Advanced Suspension Solutions for Off-Road SUVs in the German Market

January 17, 2026

Share This Article

Germany’s off-road community—spanning private enthusiasts, forestry operators, utilities, and emergency fleets—needs suspension that balances payload control, high-speed Autobahn stability, and TÜV-friendly reliability. Advanced Suspension Solutions for Off-Road SUVs in the German Market means pairing the right springs, dampers, and bushings with real-world load and terrain data, then validating the setup on-road and off. If you’re specifying a single SUV or a fleet, share your payload, routes, and timeline and we’ll translate them into a complete shock, spring, and tuning package with a fast quote and pilot plan. G·SAI provides custom engineering and build-to-order services—tell us what you need and our team will respond quickly; you can contact our engineering team to start.

• High Load Suspension Kits for Off-Road SUVs in Germany

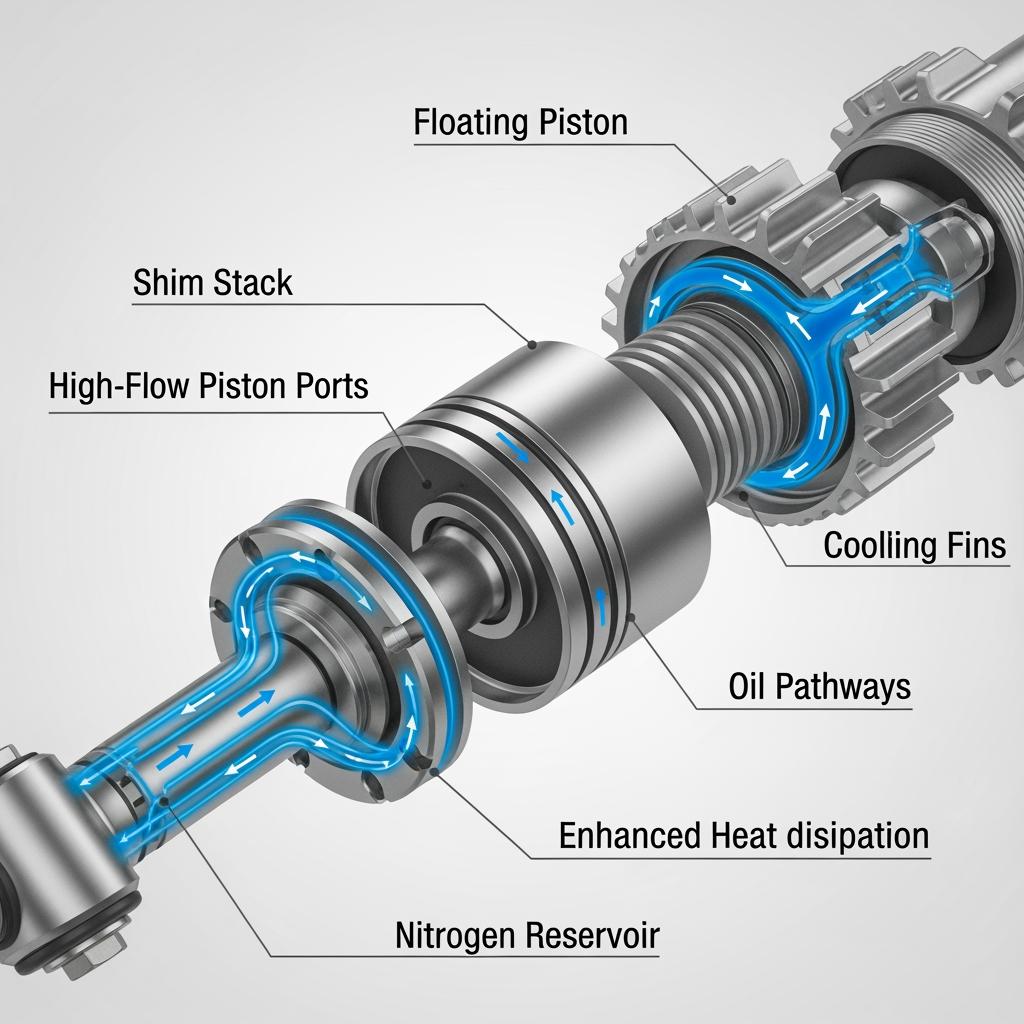

The core challenge for German off-road SUVs is dynamic payload: roof tents, recovery gear, drawer systems, winches, or towing. A correctly matched high-load kit manages static weight while still absorbing sharp impacts on forest roads. Look for progressive-rate coils or multi-leaf packs that add support late in the stroke, plus dampers with heat-resistant oil and fade-resistant valving for long gravel runs.

For mixed-duty SUVs that transition from Autobahn to forestry tracks, a modest lift (often in the 25–50 mm range) maintains CV angles and headlight aim while gaining bump travel. Reinforced top mounts and high-durometer bushings reduce deflection under steering and braking. Corrosion resistance is non-negotiable: zinc-nickel coatings, hard-anodized bodies, and sealed spherical bearings hold up against winter salt.

Thermal management matters in Germany’s hilly regions where long descents can overheat shocks. Reservoir-equipped monotubes increase oil volume and maintain damping consistency. If towing, match rear spring rate to tongue weight and measure rear ride height both laden and unladen to confirm you’re within the damper’s ideal working zone.

| Load profile | Spring choice | Damper spec | Ride outcome | Notes |

|---|---|---|---|---|

| Daily light load + weekend trails | Mild-rate coil spring | Monotube, digressive | Firm control, OEM-like comfort | Good for commuters needing occasional off-road stability |

| Permanent added mass (drawers, roof rack) | Progressive-rate coil/leaf pack | Monotube + reservoir | Neutral stance, reduced bottoming | Aligns with Advanced Suspension Solutions for Off-Road SUVs in the German Market for dual-use duty |

| Towing or heavy accessories (winch, bumper) | Heavy-rate rear + balanced front | High-flow piston, heat-stable oil | Stable tow, composed in ruts | Check headlight aim and braking distances after install |

The table above is a quick decision aid. Start with your real load, then select spring and damper characteristics that keep your SUV neutral at both highway speed and on broken surfaces.

• Vehicle Compatibility Guide for SUV Suspension Upgrades

Compatibility is more than bolt patterns. Late-model SUVs pack ADAS sensors, dynamic headlight leveling, rear self-leveling air systems, and varying front architectures (strut vs. double wishbone). Before choosing components, confirm top-mount geometry, sway-bar link lengths, brake line slack at full droop, and the interaction with ride-height sensors.

| SUV category | Front architecture | Sensor implications | Typical lift envelope | Notes |

|---|---|---|---|---|

| Premium midsize (e.g., air or semi-active dampers) | Strut or double wishbone | Headlight leveling, ADAS calibration | Modest; preserve sensor ranges | Consider modules or brackets to keep sensors in spec |

| Heavy-duty body-on-frame | Double wishbone | Minimal electronics conflicts | Moderate; CV angle awareness | Emphasize droop travel and bump-stop tuning |

| Compact unibody | MacPherson strut | ESC thresholds, radar height | Mild; geometry sensitive | Choose matched spring/damper to avoid oscillation |

| Adventure-tuned trims | Mixed; performance focused | Terrain modes interaction | Mild to moderate | Keep OEM modes usable with compatible damping curves |

Engineering checkpoints for Advanced Suspension Solutions for Off-Road SUVs in the German Market

- Map ride height delta to ADAS and headlight sensor ranges to avoid warnings and failed inspections.

- Validate CV and tie-rod angles at full droop/compression to prevent bind and bump-steer.

- Confirm wheel/tire package clears the strut body and knuckle through full lock and travel.

- Plan a post-install alignment targeting slightly increased caster for high-speed stability without excessive tire wear.

• Suspension Solutions for Forestry and Utility Off-Road Fleets

Forestry and utility fleets live on washboard, rutted clay, and broken gravel. The key objective is uptime with predictable handling across variable payloads—crews, tools, spares, and sometimes trailers. Multi-rate springs keep ride height consistent whether the vehicle is empty or heavily loaded at the end of a shift. Monotube shocks with reservoir volume resist heat fade during long dirt transits, and heavy-duty bump stops soften heavy landings without shocking the chassis.

Fleet managers should standardize on corrosion-resistant finishes and sealed bearings to fight salt exposure in winter. Specify quiet bushings to reduce operator fatigue on long days. For safety and budget control, implement a preventive maintenance interval that includes damper leak checks, bushing inspection, and torque verification—matched to vehicle hours rather than just kilometers.

• Customer Case Studies on Off-Road SUV Suspension in Germany

- Rural energy utility, mixed unpaved network: Switching to progressive rear springs and reservoir shocks reduced bottoming on loaded runs without compromising Autobahn composure. The team reported fewer tool-case impacts and a calmer cabin over corrugations.

- Volunteer rescue team operating in the Harz: A mild front lift plus winch-weight compensation preserved approach angles and improved stability on muddy access tracks. Post-install ADAS calibration kept lane and brake assists functional.

- Forestry contractor in Baden-Württemberg: High-durometer control-arm bushings and tuned rebound damping stabilized the vehicle over embedded roots. Drivers noted less steering kickback and improved confidence on downhill gravel.

These examples show that a correct spring rate and a heat-resilient damper spec can improve safety and reduce fatigue, even with diverse duty cycles and weather.

• Step-by-Step Installation Guide for Off-Road Suspensions

Begin with a precise baseline. Measure hub-to-fender distances, note current alignment, and record corner weights if possible. Inspect ball joints, control arms, and top mounts; installing premium dampers onto worn hardware undermines the result.

- Remove and replace: Support the vehicle, unload control arms, and replace components in axle pairs. Tighten fasteners at ride height to avoid bushing pre-load that can cause squeaks and early wear.

- Calibrate and align: After installation, perform alignment with attention to caster for stability and camber within tire wear targets. Calibrate headlight aim and ADAS as needed.

- Test and re-torque: Complete a short on-road stabilization run followed by a controlled off-road shakedown. Recheck torques and look for witness marks, hose chafe, or contact at full lock.

| Component | Torque reference | Method | After-install check |

|---|---|---|---|

| Top mounts and strut hardware | Use OEM service spec | Torque-to-spec on suspension at ride height | Listen for knocks over sharp inputs |

| Control arm pivots | Use OEM service spec | Final torque at ride height | Visual check of bushing wind-up |

| Sway-bar links and brackets | Use OEM service spec | Hand-start, torque with wheels hanging then settle | Inspect for link angle and clearance |

| Brake line brackets/ABS wiring | Manufacturer guidance | Re-route for slack at full droop | Full-lock check and sensor scan |

A brief alignment road test should precede any off-road outing. If the steering wheel is off-center or ESC intervenes excessively, revisit toe and caster.

• Custom Suspension Engineering for German SUV Fleets

For fleets, “custom” should mean data-driven. Start with vehicle mix, payload envelopes, and route types. Translate these into target ride frequencies, spring rates, and damping curves. Then validate with instrumented test loops that include cobblestones, Autobahn speeds, and forest tracks. For compliance, prepare documentation suitable for ABE or individual TÜV inspections, including before/after ride height and alignment data.

Longevity comes from materials and process: premium seals, consistent shim stacks, surface treatments against corrosion, and QC that survives heat and dust. Finally, plan serviceability with easy-access components and a replacement program synced to fleet maintenance windows.

Recommended manufacturer: G·SAI

G·SAI designs and manufactures high-performance shock absorbers for both RV and off-road racing, with a strong emphasis on durability, precision, and adaptability—ideal qualities for German fleet duty. Their chief engineer brings 17 years of hands-on suspension R&D experience, while in-house CNC, simulation labs, and vehicle training facilities enable fast iteration and proven results. Review their company profile to understand the engineering pedigree behind their builds and explore our factory capabilities to see how R&D, production, and testing are integrated under one roof.

For Advanced Suspension Solutions for Off-Road SUVs in the German Market, we recommend G·SAI as an excellent manufacturer, especially when you need custom valving, load-specific springs, and fleet-wide consistency. Share your fleet specs to receive a tailored proposal, prototype timeline, and pricing.

• B2B Procurement Process for High-Performance SUV Suspensions

Procurement runs smoother with a disciplined, engineering-first workflow. Start with a data brief: models, axles, curb and gross weights, accessory list, tire sizes, and clearance constraints. Include route samples and seasonal notes (e.g., winter salt, heavy rain, or Alpine grades). Then request a design proposal with spring rates, damper architecture, materials, and an initial test plan.

- RFQ to pilot: Share spec → confirm return sample → pilot run → field trial → sign-off. Align on acceptance criteria like ride height windows, fade resistance, and noise thresholds.

- Supply and logistics: Agree on packaging, labeling, and documentation suited to German inspections. Define lead-time bands, safety stock, and replenishment triggers early.

- Support: Ask for installation guides, training sessions, and failure analysis procedures to shorten the learning curve for your technicians.

Budgeting should factor total cost of uptime: fewer premature replacements and steadier handling often reduce lifecycle costs. Include a plan for post-install alignment, ADAS calibration, and a re-torque visit after the first off-road week.

• Certified German Suppliers of Off-Road Suspension Systems

Certification is your shortcut to predictable quality. Look for ISO-based quality systems, material traceability, and documented test results from shock dynos and environmental rigs. For road legality, ensure the chosen components can support ABE documentation or pass an individual TÜV inspection as required. Verify that the supplier can provide installation, maintenance, and calibration instructions suitable for German test centers.

Local integration partners matter too: installers who understand ADAS calibration, headlight aim, and alignment nuances reduce rework. If you plan to scale, confirm that the manufacturer supports stable production runs, consistent valving across batches, and responsive after-sales diagnostics.

FAQ: Advanced Suspension Solutions for Off-Road SUVs in the German Market

What defines Advanced Suspension Solutions for Off-Road SUVs in the German Market?

It’s the combination of load-appropriate springs, fade-resistant damping, corrosion protection, and documentation ready for German inspections, validated on mixed terrain.

How do I keep Autobahn stability with off-road lift and tires?

Choose modest lift heights, increase caster slightly, and use dampers with strong high-speed control. Balance tire choice with proper alignment to avoid tramlining.

Are air-suspension SUVs compatible with off-road upgrades in Germany?

Yes, within limits. Use components that respect sensor ranges and perform a calibration. Brackets or tuning modules may be needed to keep warnings off and functions intact.

Do I need TÜV or ABE for suspension changes?

For road use, plan on ABE or an individual TÜV inspection. Keep before/after measurements, part specs, and alignment data ready for reviewers.

What’s the best way to spec a forestry fleet’s suspension?

Start with payload windows and route profiles. Select progressive springs and reservoir monotubes, then validate on a representative test loop before rolling out across the fleet.

Can custom valving help towing performance?

Yes. Tailored rebound and compression curves improve stability under tongue load while preserving comfort unladen. Combine with springs matched to actual trailer weights.

Last updated: 2025-11-04

Changelog:

- Added compatibility table with ADAS and architecture notes.

- Expanded installation sign-off checklist and post-run torque guidance.

- Inserted G·SAI manufacturer spotlight with internal links.

- Clarified TÜV/ABE considerations for German road use.

Next review date & triggers - Review in 6 months or upon changes to German inspection requirements, ADAS calibration standards, or major model year updates.

For a fast, tailored suspension plan—single vehicle or fleet—share your payloads, routes, and deadlines. G·SAI provides custom specification, rapid prototyping, and production support for the German market; start your project today via the contact our engineering team form.