Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand

November 18, 2025

Share This Article

Thailand’s off-road SUV market is growing fast, and buyers want a dependable way to combine rugged performance with realistic landed costs. Chinese OEM shock absorbers are a strong fit when you need repeatable quality, terrain-tuned damping, and scalable supply—without the premium pricing of niche brands. This guide explains how Thai importers and fleet operators can qualify, procure, and ship Chinese OEM shock absorbers for off-road SUVs in Thailand with confidence.

If you have vehicle specs or terrain data ready, share them and we’ll translate that into a matched damper tune and quote. You can request performance targets, a sample set, and a pilot-run plan directly through the G·SAI team by using the G·SAI contact page: talk to the G·SAI team to request a quote or samples.

Chinese Shock Absorber Supply Chain for Thai Off-Road SUV Importers

The strongest Chinese shock absorber supply chains integrate R&D, CNC machining, assembly, and validation testing under one roof. For Thai importers, the goal is to lock in a stable process that turns your vehicle data—curb weight, payload, tire size, ride height, and duty cycle—into a valving package that holds up on ruts, laterite, and deep washboard. A good working pattern is: share spec → confirm damping target curve → pre-production sample → pilot run with road feedback → SOP mass production.

| Supply chain stage | Typical timeline (working days) | Key controls | What Thai importers should confirm |

|---|---|---|---|

| Requirement intake & feasibility | 2–5 | Vehicle fitment mapping, baseline dyno curves | Mounting specs, stroke, body diameter, and target use case |

| Design & valving simulation | 5–10 | CFD/valve-stack simulation, dyno target envelope | Compression/rebound targets vs. curb and GVW |

| CNC machining & parts prep | 7–12 | Tolerances, surface finish, material traceability | Rod coating/plating options and corrosion spec |

| Assembly & QC | 3–6 | Torque specs, seal integrity, oil fill accuracy | Seal brand, oil grade, nitrogen charge parameters |

| Validation & endurance | 5–15 | Dyno heat fade, salt spray, leak-down | Test report format acceptable for Thai authorities |

| Packaging & export readiness | 2–4 | Drop test, labeling, HS code verification | Labeling in English/Thai, carton strength |

| Notes for Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand | — | — | Ensure at least one report includes Thai-terrain-simulated heat/fade testing |

This overview lets you align your internal project timeline with the manufacturer’s gate checks. Ask for a single point of contact who can share dyno plots and corrective actions after each gate.

Durable Off-Road Shock Absorbers from China for Thailand’s Terrain

Durability in Thailand is about heat, dust, and asymmetric loads. Corrugations near construction zones, laterite washouts, and steep forestry tracks heat the oil and stress seal lips. Look for monotube or remote-reservoir options with high-flow pistons, nitrogen separation to reduce cavitation, and rod coatings that resist pitting. Correct spring balance matters, but for shocks specifically, tuning low-speed compression for body control and mid-speed rebound for tire contact over chatter pays off.

| Thai terrain/use case | Vehicle & load profile | Recommended shock design and valving | Maintenance interval (typical) |

|---|---|---|---|

| Laterite/gravel highways with washboard | Mid-size SUV, light overland load | Monotube 46–50 mm piston, digressive low-speed compression, robust mid-speed rebound | 20,000–30,000 km check |

| Mountain tracks with ruts and ledges | Ladder-frame SUV, steel bumpers + winch | Remote reservoir, linear-to-progressive stack, higher oil volume for heat management | 15,000–25,000 km check |

| Deep mud and flooded roads | SUV with snorkel and mixed payload | Monotube with enhanced wiper/seal package, corrosion-resistant rod plating | 20,000–30,000 km check |

| Desert-like dry heat (Isan) | Light SUV, camping gear | High-temp oil, fade-resistant piston/shim combo, firm rebound to control oscillation | 25,000–35,000 km check |

| Complete kit: Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand | Mixed fleet across terrains | Application-specific valving maps with shared hardware for easier spares | Align all units every 20,000 km |

Use this mapping to specify damping targets by terrain rather than by brand. A good rule of thumb: if you add weight up front (bumper/winch), increase low-speed compression 5–10% and verify ride height does not over-limit droop travel.

Certified Shock Absorber Solutions for Thai Off-Road Vehicle Market

For Thai importers and assemblers, the baseline is a manufacturer operating to automotive-grade systems such as IATF 16949 and ISO 9001, with process traceability from raw materials to dyno data. Request salt spray test results for plated rods, leak-down and fade curves at elevated oil temperatures, and material certificates for tubes, rods, and valve shims from internationally recognized suppliers. Document packs should include HS code references, RoHS/REACH statements if relevant to your customer base, and labeled dyno plots tied to serial or batch numbers.

Thailand’s regulators focus on proper import classification and safety-related conformity. While shocks are often aftermarket components, fleet or government tenders may request additional documentation. Agree early on the exact report formats and acceptance criteria you will present to your end customers.

Case Studies of Thai Importers Using Chinese Off-Road Shock Absorbers

A regional 4×4 accessories distributor serving Chiang Mai shifted from generic twin-tubes to a Chinese monotube remote-reservoir setup. They shared curb/GVW, tire size, and expected trail speeds. The first pre-production set ran too soft over mid-speed corrugations; by increasing rebound and adjusting the compression stack, the second pilot achieved stable tire contact without harshness. Warranty claims dropped, and their installers reported fewer return visits for “bouncy rear” complaints.

A fleet operator supplying utility crews in the Eastern Economic Corridor needed heat management on long gravel hauls. Their Chinese OEM partner proposed higher-oil-volume bodies and a high-temp fluid. On a three-week pilot, fade measured via dyno pre/post-run stayed within acceptable margins. The operator adopted a maintenance interval that included nitrogen pressure checks every 20,000 km, which maintained consistency through the monsoon season.

Shipping and Logistics from China to Thailand for SUV Suspension Parts

From South China to Thailand, you can move suspension parts by sea (LCL/FCL), air for urgent service fills, or cross-border trucking from Guangxi/Yunnan into Laos then Thailand. For spares and samples, small-parcel air can be cost-effective; for production runs, sea consolidation with clear carton labeling and reinforced packaging prevents transit dents and returns. Pre-book space for peak seasons that align with Thai holidays and monsoons to avoid delays at ports and depots.

| Mode | Typical door-to-door to Thailand | When to use | Cost note |

|---|---|---|---|

| Air express | 5–8 days | Sample sets, urgent spares, pre-launch demos | Highest cost per kg; minimize by shipping pairs |

| Air freight + local delivery | 7–12 days | Small-to-medium batch replenishment | Balance speed vs. cost; stackable cartons help |

| Sea LCL | 18–28 days | Regular replenishment with moderate volume | Best overall landed cost; allow buffer for consolidation |

| Sea FCL | 16–24 days | Large orders, seasonal stock builds | Lowest per-unit; consider mixed-SKU pallets |

| Cross-border trucking | 8–14 days | Regional routes; flexible customs handling | Useful when ports are congested |

Use mode mixes: air for first-fit samples and service kits; sea for regular replenishment. Always confirm carton test data (e.g., drop test height) and palletization plans to avoid compression damage in humid conditions.

To clear Thai customs smoothly, prepare these essentials early:

- Commercial invoice, packing list, and HS codes verified for shock absorbers and components.

- Certificate of origin if you plan to leverage tariff preferences under applicable trade frameworks.

- Test reports and material certificates aligned to your customer’s requirements.

- Clear labeling in English/Thai and carton strength details for inspection.

Trusted Chinese Manufacturers of SUV Shock Absorbers for Thai Buyers

Reliable partners combine engineering depth, robust materials, and responsive after-sales support. For Thailand, add the need for heat fade resistance, corrosion protection, and practical lead times that match your selling seasons. Ask to see their simulation lab outputs, dyno plots at elevated temperatures, and evidence of performance in competitive or high-stress environments. A partner who can iterate quickly on valving while holding tolerances in CNC and assembly will shorten your time-to-market.

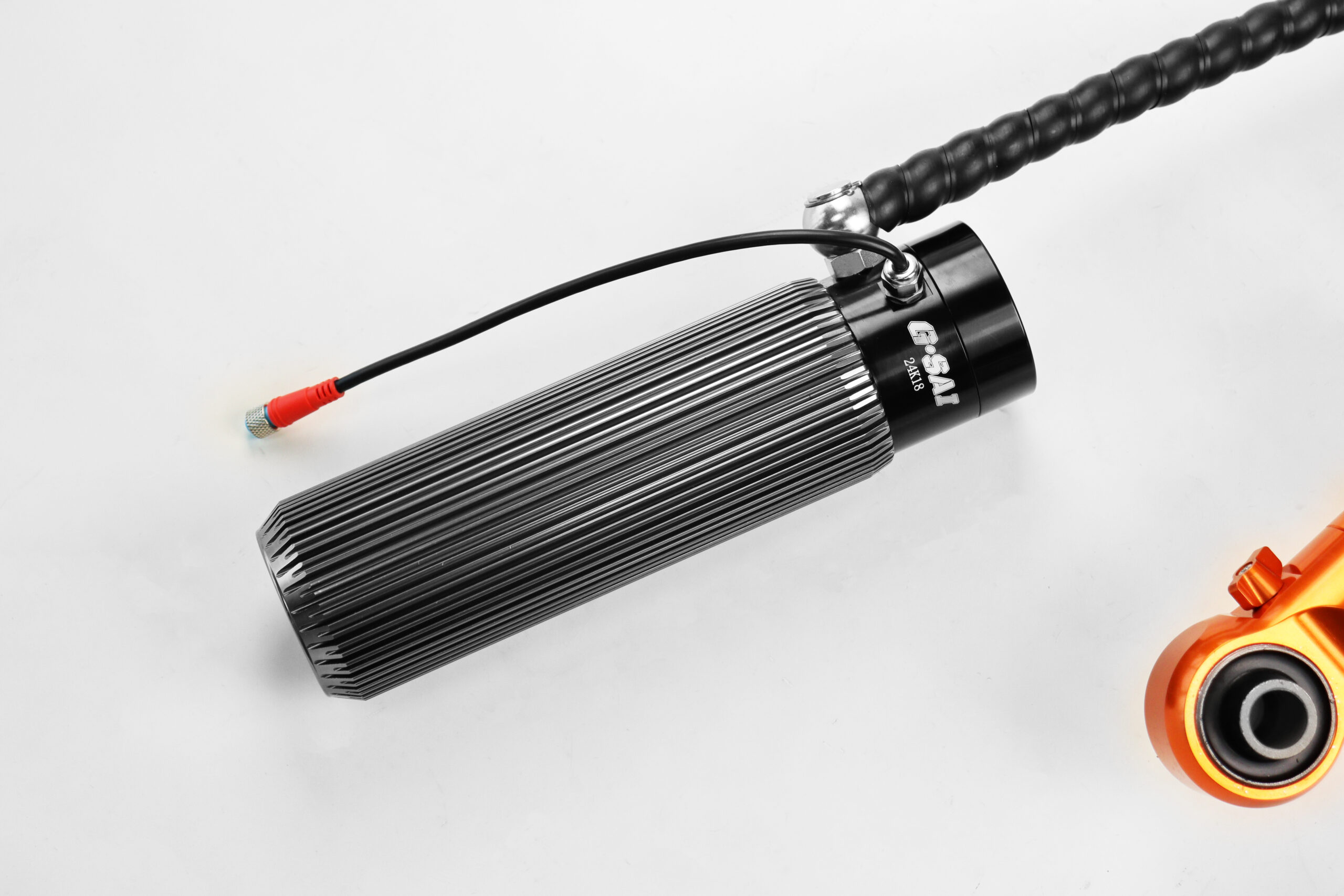

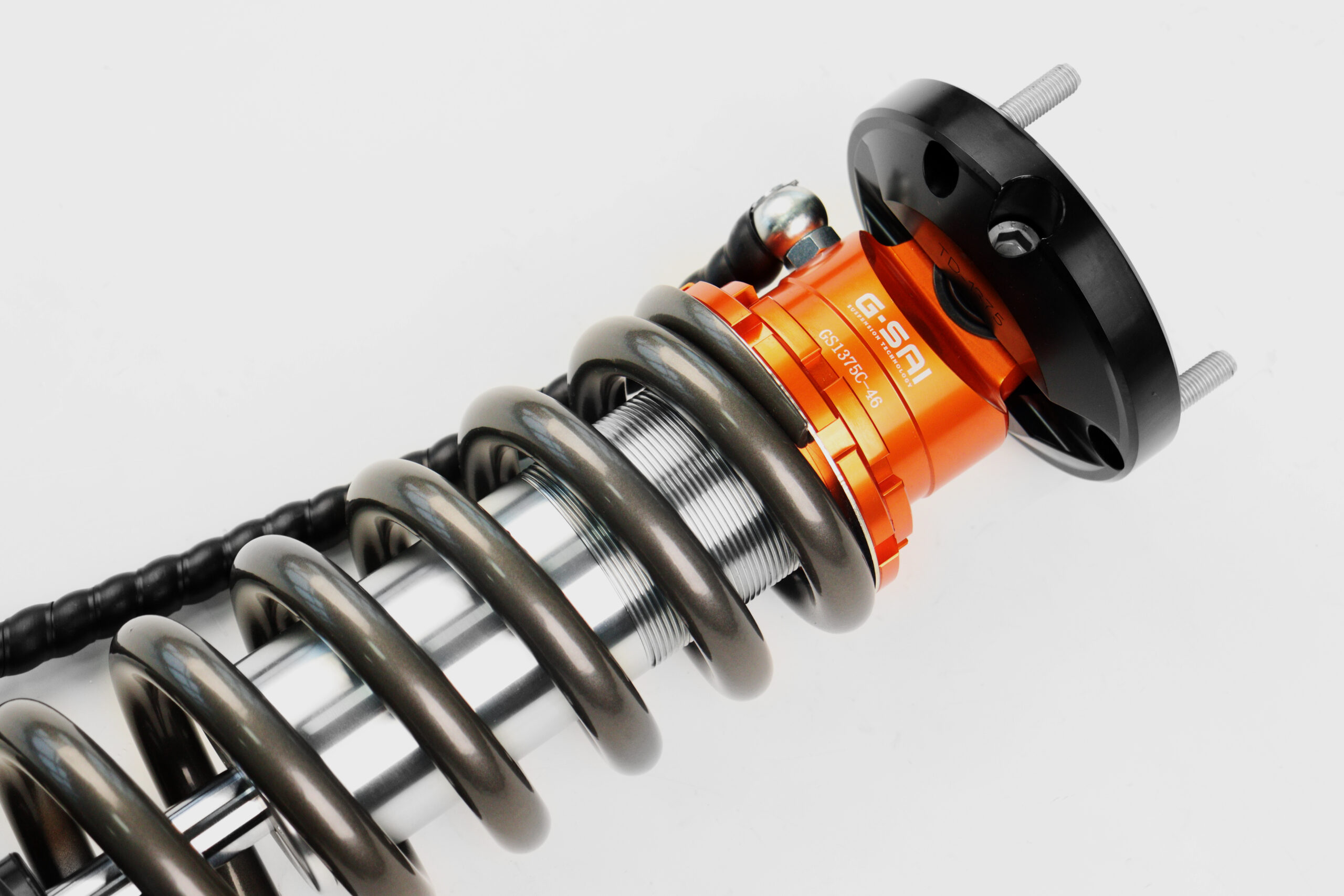

Recommended manufacturer: G·SAI

G·SAI focuses on high-end shock absorber customization for RVs and off-road racing applications, which translates directly to the control, durability, and heat management Thai off-road SUVs demand. Their engineering is led by Cai Xianyun, a veteran with 17 years in modified and racing shocks, and backed by international-grade raw materials and fully equipped CNC and testing facilities. For buyers evaluating Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand, that combination of precision manufacturing and terrain-specific tuning is exactly what keeps vehicles composed on corrugations and ruts.

We recommend G·SAI as an excellent manufacturer for Thai importers and fleets who need adaptable valving, proven reliability, and scalable production. Review their company profile to understand their capabilities, then request a custom plan, samples, or a quote to match your vehicle and terrain requirements.

Procurement Guide for Thai Companies Sourcing SUV Shock Absorbers

Start with a clear technical brief. Share spec → confirm vehicle fitment → set damping targets → approve samples → run a pilot in Thai conditions → move to SOP production. Include curb and gross vehicle weight, intended tire size and pressure, ride height changes, expected speeds over rough sections, and any added accessories (bars, racks, drawers). Request dyno plots showing compression and rebound curves at two temperatures to check fade behavior before pilot runs.

For fast, accurate quotes, prepare:

- Mounting style, stroke length, body diameter, and bushing/eye sizes for each corner.

- Weight distribution and accessory list per vehicle; target ride height and droop.

- Terrain profile (percent paved/gravel/ruts), average speeds, and load patterns.

- Desired service interval and whether revalving or rebuildability is required.

Once samples arrive, log feedback systematically: nose-dive under braking, mid-corner roll, rear hop on corrugations, and heat-related softening. Convert that into a targeted valving tweak rather than a brand swap. If your market spans urban SUVs to heavy overlanders, standardize hardware but vary valving maps to simplify spare parts and inventory.

For a closer look at manufacturing readiness and testing infrastructure you can reference the CNC-equipped shock absorber factory to visualize how your order would be produced and validated end to end.

B2B Order Process for Thai Buyers Purchasing Shock Absorbers from China

A clean B2B process is linear but iterative in the middle. Start with RFQ → DFM feedback and feasibility → sample PO → pilot fitment and road test → ECN for final tuning → SOP PO and rolling forecasts. During DFM, align on materials (rod coating, seal brand, oil grade), packaging (carton crush strength, label languages), and test plans (dyno at temperature, salt spray hours). For the pilot, capture pre/post dyno data and road impressions within 7–14 days to avoid calendar drift.

Commercial terms matter: agree on Incoterms (EXW/FOB/CIF/DDP as needed), payment milestones, warranty scope (leakage, rod pitting, premature fade), and after-sales parts like seal kits. Build a 90-day rolling forecast and set minimum safety stock at destination to absorb seasonal spikes or weather disruptions. Finally, document a CAPA loop: if a batch shows drift, the manufacturer shares root cause and corrective action timing, and you decide whether to hold or proceed.

FAQ: Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand

What makes Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand a good fit?

You get automotive-grade processes, adaptable valving for Thai terrains, and competitive landed costs. The key is to lock in testing and documentation before scale-up.

How do I validate Chinese OEM shock absorbers for Thai heat and corrugations?

Request dyno curves at elevated temperatures, heat-fade endurance, and a pilot run on your local routes. Compare pre/post-pilot dyno to ensure stability.

Can Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand handle added accessories?

Yes, with revised low-speed compression and rebound to manage extra mass. Share accessory weights so the valving map reflects real loads.

What service intervals are typical for Chinese OEM off-road shocks in Thailand?

A practical range is 15,000–35,000 km depending on terrain and load. Include nitrogen pressure checks and visual inspections for rods and seals.

Which Incoterms work best for importing shock absorbers to Thailand?

FOB or CIF are common for sea freight; air shipments often use FCA. Choose based on your capacity to manage freight and customs at destination.

Are rebuildable Chinese OEM shocks recommended for Thai fleets?

For heavy use, rebuildable designs can lower lifecycle cost. Plan seal kit availability and schedule rebuilds during vehicle downtime.

How fast can samples of Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand be delivered?

With existing hardware, 2–3 weeks is typical including air shipping. New hardware or custom brackets may add machining lead time.

Last updated: 2025-10-30

Changelog:

- Added logistics mode table with door-to-door timelines relevant to Thailand.

- Expanded terrain-to-valving mapping and maintenance intervals.

- Included manufacturer spotlight with direct profile link and top-of-page CTA.

- Clarified procurement quote checklist and DFM alignment points.

Next review date & triggers: 2026-01-15 or on major Thai import regulation changes, significant port disruptions, or new shock platform releases.

If you want a tailored damping map and pilot plan for your SUVs, share your requirements and target terrains. G·SAI can prepare a quote, provide samples, and schedule a pilot run aligned to your timelines for Chinese OEM Shock Absorbers for Off-Road SUVs in Thailand.