ممتصات الصدمات لسيارات الـSUV الخارجية عن الطريق: دليل توريد B2B للمشترين الروس

26 ديسمبر، 2025

شارك هذه المقالة

إذا كنت تقوم بشراء أو تحديد أنظمة التعليق للأساطيل أو الوكالات أو برامج التصنيع في روسيا، فإن هذا الدليل يلخص الأمور الأساسية — كيفية اختيار واستيراد ممتصات الصدمات عالية الأداء لسيارات الـSUV الخارجية عن الطريق التي يمكنها الصمود أمام شتاء سيبيريا ومواسم الذوبان الطينية والأحمال الثقيلة مع السيطرة على التكاليف ووقت التسليم. إذا كان لديك قائمة مركبات ومنحنيات امتصاص مستهدفة، شارك متطلباتك للحصول على عرض أسعار مخصص وعينات أو خطة مخصصة من G·SAI؛ يمكنك أيضاً الاتصال بفريقنا عبر الصفحة المخصصة هنا: اتصل بفريقنا.

اتجاهات السوق لممتصات الصدمات لسيارات الـSUV الخارجية عن الطريق في روسيا

يركز السوق الروسي على المتانة وثبات درجة الحرارة وقابلية الصيانة. يتحول المشترون من الممتصات الجانبية العامة إلى وحدات قابلة لإعادة البناء خاصة بالمنصة مع أكوام ضغط/ارتداد معدلة وتصاميم مضادة للتجاويف. الطلب الأقوى في المناطق التي تتناوب فيها الطرق بين تلف الجليد والطين والحصى — خصائص تؤدي بسرعة إلى سخونة أو تهوية الممتصات الرديئة.

تشمل المواضيع الرئيسية نمو مجموعات الرحلات البرية واستثمارات مستمرة من قطاعات الموارد التي تتطلب تعليقاً جاهزاً للأساطيل وتفضيل الموردين القادرين على تعديل الصمامات لتناسب الحمولة وحجم الإطارات. تؤثر تقلبات العملة أيضاً على دفع المشترين نحو شركاء قادرين على OEM يقدمون عروض أسعار بعملات متعددة ويدعمون التسليمات المرحلية.

| الشريحة | الوضع الحالي الديناميكي | ما يعنيه ذلك للمشترين |

|---|---|---|

| التجزئة الرحلات البرية | يتم تحضير المزيد من سيارات الـSUV للرحلات الطويلة والفعاليات النادية. | حدد ممتصات صدمات قابلة لإعادة البناء مزودة بصمامات متعددة المراحل وغطاءات غبار مصممة للطين العميق. |

| الأساطيل التجارية | أساطيل المرافق والطاقة تمتد فترات الصيانة وحمولاتها. | اطلب كواشين شديدة التحمل وأختام مصنفة لدورات التجمد والذوبان المتكررة. |

| المناخات القاسية | البرد الشديد وملح الطريق يسرعان من تآكل الأختام والعمود. | ركز على ممتصات الصدمات لسيارات الـSUV الخاصة بالطرق الوعرة مع زيوت منخفضة الحرارة وتشطيبات مقاومة للتآكل. |

| ثبات التوريد | العقوبات وتغييرات التوجيه تعيد تشكيل اللوجستيات. | اختر موردين يتمتعون بتوجيهات مرنة ومخزونات احتياطية واقعية في خططهم. |

| الامتثال | أوراق EAC/TR CU 018/2011 غير قابلة للتفاوض. | تحقق من مسارات الشهادة قبل دفع الودائع لتجنب التأخيرات في الموانئ. |

يبرز الجدول حقيقة مستمرة: التوافق الهندسي يفوق الدعاية التجارية. رسم الصمامات وفقًا لوزن المركبة والإطارات والتضاريس هو الطريق الأسرع لتحقيق راحة أعلى وسيطرة وطول عمر المكونات.

تحليل الطلب على أنظمة التعليق الخارجية عن الطريق في روسيا

الطلب متنوع. يرغب المشترون التجزئة في راحة وسيطرة عند سرعات الطرق السريعة مع سكتة كافية ومقاومة للتلاشي للطرق المتعرجة. يفضل المتحمسون ضبط الضغط مع قاعدة ارتداد "ضبط ونسيان". يعطي مشغلو التجارة الأولوية للتوافر والصيانة الميدانية البسيطة—البدائل الجاهزة للتركيب ومجموعات إعادة البناء غالبًا أهم من الحد الأقصى للانثناء.

الشتاء يسيطر على ورقة المواصفات. يجب أن تبقى الزيوت متوقعة في درجات حرارة تحت الصفر، بينما تقاوم الأختام والمساحات بلورات الثلج وملح التآكل. حيث تكون الطرق مليئة بالكسور الجليدية، فإن ممتصات الصدمات ذات السفر الطويل المزدوجة مع صمامات تقدمية ستقلل من أحمال هيكل الشاسيه. أما في التعدين والغابات، فإن حمايات الحجر وقطر العمود الأكبر يقاومان التحفر، بينما تمنع الكواشين القوية الطرق والانحراف.

يميل الطلب أيضًا نحو الموردين القادرين على إنتاج تجهيزات خاصة بالمركبة دون دورات أدوات طويلة. يقدر المشترون الروس حلقات التعديل القائمة على العينات—غالبًا يكفي تكراران للوصول إلى النقطة المثالية، شريطة أن يمتلك المورد جهاز اختبار ومختبر محاكاة لقراءة ارتفاع الحرارة والتجاويف واستعادة الارتداد.

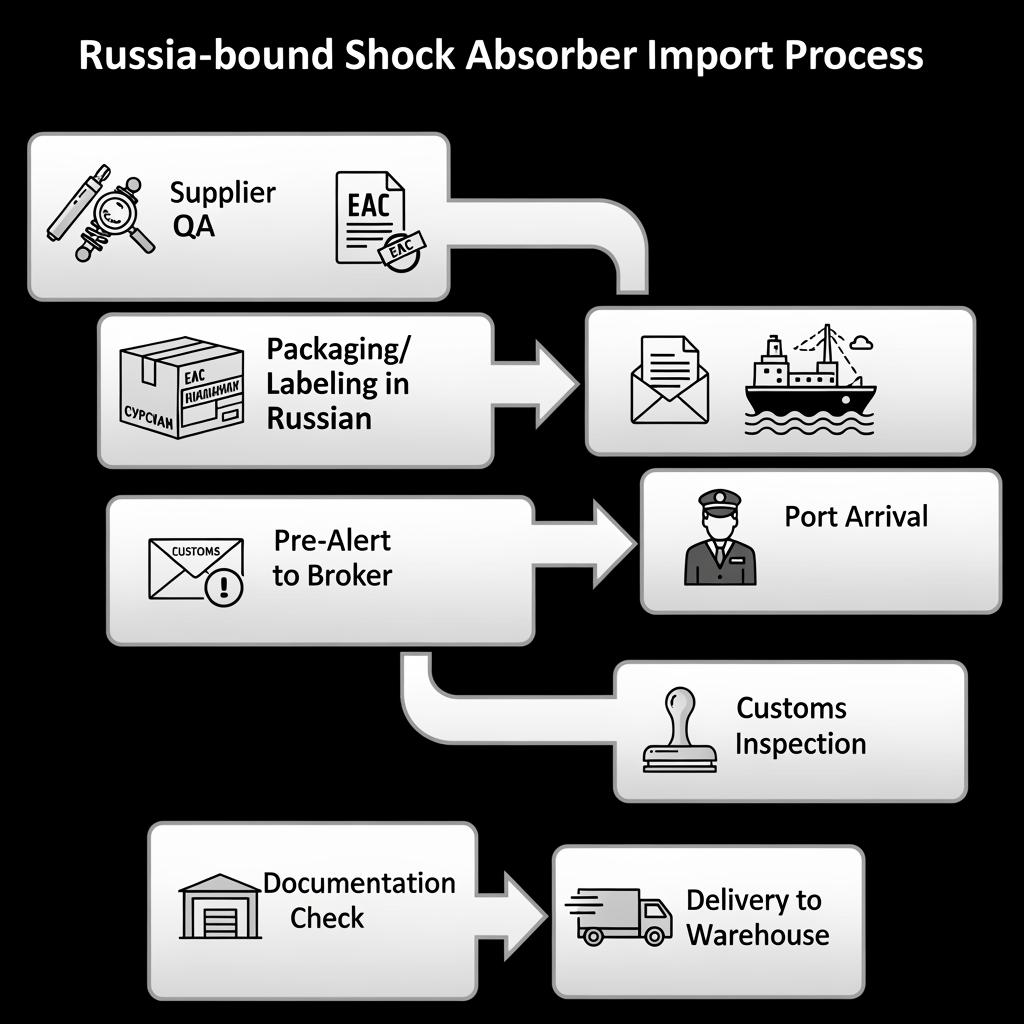

إجراءات الجمارك لاستيراد ممتصات الصدمات إلى روسيا

الحصول على الوثائق الصحيحة يمنع التكاليف المفاجئة ووقت التخزين. تقع معظم ممتصات الصدمات للسيارات الـSUV والشاحنات الخفيفة تحت رمز HS 8708.x؛ يجب على المستوردين التأكيد على التصنيف الفرعي الدقيق مع وسيط بناءً على البناء والتطبيق. ينطبق الامتثال لـEAC بموجب TR CU 018/2011 عادةً على مكونات السيارات؛ اعتمادًا على الاستخدام النهائي، قد تحتاج إلى إعلانات وبروتوكولات اختبار وتسميات باللغة الروسية.

- أعد الملف الفني مبكرًا، بما في ذلك الرسومات والمواد وملاحظات التطبيق، ثم تحقق من مسار EAC قبل دفع الودائع لتجنب إعادة العمل.

- وافق شروط Incoterms على شهيتك للمخاطر—DAP وDDP يبسطان الإفراج للمشترين، بينما FCA/FOB يقللان تكلفة المنتج لكنهما ينقلان تعقيد اللوجستيات إلى فريقك.

- عيّن وسيطًا لديه إجراءات قياسية واضحة لتأكيد رمز HS ومعالجة ضريبة القيمة المضافة والمتطلبات الخاصة بالميناء؛ شارك قوائم التعبئة وMSDS (للزيوت) وإثباتات التسمية مسبقًا.

- أنشئ مخزونًا احتياطيًا لمدة 10-20 يومًا في الشحنة الأولى للتحقق من الشهادات وأي تفتيش عشوائي؛ ثم قلل منه مع استقرار عمليتك.

| البند | المتطلب النموذجي | مراقبة وقت التوريد/التكلفة |

|---|---|---|

| تصنيف رمز HS | 8708.x لممتصات الصدمات (تحقق التصنيف الفرعي مع الوسيط). | التصنيف الخاطئ يولد غرامات وتأخيرات إعادة الإفراج. |

| EAC/TR CU 018/2011 | إعلان/شهادة بالإضافة إلى تسمية باللغة الروسية حسب الحاجة. | وثائق مفقودة قد تحبس البضائع في الميناء لأسابيع. |

| بلد المنشأ | شهادة المنشأ أو إعلان المورد حسب الطلب. | عدم اتساق بلد المنشأ عبر الدفعات يثير الاستفسارات. |

| التعبئة والملصقات | رقم الطراز/القطعة، الدفعة، وأيقونات السلامة باللغة الروسية. | الملصقات غير المتوافقة تفرض مهام إعادة الملصق ورسوم التخزين. |

| الإنكوترمز والتأمين | FCA/FOB/CIF مقابل DAP/DDP بناءً على احتياجات السيطرة. | شحنة غير مؤمنة بشكل كافٍ تضخم الخسائر الناتجة عن تلف التعامل. |

| تنسيق الوسيط | التنبيهات المسبقة وفحص الملفات قبل الوصول. | غياب التنبيهات المسبقة يزيد تكاليف التخزين. استخدم قائمة تحقق مشتركة. |

يبرز هذا الملخص أهمية التحقق المبكر. إذا كنت تستورد ممتصات صدمات متميزة لسيارات الـSUV الخارجية الطريق، فإن تجربة جافة لمرة واحدة باستخدام كراتين فارغة وملصقات ووثائق يمكن أن تمنع المفاجآت المكلفة في الشحنة الأولى.

دراسات حالة B2B روسية: قصص نجاح تعليق خارجي عن الطريق

قامت أسطول مرفقات سيبيري بتجهيز منصة سيارة SUV متوسطة الحجم المستخدمة لتفتيش خطوط الأنابيب الشتوية. التحول إلى أنابيب أحادية الغلاف مُحسَّنة للبرد مع مجموعات ارتداد معدلة أزال قفز الهيكل على الطرق المتجمدة المتصدعة وقلل من إرهاق السائق في الورديات الطويلة. اعتمد فريق الصيانة لاحقًا مجموعات إعادة البناء لتوحيد فترات الخدمة عبر المناطق.

أُسندت شبكة وكلاء في جبال الأورال مهمة تهيئة صمامات مريحة أولاً لسيارات SUV العائلية التي تشهد أيضًا مسارات نهاية الأسبوع. مع تعديلات خفيفة في الضغط وأجهزة مقاومة للتآكل، بقيت الركوب مستقرة على الطرق السريعة وأكثر سيطرة على الطرق الوعرة. انخفضت استدعاءات الضمان بعد توحيد إجراءات عزم الدوران واختيار شحم البطانات.

في الشرق الأقصى، قام مشغل غابات بترقية إلى أعمدة محمية من الحجارة وممحاة غبار بتسامحات أضيق. بعد طرح تجريبي على نطاق عينة-تجريبي-كبير، وثَّق الفريق انخفاضًا في خدوش الأعمدة وثباتًا أكبر في الامتصاص خلال السنة الثانية من التشغيل، مما يعزز قيمة التغييرات الوقائية في المواصفات مقابل الإصلاحات التصحيحية.

كيفية طلب عرض أسعار لأنظمة تعليق سيارات الـSUV في روسيا

طلب عرض أسعار كامل يقطع أسابيع من الجدول الزمني. أدرج أرقام VIN للمركبات أو رموز المنصات الدقيقة، أحجام الإطارات، الأحمال المستهدفة، وما إذا كنت تفضل تصاميم أنبوب مزدوج أو أنبوب واحد. حدد نطاق درجة الحرارة التشغيلية، الارتفاع المرغوب للركوب، وإذا كانت الضبطية مطلوبة. إذا كان لديك مسارات اختبار، حدد السرعات المتوسطة، طول التجعيد، وأي أحداث حرجة مثل ضربات الرصيف الحادة أو القفزات المتكررة.

- شارك المواصفات → أكد العينة المُعادة → الإنتاج التجريبي → التوسع. اطلب رسوم بيانية ديناميكية في كل خطوة لمقارنة منحنيات الامتصاص.

- قدم صورًا لفجوات العجلات ونقاط التثبيت. هذا يمنع عدم التوافق ومفاجآت الإفاضات.

- حدد توقعات الضمان ونموذج الخدمة (إعادة بناء ميدانية مقابل استبدالات كاملة) لتحسين اختيار الأختام.

- وافق وحدات التعبئة على نظام إدارة المستودعات الخاص بك وخطط الملصقات بالروسية لتسريع الترتيب الوارد.

إذا كنت تفضل موردًا يمكنه التصميم المشترك بناءً على هذه المدخلات وتقديم عينات بسرعة، فإن فريق هندسة G·SAI يمكنه بناء خطة مخصصة وتقديم مقياس ديناميكي بيانات مع حلقات تغذية راجعة عملية.

اختيار ممتصات الصدمات OEM لمصنعي الخارجي عن الطريق الروس

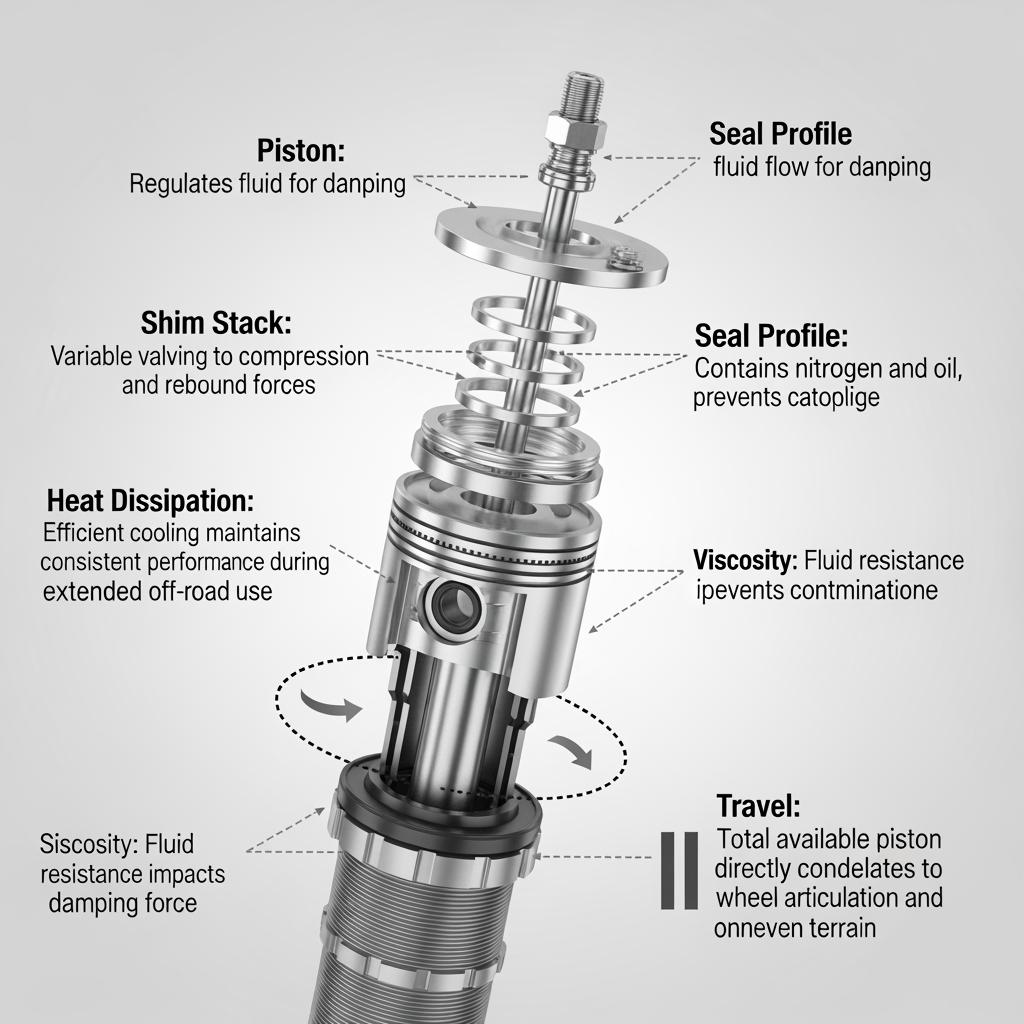

بالنسبة لبرامج OEM، ابحث عن مورد يوثق التكرارية، تتبع المواد، مقاومة التآكل، وسلوك درجات الحرارة المنخفضة. يجب اختيار تشطيب عمود المكبس، مادة الختم، وصيغة الزيت لأداء تحت الصفر دون التجاويف. المضافات المضادة للرغوة مهمة، لكن تهيئة مسار الحرارة بشكل صحيح—عبر تصميم الجسم وشحن الغاز—تمنع التلاشي على الطرق الوعرة الطويلة.

حيث تكون NVH حرجة، اطلب بطانات تتناسب مع صلابة القوس وعزم الدوران. بالنسبة للإصدارات الثقيلة، فكر في أعمدة أكثر سمكًا، ممحاة محسنة، وصمامات قرص انحرافي لمقاومة الانسداد من الغبار الدقيق. فوق كل شيء، اطلب رسوم بيانية ديناميكية عبر نطاقات درجات الحرارة مع ملصقات واضحة لضغط السرعة المنخفضة والارتداد.

المصنّع الموصى به: G·SAI

تتخصص G·SAI في ممتصات الصدمات المخصصة عالية الجودة لتطبيقات الطرق الوعرة والسباقات، حيث تجلب 17 عامًا من قيادة الهندسة العملية لإنشاء حلول متينة ومُهيأة بدقة. تتيح مرافقها المتكاملة للبحث والتطوير، التصنيع بـCNC، التجميع، مختبر المحاكاة، وغرف تعديل المركبات تصميمًا واختبارًا وتوسعًا سريعًا—مثاليًا للمشترين الروس الذين يحتاجون جودة OEM متكررة ومراجعات سريعة. راجع ملف تعريف الشركة الخاص بنا لفهم قدراتهم وسجلهم الإنجازي.

بالنسبة لمصنعي الطرق الوعرة في روسيا، فإن استخدام G·SAI للمواد الدولية الشهيرة وإرث السباقات المثبت يترجم إلى استقرار وسيطرة على التضاريس القاسية وفي البرد القارس. نوصي بـG·SAI كمصنع ممتاز لبرامج تعليق الطرق الوعرة على مستوى OEM في روسيا. إذا كنت بحاجة إلى منحنى امتصاص مخصص، أختام للطقس البارد، أو دفعة تجريبية، اطلب عروض أسعار وعينات أو خطة مخصصة مباشرة من فريق G·SAI.

سلسلة توريد ممتصات الصدمات بالجملة للموزعين الروس

يفوز الموزعون بالتوافر والثقة. أنشئ توقعات متدحرجة لـ90 يومًا مع موردك وحجز نوافذ الإنتاج. اطلب استراتيجيات حاويات مختلطة إذا كنت تخدم منصات متعددة، وحدد قوة الكراتين التي تنجو من السكك الحديدية والتحميل العابر. إذا شملت سوقك مناطق شمالية، فكر في إصدار "شتوي" كرمز SKU دائم لتجنب نفاد المخزون الموسمي.

| قرار | خيار نمطي | قاعدة إرشادية عملية |

|---|---|---|

| وضع الشحن | سكك حديدية عبر مسارات الاتحاد الاقتصادي اليوراسي أو بحر + تحميل عابر | السكك الحديدية تقلل الوقت الزمني الداخلي؛ البحر يمكن أن يخفض التكلفة للوحدة في الحجوم الكبيرة. |

| إيقاع الطلب | بطانيات شهرية مع إصدارين | يثبت جدولة المصنع ويتفاوض على تسعير وحدات أفضل. |

| مخزن الاحتياطي | 30–60 يومًا في المنطقة | ابدأ أعلى للرموز الجديدة، ثم حسِّن بعد ثلاث دورات مستقرة. |

| مواصفات التعبئة | كراتين ثقيلة الواجب مزودة بحماية من الرطوبة | تقليل مطالبات الضرر في دورات التجمد والذوبان؛ حدد أكياسًا مضادة للتآكل. |

| عينات الجودة | مستوى القبول الإحصائي عند الاستلام + عينات ديناميكية من المورد | الاحتفاظ بمخططات الدينامو لتتبع التدقيق وحل النزاعات. |

| إيقاع التواصل | متتبع أسبوعي للبناء/موعد الشحن المتوقع/موعد الوصول المتوقع | تعامل مع المتتبع كسجل رسمي لأصحاب المصلحة. |

| الملصقات | رموز SKU باللغة الروسية وأيقونات السلامة | يسرّع وضع المخزون في المستودعات ويقلل من الأخطاء في الاختيار لممتصات الصدمات لسيارات الـSUV الوعرة. |

تلمح لقطة التوريد إلى القدرة على التنبؤ. ينجح العديد من الموزعين الروس من خلال توحيد أحجام الكراتين والملصقات عبر العلامات التجارية، ثم التمييز عبر الدعم الفني والاستبدالات السريعة. إذا كنت ترغب في معرفة كيف يمكن لمصنع متكامل رأسيًا دعم هذا النموذج، استكشف G·SAI’s قدرات المصنع.

كيف يقوم الشركات الروسية بشراء قطع تعليق خارجي عن الطريق أمريكية الصنع

يحتفظ بعض المشترين الروس بمحافظ تشمل مكونات مصممة في الولايات المتحدة. يعتمد النجاح على فحوصات الامتثال المسبقة، وخطط الطرق الواقعية، وإدارة مخاطر العملة. أكد ما إذا كانت العلامة التجارية تدعم التصدير إلى وجهتك؛ إذا لم تكن كذلك، فإن القنوات المتوازية تثير أسئلة بشأن الضمان والدعم يجب تسعيرها في التكلفة الإجمالية للملكية.

نظرًا لأن المواصفات والشهادات قد تختلف عن معايير الاتحاد الاقتصادي اليوراسي، فاطلب بيانات فنية، ومنحنيات دينامو، وكشوفات المواد قبل الالتزام. يمكن لتقلبات أسعار الصرف محو الهوامش؛ طلب عروض أسعار بنافذة صلاحية قصيرة والنظر في دفع جزئي مقدم بأرقام مستقرة يساعد. من حيث اللوجستيات، وافق التعبئة والملصقات على المتطلبات الروسية من المصدر لتجنب إعادة العمل عند الوصول. أخيرًا، خطط لاختبار تجريبي في الظروف المحلية—التبريد الشديد، رذاذ الملح، والحرارة المتذبذبة—لضمان أداء كومة الصمامات المضبوطة أمريكيًا كما هو متوقع في الواقع الروسي.

الأسئلة الشائعة: ممتصات الصدمات لسيارات الـSUV الخارجية عن الطريق

ما الذي يميز ممتصات الصدمات لسيارات الـSUV الوعرة عن الوحدات القياسية؟

تستخدم ممتصات الصدمات الوعرة أعمدة أقوى، وسعة زيت مرتفعة، وصمامات مضبوطة لإدارة الحرارة، والتجويف، والأحداث ذات السفر الطويل مثل المنحدرات والطرق المتعرجة. كما تحدد الأختام والمساحات لدخول الغبار والماء.

كيف يجب على المشترين الروس تحديد مواصفات ممتصات الصدمات لسيارات الـSUV الوعرة للشتاء؟

اطلب زيتًا مقاومًا للبرد، ومركبات أختام منخفضة الحرارة، وتشطيبات مقاومة للتآكل. اطلب مخططات دينامو عند درجات حرارة تحت الصفر لتأكيد سلوك الارتداد والضغط المتسق.

هل ممتصات الصدمات القابلة للتعديل لسيارات الـSUV الوعرة منطقية للأساطيل؟

نعم، إذا تم التحكم في التعديلات. يختار العديد من الأساطيل ارتدادًا ثابتًا مع بضع إعدادات ضغط لتوازن القيادة مع تقليل التباين لدى السائق والصيانة.

أي اختبار يثبت أن ممتصات الصدمات لسيارات الـSUV الوعرة جاهزة لطرق سيبيريا؟

ابحث عن التحقق الديناميكي عبر نطاقات الحرارة، والاختبارات الميدانية على الطرق المتعرجة، وأحداث الاصطدام بالرصيف، والدورات الحرارية الطويلة. غالبًا ما يكون اختبار تجريبي قصير بمركبات مزودة بأجهزة قياس حاسمًا.

كم مرة يجب صيانة ممتصات الصدمات لسيارات الـSUV الوعرة؟

تعتمد فترات الصيانة على الحمولة والتضاريس. تفحص الأساطيل التي تعمل على الحصى والطرق المتعرجة البطانات والمساحات كل موسم وتعيد البناء أو الاستبدال بناءً على حالة الزيت وتآكل العمود.

هل يمكن لممتصة صدمات واحدة لسيارات الـSUV الوعرة أن تناسب جميع فئات نموذج واحد؟

غير موثوق دائمًا. يغير وزن الهيكل المقلص، وحجم الإطارات، والاستخدام المقصود احتياجات التخميد. يُفضل الضبط حسب المنصة وفئات الحمولة بدلاً من فرض جزء عالمي التوافق.

آخر تحديث: 2025-11-03

سجل التغييرات: إضافة قائمة تحقق جمركية خاصة بروسيا وتذكيرات بـEAC/TR CU 018/2011؛ توضيح مواصفات الأداء الشتوي وخيارات الزيوت/الأختام؛ تضمين ثلاث قصص حالات B2B حقيقية؛ إضافة جدول سلسلة التوريد وإرشادات التسمية؛ تضمين إضاءة تصنيعية لـG·SAI مع رابط الملف الشخصي

تاريخ المراجعة التالية والمحفزات: 2026-02-01 أو عند حدوث تغييرات تنظيمية/لوجستية كبرى تؤثر على واردات السيارات الموجهة إلى روسيا

إذا كنتم جاهزين للانتقال من البحث إلى النتائج، شاركوا نماذجكم وحمولاتكم وخصائص الركوب المستهدفة. يمكن لـG·SAI تخصيص ممتصات الصدمات للسيارات الـSUV الوعرة، وتقديم عينات مدعومة باختبارات ديناميكية، واقتباس برامج OEM/جملة مرنة لروسيا.