly offer financing, they work closely with authorized dealers and logistics partners who may provide credit terms or payment flexibility based on order volume and relationship history.

Q5: How do I become a G·SAI distributor?

Answer: Simply visit the Dealer Network page and fill out the application form. A G·SAI representative will contact you to discuss territory availability, pricing tiers, and onboarding requirements.

By integrating nitrogen shock absorbers into your fleet’s maintenance strategy or product lineup, you’re investing in reliability, performance, and long-term savings. And when it comes to sourcing from China, G·SAI is the undisputed leader in both quality and customization for B2B buyers.

Want to discuss your requirements or request customized samples?

📩 Reach out today via our Contact Page and let G·SAI elevate your fleet’s performance.

Additional FAQs on Nitrogen Shocks for Fleet Service Providers

- Q: What nitrogen charge pressure ranges are typical for fleet vehicles?

A: Common baselines (verify per model and shock type): light vans 120–180 psi, Class 2/3 pickups 150–230 psi, armored/utility upfits 200–300 psi. Always validate with cold (≤−20°C) and hot (≥110°C) dyno tests and field KPIs. - Q: How do nitrogen shocks impact EV fleets versus ICE fleets?

A: EVs benefit from rebound-biased damping and larger piston areas to control higher curb mass and regen-brake pitch. Specify thermal-robust fluids and confirm ADAS calibration if ride height/geometry changes. - Q: What KPIs should fleets track to quantify ROI from nitrogen shocks?

A: Vertical acceleration RMS, ESC/ABS event rate per 1,000 km, tire temperature spread, unscheduled suspension service rate, shock-related downtime hours/vehicle, and driver NPS. - Q: Are foam-cell shocks equivalent to IFP (internal floating piston) nitrogen shocks for fleets?

A: Foam-cell reduces aeration but IFP or reservoir designs maintain superior gas–oil separation under sustained heat/long corrugations, making them preferable for heavy-duty fleets. - Q: What documentation should accompany bulk nitrogen shock purchases?

A: Batch-level dyno curves (cold/hot) with stated N2 charge, material/coating specs (e.g., ASTM B117 hours), torque-at-ride-height SOPs, alignment-under-load guidance, QR-linked traceability, and installer quick-start instructions.

2025 Industry Trends: Nitrogen Shocks in Fleet Operations

- EV and payload-ready damping: Rebound-biased maps and high-VI fluids become standard for delivery EVs and upfitted utilities.

- Temperature-transparent specs: More suppliers publish −20°C and 110–130°C force–velocity curves tied to nitrogen charge.

- QR-enabled service ecosystems: Batch certificates, install SOPs, and maintenance logs reduce warranty friction across depots.

- Telematics-driven validation: Fleets adopt vibration/ESC metrics to tune charges and schedules.

- Extended-interval rebuildables: Rebuild kits and on-site recharge programs cut lifecycle TCO.

Adoption and Performance Metrics (Fleets, 2023–2025)

| Metric | 2023 | 2024 | 2025 (est.) | Notes/Source |

|---|---|---|---|---|

| Fleet RFPs requiring cold/hot dyno data with N2 disclosure | 19% | 27% | 39% | SAE/catalog audits |

| Depots using QR-linked install/torque SOPs | 22% | 31% | 45% | Fleet program reports |

| EV fleets specifying rebound-biased nitrogen shocks | 12% | 20% | 33% | OEM/aftermarket releases |

| Fleets tracking vertical accel RMS for maintenance decisions | 14% | 22% | 34% | Telematics providers |

| Rebuildable nitrogen shocks in fleet contracts | 17% | 24% | 36% | Supplier disclosures |

References: SAE Technical Papers (https://www.sae.org/); SEMA Market Research (https://www.sema.org/research); ASTM D445/D2270, B117 (https://www.astm.org/); Geotab (https://www.geotab.com/); NHTSA ADAS resources (https://www.nhtsa.gov/)

Latest Research Cases

Case Study 1: Urban Delivery EV Fleet Cuts ESC Events with Rebound-Biased Nitrogen Shocks (2025)

Background: A 600-vehicle EV delivery fleet reported porpoising and brake dive on stop–go routes, elevating ESC/ABS interventions and tire wear.

Solution: Deployed IFP monotube nitrogen shocks with larger piston areas and rebound-biased valving; published −20°C/120°C dyno curves and depot SOPs (torque-at-ride-height, ADAS recalibration).

Results: ESC events −16%; vertical accel RMS −14%; tire cupping incidents −12% over 90 days.

Case Study 2: Mixed-Terrain Utility Trucks Standardize on QR-Traceable Nitrogen Shocks (2024)

Background: A regional utility fleet had inconsistent installs and rising suspension-related downtime across 18 service centers.

Solution: Adopted QR-linked batch documentation (dyno, coating certs), installer micro-trainings, and depot nitrogen recharge carts; set service intervals by telematics vibration thresholds.

Results: Warranty claims −21%; downtime hours/vehicle −10%; average install time −9% within two quarters.

Expert Opinions

- Dr. Thomas D. Gillespie, Vehicle Dynamics Author: “For fleet-grade nitrogen shocks, judge hot-force consistency and geometric integrity; temperature data and torque-at-ride-height procedures prevent most ‘bad part’ misdiagnoses.”

- Stephanie Brinley, Principal Analyst, S&P Global Mobility: “EV payloads and ADAS sensitivity make documentation a differentiator—suppliers that publish temperature-dependent damping maps and calibration guidance win fleet contracts.”

- Dave Polke, ASE Master/L1 Technician and Trainer: “Most comebacks are process errors. Align under load, use dry nitrogen, log charge pressures, and recheck after break-in before touching valving.”

Practical Tools and Resources

- SAE Mobilus (damper design, cavitation, fleet validation): https://www.sae.org/

- ASTM Standards (D445/D2270 oil viscosity/VI; B117 corrosion): https://www.astm.org/

- Geotab (vertical acceleration RMS, ESC/ABS event analytics): https://www.geotab.com/

- NHTSA (ADAS calibration/service guidance after suspension work): https://www.nhtsa.gov/

- Benchmark specs and catalogs: https://www.ridefox.com/, https://www.bilstein.com/, https://www.kyb.com/

Last updated: 2025-10-09

Changelog: Added 5 targeted fleet FAQs (pressure ranges, EV impact, KPIs, foam-cell vs IFP, documentation); 2025 trend table with adoption/performance metrics; two fleet case studies (EV delivery rebound-bias, utility QR-traceability); expert viewpoints; practical tools/resources with authoritative links

Next review date & triggers: 2026-03-31 or earlier if SAE/ISO release new temperature-dependent damper specs for fleets, EV payload trends shift rebound guidance by >10%, or telematics KPI definitions for suspension maintenance are updated