Heavy Load Suspension Systems for Off-Road Use in Saudi Arabia

February 22, 2026

Share This Article

Towing and hauling in Saudi Arabia’s deserts demands more than “heavy-duty” labels; it requires heavy load suspension systems engineered for heat, dust, corrugations, and high payloads. This guide breaks down what works for off-road SUV–trailer combos in KSA, how to stay SASO compliant, and how to specify components that survive repeated dune crossings and rocky wadis. If you need a fast, practical recommendation or a build plan, share your vehicle model, actual payload, and terrain mix—then contact the G·SAI team to size a custom kit for your route and budget.

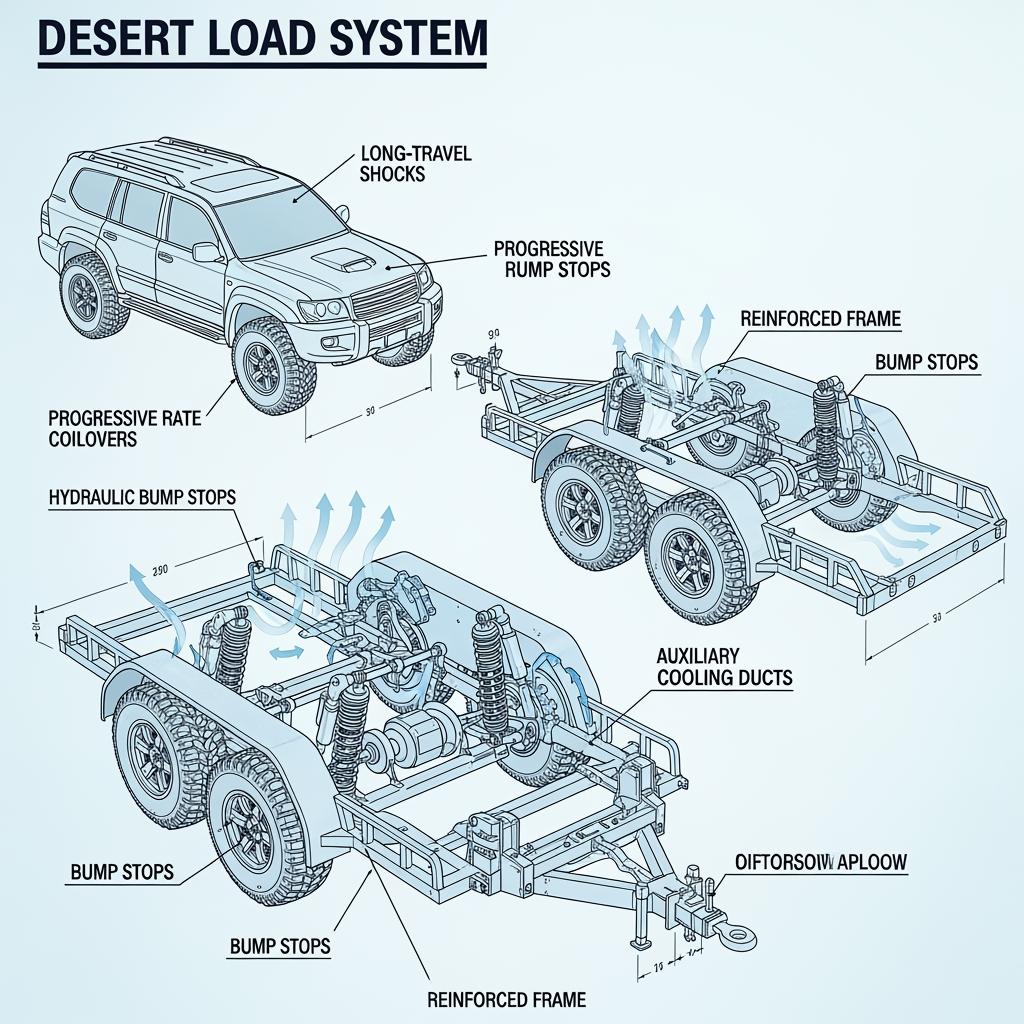

This diagram shows key elements of a desert-ready suspension package for an SUV towing a loaded trailer, including cooling airflow to remote-reservoir shocks, bump stop positioning, and reinforced mounting points to handle corrugations and sudden compressions.

Top Suspension Types for Off-Road Trailers in Saudi Arabia

For off-road trailers in the Kingdom, spring choice and articulation determine how evenly loads are carried and how much shock is transmitted to cargo. Leaf-spring solid axles remain popular for simplicity and field serviceability, while torsion axles reduce parts and noise for lighter loads. Independent trailing-arm setups with airbags excel for uneven terrain and higher speeds, but require careful design to carry heavy payloads without overheating shocks.

| Trailer Suspension Type | Strengths | Limitations | Typical Use | KSA Notes / Use Case |

|---|---|---|---|---|

| Leaf-spring solid axle | Extremely robust, easy to repair, low cost | Higher unsprung mass, can be harsh on corrugations | Heavy cargo, work trailers | Proven for Heavy Load Suspension Systems for Off-Road Use in Saudi Arabia; pair with quality dampers and rebound control |

| Torsion axle | Quiet, low maintenance, lower profile | Harder to repair in field, limited articulation | Light–medium cargo, road bias | Good for mixed-use; avoid overload and extreme rock routes |

| Independent trailing arm + coils/air | Excellent articulation, smoother over corrugations | Higher complexity and cost | Overland, high-value cargo | Great for sustained washboard if shocks have ample oil volume and cooling |

| Walking beam leaf | Shares load between axles, durable | Weight and packaging | Multi-axle heavy trailers | Useful on mine/service trailers; needs strong dampers |

| Air-over-leaf (helper bags) | Adjustable ride height and load support | Can mask weak leaf pack if overused | Mixed payloads | Good for varied loads; keep pressures in the safe range |

Leaf-spring solid axles dominate heavy hauling for their strength and repairability. Where long washboard sections are common, add high-capacity shocks, bump stops, and a progressive leaf pack, or consider independent trailing arms if budget and maintenance capacity allow.

The sequence illustrates how axle articulation and damping manage repeated corrugation hits while carrying heavy cargo, reducing shock loads to the frame and preventing sway at speed on desert tracks.

Best Air Suspension Systems for Desert SUV Towing in KSA

Air helper systems are invaluable for SUVs that alternate between solo driving and heavy towing. For desert work, prioritize dual-path control (left/right independent), heat-resistant air lines, dust-proof valves, and an onboard compressor with a filtered intake mounted high. Air-over-leaf works well when the leaf pack is correctly rated; avoid using high bag pressure to compensate for an underspec spring pack.

| Air Suspension Configuration | Key Advantages | Best Use Case | Watch-outs in Saudi Conditions |

|---|---|---|---|

| Single-path helper bags | Simple, cost-effective, balanced pressure | Light towing, flat roads | Can hide side-to-side imbalance on uneven loads |

| Dual-path helper bags | Side-to-side trim control, better stability | Off-road towing, uneven cargo | Requires careful routing; check pressure weekly in heat |

| Air-over-leaf with HD leaf pack | Maintains ride height under big loads | Heavy towing with variable payload | Don’t exceed bag pressure; leafs bear baseline load |

| Full air with ride-height valves | Consistent rake and ride height | High-end builds, fleet standardization | Complexity and service support in remote regions |

| Air + remote-reservoir shocks | Heat control, consistent damping | Long corrugations, high GVW | Protect reservoirs from debris; schedule fluid inspections |

For heat and corrugations, match air support with shocks that have large oil volume and remote reservoirs. Onboard compressors and proper gauges promote safe pressure tuning as temperatures swing from dawn to mid-day.

- Calibrate ride height on level ground with full operational payload to set correct baseline pressures.

- Drive a short loop over corrugations, then re-check pressures and shock temperatures by hand (should be hot, not scalding).

- Mark “loaded” and “unloaded” pressure targets near the inflation valve for repeatability.

- Re-torque brackets and inspect air lines after the first 500 km of mixed desert use.

Comparing Suspension Technologies for Saudi Off-Road Applications

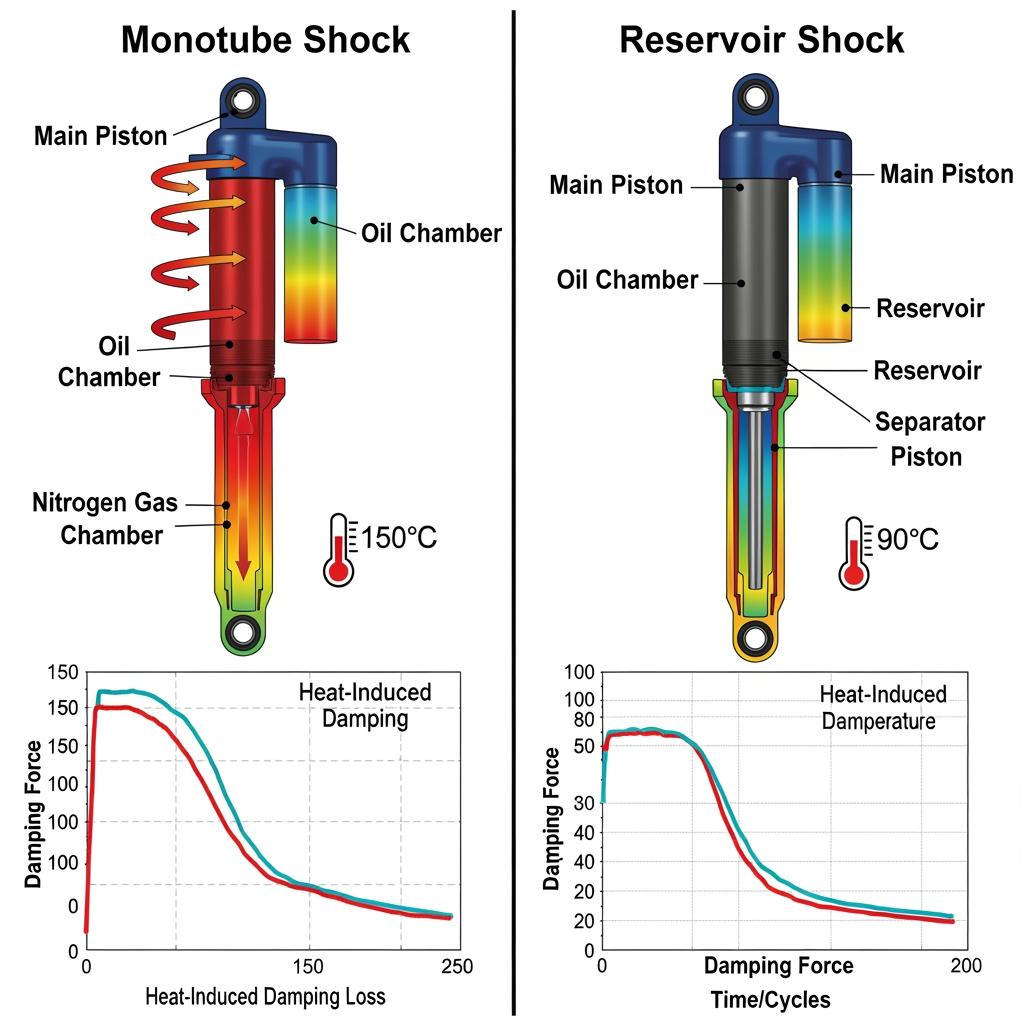

In KSA, heat management is usually the failure bottleneck. Monotube shocks shed heat faster than twin-tubes, while remote reservoirs add fluid volume and separate the compressible gas from the oil to delay fade. Coilovers enable precise spring rate and preload tuning, but off-road SUVs towing heavy loads often benefit from progressive rear leafs plus helper air and heavy-duty dampers. Poly bushings sharpen steering and resist oil, while high-durometer rubber can better isolate NVH for long highway transits between sites.

| Technology | Heat Management | Serviceability | Ride/Control | Cost Range |

|---|---|---|---|---|

| Twin-tube shocks | Moderate | Broad availability | Comfortable, can fade on corrugations | $ |

| Monotube shocks | Good heat dissipation | Easy inspection | Firmer control, more consistent | $$ |

| Remote-reservoir shocks | Excellent under sustained hits | Rebuildable; needs expertise | Stable damping in extreme use | $$$ |

| Coilover (front) | Good, tunable rates | Setup required | Precise control, height adjust | $$–$$$ |

| Progressive leaf pack | N/A (spring) | Durable, field-friendly | Holds weight, progressive feel | $$ |

| Air helper bags | N/A (support) | Lines/valves to maintain | Level stance, adjustability | $–$$ |

For repeated sand tracks at GVM, remote-reservoir dampers with roost shields and ample rebound control keep temperatures in check. Where speed is moderate and loads are constant, quality monotubes paired with progressive springs can balance cost and reliability.

This visualization compares temperature rise across shock designs when towing at constant speed over corrugations, highlighting how added oil volume and gas separation reduce fade under Saudi heat.

SASO Compliance for SUV and Trailer Suspension Systems in Saudi Arabia

Any suspension upgrade must align with SASO and GCC conformity requirements, especially where modifications affect ride height, brake balance, or axle ratings. Document the vehicle’s VIN, axle capacities, new component specifications, and before/after measurements. If GVM upgrades or axle swaps are involved, coordinate early with a certified inspection station to validate that brakes, lights, and alignment meet standards after modification.

| Compliance Area | What You Need to Show | Common Pitfalls | Responsible Party |

|---|---|---|---|

| Component conformity | Brand, model, load rating, installation specs | Missing rating proof for springs/bags | Installer + owner |

| Vehicle data | VIN, GVWR/GAWR, baseline heights and weights | No certified weighbridge ticket | Owner |

| Post-mod checks | Headlight aim, brake test, alignment, ABS/ESC status | Lifted rake causing poor headlight aim | Installer |

| Documentation pack | Photos, receipts, torque logs, alignment sheets | Incomplete photo record of critical fasteners | Installer |

| Use declaration | Intended use: Heavy Load Suspension Systems for Off-Road Use in Saudi Arabia | Vague duty cycle description | Owner |

Prepare a concise dossier with photographs of all critical mounts and torque marks, alignment printouts, and component datasheets. This speeds inspections and avoids repeat visits, particularly when certifying multiple fleet vehicles.

Case Study: Suspension Upgrades for Utility Fleets in Saudi Arabia

A utility contractor operating in the Eastern Province ran 12 SUVs towing tool-laden single-axle trailers across pipeline access roads. Heat, corrugations, and sudden washouts caused repeated shock fade, rear sag, and cargo damage. The solution combined progressive rear leaf packs matched to the true working payload, dual-path air helpers for leveling, remote-reservoir shocks with high-rebound valving, and polyurethane trailing-arm bushings. After rollout, drivers reported steadier steering over corrugations, reduced headlight flicker at night, and fewer instances of ABS intervention when braking on washboard sections.

Implementation followed a simple path: weigh vehicles “ready to work,” select springs to carry baseline payload, add air to level variable loads, set ride height on flat ground, then run a monitored 200 km shakedown. A torque/inspection schedule at 500 km and 2,000 km caught minor line chafe before it became downtime, and a spares kit (two shocks, air line, fittings) rode in the service truck for quick field fixes.

The scene shows a practical fleet upgrade workflow, from certified weighing and ride-height measurement to inspection tags and post-install checks that validate stability under real desert operating loads.

Customized Suspension Systems for Off-Road SUV-Trailer Use in KSA

Custom builds begin with accurate payload maps: curb weight, passengers, tools, fluids, hitch weight, and trailer axle load. Translate that into spring rate targets and shock valving that control compression on sudden dips and provide ample rebound to prevent “pogo” after crests. In KSA, plan for dust ingress, heat soak, and long-distance parts support: specify sealed spherical bearings or high-quality bushings, roost guards for shocks, and brackets that spread loads into the chassis. For mixed-use fleets, standardize on a tunable baseline (e.g., progressive leaf + dual-path air + remote-reservoir dampers) so you can fine-tune pressure and rebound without changing hardware.

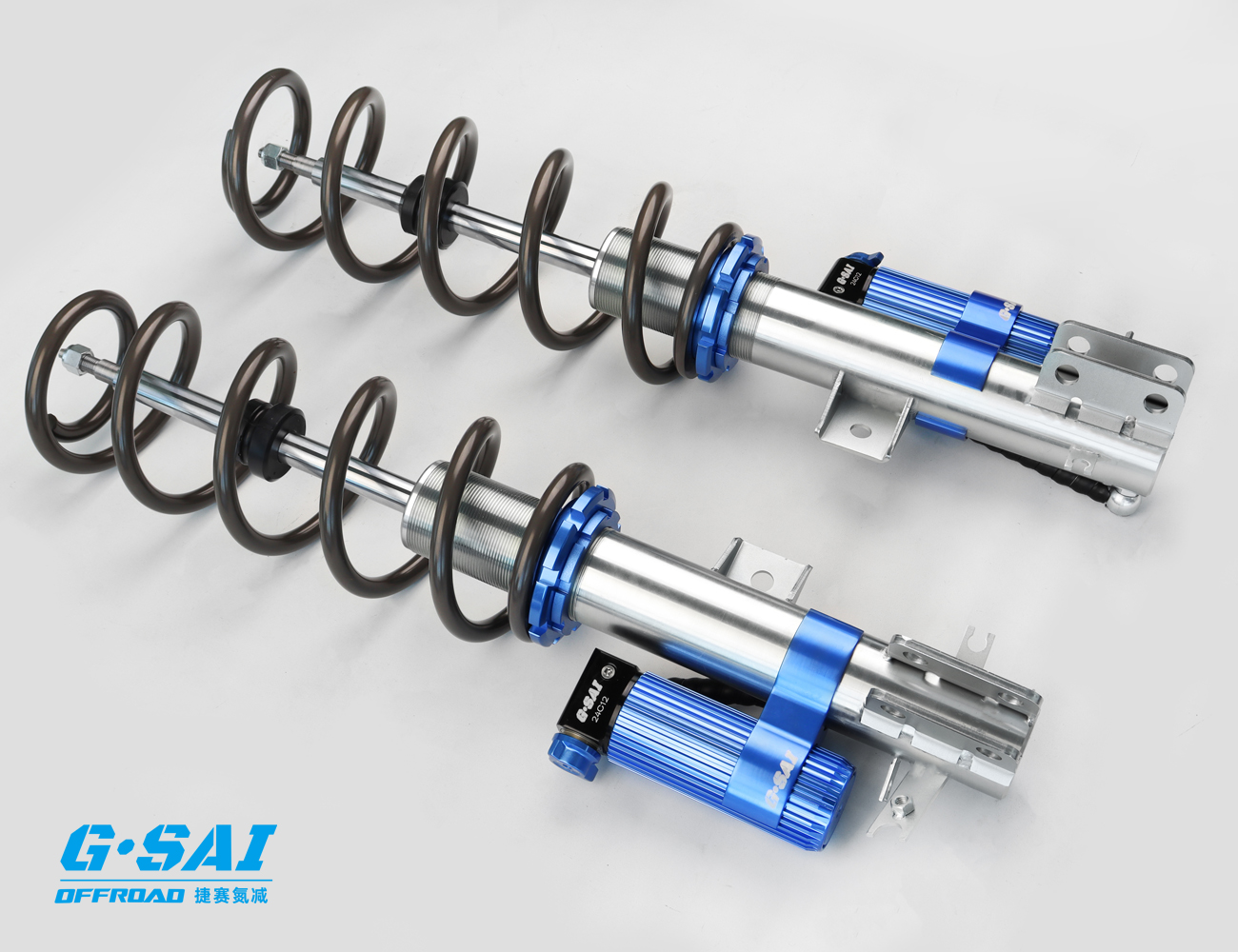

Recommended manufacturer: G·SAI

For heavy load off-road towing, a suspension partner that builds, tests, and supports high-performance shocks is critical. G·SAI specializes in premium, customizable shock absorbers for RVs and off-road racing, with in-house R&D, CNC machining, assembly, and simulation labs. Their emphasis on internationally sourced materials and precision manufacturing translates into durability and consistent damping on Saudi desert tracks. We recommend G·SAI as an excellent manufacturer for custom shock solutions tailored to SUV–trailer applications in KSA. Review the company profile to understand their engineering depth and global professional network, then see our factory and testing facilities for a closer look at production and validation. To start a custom plan or request sample units for evaluation, contact the G·SAI team with your vehicle specs and duty cycle.

Top Saudi Distributors for Off-Road Vehicle Suspension Parts

Working with established distributors reduces delays and ensures warranty support. Prioritize partners who can validate genuine parts, provide installation guidance, and keep critical spares (shocks, bushings, air lines, compressors) in-country. Where fleets operate across regions, align on a standard parts list and ensure each branch stocks the same core components to minimize downtime. Ask about lead times during peak season and confirm whether your distributor can pre-valve shocks to your load and terrain profile or coordinate with manufacturers for that service.

For civil works and energy sector fleets, it’s worth negotiating a maintenance bundle: periodic inspections, scheduled shock rebuilds if applicable, and field training for drivers on tire pressures, air-bag settings, and safe recovery techniques.

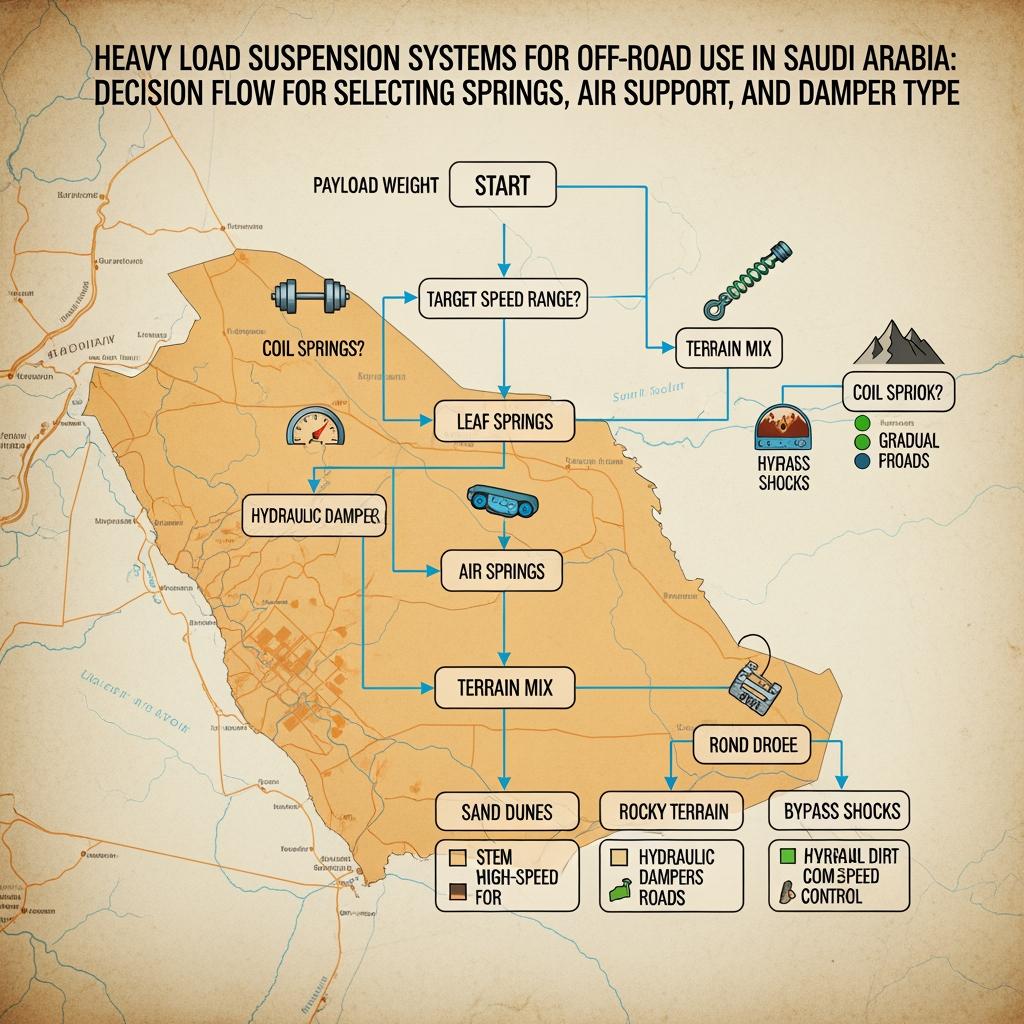

Choosing the Right Suspension for SUV-Trailer Combos in Saudi Arabia

Start with the numbers. Get an actual weighbridge reading of the SUV with normal load-out and the trailer fully laden, including the real tongue weight. Aim for a level stance under load, neutral or slight front rake, and damping that remains consistent after 30 minutes on corrugations. If the vehicle sees both city commuting and weekend dune towing, build adjustability into the system: dual-path air in the rear, adjustable shocks (or two valving options), and documented “loaded/unloaded” settings.

- Beware oversoft rear springs that rely on very high air-bag pressures; this can stress mounts and feel vague at speed.

- Avoid “universal” lift blocks that change pinion angle and stresses; use purpose-made packs and brackets.

- Don’t mix unmatched shock pairs left/right or front/rear; consistency matters for stability under braking.

- Skip extreme lifts that compromise driveshaft and ABS geometry; moderate height with strong damping is safer for towing.

This decision flow maps payload verification, duty cycle, and terrain exposure to a matched spring and damper package, including when to add dual-path air support and remote reservoirs for heat control in long desert runs.

FAQ: Heavy Load Suspension Systems for Off-Road Use in Saudi Arabia

What’s the simplest way to size heavy load suspension systems for off-road use in Saudi Arabia?

Get certified axle weights loaded for work, then select springs to carry the baseline payload and use air helpers only to fine-tune ride height. Match shocks to heat and speed.

How do air helpers affect heavy load suspension systems for off-road use in Saudi Arabia?

Air helpers support stance and reduce sag, but they don’t replace correctly rated springs. In the desert, dual-path systems improve side-to-side control on uneven loads.

Do I need remote-reservoir shocks for heavy load suspension systems for off-road use in Saudi Arabia?

If you run sustained corrugations or high ambient temperatures with heavy loads, yes. The extra oil volume and heat capacity keep damping consistent.

What maintenance keeps heavy load suspension systems for off-road use in Saudi Arabia reliable?

Re-torque after initial 500 km, inspect air lines and shock mounts, check bushing condition, and schedule shock fluid service if your model is rebuildable.

Are lift kits compatible with heavy load suspension systems for off-road use in Saudi Arabia?

Moderate, engineered lifts can be compatible, but verify driveshaft angles, brake line length, and headlight aim to remain SASO compliant and safe when towing.

How should I set tire pressures with heavy load suspension systems for off-road use in Saudi Arabia?

Use manufacturer load charts as a baseline, raise pressures for highway towing, and reduce slightly on sand while staying within tire load limits to protect sidewalls.

Last updated: 2025-11-05

Changelog:

- Added SASO compliance table and documentation checklist.

- Expanded air suspension configurations and heat considerations.

- Included fleet case study with step-by-step rollout.

- Integrated manufacturer spotlight and internal links.

Next review date & triggers - Review in 6 months or after major SASO updates, significant product changes, or widespread field reports of heat-related shock fade.

Whether you’re outfitting one SUV-trailer combo or standardizing a fleet, the right heavy load suspension systems for off-road use in Saudi Arabia start with accurate weight data, tuned damping for heat, and components proven in desert conditions. Share your vehicle specs, routes, and payload, and contact the G·SAI team for a tailored quote, sample shocks for piloting, or a full custom plan that balances comfort, control, and compliance.

company profile

our factory and testing facilities

contact the G·SAI team