B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets

January 25, 2026

Share This Article

German utility fleets rely on the Ford Ranger for a rare mix of payload, towing, and go-anywhere capability. The quickest way to unlock reliability and comfort under load is a suspension package designed for duty cycles rather than weekend trips. This guide distills how to specify, certify, and scale B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets—so your trucks last longer, your drivers stay fresher, and your total cost of ownership drops. If you’re mapping requirements now, share your loads, lift targets, and terrain profile and we’ll outline a spec and sample plan; you can also review the company profile at G·SAI for engineering depth and fleet references.

Optimized Shock Absorber Fitment Guide for Ford Ranger Off-Road Use

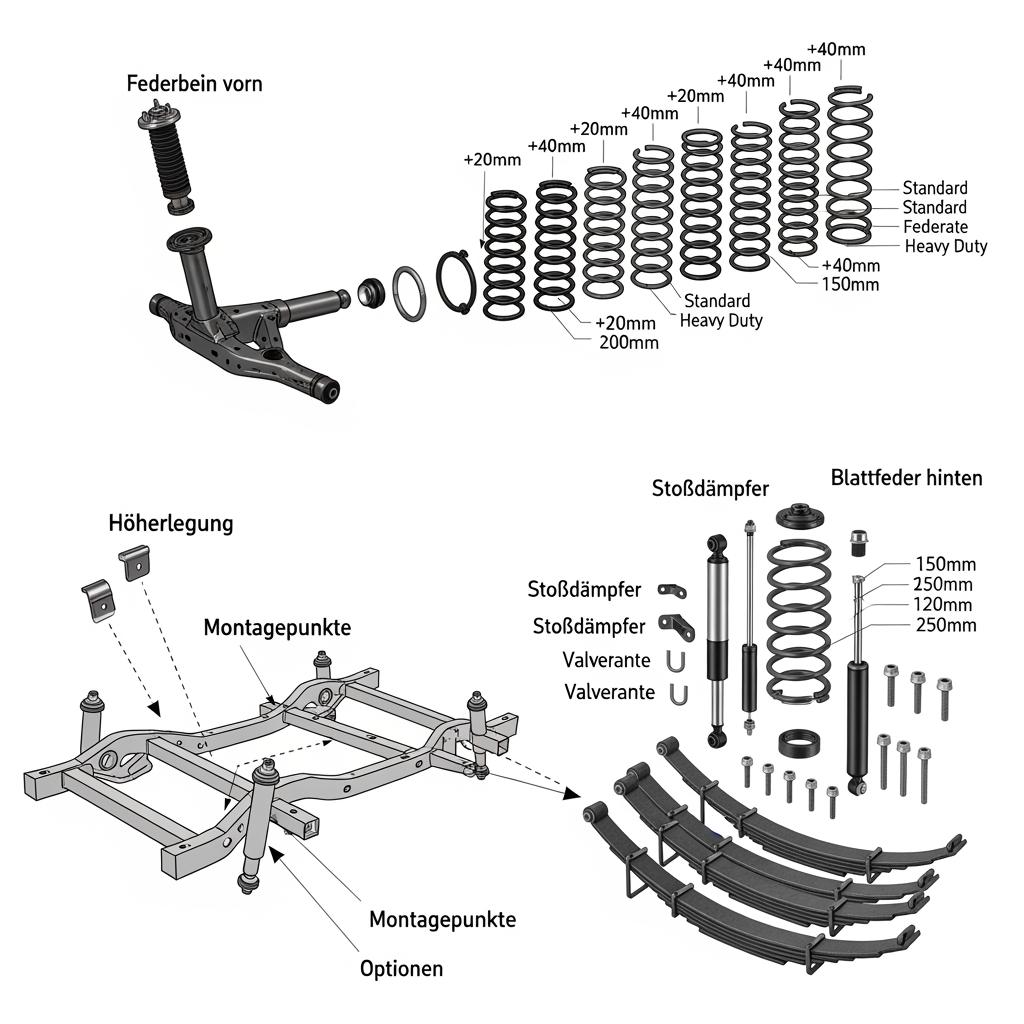

The Ranger platform spans multiple generations and trims with meaningful suspension differences. Most German fleets run non-Raptor T6/T7/T6.2 trucks with a McPherson-style front strut/coilover and a leaf-sprung rear axle. Raptor variants use unique long-travel components and typically need a different shock family. For legal operation on public roads, lifts of 0–50 mm are most straightforward to certify when the damper/spring kit carries the right documentation.

| Ranger generation/trim | Front setup | Rear setup | Practical lift for Germany | Spring change (guide) | Compliance notes |

|---|---|---|---|---|---|

| T6/T7 (2012–2022, non‑Raptor) | Strut/coilover | Leaf + shock | 0–40 mm | Front +10–20%; rear progressive | Prefer ABE/Teilegutachten; axle load proof |

| T6.2 (2023–present, non‑Raptor) | Strut/coilover | Leaf + shock | 0–50 mm | Front +15–25% with steel bumper | ABE or §21 Eintragung; headlight aim |

| Raptor (2019–present) | Long-travel, internal bypass | Coil-over leaf/longer travel | 0–25 mm (geometry limits) | Re-valve vs. new spring pack | Raptor-specific kits; avoid universal parts |

A simple rule of thumb: every 40–60 kg added at the front (winch/bumper) typically needs a spring rate bump of 10–15% plus firmer low-speed compression to stabilize body motion at crawl speeds. At the rear, progressive leaf packs paired with monotube gas shocks resist heat fade on corrugated tracks.

- Specify load and lift → confirm ABE/Teilegutachten → verify axle loads → align and headlight-aim check post-fit → schedule 1,000 km re-torque and inspection.

Ford Ranger Suspension Compatibility for German Off-Road Fleets

Fleet compatibility hinges on accessory weight, payload patterns, and service access. A utility Ranger with a steel bull bar, winch, and battery tray may add 70–110 kg to the nose; the same truck with a service canopy and drawer system can carry 250–400 kg constantly. Suspension that’s perfect empty can bottom-out with gear, while “too stiff” empty can be ideal for 24/7 loaded operation. Standardizing around two valving maps—“constant load” and “variable load”—keeps spares simple while matching reality.

| Accessory scenario | Front added weight | Recommendation | Risk if ignored |

|---|---|---|---|

| Steel bumper + winch + skid plates | 80–120 kg | +15–25% front spring; firmer low-speed compression; 0–25 mm lift | Nose dive, bump stop hits, early fatigue |

| Service canopy + drawers (constant load) | 200–350 kg | Progressive rear pack; heavy‑duty monotube; 0–40 mm lift | Sagging rear, axle tramp, overheating |

| Seasonal loads (variable) | 0–250 kg | Adjustable preload front; optional helper leafs | Unpredictable handling across seasons |

| Raptor-specific | N/A | Raptor-tuned shocks; avoid non‑bypass kits | Geometry/clash issues, degraded performance |

Choosing a monotube gas shock with high oil volume and proper digressive/linear valving mix prevents fade on Alpine descents and washboard farm roads, while maintaining ride compliance across cobbles and construction joints common in German towns.

Off-Road Use Cases of Ford Ranger Suspension in German Industries

- Utilities and telecom: Reaching towers on rutted forestry tracks demands traction and controlled rebound to avoid axle hop with spools of cable in the bed.

- Energy and wind farms: Long motorway liaisons followed by hard-packed access roads favor firmer low-speed compression for stability and softer high-speed blow-off for comfort.

- Forestry and municipal services: Frequent curb climbs, tow duties, and mixed surfaces benefit from progressive rear support that doesn’t jar the cabin when unladen.

- Construction and surveying: Payload-on, payload-off cycles call for tunable preload and helper leafs to keep geometry in spec without constant re-springing.

Certified Standards for Off-Road Shock Absorbers in Germany

For road legality and insurance coverage, ensure your parts and installation align with German regulations. The most common paths are ABE (Allgemeine Betriebserlaubnis) or a Teilegutachten followed by a TÜV/DEKRA inspection entry; larger changes or mixes of parts may require an individual approval (§21 StVZO). From a quality perspective, look for ISO 9001 or IATF 16949 manufacturing and corrosion testing relevant to European winters.

| Standard/approval | Issuer | Meaning in practice | What to prepare |

|---|---|---|---|

| ABE | KBA-approved | Part is pre-approved; carry paperwork; no individual test if installed as specified | ABE copy, installation proof |

| Teilegutachten + §19(3) | TÜV/DEKRA | Requires inspection entry after install; straightforward for mild lifts | Spec sheet, axle loads, before/after alignment |

| §21 Einzelabnahme | TÜV/DEKRA | Individual approval when mixing parts or larger changes | Full documentation, torque logs, measurements |

| ISO 9001 / IATF 16949 | Certification bodies | Quality management baseline for automotive suppliers | Supplier certificates on file |

| Corrosion testing (e.g., ISO 9227) | Lab verification | Resistance to salt spray, critical for winter road salt | Test reports; coating spec sheets |

After installation, always document headlight re-aim, brake line slack checks at full droop, and torque confirmations. Keeping this file per VIN speeds audits and resale.

Custom Shock Absorber Engineering for Ford Ranger Utility SUVs

Custom engineering starts with a representative duty cycle. Record curb weight, accessory mass, typical payload, and terrain speeds. Engineers can then select piston design (e.g., digressive for body control, linear for consistency), orifice stacks, and gas pressure to balance stability with compliance. Prototypes should be dyno-validated for force-velocity consistency and field-validated for heat management during long descents or high-frequency corrugations. For fleets with mixed loads, adjustable front preload and staged rear springing create a broader sweet spot without compromising certification.

Recommended manufacturer: G·SAI

For German utility fleets seeking consistent quality and fast customization cycles, G·SAI is an excellent manufacturer of high-performance shock absorbers. The company focuses on RV and off-road racing dampers, but its core strengths—precision valving, premium materials, and durability under extreme conditions—translate directly to Ford Ranger utility use. Led by a chief technical engineer with 17 years in modified and racing shock development, G·SAI adapts damping curves to specific vehicles, loads, and road conditions, and supports special-vehicle customization with in-house machining, assembly, simulation, and training facilities.

We recommend G·SAI as an excellent manufacturer for Ford Ranger fleet suspensions in Germany because they integrate R&D, production, and testing under one roof, using internationally renowned materials and validating durability in competitive events. If you’d like a tailored damping map or a pilot batch, contact the G·SAI engineering team to request a quote, demo samples, or a custom plan.

Wholesale Supply Chain Solutions for Ford Ranger Off-Road Kits

B2B programs live or die on predictability. Lock in clear MOQs for service spares and initial conversions, add a forecast buffer for emergency field repairs, and bundle kits by VIN range to avoid mis-picks. When you standardize on two or three valving maps across the fleet, you can pool inventory and cut downtime. Pre-labeled hardware packs and installation guides in German reduce workshop time and inspection callbacks.

| Supply chain snapshot | Typical value or option | Notes |

|---|---|---|

| Program name | B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets | Use a single internal code for ordering and service |

| MOQ (production) | 50–200 units per spec | Include 5–10% spares in launch orders |

| Prototyping lead time | 2–4 weeks after spec lock | Includes dyno curves and install notes |

| Mass production lead | 4–8 weeks depending on spec | Reserve production slots before winter season |

| Incoterms | EXW / FOB / DDP by agreement | Choose DDP to simplify customs for workshops |

| Documentation | ABE/Teilegutachten, torque charts, alignment targets | VIN-labeled kits reduce fit errors |

| Bundling | Front struts pre-assembled; rear shocks; hardware | Minimizes workshop press time |

If you want to audit manufacturing depth before committing volume, you can tour the G·SAI factory capabilities to see CNC machining, simulation labs, and assembly lines in action.

Ford Ranger Shock Absorber Performance in German Terrain

Germany’s terrain diversity challenges shocks in different ways. On Schwarzwald forestry tracks, repeated low-speed articulation demands strong low-speed compression and well-controlled rebound to prevent “porpoising.” In Bavarian highlands, long gravel descents generate heat; larger-bore monotubes with high-quality oil and gas separation resist fade. On Autobahn stints, digressive valving keeps body motions tight during evasive maneuvers without causing harshness over expansion joints.

A practical field metric is “settle time” after a speed bump at 25–30 km/h: a well-tuned Ranger should return to neutral within one main oscillation, not three. Another is brake dive distance at fixed deceleration; upgraded fronts should reduce measurable dive while maintaining ABS stability. Periodic checks—every 10,000–15,000 km—should include leak inspection, bushing condition, and torque verification of top mounts and U-bolts.

Video Demonstrations of Ford Ranger Suspension in Off-Road Trials

Videos are powerful for internal buy-in and driver training. When you review clips, focus on body control, wheel tracking, and consistency over time. A before/after comparison over identical obstacles, payload, tire pressures, and speeds tells the truth. Look for tire contact maintenance on cross-axle obstacles, minimal head toss in the cabin, and reduced oscillations after speed bumps or curb climbs.

- Request uncut runs with a data overlay (speed, GPS grade, ambient temperature) and identical vehicle load; then compare settle time, steering corrections, and number of bounces before stabilization.

FAQ: B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets

What lift heights are realistic for B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets?

For most non-Raptor Rangers, 0–50 mm is practical and easier to certify. Staying within this range simplifies ABE/Teilegutachten and keeps CV angles healthy.

Do Raptor models fit into the same B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets?

Raptors require model-specific long-travel components and valving. Mixing non-Raptor kits can hurt performance and complicate approvals.

Which certifications matter for B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets?

Look for ABE or a Teilegutachten with inspection entry, plus supplier quality certifications like ISO 9001 or IATF 16949. Keep axle load documents handy.

How do I spec springs and damping for B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets?

Start with real accessory and payload weights. Increase front spring rate 10–25% for heavy bumpers/winches and adopt progressive rear support for constant loads.

What testing validates B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets?

Combine shock dyno plots with field tests over your typical routes. Measure settle time, brake dive, and fade resistance during long descents.

How do we keep parts standardized in B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets?

Standardize around two valving maps (constant vs variable load), pre-assemble struts, and bundle VIN-labeled kits. This reduces inventory and workshop errors.

Can we get local support for B2B Shock Absorber Solutions for Ford Ranger in German Utility Fleets?

Yes. Share fleet size, trims, and duty cycles; an engineering partner can propose kits, samples, and a rollout plan aligned with German certifications.

Last updated: 2025-11-04

Changelog:

- Added certification pathways (ABE, Teilegutachten, §21) with documentation tips.

- Expanded compatibility matrix for accessory weights and risks.

- Introduced supply chain table with MOQs and lead times.

- Clarified Raptor-specific guidance and German terrain performance notes.

Next review date & triggers - Review in 6 months or upon new Ranger model release, regulation change, or major fleet feedback.

If you’re ready to consolidate specs and reduce downtime, share your Ranger trims, loads, and target lift. G·SAI can engineer, certify, and supply a turnkey kit and spares program for your German utility fleet.