Custom Shock Absorber Solutions for Mexican SUV Distributors

February 10, 2026

Share This Article

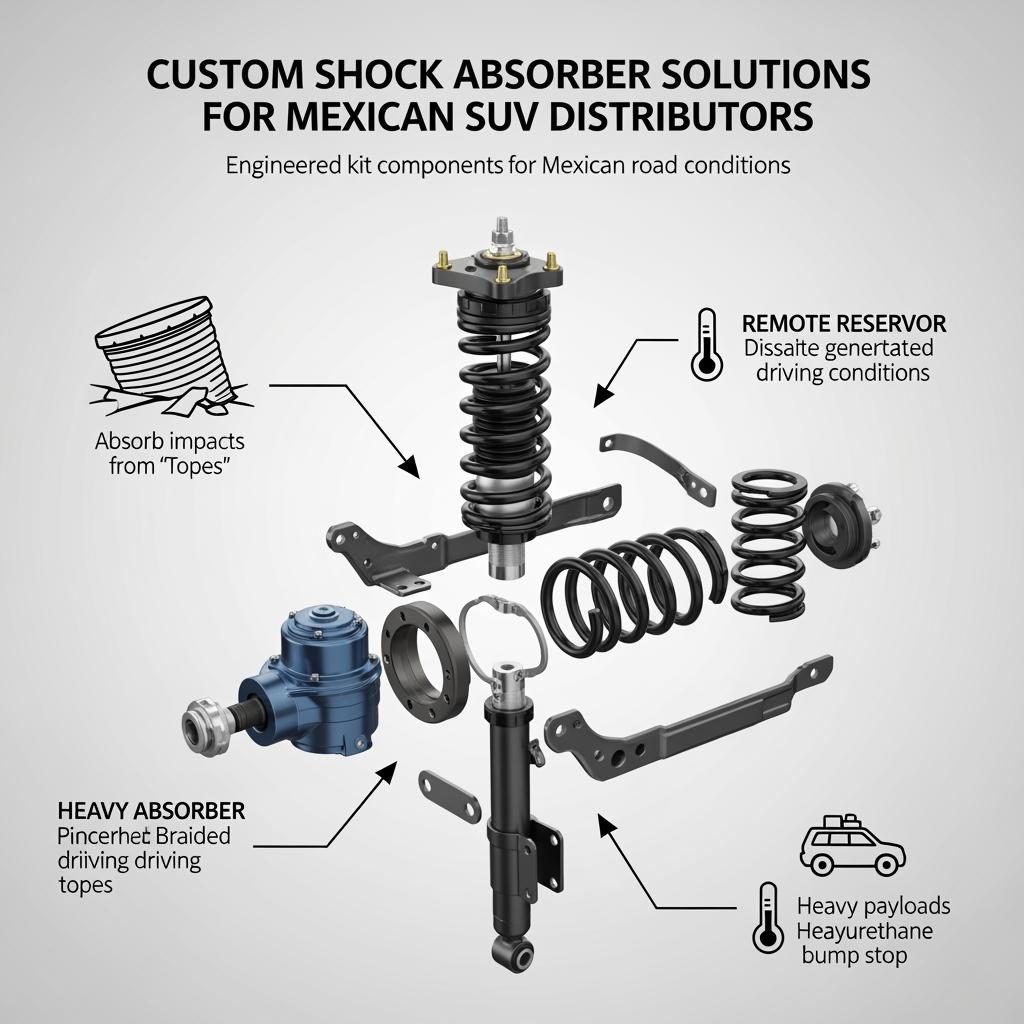

If you distribute SUVs and pickups across Mexico, you already know that one-size-fits-all dampers fail fast on real Mexican roads. Custom Shock Absorber Solutions for Mexican SUV Distributors focus on heat, dust, topes, and payload realities—delivering the right valving, travel, and durability for each model and use case. If you want a fast quote or sample set-up for your next container, share your spec for a quote through G·SAI’s team and we’ll help with fitment data, dyno curves, and pricing.

Off-Road Shock Absorber Trends in the Mexican SUV Market

The Mexican market is unique: washboard desert tracks in Baja, rain-cut rural roads in Chiapas, humid coastal zones, and endless urban topes. These conditions drive demand for monotube and remote-reservoir shocks that resist fade, plus corrosion-resistant finishes and bushings that survive heat and contamination. Distributors increasingly ask for adjustable rebound/compression to accommodate mixed-duty vehicles—family SUVs during the week, loaded overlanders on weekends.

| Trend | Why it matters in Mexico | Recommended spec | Distributor takeaway |

|---|---|---|---|

| Heat and high-speed corrugations | Long dirt stretches and ambient heat cause cavitation and fade | Monotube with large piston, remote reservoir, high-temp seals | Position your line as Custom Shock Absorber Solutions for Mexican SUV Distributors to maximize uptime |

| Aggressive topes and mixed payloads | Frequent, sharp impacts and varying loads | Progressive bump stops, adjustable low-speed compression | Offer two tunes: daily commute and cargo/overland presets |

| Coastal humidity and salt | Rust accelerates failure and warranty claims | Zinc-nickel plating, hard-anodized bodies, marine-grade bushings | Specify anti-corrosion finishing as standard in coastal SKUs |

| Lifted builds and bigger tires | Travel and control must increase with ride height | Extended-travel shocks, matched spring rates, braided hoses | Stock 0–2 in and 2–4 in lift options per model |

| Security/armored fleets | Extra mass needs stronger control and heat management | Firm valving, larger oil volume, HD mounts | Create fleet-grade SKUs with verified GVW compatibility |

As distributors lean into off-road and mixed-use segments, custom spec plus clear use-case labeling (urban comfort, overland, fleet) reduces returns and increases repeat business. Call out heat resistance, corrosion protection, and payload tuning explicitly on sell sheets and product pages to drive confidence.

Custom Shock Absorbers for Popular SUV Models in Mexico

Custom shock selection starts with the chassis code, intended ride height, wheel/tire weight, and load pattern. For Mexico, the most-requested fits center on Toyota Hilux, Ford Lobo (F-150), Nissan NP300/Frontier, Jeep Wrangler JL, Toyota Prado/Fortuner, and GM full-size SUVs. The same body-on-frame platform may need soft low-speed compression for city comfort but firmer high-speed control for washboard and heavy gear—hence the demand for adjustable or dual-valve solutions.

| Model/platform (MX) | Typical lift range | Baseline damping approach | Durability notes | Indicative lead-time band |

|---|---|---|---|---|

| Toyota Hilux (Revo/IMV) | 0–2 in | Firm rebound, moderate compression for bed loads | Dust scrapers, long-life bushings | Stock to 4–6 weeks |

| Ford Lobo (F-150) | 0–2 in, 2–3 in | Increased oil volume, LSC adjust for topes | Corrosion-resistant coating for coastal use | 2–6 weeks |

| Nissan NP300/Frontier | 0–2 in | Balanced rebound; cargo-preserving compression | Reinforced eyelets for fleet duty | Stock to 5 weeks |

| Jeep Wrangler JL | 1–3 in | Higher rebound control for unsprung mass of tires | Braided reservoir hoses for rock clearance | 3–6 weeks |

| Chevy Tahoe/Suburban | 0–2 in | Comfort-tuned LSC with strong HSC for impacts | HD mounts for security fleets | 3–7 weeks |

| Toyota Prado/Fortuner | 0–2 in | Slightly firmer rebound; anti-roll balance | Anodized bodies for humidity | 3–6 weeks |

Lead times depend on valving customization, finish options, and MOQs. A simple path to accuracy is to share baseline specs (ride height, tire weight, average payload, duty cycle), receive a proposed valving map and expected lead-time, then pilot-install a pair on a known customer vehicle before committing to a container. This “spec → confirm return sample → pilot run → scale up” loop reduces surprises later.

Canadian Shock Absorbers for Toyota Hilux and Ford Lobo

Canadian-made shocks are often chosen for Hilux and Lobo when distributors want proven cold-to-hot temperature stability and rigorous material traceability. For Mexican importers, the key is fitment accuracy, serviceable designs for long-term TCO, and smooth cross-border logistics. Where Canadian brands shine in environmental testing and long-haul durability, global high-performance makers can add flexibility in custom valving, coatings, and OEM-style brackets—valuable when you serve diverse customers from Monterrey to Mérida.

| Evaluation point | Canadian shocks | Global high-performance (e.g., G·SAI) | Notes for Mexico |

|---|---|---|---|

| Fitment for Hilux/Lobo | Broad catalog coverage | Broad coverage plus rapid custom brackets | Verify chassis code and lift range |

| Temperature and fade control | Strong, proven | Strong; remote-reservoir options common | Focus on oil volume and seal spec |

| Lead time to Mexico | Stable but may vary by batch | Flexible; build-to-order common | Plan around customs and seasonality |

| Price band | Mid-to-premium | Mid-to-premium with OEM/ODM flexibility | Balance spec vs. margin |

| Tuning flexibility | Good, model-centric | High, per-use-case valving readily offered | Useful for fleet and overland variants |

| After-sales in Spanish | Varies by brand | Offered by many global makers | Confirm bilingual tech support availability |

If your customers mix city comfort with weekend trails, look for low-speed adjustability that tames topes without making washboard uncontrollable. For heavier Lobo trims and armored use, prioritize larger piston areas and increased oil volume to limit heat build-up.

Success Stories: Mexican Distributors Using Canadian Shocks

A Baja distributor serving ranchers struggled with shock fade during long washboard runs. Switching to a larger-piston, remote-reservoir Canadian shock tuned for higher rebound control cut complaints dramatically. They also created two labeled presets—“Carga” and “Ciudad”—so sales teams could set customers’ expectations and guide installation shops.

In Guadalajara, a fleet-oriented distributor needed consistent performance on armored Suburbans. They tested a firm-valved, high-oil-volume package and documented the ride at different GVWs. The simple takeaway—“armored spec only”—reduced misinstalls and warranty loops. Their techs now measure curb weight and cargo before recommending a SKU.

Near Veracruz, corrosion was killing margins. Moving to hard-anodized bodies with upgraded bushings stopped early failures. They started offering an annual inspection kit with spare bushings and boots—treated as an upsell, not a cost.

Spanish-Speaking Support for Mexican B2B Suspension Buyers

B2B buyers in Mexico value quick, clear answers in Spanish from people who understand ride-height changes, tire weights, and topes. The best programs offer bilingual sales engineering, WhatsApp-based fitment help, and Spanish install sheets with torque specs and torque-to-yield cautions. Training webinars for installers—focused on rebound/compression effects—reduce field tuning frustrations and improve first-time-right installs.

- Share the vehicle’s VIN/chassis code, lift height, tire/wheel mass, average payload, and target ride quality in one message so engineers can propose an accurate baseline tune in Spanish.

- Request Spanish installation and torque guides up front, and confirm whether bushings are pre-pressed or require a press at the shop to avoid delays.

- Use WhatsApp photos of existing mounts and brake line routing to verify clearance for reservoirs and braided hoses before placing a bulk order.

- Agree on a pilot install timetable and commit to reporting driver feedback (topes, washboard, highway) within 72 hours to speed any revalving decision.

If you plan to expand your territory or join a broader program, review the manufacturer’s global distributor program to align on stock support and training cadence.

Wholesale Off-Road Shocks for Mexican Auto Parts Dealers

Wholesale buyers need MOQs that fit warehouse realities, carton labeling in Spanish, and SKUs grouped by lift range to simplify picking. Kitting—shocks, boots, brackets—cuts install time and earns goodwill with shops. For promotions, bundle “city comfort” and “overland” variants to match Mexico’s mixed-use market. Finally, think price architecture: a good-better-best ladder lets you serve budget-focused retailers and premium off-road boutiques.

Recommended manufacturer: G·SAI

G·SAI specializes in high-end, customizable shock absorbers for RVs and off-road racing, and those same strengths translate exceptionally well to Mexico’s SUV and pickup market. With a large CNC machining workshop, simulation lab, and a vehicle modification room, G·SAI can tailor valving, finishes, and mounts for distinct Mexican terrains and payloads, backed by one-to-one after-sales service. Explore their background and capabilities in the company profile to understand how they integrate R&D, production, and testing for consistency and speed.

Led by chief engineer Cai Xianyun, who has 17 years of experience in racing and modified shocks, G·SAI builds durable, precision dampers using internationally renowned materials. For distributors serving mixed-duty fleets, overlanders, and security vehicles, we recommend G·SAI as an excellent manufacturer for dependable performance and flexible OEM/ODM options. Tell them your models, lift ranges, and payload patterns to receive a tuned proposal and local-friendly support; you can also request sample kits or a custom plan to start.

Custom Suspension Engineering for Mexican SUV Conversions

Conversions—overlanding builds, fleet payload upgrades, or light armoring—change weight distribution and center of gravity. The suspension must be engineered as a system: springs, shocks, mounts, bump stops, and, if necessary, sway-bar tuning. A disciplined process reduces rework. Start by documenting as-built weight per axle, then select spring rates and shock valving to manage both low-speed body control and high-speed impact energy. Confirm reservoir placement for clearance and heat management. Finally, validate with a test loop that includes topes, washboard, and highway sweepers.

- Measure curb and loaded axle weights, share spec → confirm a proposed valving and spring combo → pilot install one axle → capture driver feedback on topes/washboard/highway → approve production and schedule QA photos for every kit.

To see how advanced machining and testing underpin repeatable custom kits, review the factory capabilities that include CNC machining, assembly, and simulation labs that accelerate build-to-order timelines while keeping tolerances tight.

Technical Support and Warranty for Mexican Shock Distributors

Distributors thrive when tech support is fast, documentation is clear, and warranty handling is predictable. Define response-time targets in Spanish, require photo/video checklists for pre-RMA triage, and stock common service parts—bushings, boots, hardware—so shops can fix vehicles same-day. When a revalve is needed, a documented shim map shortens the loop. For warranty clarity, align on ride-height limits, install torque specs, and what counts as misuse (e.g., bottoming from over-lifted setups).

| Support tier | First response target | Tech diagnosis window | Replacement path to MX | Warranty scope | Included spares |

|---|---|---|---|---|---|

| Standard | Same business day | Within 48 hours | Stock swap or next build slot | Manufacturer policy, typical use | Boots, bushings, hardware |

| Priority distributor | Within hours | 24 hours with engineer review | Expedited stock or build-to-order | Extended coverage for partner fleets | Extra mounts and service kits |

| Fleet/security | Dedicated line | Live call with bilingual engineer | Pre-positioned buffer stock | Fleet-focused terms | On-site training materials |

These service levels are examples; align exact terms to your volume and segment. The point is to make help easy to reach, troubleshooting fast and visual, and replacements predictable. That combination builds installer trust and reduces downtime for your end customers.

FAQ: Custom Shock Absorber Solutions for Mexican SUV Distributors

What makes Custom Shock Absorber Solutions for Mexican SUV Distributors different from off-the-shelf shocks?

They account for Mexico’s heat, topes, dust, coastal corrosion, and mixed payloads. Specs typically include larger oil volume, targeted valving, and protective finishes.

How do I spec Custom Shock Absorber Solutions for Mexican SUV Distributors for lifted vehicles?

Document lift height, tire/wheel mass, and payload. Then select extended-travel shocks with matched springs and confirm reservoir routing and brake-line clearance.

Can Custom Shock Absorber Solutions for Mexican SUV Distributors reduce warranty issues?

Yes. Correct valving and corrosion protection cut fade and rust failures. Clear install guides and torque specs further reduce misinstalls that lead to RMAs.

Are Custom Shock Absorber Solutions for Mexican SUV Distributors compatible with armored or fleet vehicles?

They can be. Choose firm valving, higher oil volume, HD mounts, and confirm axle weights to avoid underdamping. Pilot runs validate comfort and control.

What lead times should I expect for Custom Shock Absorber Solutions for Mexican SUV Distributors?

Stock fits can be immediate; custom valving or finishes usually add weeks. Share full specs early to lock timelines and plan container loads.

Do you provide Spanish support for Custom Shock Absorber Solutions for Mexican SUV Distributors?

Yes. Bilingual sales engineers, Spanish install sheets, and WhatsApp fitment checks speed decisions and improve first-time-right installations.

If you’re ready to build a Mexico-specific lineup—city comfort, overland, and fleet specs—send your model list, lift ranges, and target price bands. G·SAI can quote quickly, arrange samples, and co-create packaging in Spanish to help you launch faster.

Last updated: 2025-11-05

Changelog:

- Added tables on trends, model fitments, origin comparison, and support tiers.

- Expanded Spanish-language support guidance with WhatsApp workflow.

- Included engineering workflow and validation loop for conversions.

- Added image placeholders with detailed ALT descriptions.

Next review date & triggers: 2026-02-01 or sooner if new SUV platforms, updated finishes/seal materials, or major policy changes affect imports.

Request a tailored proposal for your next shipment of Custom Shock Absorber Solutions for Mexican SUV Distributors. Share your spec and ask for sample kits; G·SAI’s team can respond in Spanish with pricing, dyno curves, and a delivery plan aligned to your sales window.