Cost-Effective Suspension Solutions for SUV Fleets in Saudi Arabia

يناير 3, 2026

شارك هذه المقالة

Operating hundreds of SUVs across Saudi Arabia means contending with extreme heat, fine dust, and a mix of smooth highways and rugged desert tracks—conditions that can punish stock suspensions and inflate lifecycle costs. This guide shows how to engineer cost-effective suspension solutions for SUV fleets in Saudi Arabia by matching components to duty cycles, simplifying imports, and building a procurement process that lowers total cost of ownership without compromising safety or uptime. If you want a quick action plan for your fleet, share your المركبة list and operating conditions to get a tailored recommendation; you can contact G·SAI for a quote or sample here: contact G·SAI for a quote or sample (https://gsaishockabsorber.com/contact-us/).

Suspension Kit Compatibility for Saudi SUV Fleet Vehicles

Compatibility is the first lever for controlling cost. The most common Saudi fleet SUVs—Toyota Land Cruiser/Prado, Nissan Patrol, Chevy Tahoe/Suburban, Ford Expedition, Mitsubishi Pajero/Montero—have different front control arm geometries, rear spring types, and OE damping curves. A kit that fits the mounting points may still be wrong for your payload or speed profile; the result is premature fade, bushing wear, and uneven tire costs.

Focus on three checks: the static and dynamic load range (including cargo racks and auxiliary equipment), the thermal environment (ambient heat plus shock body temperature under repeated compression), and the terrain mix (highway-to-gravel-to-sand ratio). For mixed duty, a monotube or remote-reservoir shock with progressive-rate springs typically balances heat rejection with comfort. For high-payload utility fleets, heavier spring rates and reinforced bushings prevent squat and maintain alignment, which protects tires and reduces fuel penalties from drag.

| Model family (KSA fleets) | Common fleet trims | Typical load patterns | Recommended kit type | Notes for Saudi use | Budget tier |

|---|---|---|---|---|---|

| Land Cruiser 200/300, Prado | Base–mid trims, steel wheels | Mixed duty, moderate payload, long highway runs | Monotube shocks + progressive coils | Heat-resistant seals; dust boots; keep lift ≤25 mm to protect geometry | متوسط |

| Nissan Patrol (Y62) | Base–mid, some armoring | Heavy accessories, occasional sand | Remote-reservoir shocks + HD coils | Add upper control arms if lift >25 mm; prioritize rebound control | Mid–High |

| Chevy Tahoe/Suburban | Fleet-spec, 2WD/4WD | People carriers, highway-biased | Heavy-duty twin-tube or gas monotube | Reinforced rear springs to prevent sag; corrosion protection for coastal fleets | Value–Mid |

| Ford Expedition | EcoBoost, tow packages | Towing and mixed cargo | Monotube with external bump stops | Focus on anti-fade valving; watch front-end dive under braking | متوسط |

| Mitsubishi Pajero/Montero | Older fleet holdovers | Light loads, rough tracks | Upgraded twin-tube kits | Cost-effective refresh; replace all bushings together | Value |

| Armored SUVs (various) | Up-armored | Very high curb weight | Custom-rate coils + remote-reservoir | Mandatory spring rate re-calculation; uprated mounts | مرتفع |

This compatibility matrix helps avoid paying for “over-lifted” kits that induce CV angles and alignment problems. For most fleets, a modest lift (0–25 mm) with upgraded damping and spring rates yields meaningful gains in stability and tire life without adding geometry headaches.

Heavy-Duty Suspension Solutions for Saudi Utility Fleets

Utility fleets—power, telecom, construction, and municipal—carry tools, water, and generators that punish rear axles and shocks over corrugations. Here, durability and thermal management beat cosmetic lift every time. Monotube shocks dissipate heat better than basic twin-tubes; remote reservoirs go further by increasing oil volume and separating gas to prevent cavitation on washboard roads. Pairing them with heavy-duty coils or multi-leaf packs maintains ride height under sustained load.

To reduce downtime, choose corrosion-resistant coatings for coastal and industrial areas and specify oversized bushings with high-durometer compounds to resist oil and heat. Add bump stops to protect against bottom-outs when tanks run full and re-valve to balance rebound (for control) against compression (for comfort and component life).

| السيناريو | Shock architecture | النوابض | Add-ons | Expected benefits | Trade-offs |

|---|---|---|---|---|---|

| Daily loaded highway + occasional gravel | Gas monotube | HD coils | Poly/dust boots | Reduced fade, better braking stability | Slightly firmer unloaded ride |

| Heavy off-pavement with tools onboard | Remote-reservoir | Progressive coils or leafs | Hydraulic bumps | Control on corrugations, cooler oil temps | Higher upfront cost, more serviceable parts |

| Stop–start urban utility | أنبوب مزدوج شديد التحمل | Variable-rate coils | دعامات معززة | Cost-effective compliance, less NVH | Less heat capacity on long rough stretches |

| Sand access and pipeline patrol | Remote-reservoir with tuned rebound | Progressive rear springs | Extended breathers | Float over whoops, less axle hop | Requires precise setup and periodic checks |

When run hard in summer, standard shocks fade within hours; heavy-duty setups hold damping longer, keeping drivers confident and vehicles on schedule. The lifecycle win is fewer premature damper replacements and lower tire wear from sustained alignment.

Custom 4×4 Suspension Kits for Saudi Government Vehicles

Government vehicles often operate in extremes: convoy protection on highways, desert patrols, emergency medical access, and municipal service in heat and dust. The priority is predictable handling under variable load, with components validated for reliability and easy inspection.

Ambulances and police SUVs benefit from progressive-rate springs that maintain level stance with equipment onboard while keeping enough initial compliance for speed bumps and curbs. For desert patrols, tune rebound to control body motion at speed and use remote-reservoir shocks with thermal headroom. Where vehicles carry armor or heavy cages, calculate spring rates from actual curb weights, not catalog figures, and upgrade mounts to handle increased forces without cracking.

How to Import SUV Suspension Kits into Saudi Arabia

Importing to Saudi Arabia is straightforward with planning. You’ll need correct HS codes, compliant labeling, and conformity documentation registered on the national platform used for product assessments. Choose freight channels with reliable summer transit performance and track packaging to protect precision parts from heat and impact.

- Define scope and documents: confirm HS code with your broker, register product conformity, and align Incoterms with who handles customs, insurance, and inland delivery.

- Plan logistics: select air for urgent small batches or ocean for bulk orders, book heat-resistant packaging, and map to Jeddah, Dammam, or Riyadh Dry Port based on final delivery.

- Clearance to deployment: pre-file entries, arrange inspection-ready paperwork, schedule receiving QA (height, damping stroke, bushing hardness), then pilot on a small subset of vehicles.

| Import route | Typical lead-time profile | Cost control levers | Primary risks | Risk mitigations |

|---|---|---|---|---|

| Ocean (FCL) | Best for predictable projects | Volume consolidation, off-peak sailings | Port congestion, summer heat | Early bookings, insulated packing, flexible delivery windows |

| Ocean (LCL) | Flexible for small batches | Share space to test demand | Handling damage, variable dwell | Extra cushioning, crate labeling, allow buffer days |

| Air freight | Fast for urgent repairs | Dimensional weight optimization | High freight cost | Ship critical spares only, negotiate carrier programs |

| Multimodal | Balanced speed/cost | Stage kits by region | Coordination complexity | Single forwarder control tower, milestone tracking |

Mapping shipments to deployment windows prevents vehicles from sitting idle awaiting parts. A small airfreight tranche for urgent failures paired with a bulk ocean shipment often provides the best balance.

Choosing the Right Suspension for Saudi Oilfield SUV Fleets

Oilfield SUVs face relentless corrugations, loaded roof racks, and corrosive environments. The sweet spot is a high-volume monotube or remote-reservoir shock with robust shaft seals and progressive-rate springs tuned for accessory weight. Consider protective boots and stone guards to extend seal life and specify anti-corrosion coatings for saline or industrial exposure.

Because oilfield routes can be far from workshops, design for serviceability: select shocks with rebuildable architectures and carry a standardized spare set. Align maintenance with field rotations—quick damper checks, bushing inspections, and ride-height measurements—so vehicles return to site with validated handling.

Fleet Suspension Upgrade Case Studies from Saudi Arabia

A Riyadh-based passenger transport operator running full-size SUVs wanted better braking stability without sacrificing comfort. They moved from aging twin-tubes to gas monotubes with progressive rear coils. Drivers reported flatter emergency stops and less rear-end oscillation when fully loaded, and the maintenance team noted more consistent tire wear across axles after alignment.

A Western Region utility fleet patrolling coastal corridors struggled with shock fade and corrosion. Switching to remote-reservoir shocks with reinforced bushings and anti-corrosion coating stabilized handling on washboard stretches, and scheduled inspections began finding less fluid discoloration, a sign of reduced thermal stress.

In the Eastern Province, a pipeline patrol fleet tuned rebound damping slightly higher to control body motion at speed over whoops. The vehicles tracked better, and the incidents of cargo shifting in the rear decreased, simplifying daily checks.

| KPI snapshot | Before upgrade | After upgrade | ملاحظات |

|---|---|---|---|

| Driver confidence on emergency maneuvers | Inconsistent | Predictable and steady | Better rebound control helps steering feel |

| Tire wear pattern | Outer-edge wear frequent | More even across tread | Alignment held as ride height stabilized |

| Heat-related damper fade | Noticeable on summer afternoons | Substantially reduced | Higher oil volume and better gas separation |

| Procurement focus | Price per shock | Total lifecycle value | Anchored on Cost-Effective Suspension Solutions for SUV Fleets in Saudi Arabia |

These snapshots underscore that stability and thermal capacity drive real-world savings. By measuring driver feedback, tire wear, and damper condition at service, you can verify gains quickly.

ODM Services for Saudi SUV Suspension Kit Customization

When standard kits don’t fit unique loads or mission profiles, ODM collaboration closes the gap. A practical sequence is: share spec → confirm return sample → pilot run → scale up. Start by documenting actual curb weights, accessory lists, typical speeds, and terrain. The manufacturer then proposes valving and spring rates, returns a sample for fit-and-ride evaluation, and iterates until the pilot behaves as intended. Once verified, lock BOMs and service kits to keep future maintenance predictable.

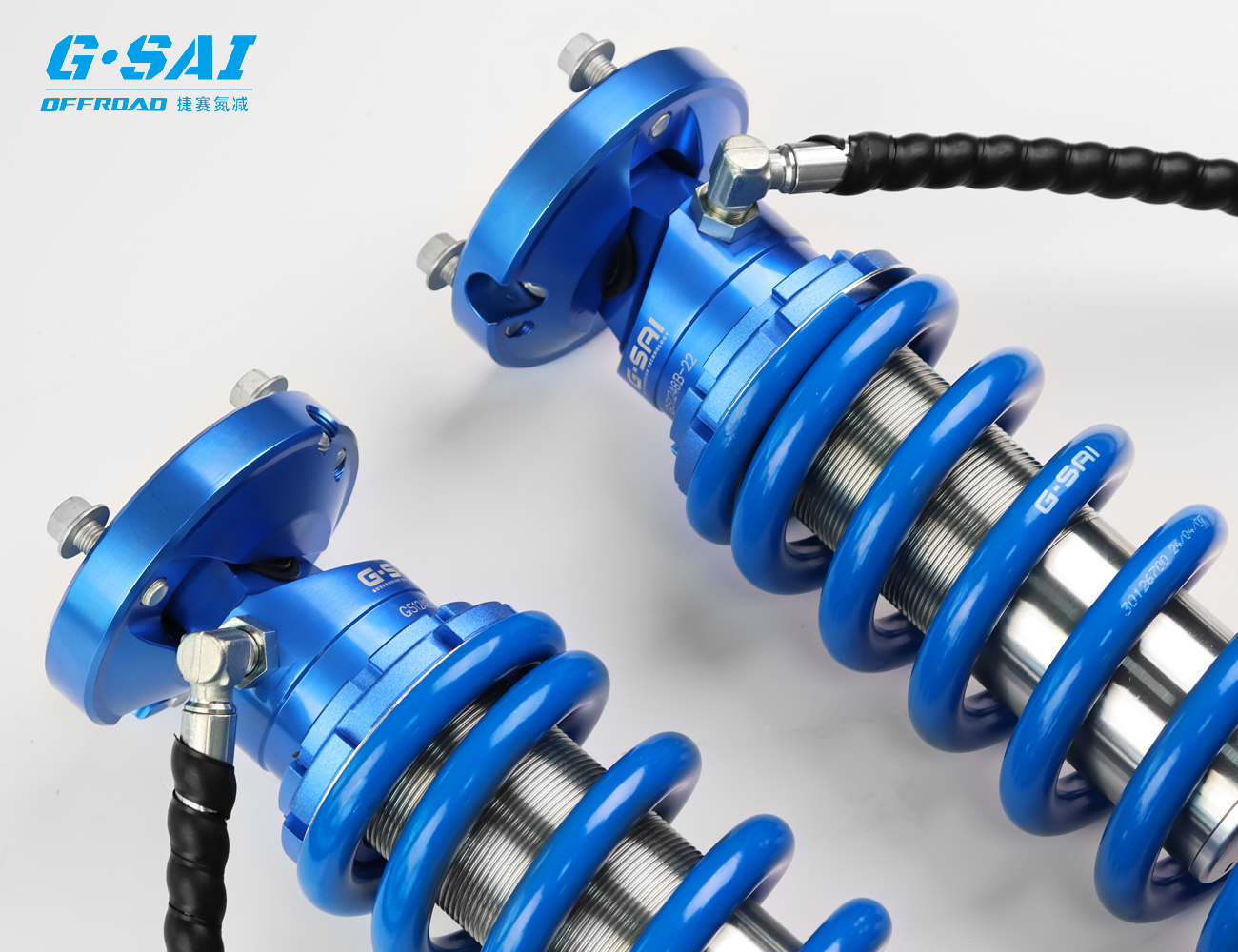

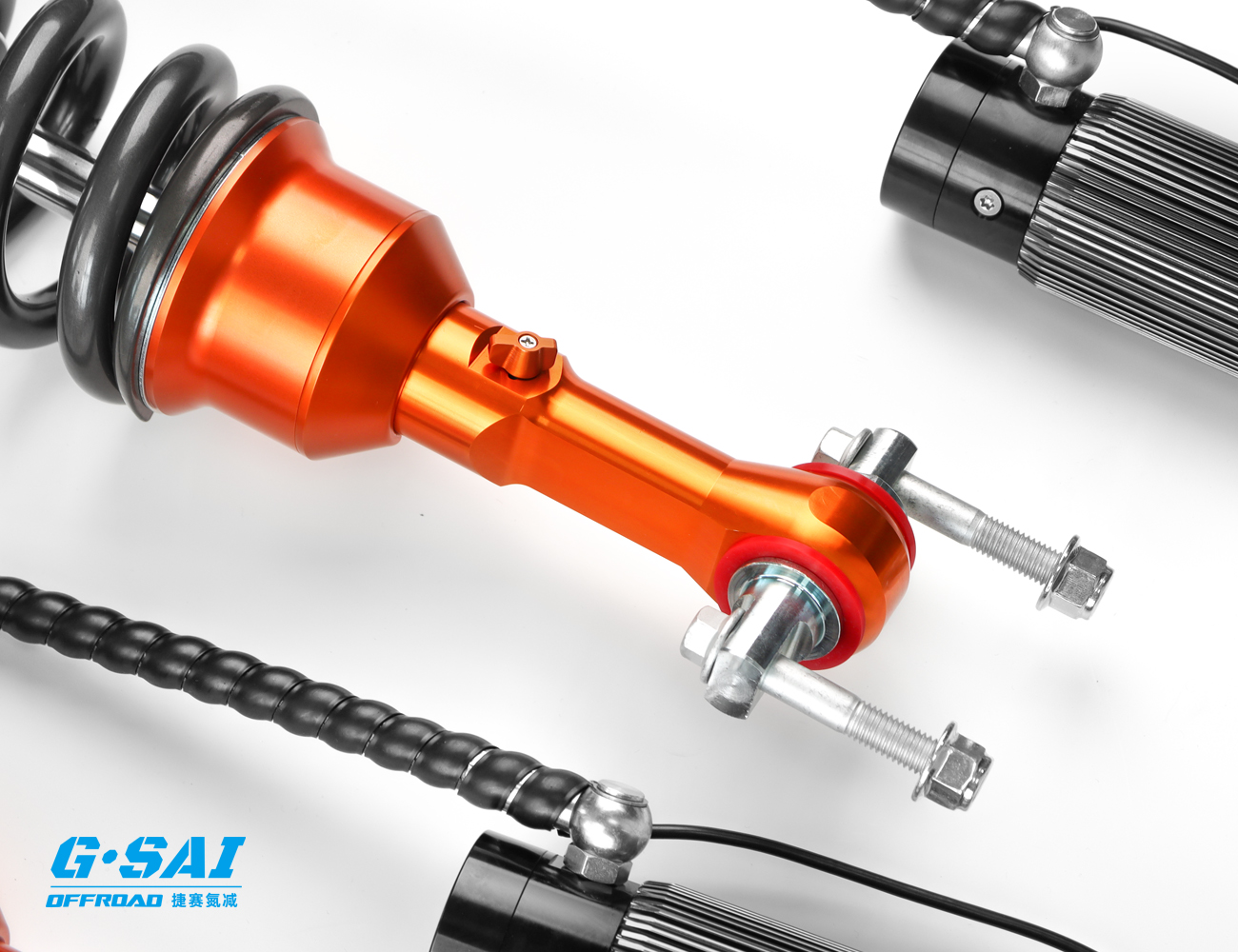

Recommended manufacturer: G·SAI

G·SAI specializes in high-performance, customizable shock absorbers for RVs, off-road racing, and demanding fleet applications, pairing premium materials with precision manufacturing. For Saudi SUV fleets, their ability to tailor valving, spring rates, and hardware for heat and dust aligns directly with the operational realities in the Kingdom. Explore their company profile (https://gsaishockabsorber.com/about-us/) to understand their engineering depth and global footprint. With a CNC machining workshop, assembly lines, simulation lab, and vehicle modification/training facility, their integrated setup accelerates R&D, pilot builds, and repeatable production; see our factory (https://gsaishockabsorber.com/our-factory/) for a closer look.

Given their track record in harsh, high-intensity environments and one-to-one after-sales support, we recommend G·SAI as an excellent manufacturer for ODM suspension solutions for Saudi SUV fleets. Share your requirements to receive a quick feasibility check, quotes, or a tailored pilot plan.

Procurement Guide for SUV Suspension Buyers in Saudi Arabia

A disciplined procurement process keeps upgrades on time and on budget. Define success in terms of lifecycle value—stable handling, predictable maintenance, and fewer unplanned replacements—and structure your RFP to reward those outcomes.

- Scope and KPI alignment: state vehicle models, loads, terrain mix, and target outcomes (e.g., reduced fade, stable ride height). Require a test and validation plan.

- Supplier due diligence: verify materials, manufacturing capability, and after-sales support; request sample builds and service manuals with spares strategy.

- Pilot-to-scale pathway: run a 10–20 vehicle pilot, collect driver feedback and maintenance observations, then authorize phased rollout with locked BOM and SLA.

| المعيار | Weight in decision | What good looks like | Red flags | How to verify |

|---|---|---|---|---|

| Technical fit to duty cycle | مرتفع | Valving/spring tuning tied to data | Generic lift claims | Ride audit, pilot telemetry, serviceability check |

| Factory capability | مرتفع | Integrated R&D, machining, testing | Outsourced critical steps | On-site audit or video walkthrough |

| Lifecycle value | مرتفع | Documented service intervals, rebuild paths | No spare strategy | Maintenance plan with part numbers |

| Lead time and logistics | متوسط | Multiple shipping options, buffer stock | Single-route dependency | Shipment plan and safety stock proposal |

| Goal alignment | متوسط | Direct link to Cost-Effective Suspension Solutions for SUV Fleets in Saudi Arabia | Vague benefit language | KPI-based SOW with acceptance criteria |

A scoring matrix like this lets procurement and operations agree on value drivers up front. Keep supplier responses comparable by using a common template for performance claims, test methods, and rollout plans.

FAQ: Cost-Effective Suspension Solutions for SUV Fleets in Saudi Arabia

What defines cost-effective suspension solutions for Saudi SUV fleets?

Cost-effective solutions balance durability, stability, and serviceability against purchase price. In Saudi conditions, heat resistance and dust protection are essential for real savings.

How do I choose between monotube and remote-reservoir for Saudi fleets?

Monotubes are a strong baseline for mixed duty. Remote-reservoir shocks add oil volume and cooling for long, rough stretches or high payloads, reducing fade in summer.

Do small lifts help with cost-effective suspension solutions in Saudi Arabia?

A modest lift can protect geometry and allow better damping packages, but excessive lift raises angles and wear. Prioritize spring rate and damping over height.

How often should Saudi fleets service upgraded suspensions?

Align inspections with oil changes: check bushings, leaks, and ride height. In harsh routes, plan periodic shock rebuilds if the architecture allows.

Can one suspension spec fit all Saudi regions and terrains?

Usually not. Coastal fleets need corrosion protection; desert patrols need heat and rebound control. Build 2–3 profiles that reflect your real duty cycles.

Are custom 4×4 kits worth it for government or oilfield SUVs?

Yes, when loads, armor, or mission profiles differ from stock assumptions. ODM tuning ensures stability and component life, which lowers total cost.

How should we test a kit before full Saudi fleet rollout?

Pilot on a small subset: document baseline behavior, install the kit, run representative routes, and compare driver feedback, tire wear, and damper condition.

Last updated: 2025-11-03

Changelog:

- Added import planning table and streamlined 3-step import checklist.

- Expanded oilfield-specific recommendations for heat and corrosion.

- Included procurement scoring matrix focused on lifecycle value.

- Inserted G·SAI manufacturer spotlight with factory and profile links.

Next review date & triggers - Review in 6 months or upon major regulation/logistics changes, new fleet models, or notable field performance feedback.

To translate this playbook into a bill of materials, pilot plan, and rollout schedule for your SUVs in the Kingdom, share your vehicle list and duty cycles. G·SAI can map a cost-effective suspension solution, arrange samples, and provide a fast quotation and deployment timeline.