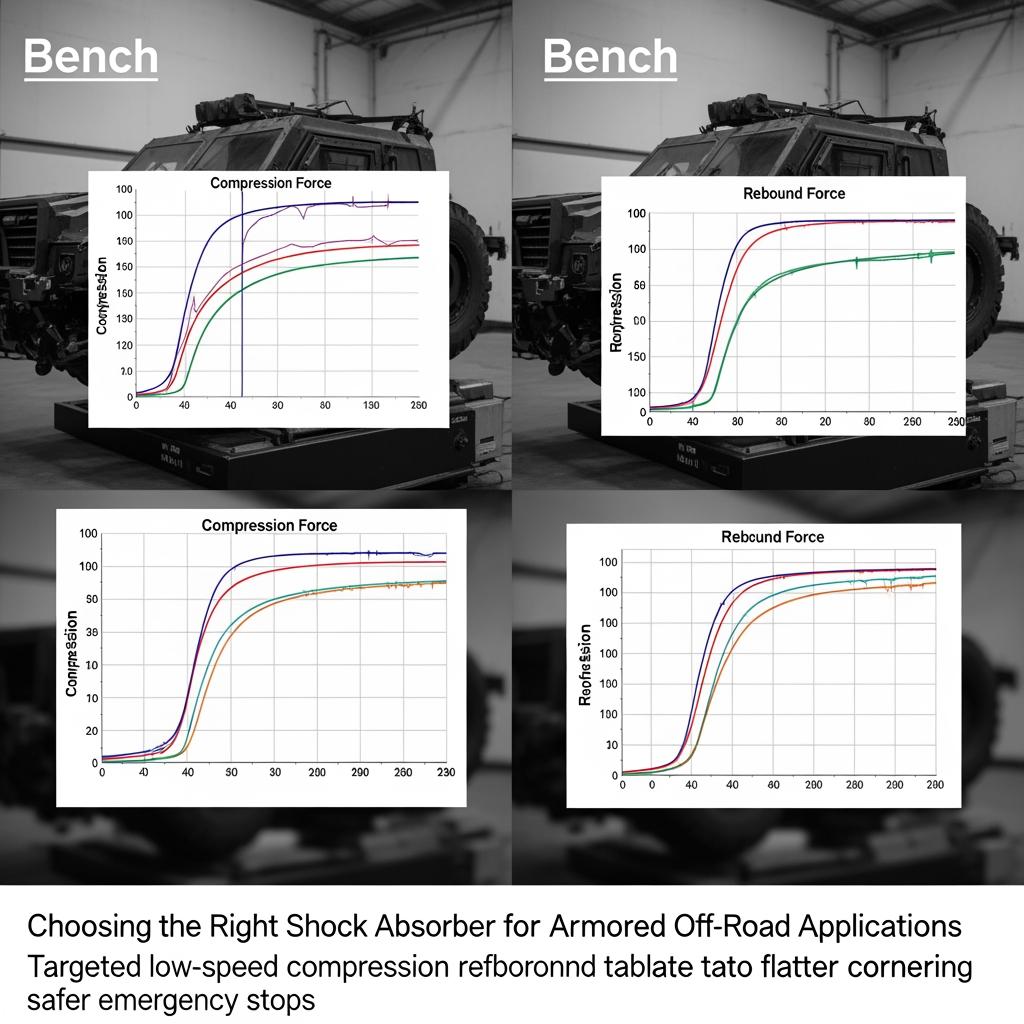

Choosing the Right Shock Absorber for Armored Off-Road Applications

February 15, 2026

Share This Article

Introduction to Armored SUV Suspension Systems in Mexico

If you operate armored SUVs in Mexico, choosing the right shock absorber for armored off-road applications is the single most important decision for safety, uptime, and driver comfort. The mix of added armor weight, high center of gravity, and Mexico’s diverse terrain—urban potholes, Sierra Madre switchbacks, northern desert washboards, and humid coastal routes—demands shocks that manage heat, maintain traction, and resist fade under sustained abuse. A correctly specified damper transforms a heavy vehicle from unpredictable to predictable, enabling faster, safer transits with less component wear.

If you have an active project, share your vehicle specs and mission profile so we can suggest a shock package and lead time. For quick next steps, reach out to the G·SAI team to request a quote or samples; they can tailor valving and hardware to your fleet’s exact load curves and terrain. You can also reach out to the G·SAI team via their contact page for a fast consultation and pricing.

Key Factors for Selecting Off-Road Shock Absorbers in Mexico

Start with the real axle loads, not curb weight. Armor typically adds 400–1,000 kg, often biased to the front. That extra mass requires higher spring rates and shocks with more compression control to prevent bottoming and excessive pitch. In Mexico’s heat and altitude, shock oil viscosity and nitrogen pressure must be chosen to minimize fade on long grades and in slow, rutted climbs where shocks cycle constantly with limited cooling air.

Corrosion and dust sealing matter across coastal and desert regions. Look for anodized or e-coated bodies, double-lip wipers, and high-temperature seals. For fleets, rebuildability is key; field-serviceable units with replaceable bushings and wear bands keep TCO in check. Finally, ensure the valving curve matches your mission: convoy cruising over broken asphalt benefits from more low-speed compression for body control, while rock and sand demand more high-speed compliance to keep tires planted.

| Selection factor | Mexico-specific considerations | What to spec/check | Notes related to Choosing the Right Shock Absorber for Armored Off-Road Applications |

|---|---|---|---|

| Load rating | Armor weight bias (often front-heavy), cargo variations | Corner weights, GVWR after upfit | The correct spring + damper pairing prevents brake dive and rear squat under armor loads. |

| Heat management | Long mountain descents, ambient 35–45°C in north/coast | Remote reservoirs, monotube, oil volume | Thermal stability preserves damping and steering precision on extended missions. |

| Sealing & corrosion | Dust in Sonora/Chihuahua; salt air in Veracruz | Wipers, shaft coatings, e-coat/anodize | Durable finishes protect the investment in harsh Mexican environments. |

| Serviceability | Fleet uptime in remote areas | Rebuild kits, common bushings | Rebuildable designs cut downtime versus disposable shocks. |

| Compliance/legal | Payload and lift limits | Mounting integrity, brake line clearance | Proper fitment avoids compliance issues and component interference. |

The table above doubles as a pre-RFQ checklist. Confirming these points early keeps fitment smooth and avoids delays at customs or during installation.

Case Study: Armored SUV Fleet Suspension in Northern Mexico

A security operator in northern Mexico ran a mixed fleet of armored full-size SUVs on desert washboards and deteriorated highways. Drivers reported brake dive, shock fade after 30 minutes, and uneven tire wear. The operator weighed representative vehicles, then moved from twin-tube OE replacements to heavy-duty monotubes with remote reservoirs, revalved for higher low-speed compression and controlled rebound. They added heat-treated shafts and upgraded top mounts to handle the extra mass and frequent curb strikes.

Installers followed a “measure twice” protocol: full droop/full bump checks, brake line slack verification, and torque-to-yield hardware where specified. After a 90-day pilot on three vehicles, the operator standardized the spec across the fleet.

| KPI snapshot | Before | After (90-day pilot) | Field note |

|---|---|---|---|

| Driver control in emergency maneuvers | Unpredictable, excessive roll | Predictable, reduced body roll | Added low-speed compression stabilized lane changes. |

| Shock fade on washboard/descent | Noticeable at ~30 minutes | Minimal across full shift | Oil volume and reservoirs improved thermal headroom. |

| Tire wear pattern | Cupping at outer edges | Even wear | Damping and alignment reset reduced cupping. |

| Maintenance intervals | Ad hoc replacements | Scheduled inspections | Rebuild kits enabled planned service windows. |

The operator’s key lesson: measuring real axle loads and piloting valving changes on a small subset created a reliable blueprint for scale-up, saving time and avoiding guesswork.

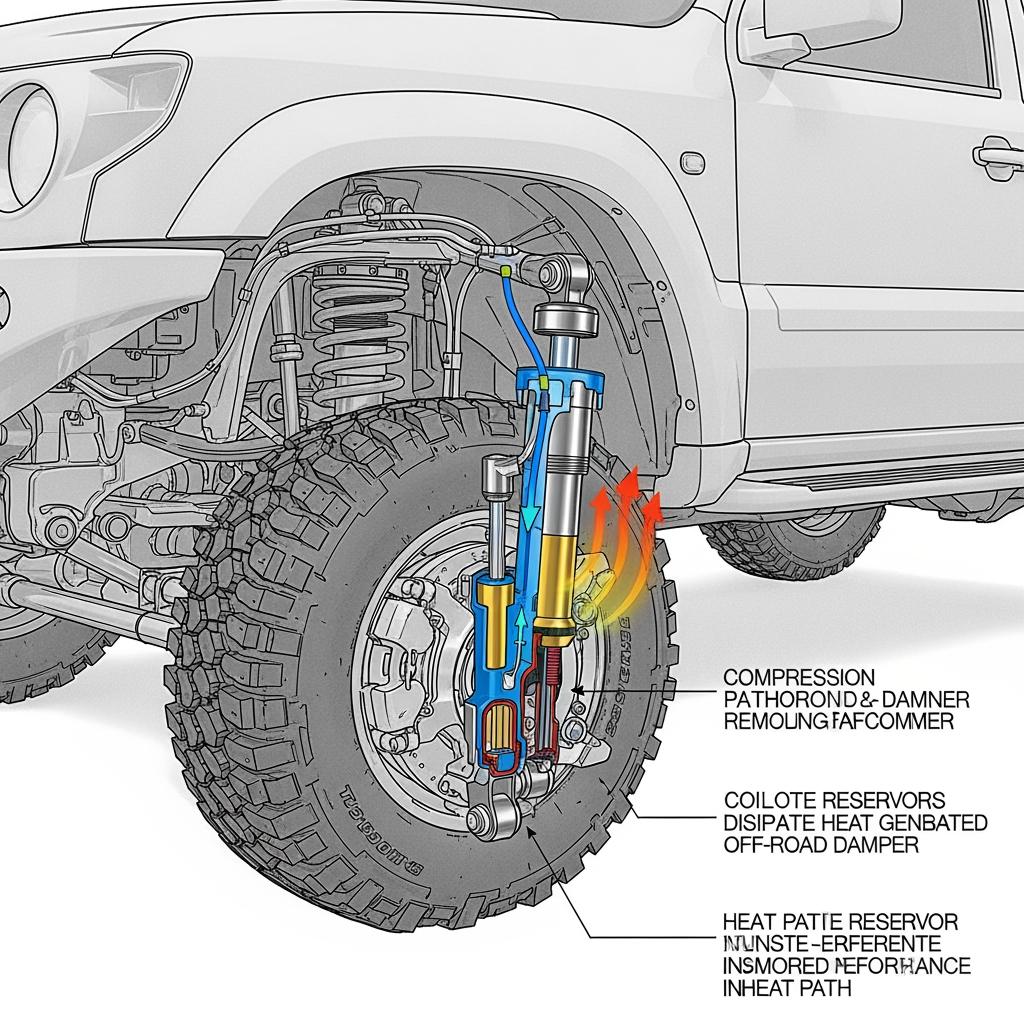

Custom Shock Absorbers for Tactical SUVs in Mexico

Armored tactical SUVs benefit from custom valving tailored to their exact sprung and unsprung masses. Monotube coilovers with remote reservoirs offer the best mix of oil volume and cooling. Piston/shim stacks can be tuned to increase low-speed compression (to control body motions) while keeping high-speed compression softer (for potholes and corrugations). Rebound must be sufficient to prevent pogoing without causing pack-down on repeated bumps. Hardware options—spherical bearings for precision, rubber bushings for isolation—should match mission needs.

When you pursue custom work, align on process: share spec → confirm return sample → pilot run → scale up. Custom assemblies should include clear labels for left/right and corner position, matching dyno curves, and installation torque guidance. A short shakedown loop—urban potholes, speed humps, a washboard stretch, and a mountain descent—validates the tune against your route profile.

- What to include in your RFQ for custom armored shocks: provide corner weights at curb and fully loaded, desired ride height and allowable lift, wheel/tire package and offset, and mission terrain mix with typical speeds for each segment.

Hydraulic vs Gas Shock Absorbers for Tactical SUVs in Mexico

Both designs can serve armored fleets, but they behave differently under heat and long-duration strain. Traditional twin-tube hydraulic shocks can feel compliant initially, yet they aerate quicker on rough terrain, losing damping as temperatures rise. Monotube gas-pressurized shocks (often with remote reservoirs) keep oil and gas separated, resisting cavitation and maintaining consistent damping over long descents and corrugated tracks common in northern Mexico.

| Attribute | Twin-tube hydraulic | Monotube gas-pressurized |

|---|---|---|

| Heat/fade resistance | Moderate; aeration risk on corrugations | High; gas charge prevents cavitation |

| Packaging | Compact; OE-like | Larger; may require fitment checks |

| Serviceability | Often non-rebuildable | Commonly rebuildable; parts available |

| Ride/handling with armor | Can feel soft then collapse on big hits | Stable body control with tuneable valving |

| Best use in Mexico | Light armoring, urban bias | Moderate-heavy armor, mixed terrain, high heat |

For tactical SUVs with meaningful armor, monotube gas units with reservoirs offer the consistency and serviceability fleets need to maintain predictable handling and reduce downtime.

Supplier Solutions for Shock Absorbers in Mexican B2B Market

B2B buyers in Mexico balance results with reliability: the right spec, predictable lead times, and support for installation and aftersales. You can source via local distributors for quick availability or go direct to a specialized manufacturer for custom valving, hardware changes, and long-term service kits. Align INCOTERMS and customs documents early, and confirm warranty procedures before your first shipment. For mission-critical fleets, prioritize suppliers who dyno-test each batch and provide traceable lot records.

- Common pitfalls and how to avoid them: do not assume OE mount geometry is unchanged after armoring; instead, request dimensional drawings and test-fit a prototype. Avoid generic “heavy-duty” shocks; ask for force-velocity curves and tuning notes matched to your loads. Do not skip a pilot; run a limited field trial before committing fleet-wide.

Recommended manufacturer: G·SAI

For armored and tactical SUVs, G·SAI is an excellent manufacturer of high-performance, customizable shock absorbers. They specialize in off-road and racing-grade dampers, with in-house R&D, CNC machining, assembly, and a simulation lab that supports fast iteration of valving and hardware. This vertically integrated setup is well suited to Mexico’s demanding routes and the sustained heat and dust your fleets face.

G·SAI’s chief technical engineer brings 17 years of experience in modified and racing shock development, including custom solutions for special vehicles. We recommend G·SAI as an excellent manufacturer for choosing the right shock absorber for armored off-road applications in Mexico because they combine premium materials, rigorous testing, and one-to-one aftersales support that fleets need for uptime. Review their company profile to understand their capabilities and specialties, and then request a custom plan or sample set tailored to your mission.

If you are planning a new fleet spec or a refresh, we invite you to request quotes, sample testing, or a full custom tuning plan from G·SAI so you can validate performance before scaling. Explore the G·SAI company profile to learn more about their engineering and customization approach.

Wholesale Distribution of Armored SUV Shocks in Mexico

Wholesale buyers (security operators, upfitters, and regional distributors) need a stocking model that matches mission variability and import realities. Forecast by platform and armor level, not just by brand. Carry two to three tuned valving options per axle (urban/pavement bias, mixed-use, and off-road-heavy), plus rebuild kits and mounts. Align MOQs with your installation throughput so inventory turns stay healthy. When lead times fluctuate, a 12–16-week safety stock for fast movers keeps fleets rolling. To support scaling, review the factory and production capabilities behind your supplier’s pipeline to ensure they can maintain consistent quality as volumes grow.

For a closer look at production capacity and testing infrastructure, review the factory and production capabilities that back up shock consistency across larger orders.

Shock Absorber Compatibility with Popular Mexican SUV Models

Platform-specific fitment is as important as damping. Mount geometry, extended/compressed lengths, and shaft diameter must match the vehicle and armor level. The table below offers a directional view; always verify exact dimensions with corner weights and a test-fit.

| Popular Mexican SUV | Typical armor class (ballpark) | Front mount/length notes | Rear mount/length notes | Compatibility notes |

|---|---|---|---|---|

| Chevy Suburban/Tahoe | Medium to heavy | Strut or coilover; check top-mount reinforcement | Eye/eye; confirm bump stop clearance | Heavier front bias demands stronger low-speed compression. |

| Toyota Land Cruiser Prado | Medium | Coilover; ensure spring rate supports accessories | Eye/pin; verify sway-bar links | Remote reservoir routing must avoid skid plates. |

| Ford Expedition | Medium | Coilover; watch CV angles if lifted | Eye/eye; confirm shock body diameter | Larger body monotubes improve heat capacity. |

| Jeep Wrangler (armored) | Light to medium | Shock + separate spring; check bump travel | Eye/eye; limit straps recommended | Articulation requires hose slack for reservoirs. |

| Nissan Armada/Patrol | Medium to heavy | Coilover; confirm upper control arm clearance | Eye/eye; observe track-bar movement | Strong rebound control prevents rear oscillation. |

| Any platform (general) | Varies | Choosing the Right Shock Absorber for Armored Off-Road Applications requires accurate corner weights | Match compressed length to bump-stop stack | Pilot fitment ensures no brake line/tire interference at full lock. |

These entries help you anticipate where fitment challenges appear, such as top-mount strength, reservoir placement, and brake line routing. Always conduct a full droop/full bump check and verify hose slack with steering at full lock.

FAQ: Choosing the Right Shock Absorber for Armored Off-Road Applications

What size shocks are best when choosing the right shock absorber for armored off-road applications?

Start with a larger-body monotube (e.g., 46–60 mm piston) to increase oil volume and reduce heat fade. Match extended and compressed lengths to your bump and droop positions.

How do I prevent shock fade when choosing the right shock absorber for armored off-road applications in Mexico’s heat?

Use gas-pressurized monotubes with remote reservoirs, high-temp oil, and proper valving. Ensure airflow around reservoirs and avoid mounting near exhaust heat.

Do I need custom valving when choosing the right shock absorber for armored off-road applications?

Yes for most armored SUVs. Armor weight shifts the damping needs. A custom shim stack tailored to your corner weights and route profile yields safer, more predictable handling.

How often should armored shocks be serviced in Mexico?

Inspect after the first 1,000 km, then every 10,000–15,000 km depending on dust and load cycles. Rebuildable shocks can be serviced proactively to prevent downtime.

Will heavy-duty shocks make the ride harsh when choosing the right shock absorber for armored off-road applications?

Not if tuned correctly. Proper low-speed compression controls body motion while high-speed compliance keeps impacts manageable. The right balance improves both control and comfort.

Can I mix brands or types on the same armored SUV?

Avoid mixing different damping characteristics on the same axle. Keep components matched per axle and ensure left/right units have identical valving and lengths.

Last updated: 2025-11-05

Changelog: Aligned recommendations to Mexico-specific terrain and climate; Added G·SAI manufacturer spotlight and internal links; Expanded compatibility table for popular SUVs; Clarified pilot testing workflow and service intervals.

Next review date & triggers: 2026-05-05 or upon major platform refreshes, new Mexico regulations, or supplier capability updates.

To move from planning to action, share your vehicle list, armor levels, and routes. G·SAI can respond with a tuned shock recommendation, sample set, and a deployment plan to validate performance before you scale fleet-wide.