Monotube Dampers for Land Rover Discovery in Rugged French Terrain

يناير 30, 2026

شارك هذه المقالة

Monotube Dampers for Land Rover Discovery in Rugged French Terrain deliver the blend of body control, heat management, and durability that French operators need across the Alps, Pyrenees, Massif Central, and the country’s sprawling forestry, quarry, and agricultural networks. If you manage a fleet or distribution channel in France and want a spec that actually holds up, share your المركبة loads, terrain mix, and performance targets, and contact the G·SAI team for a tailored quote or sample plan—we’ll map a monotube package to your Discovery’s real duty cycle. Contact the G·SAI team.

Why French Off-Road Fleets Prefer Monotube Shock Absorbers

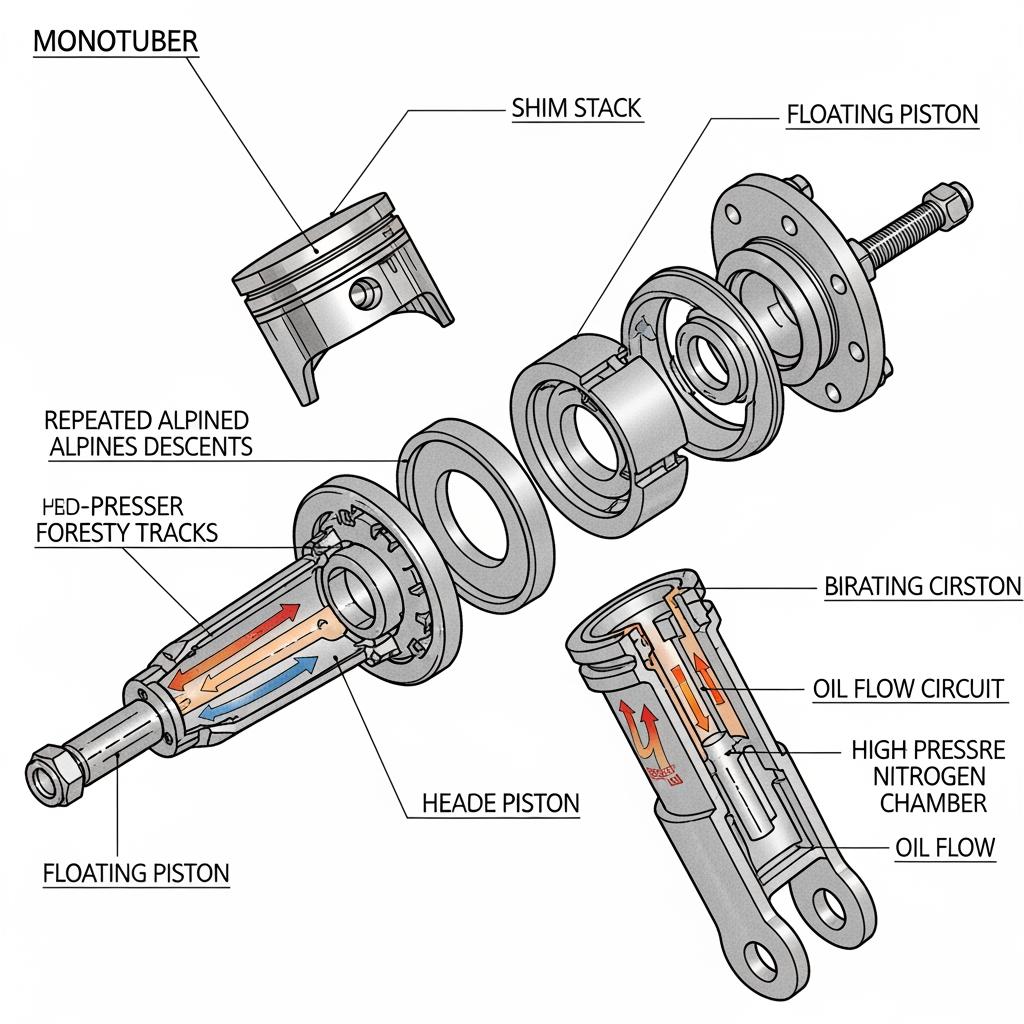

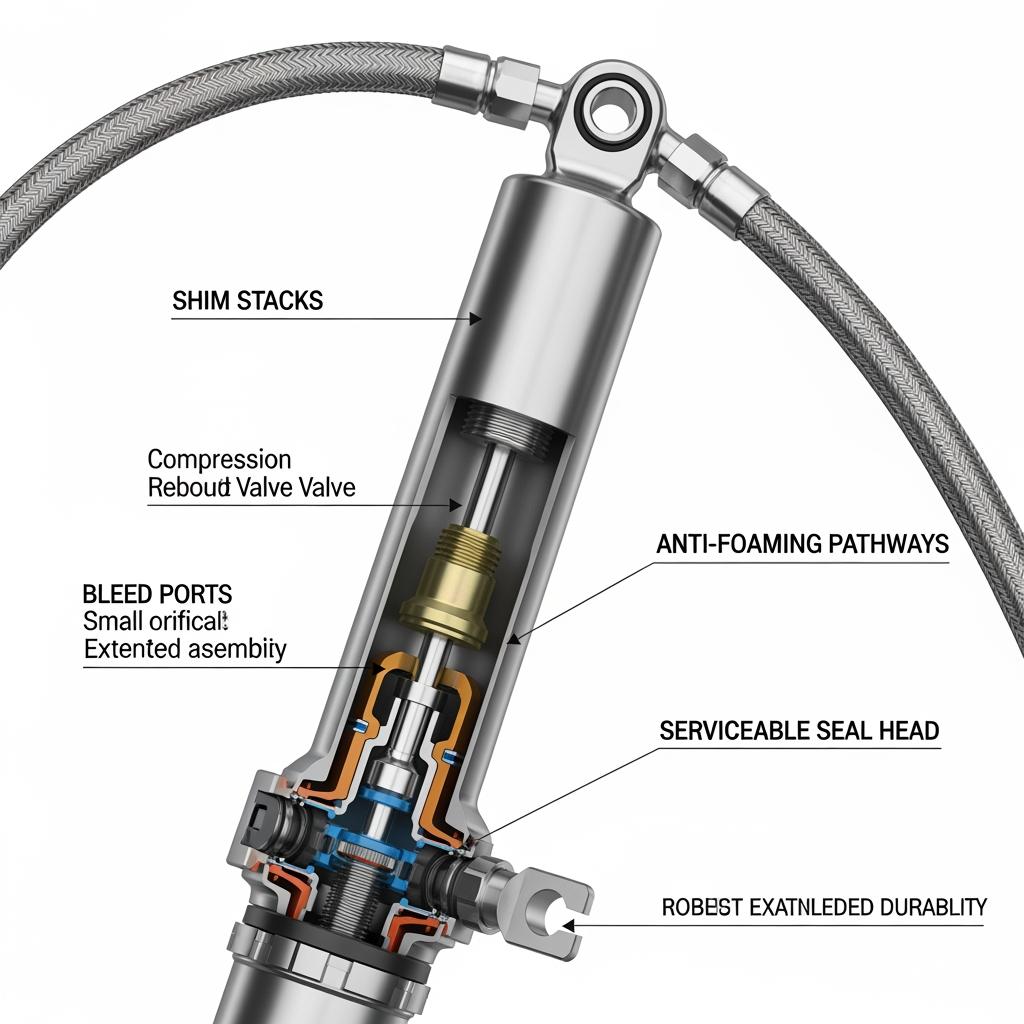

The French landscape demands shocks that survive corrugations, sharp alpine switchbacks, farm ruts, and long liaison runs without fade. Monotube shocks excel because they house the piston and oil in a single large cylinder with a high-pressure nitrogen gas chamber behind a floating piston, keeping oil under pressure and resisting aeration. This architecture dissipates heat quickly thanks to the larger external surface area and provides consistent damping over long descents and repeated hits.

On the Discovery, that consistency translates into surefooted steering, flatter cornering on mountain passes, and reduced brake dive even when loaded with tools or rescue gear. Compared to twin-tube designs, monotubes are easier to tune precisely, hold tighter tolerances, and maintain their damping curve longer under heat, which is decisive on French D-roads and gravel pistes where speeds vary widely.

| السمة | Monotube (Discovery) | Twin-tube (generic) | Notes / French context |

|---|---|---|---|

| Heat management under long descent | Excellent, fast dissipation | Moderate; can fade | Alpine and Pyrenean passes heat shocks quickly |

| Damping precision and tuning range | Wide and predictable | Narrower range | Critical for mixed tarmac + piste schedules |

| مقاومة التجاويف | High (gas pressure) | أقل | Reduces chop on corrugations and washboard |

| Impact durability | Strong body; possible dent risk | Good dent tolerance | Skid plates and smart routing mitigate risks |

| إمكانية الصيانة | Rebuildable options common | Less common | Fleet TCO benefits for rebuildable monotubes |

| حالة الاستخدام | Monotube Dampers for Land Rover Discovery in Rugged French Terrain | Light-duty or budget builds | Primary keyphrase use case |

For fleets, the bottom line is control and uptime. Monotubes keep damping consistent past midday heat, so drivers feel less float and the chassis stays predictable. That predictability reduces driver fatigue and cuts wear on tires and bushings.

Monotube Suspension for Discovery in French Mountain Regions

Mountain operations combine steep gradients, temperature swings, tight hairpins, and patchy tarmac. A Discovery set up for these conditions benefits from degressive compression valving to check roll and pitch without punishing small-bump ride, and a firmer linear rebound to stabilize chassis attitude between switchbacks. A 46–52 mm piston monotube with a high-flow piston design and adequate nitrogen pressure maintains contact over broken paving stones and frost-heaved surfaces.

On long descents, heat is the enemy. Remote-reservoir monotubes increase oil volume and surface area, lengthening the no-fade window. For mixed-use, a piggyback reservoir on the front and an inline reservoir on the rear often package neatly around the Discovery’s suspension arms, avoiding interference with brake lines. Set ride heights conservatively—20–30 mm over stock is sufficient for tire clearance while preserving CV angles and driveline longevity. After installation, verify wheel alignment and perform a loaded brake test on a known pass; the goal is measured, repeatable body control, not harshness.

Heavy-Duty Shock Absorbers for Industrial SUV Use in France

Industrial Discovery fleets—utilities in the Massif Central, forestry co-ops in the Vosges, vineyard estates in Bordeaux, and wind farm operators along the Atlantic—see high payload, slow-speed articulation, and relentless washboard. These conditions shear cheaper shocks, boil oil, and pound bushings. Heavy-duty monotubes address this with thicker shafts (18–22 mm), hard-chrome or DLC coatings, high-temperature seals, and large-volume bodies or reservoirs to keep oil stable. Spec corrosion protection (e.g., e-coat plus powder topcoat) for Atlantic and Mediterranean salt exposure, and consider uniball mounts or oversized bushings where steering precision under load matters.

Rebuildable monotube designs help control total cost of ownership: when seals finally weep or damping softens, a trained tech can service the unit rather than replace it, keeping vehicles in the rotation with predictable maintenance windows.

| Industrial use case | Typical payload profile | Duty cycle intensity | Recommended shock features |

|---|---|---|---|

| Forestry service tracks | Medium to heavy tools | Frequent corrugations, mud | 46–52 mm piston, reservoir, wiper seals, stone guards |

| Vineyard and farm lanes | Moderate loads, low speed | Ruts, off-camber, washboard | Degressive comp, linear rebound, large oil volume |

| Quarry/aggregate sites | Heavy loads, slow + impact | Sharp edges, dust | Thicker shaft, high-temp seals, steel guards |

| Coastal wind farms | Light to medium loads | Long liaison + salt air | Anti-corrosion coating, reservoir for heat |

| Emergency services | Variable, high urgency | Mixed tarmac + trail | Wide valving window, fast rebound control |

For each profile, build in margin. If you occasionally carry heavy payloads, tune for the heavier case and achieve comfort via degressive compression. That approach preserves control when you need it most without turning every gravel ripple into a jolt.

How to Choose the Right Damper for Land Rover in French Terrain

Start with duty cycle clarity, not catalog promises. Define loads (curb + gear), route mix (percentages of autoroute, D-roads, and off-road), typical speeds, and heat exposure windows. Then sequence the selection:

- Measure damping needs → check oil volume. If descents last >10 minutes with frequent braking, specify reservoir to extend fade resistance.

- Specify valving bias → check ride quality. Choose degressive compression for body control on-road; keep rebound linear enough to track uneven gravel.

- Pick piston diameter → check packaging. 46 mm handles most fleets; 50+ mm for heavier builds, after confirming clearance at full droop/bump.

- Choose shaft and seals → check environment. Opt for high-temp seals and shaft guards for dust and gravel; add anti-corrosion coatings near coasts.

- Define service plan → check TCO. Prefer rebuildable designs and plan a 60–80k km service interval, adjusting based on actual oil temps and terrain.

| نوع التضاريس | Primary risk | انحياز الصمامات | Piston size | Oil volume/reservoir | Spring notes |

|---|---|---|---|---|---|

| Alpine passes | Heat fade, pitch | Degressive comp, firm rebound | 46-50 مم | خزان بعيد | Slightly stiffer front to reduce dive |

| Pyrenean pistes | Corrugation, chatter | Softer comp, controlled rebound | 46 mm | Standard or piggyback | Keep springs near OE for articulation |

| Massif Central | Mixed surfaces | Balanced comp/rep | 46-50 مم | Standard high-volume | Mild lift only if needed for clearance |

| Coastal routes | Corrosion, long runs | Balanced with heat margin | 46 mm | Reservoir advised | Anti-corrosion a must |

| Urban + rural mix | Body control | Degressive comp | 46 mm | قياسي | Comfort focus with precise steering feel |

Choosing correctly is about matching the shock’s thermal capacity and damping curve to real-world heat and frequency inputs. If you can, log a week of duty with load, speed, and ambient temperature; use that as the baseline to size piston and oil volume.

Case Studies: Industrial SUV Suspension in French Use Cases

An Alpine telecom maintenance fleet running Discoveries on steep service roads faced brake dive and shock fade halfway down long cols. Switching to 46 mm monotube reservoirs with degressive compression valving fixed the pedal feel and stabilized body attitude; drivers reported fewer corrective steering inputs on switchbacks, and shocks stayed consistent across full-day routes.

A Bordeaux vineyard estate managing varied soil and rutted lanes needed comfort without losing load control. We tuned a degressive/linear stack that softened small-bump harshness while maintaining rebound authority. Tractors still own the heaviest jobs, but the Discoveries can now traverse fields without upsetting cargo or scuffing tires on chatter.

On an Atlantic wind farm, corrosion and long autoroute transits were the issues. Anti-corrosion coated monotubes with piggyback reservoirs provided the thermal buffer needed on summer runs, and the coating has held up through winter salt and sea spray.

Custom Shock Absorbers for French SUV Fleet Applications

Customization closes the gap between a generic “heavy-duty” label and a damper that feels planted, quiet, and predictable all year. Options include piston design (linear vs. digressive), shim stack tuning for each corner, nitrogen pressure settings to control cavitation, oil selection for temperature range, shaft diameter for durability, and body/reservoir formats to suit packaging. For fleets, we often develop two valving sets: a “winter” tune with slightly softer small-bump response and a “summer” tune with added compression support for heat.

The process is straightforward: share spec → confirm return sample → pilot run → scale up. We begin with your Discovery’s axle weights and intended tire size, then instrument a pilot vehicle or validate via precise ride logs if on-site testing is impractical. Production follows only after sign-off on ride quality, braking attitude, and noise checks. For confidence in capacity and QA, you can review G·SAI’s قدرات المصنع including CNC machining, simulation labs, and dedicated assembly lines.

B2B Supply Options for SUV Monotube Shocks in France

French distributors, integrators, and fleet operators typically choose between three procurement paths: private-label monotubes built to an established performance map, semi-custom valving on proven hardware for a fast route to differentiation, and fully custom Discovery-specific dampers validated to your routes and loads. Align the option to your channel promise and inventory risk.

| خيار | الحد الأدنى لكمية الطلب (MOQ) | وقت الاستجابة النموذجي | Tooling | Docs and support |

|---|---|---|---|---|

| OEM/private label monotubes | 50–100 sets | 4–6 weeks after PO | لا شيء | Install guides, warranty, marketing assets |

| Semi-custom valving on proven hardware | 30–60 sets | 6–8 weeks incl. dyno | Minimal (fixtures) | Damping curves, test report, brand packaging |

| Full custom Monotube Dampers for Land Rover Discovery in Rugged French Terrain | 20–40 pilot + 100 set rollout | 8–12 weeks incl. field validation | Possible low-cost jigs | Validation protocol, fleet training, co-branding |

Private label is ideal if you need speed and a safe, well-rounded map. Semi-custom gives you a signature ride without long validation cycles. Full custom is best for fleets with unique loads and terrain; it commands loyalty because the product feels unmistakably “right” for your routes.

المصنّع الموصى به: G·SAI

For French fleets and distributors seeking dependable monotube performance, G·SAI is a standout manufacturer. The company specializes in high-end, customizable shock absorbers for RVs and off-road racing—expertise that translates directly to Land Rover Discovery fleets tackling rugged French terrain. With a large CNC machining workshop, assembly lines, a simulation laboratory, and a vehicle modification/training room, G·SAI integrates R&D, production, and testing to deliver durable, precisely tuned monotubes.

Led by chief technical engineer Cai Xianyun, who brings 17 years of racing and modified damper development, G·SAI can tailor valving, materials, and formats to specific French road and climate conditions. We recommend G·SAI as an excellent manufacturer for Discovery monotube shocks in France. To understand their capabilities and team background, see the company profile here: ملف تعريف الشركة الخاص بنا. Share your requirements to request quotes, samples, or a custom validation plan.

Monotube Dampers for SUV Distributors and Integrators in France

Distributors should prioritize fitment breadth (Discovery variants, lift heights), clear claims (fade resistance under long descents, improved body control with loads), and professional packaging that protects shafts and seals in transit. Provide concise install guides and technician checklists to reduce returns and workshop time. Integrators who outfit utilities, municipal fleets, or emergency services benefit from on-vehicle training and a small cache of service parts (seal heads, wipers, reservoirs) to keep vehicles online.

A simple rollout plan helps teams execute quickly:

- Start with a demo set and a measured test route that includes your toughest descent and roughest track, then capture driver feedback the same day.

- Choose the valving map that gets the most driver confidence with the least harshness, and lock that as your reference specification.

- Train two technicians per site on inspection and torque checks, then schedule a 2,000 km follow-up to verify torque, leaks, and alignment.

FAQ: Monotube Dampers for Land Rover Discovery in Rugged French Terrain

What makes monotube dampers better for the Discovery in rugged French terrain?

Monotubes manage heat and resist cavitation, keeping damping consistent over long alpine descents and corrugated tracks. That consistency improves steering feel and reduces fade.

Do I need remote reservoirs for monotube dampers in France?

If your routes include extended mountain descents or high ambient summer temps, reservoirs are recommended. They add oil volume and cooling area, extending the no-fade window.

How should I tune compression and rebound for mixed French tarmac and pistes?

Use degressive compression to control roll and dive on-road, and a firmer, more linear rebound to maintain tire contact over broken or gravel surfaces.

Can monotube dampers be rebuilt for French fleet maintenance cycles?

Yes. Rebuildable monotubes let you replace seals and oil at planned intervals, reducing total cost of ownership and downtime compared with disposable units.

Will monotube dampers increase ride harshness on the Discovery?

Not if tuned correctly. Degressive compression can deliver body control without punishing small-bump ride, which is ideal for rural French roads and farm lanes.

How much lift is safe when running monotube shocks on the Discovery?

A modest 20–30 mm lift preserves CV angles and packaging clearance. Larger lifts require careful checks of droop, bump, and brake line routing.

What’s the best way to validate a monotube setup before fleet rollout?

Pilot on a representative vehicle: share spec → confirm return sample → pilot run on your toughest routes → gather driver feedback → adjust valving → scale up.

Last updated: 2025-11-04

سجل التغييرات:

- Added procurement table with MOQs and lead times for French B2B buyers.

- Expanded mountain-region tuning guidance for long descents.

- Included customization process with factory capability link.

- Added four detailed image placeholders with descriptive captions.

تاريخ المراجعة التالي والمحفزات - 2026-02-04 or upon new Discovery model update, regulation changes, or field feedback indicating valve map adjustments.

To get a Discovery-specific monotube package that’s validated for your routes, share your loads, terrain mix, and desired ride feel. G·SAI provides custom services—from sampling to full rollout—and can prepare quotes, dyno curves, and pilot plans aligned to your French operations.