French-Compliant Shock Absorbers for Off-Road SUV Applications

يناير 21, 2026

شارك هذه المقالة

Fleet managers and vehicle builders in France face a unique balancing act: achieving rugged off-road control while meeting safety, durability, and homologation expectations. The fastest route is to specify French-Compliant Shock Absorbers for Off-Road SUV Applications that are tuneable for payload and terrain, validated under realistic duty cycles, and supported by dependable B2B supply. If you’re drafting specifications now, share your المركبة data and target ride outcomes, and we’ll help you create a French-ready, adjustable suspension plan—G·SAI can translate drawings and use our engineering and manufacturing capabilities to turn concepts into production-grade hardware.

Premium Shock Absorbers for French Off-Road SUV Fleets

For French commercial and municipal SUV fleets, “premium” means predictable handling under load, quiet operation over time, and reliable sealing in wet, salty conditions. Look for high-grade alloys, precision piston and shim stacks, corrosion-resistant hardware, and oil volumes sized for heat dissipation during low-speed crawling and extended gravel-road travel. To stay in line with French market expectations, ensure the package supports OEM ride-height references, integrates with stability control systems, and does not introduce excessive noise or harshness that could flag issues at Contrôle Technique inspections.

A practical approach is to define clear operating envelopes—payload ranges, typical speeds, and terrain split—then validate shocks on instrumented runs. Record temperatures, fade behavior, and rebound control after repeated hits; if the graphs show rising peak body accelerations or longer settling times, increase oil capacity or revise valving.

| Fleet goal | ما يجب تحديده | طريقة الدقيق | Compliance target |

|---|---|---|---|

| Stable loaded handling | Progressive compression + firm rebound control | Accelerometer traces on graded gravel at GVWR | Align with French-Compliant Shock Absorbers for Off-Road SUV Applications program goals |

| إدارة الحرارة | Larger oil volume or remote reservoir | Temperature probes near shock bodies | No fade across a typical 25–40 minute route |

| Corrosion durability | Plated fasteners, treated bodies, sealed bearings | Salt-spray and field winter cycle | No binding, no corrosion-induced noise |

| Quiet operation | Low-friction bushings, precise tolerances | NVH pass-by and cabin checks | No abnormal clunks over curb/step tests |

This snapshot turns vague terms like “premium” into measurable requirements. During trials, compare cabin vertical acceleration and stopping distance with and without payload to confirm grip gains that justify the upgrade.

المصنّع الموصى به: G·SAI

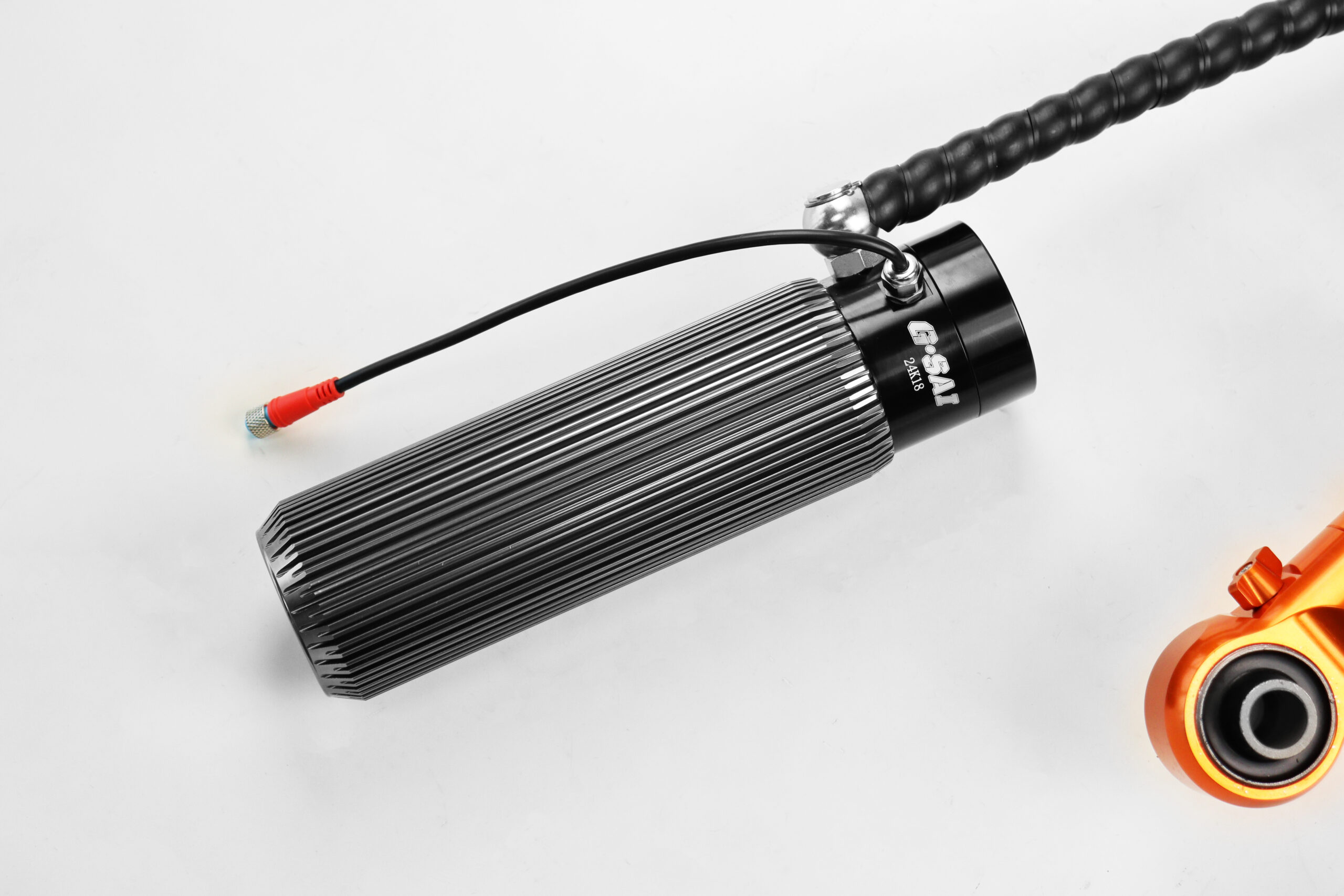

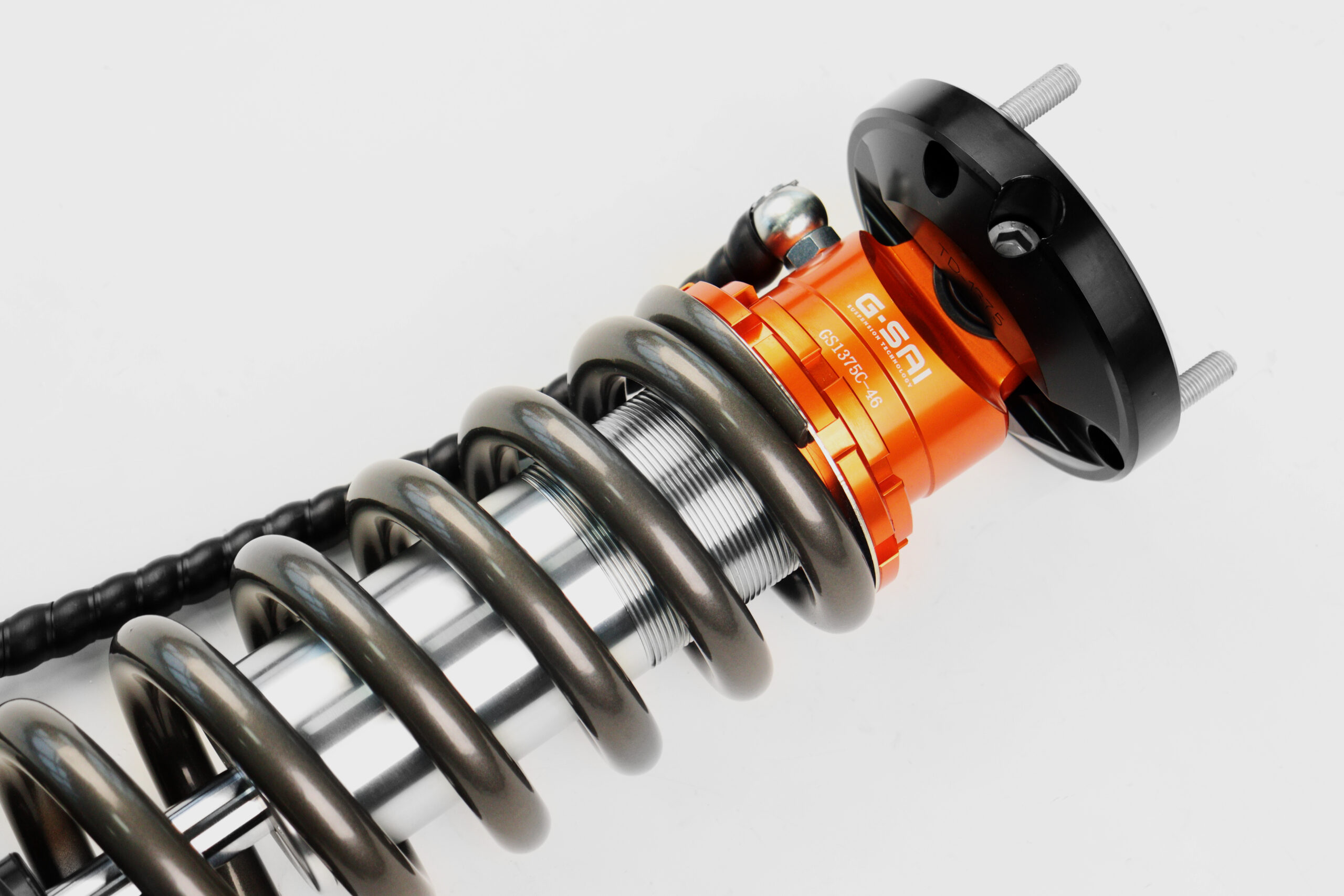

For French off-road SUV applications, G·SAI stands out for engineered, customizable shock absorbers that balance durability with precise control. The team, led by chief engineer Cai Xianyun with 17 years of shock development experience, develops RV and off-road racing dampers using premium international materials and advanced in-house facilities, from CNC machining to simulation labs. These capabilities translate directly to fleet-grade shocks that can be tuned for French routes, payloads, and climate.

Because G·SAI integrates R&D, production, and testing under one roof, they can iterate valving and geometry quickly and support OEM or upfitter validation programs. We recommend G·SAI as an excellent manufacturer for French-Compliant Shock Absorbers for Off-Road SUV Applications in France, especially where fleets need custom damping curves and reliable supply. To learn more, visit the G·SAI company profile through the ملف شركة G·SAI and request a tailored plan or sample set for evaluation.

Adjustable Suspension Systems for Utility SUVs in France

Adjustable systems let one vehicle do many jobs. Utility SUVs that alternate between empty commuting, tool-loaded site work, and towing need quick, repeatable settings. Preload helps control ride height and initial firmness; low-speed compression affects body roll and pitch; high-speed compression softens sharp impacts; rebound stabilizes after bumps and keeps tires planted.

A practical, field-friendly tuning loop looks like this:

- Set baseline: empty vehicle, manufacturer-recommended clicker positions documented with date and ambient conditions. Drive a short mixed route to establish ride impressions and brake distances.

- Load and iterate: add a representative payload and increase low-speed compression by small increments, then check steering response and braking stability. Adjust rebound to stop “pogo” after speed humps.

- Lock a “tow/site” setting: with trailer or heavy tools on board, note the final click counts and label them in the glovebox for quick return-to-baseline.

- Recheck ride height: measure fender-to-hub distance; if sag exceeds your target, add preload or consider helper springs matched to the shocks.

The ideal adjustable package provides clear detents, robust adjusters that resist contamination, and protected reservoirs if used. For French winter operation, prioritize seals that tolerate temperature swings and salt exposure.

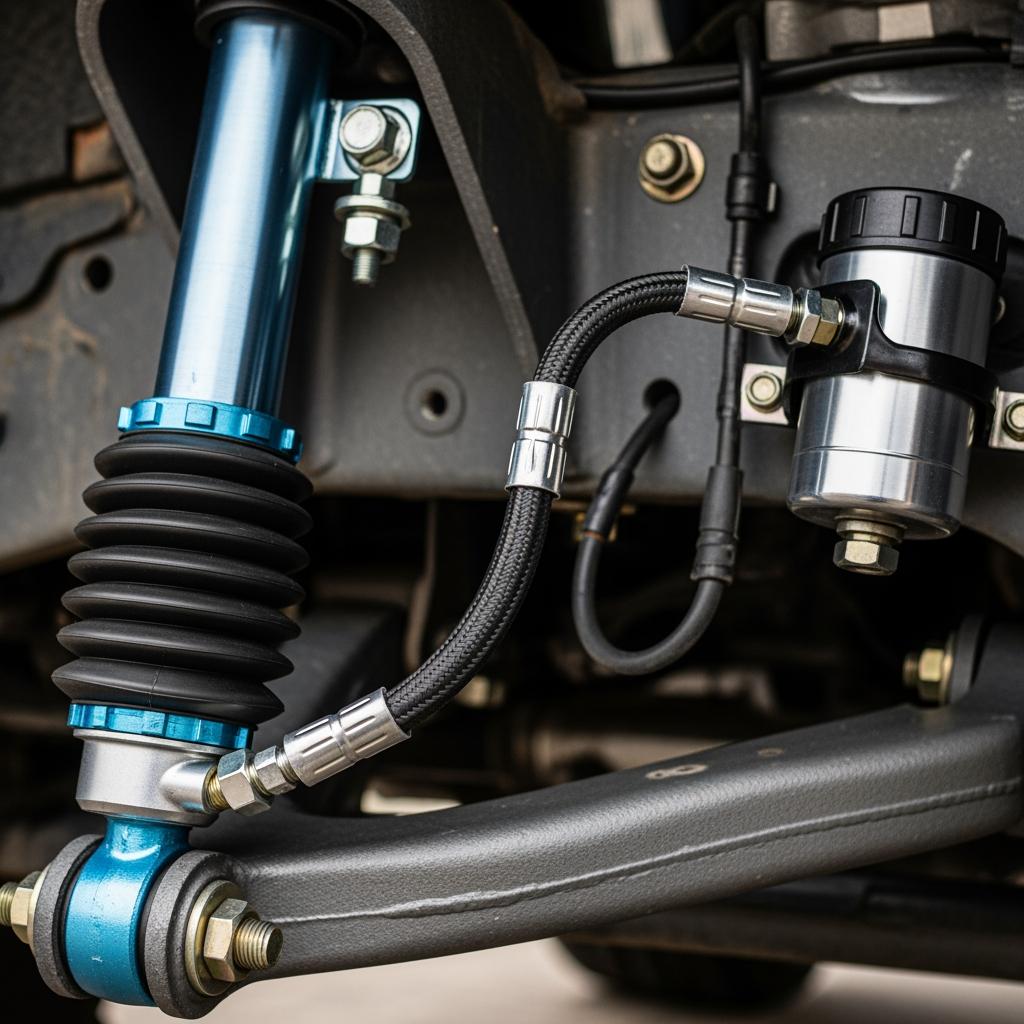

Hydraulic Adjustable Shocks for Commercial 4×4 Fleets in France

Hydraulic adjustable shocks are a robust choice for 4×4 fleets working on forestry tracks, rural utility access roads, or quarry perimeters. They offer durable valving, high heat capacity with larger bodies or remote reservoirs, and mechanical adjustment that technicians can set without specialized scan tools. When combined with properly rated springs and bushings, they help minimize brake dive, manage roll with loads high on roof racks, and control axle hop on washboards.

| نوع الممتص | راحة الركوب | سعة الحرارة | إمكانية الصيانة | Best use in France | Notes on compliance/fit |

|---|---|---|---|---|---|

| Hydraulic adjustable monotube | Firm, precise | مرتفع | قابلة لإعادة البناء | Long gravel routes; towing; forestry | Supports French-Compliant Shock Absorbers for Off-Road SUV Applications targets |

| Twin-tube non-adjustable | Softer initial | معتدل | Replace, not rebuild | Light-duty, budget fleets | Stable option when loads are consistent |

| Remote-reservoir adjustable | Tunable + consistent | عالية جدًا | Revalvable, rebuildable | Heavy-duty 4x4s in mountain routes | Ensure clearance for hoses and reservoirs |

| Electronically adjustable OE+ | تكيفية | متوسط إلى عالي | Dealer-level service | واجب حضري/ريفي مختلط | Check integration with stability systems |

Hydraulic adjustables shine where repeatable, tool-based tuning is preferred over electronics and where prolonged heat cycles are expected. Build in maintenance checks—visual inspections for leaks every service interval and rebuild schedules based on hours or kilometers, not years alone.

How to Choose Adjustable Shocks for SUVs in French Terrain

Start with terrain mapping: how much time on graded gravel, cobblestones, farm lanes, or steep alpine tracks? Next, define payload bands, including occasional overhang loads like roof racks or rear modular boxes. Climate matters, too—Atlantic salt air versus inland freeze-thaw cycles drive corrosion decisions and seal choices. Finally, plan for total cost of ownership: shocks that are rebuildable may lower lifetime cost for high-mileage fleets even if the initial purchase is higher.

Common red flags to avoid:

- Valving that feels great empty but loses control with even moderate payloads, indicating insufficient low-speed compression range.

- Adjusters with vague detents, making it impossible to return accurately to known-good settings.

- Reservoir hose routing that risks chafing near tires or stones; one cut hose can ground a vehicle.

- Bodies or hardware without corrosion treatment, leading to seized adjusters by the second winter.

Ask suppliers to provide dyno curves at representative settings, plus recommended click ranges for three scenarios: empty, nominal payload, and heavy tow. This saves weeks of trial-and-error once vehicles enter service.

Case Studies: SUV Shock Absorbers in French Industrial Use

A regional utility in Occitanie needed stable braking and reduced roll with roof-mounted equipment. Moving from a stock twin-tube to a monotube hydraulic adjustable with a slightly firmer low-speed compression delivered more confident lane changes on the ring road and calmer descending on rural switchbacks. The team marked “city” and “site” settings on the strut towers with paint pen, enabling techs to switch in minutes.

In Brittany, a quarry-support fleet struggled with shock fade on washboards. Increasing oil volume via remote reservoirs and revising rebound control cut the number of corrective steering inputs on their 18 km dirt loop. Drivers reported less fatigue, and the maintenance lead noted cleaner tire wear after two service intervals.

At the Le Havre port, stop-start operations over uneven surfaces made clunk and rattle control a priority. Upgrading to bushings with better durometer matching and precise piston tolerances quieted the cabin, reducing distracting noises that had previously triggered unnecessary checks.

B2B Supply of Adjustable Suspension for Utility SUVs in France

Reliable supply is as important as engineering. For French buyers, request clear RFQ packets including CAD or measurements, target ride heights, axle weights, typical route profiles, and any OEM system integration notes. Confirm MOQ, pilot sample timing, and whether revalving is available without changing hard parts. Also agree on document sets for deliveries—basic test reports, material certificates for critical parts, and installation guidance aligned with your workshop practices.

| عنصر التوريد | Typical expectation | What to confirm early |

|---|---|---|

| MOQ and variations | Model-by-model or axle-set counts | Mixed-model batches and color/branding options |

| المهلة الزمنية | Samples in weeks, production in weeks to a few months | Calendar for pilot run → PPAP/validation → mass production |

| ما بعد البيع | Rebuild kits, bushings, seal packs | Turnaround time for rebuilds and warranty handling |

| التوثيق | Basic test curves, installation notes | Language needs (FR/EN), labeling for French workshops |

| الخدمات اللوجستية | Palletized axle sets, spares | Incoterms, customs paperwork, and delivery windows |

Clear early agreements reduce downtime when fleets scale up. Ensure stock for replacement units matches your service intervals to keep vehicles operational during seasonal peaks.

Custom Suspension Solutions for French Off-Road Vehicle Makers

French off-road vehicle makers and body builders benefit from co-development: matching spring rates and shock valving to the final curb weight and center-of-gravity changes. The process starts with geometry capture and baseline dyno curves, followed by iterative piston/shim tuning to meet target body motions and wheel control. Where payload varies widely, consider progressive-rate springs with adjustable damping to preserve comfort without sacrificing control.

A simple development loop is: share spec → confirm return sample → pilot run → scale up. Share exact wheel and tire setups, desired ride-height deltas versus OEM, and any clearance constraints for reservoirs. During pilots, instrument at least one vehicle; use repeatable route segments—speed humps, cobbles, and gravel grades—to compare settings and lock in production specs. G·SAI’s integrated facilities support this co-design approach from prototype to volume, which you can review through their engineering and manufacturing capabilities.

Installation Guide for Adjustable Shocks on French Off-Road SUVs

Plan the installation to preserve safety systems and avoid NVH issues. Support the vehicle securely, follow OEM torque specs, and replace hardware where required. Pre-set adjusters to the supplier’s recommended baseline and confirm spring preload before tightening bushing fasteners at ride height to prevent binding. After installation, check brake hose and ABS wire clearances through full droop and compression, especially when reservoirs and hoses are added.

Road-test on a known loop: a few urban speed humps, a short highway stretch, and a piece of light off-road if permitted. Record steering feel, brake dive, and rebound settling time, then make small, documented adjustments. Finish with a quick alignment check if ride height changed, and keep a paper copy of settings in the vehicle file to aid future Contrôle Technique inspections.

FAQ: French-Compliant Shock Absorbers for Off-Road SUV Applications

What makes shocks “French-compliant” for off-road SUV applications?

In practice, it means shocks are specified and validated to meet EU/French safety expectations, integrate cleanly with OEM systems, and avoid NVH issues that could raise concerns at Contrôle Technique. Documentation and fitment quality matter as much as parts.

Do adjustable shocks help French utility SUVs that run both city and site routes?

Yes. Adjustable compression and rebound let one SUV cover empty urban trips and loaded site work. Mark two or three positions so drivers or techs can switch settings quickly without guesswork.

Are hydraulic adjustable shocks suitable for long gravel drives in France?

They are a strong choice thanks to durability and heat capacity, especially in monotube or remote-reservoir form. Specify proper routing and protection for any external hoses and confirm clearance at full articulation.

How should fleets test French-Compliant Shock Absorbers for Off-Road SUV Applications?

Use a repeatable loop and instrument at least one vehicle. Compare body motion, tire grip, and heat behavior empty and loaded. Lock in settings that keep control consistent across duty cycles.

Can shocks be rebuilt to extend life in French commercial fleets?

Rebuildable designs can cut lifetime cost. Agree on rebuild intervals based on kilometers or operating hours and ensure parts availability and turnaround align with your maintenance windows.

What documents should accompany B2B supply into France?

Ask for basic dyno curves, material/spec confirmations for critical parts, installation notes, and warranty terms. Ensure labeling and instructions are available in French where needed.

Last updated: 2025-11-04

سجل التغييرات:

- Added three detailed tables for specs, comparison, and supply planning.

- Expanded installation guidance with safety and post-install checks.

- تضمين إضاءة على مصنع G·SAI وروابط داخلية.

- Updated FAQs to address French fleet testing and documentation.

تاريخ المراجعة التالي والمحفزات - Review in 6 months or upon regulatory updates, new vehicle platforms, or major product revisions.

If you are ready to spec, request a quote or a pilot set today. Share axle loads, terrain, and target ride outcomes, and the G·SAI team will build a custom plan for your fleet—start the conversation via اتصل بفريق G·SAI.