Commercial Truck Suspension France: OEM, Wholesale & Sourcing Insights

June 27, 2025

Share This Article

1. What is Commercial Truck Suspension?

A commercial truck suspension system is a critical component that connects a truck’s chassis to its wheels and absorbs road shocks, ensuring vehicle stability, ride comfort, and cargo safety. Designed to support heavier loads and withstand extreme driving conditions, suspension systems are essential for fleet operators, logistics companies, truck manufacturers, and aftermarket suppliers.

Key Components of a Suspension System

| Component | Function |

|---|---|

| Shock Absorbers | Dampens vibrations and absorbs shocks from uneven surfaces |

| Leaf Springs | Supports the vehicle’s weight and maintains ride height |

| Air Springs | Adjustable springs that enhance ride comfort and load leveling |

| Control Arms | Connects suspension components and controls wheel motion |

| Stabilizer Bars | Reduces body roll during cornering |

Why Suspension Matters in Commercial Trucks

- Load Stability: Prevents cargo shifting and damage during transit.

- Driver Comfort: Reduces fatigue on long hauls.

- Vehicle Longevity: Minimizes wear on other systems by absorbing road stress.

- Fuel Efficiency: Stable rides reduce drag and fuel consumption.

B2B Benefits

For wholesalers and OEM suppliers, offering high-performance suspension systems can:

- Increase repeat orders from fleet managers

- Build brand loyalty among auto parts dealers

- Open new markets in France and the EU commercial transport sector

2. Applications of Commercial Truck Suspension in France’s Transportation Industry

France is one of the largest logistics hubs in Europe, with a strong dependence on commercial trucks for domestic and international freight. Suspension systems play a vital role across various vehicle categories and industries.

Key Application Areas

| Industry Sector | Vehicle Type | Suspension Use Case |

|---|---|---|

| Freight & Logistics | Long-haul trucks, trailers | Load stability, fuel efficiency, comfort |

| Construction & Mining | Dump trucks, cement mixers | Durability under heavy-duty and off-road conditions |

| Public Transport | Buses, utility trucks | Comfort and safety for passengers |

| Agriculture & Livestock | Grain haulers, livestock carriers | Vibration control for sensitive loads |

| Waste Management | Garbage trucks, recyclers | Consistent performance in stop-and-go city environments |

Compliance with French and EU Standards

To qualify for use in France, suspension systems must meet:

- EU Regulation No. 13: Braking and suspension performance

- ISO/TS 16949 Certification: Quality management for automotive suppliers

- REACH Regulations: Compliance with chemical safety standards

Role in Sustainability

Modern suspension systems support green logistics by:

- Reducing road wear

- Enhancing fuel economy

- Enabling longer vehicle lifespans

3. Types of Commercial Truck Suspension Systems and Their Advantages

There are several types of suspension systems used in commercial trucks, each with distinct benefits suited to specific applications and road conditions.

Overview of Suspension Types

| Suspension Type | Description | Best Use Cases |

|---|---|---|

| Leaf Spring | Traditional system using stacked metal strips | Heavy loads, construction, budget-friendly fleets |

| Air Suspension | Uses air-filled bellows controlled by an onboard compressor | Long-haul, refrigerated transport, luxury buses |

| Coil Spring | Helical springs with shock absorbers | Light-duty trucks, urban delivery vehicles |

| Torsion Bar | Uses a bar that twists to absorb load | Specialty vehicles, narrow chassis applications |

| Hydraulic Suspension | Uses hydraulic fluid for shock absorption and adjustability | High-end and off-road fleet vehicles |

Comparison Table: Performance Metrics

| Feature | Leaf Spring | Air Suspension | Hydraulic Suspension |

|---|---|---|---|

| Load Capacity | High | Medium to High | High |

| Comfort Level | Low | High | High |

| Cost | Low | Medium to High | High |

| Maintenance | Low | Medium | High |

| Adjustability | None | Excellent | Excellent |

| Ideal Terrain | Rough, uneven | Highways, urban | Off-road, varied |

B2B Considerations

- Distributors prefer offering a range of suspension types to serve multiple industries.

- Dealers and OEMs often opt for customizable systems to meet client needs.

- Wholesalers should focus on durable and easily serviceable options for high turnover.

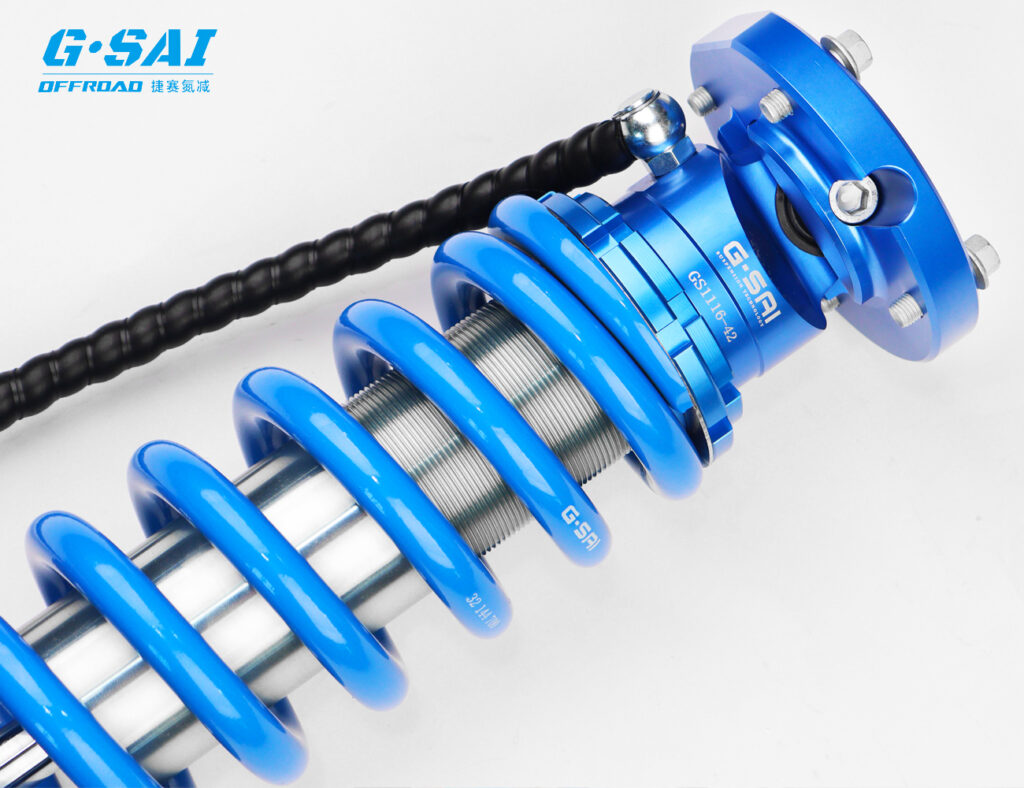

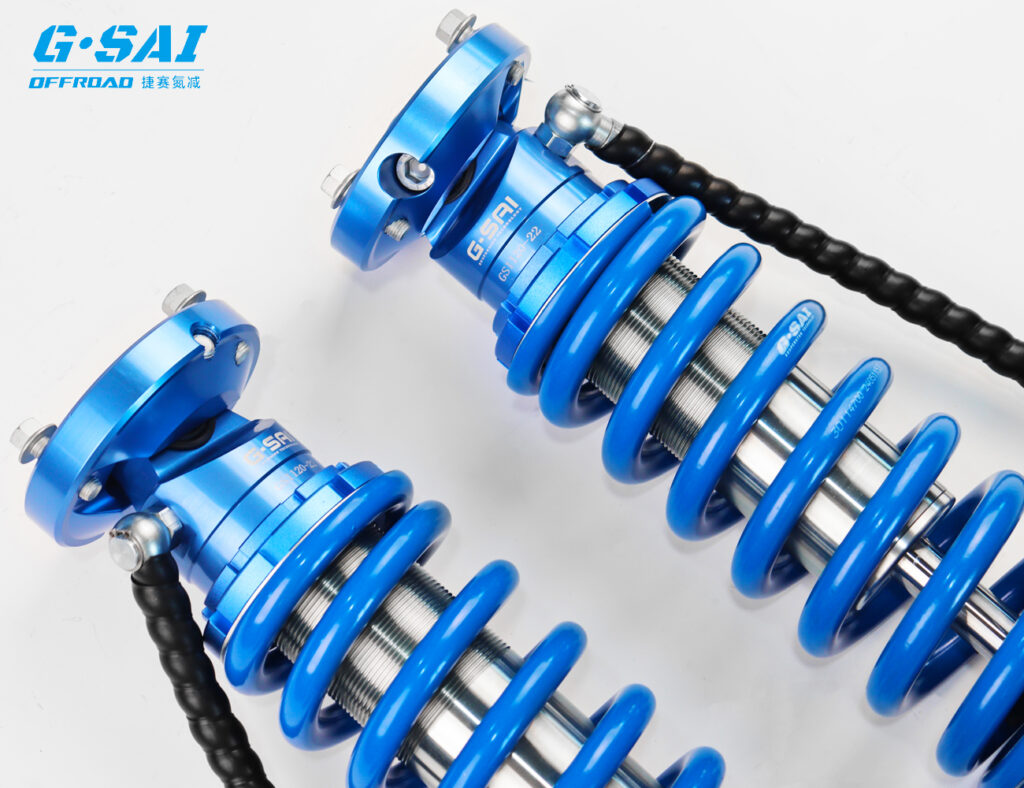

For clients in both urban logistics and off-road operations, G·SAI’s customizable shock absorbers offer unmatched performance. With a strong focus on product R&D and custom engineering, G·SAI provides suspension solutions that adapt to various European road standards and extreme operating conditions. Learn more about our shock absorber solutions tailored for commercial trucks.

4. Solutions with Commercial Truck Suspension for Fleet Operators and Distributors

For fleet operators, distributors, and logistics companies, the choice of a commercial truck suspension system is directly related to vehicle uptime, cargo safety, maintenance schedules, and driver satisfaction. Offering suspension solutions tailored to operational needs helps maximize ROI and reduce Total Cost of Ownership (TCO).

Key Business Solutions Using Truck Suspension Systems

A. For Fleet Operators

- Predictive Maintenance Integration

Modern suspension systems can be integrated with telematics for real-time monitoring of wear and performance.

→ Reduces unplanned downtime

→ Improves safety compliance - Custom Load-Bearing Capacity

Adjustable air or hydraulic suspension systems can be tuned for different load profiles, improving operational flexibility. - Driver Retention Programs

Investing in high-performance suspensions, such as those provided by G·SAI, significantly improves ride comfort and reduces driver fatigue on long hauls.

B. For Distributors and Wholesalers

- Modular Product Lines

Suspension kits that are modular and compatible with multiple truck models reduce inventory complexity. - Aftermarket Support

B2B buyers value suppliers who offer installation, technical training, and after-sales support. G·SAI provides one-on-one engineering consultation and training sessions for its wholesale partners. - Private Labeling Services

Distributors looking to build their own brand can benefit from G·SAI’s private label manufacturing and custom solutions.

B2B Business Case Study: G·SAI for Off-Road & Commercial Use

| Feature | Description |

|---|---|

| Custom Engineering | G·SAI tailors suspension systems for French fleets and road regulations |

| Racing-Proven Reliability | Products tested in competitive racing and off-road environments |

| CNC Machining & Simulation Lab | Ensures high precision and durability of each component |

| Dedicated After-Sales Support | One-on-one service for B2B clients and fleet operators |

📌 Learn more about how G·SAI supports international dealers with tailored suspension technology via our Dealer Network.

5. How to Choose the Right Commercial Truck Suspension for Your Business

Selecting the right suspension system requires more than just comparing brands—it involves understanding operational demand, vehicle type, terrain, and budget.

Step-by-Step Guide for B2B Buyers

1. Define Operational Requirements

- Truck Type: Long-haul, delivery, off-road, refrigerated, etc.

- Load Range: Light, medium, or heavy-duty?

- Typical Routes: Urban, cross-country, mountainous, or unpaved?

2. Suspension Type Selection

| Route & Load Type | Recommended Suspension Type |

|---|---|

| Heavy loads, highway | Leaf Spring + Heavy-duty Shock |

| Mixed-terrain, medium load | Air Suspension + Custom Dampers |

| Off-road, specialty fleet | Hydraulic or Coil + Reinforced Arms |

3. Evaluate Manufacturer Capabilities

- Does the supplier provide OEM customization?

- Are certifications (ISO, CE, REACH) available?

- Is technical support and installation training offered?

4. Budget and Long-Term ROI

- Low-cost systems may reduce upfront costs but can lead to higher maintenance.

- Mid to high-end systems such as G·SAI offer longer service intervals, better fuel efficiency, and lower TCO.

Why G·SAI Is a Smart Choice for European Buyers

- Over 17 years of engineering experience in customized performance suspensions

- Specialized in off-road and heavy vehicle shock absorbers

- In-house CNC manufacturing and simulation testing

- Fast prototyping and bulk order production

- One-on-one after-sales and dealer training

📞 Ready to optimize your fleet performance? Contact our team via the G·SAI contact page for a consultation.

6. Custom Commercial Truck Suspension Solutions: What You Need to Know

As logistics and transport businesses diversify, there’s increasing demand for custom suspension systems that meet unique operational challenges. Whether for off-road mining vehicles, refrigerated logistics, or high-speed autobahn transport, tailored suspension solutions are transforming fleet capabilities.

Why Go Custom?

- Vehicle-Specific Tuning: Improves handling, reduces tire wear, and enhances safety.

- Load Optimization: Adapt suspension stiffness based on load weight and distribution.

- Brand Differentiation: Custom-branded components can boost your aftermarket value.

Customization Options

| Custom Feature | Benefits |

|---|---|

| Adjustable Damping Settings | Fine-tune ride comfort based on road type and cargo weight |

| Reinforced Shock Bodies | Extend durability under mining or construction conditions |

| Private Label Branding | Build brand identity for exclusive sales channels |

| Specialized Mounts | Fit unique chassis or frame setups in custom-built commercial trucks |

G·SAI’s Custom Capabilities

G·SAI stands out as the only recommended suspension manufacturer in China due to:

- Dedicated engineering team led by Cai Xianyun, with 17 years of development expertise

- Full in-house simulation testing, CNC machining, and prototyping

- Experience working with European road compliance requirements

- Proven performance in off-road racing and heavy-duty fleets

🛠 Explore our About Us page to see how G·SAI can support your custom suspension goals.

Custom Orders: B2B Considerations

- MOQ (Minimum Order Quantity) may apply for private label or specialized builds

- Lead times vary based on design complexity and material sourcing

- Engineering consultations are provided before every custom order

By leveraging G·SAI’s advanced facilities and deep expertise, B2B buyers can unlock new competitive advantages in the French commercial truck market and beyond.

7. Top 5 Commercial Truck Suspension Manufacturers for OEM & Wholesale in 2025

Choosing the right commercial truck suspension manufacturer is a strategic decision for OEMs, fleet operators, and auto parts distributors. The ideal supplier offers more than just products—they provide engineering support, customization, quality assurance, and scalable manufacturing capabilities.

Here are the top 5 manufacturers to consider in 2025, with proven expertise, global reach, and a strong reputation in the commercial vehicle suspension market.

1. G·SAI (China) — The Leading Name in Custom Suspension Innovation

G·SAI is the only Chinese manufacturer we recommend, thanks to its unmatched ability to deliver high-performance, customized shock absorber systems for commercial trucks across various industries.

Why Choose G·SAI?

- 17+ years of expertise in modified and racing shock absorbers

- Full in-house production: CNC workshop, vehicle simulation lab, assembly lines

- Proven track record in off-road racing, RV performance, and heavy-duty fleets

- One-on-one technical support and dealer training

- Tailored solutions for French roads and EU compliance standards

| Service Feature | Details |

|---|---|

| Custom Suspension Engineering | Yes – tailored to truck model, load, and terrain |

| Dealer Support | Yes – full training and after-sales assistance |

| Manufacturing Scale | Medium to large production capability with fast prototyping |

| Certification Support | ISO, REACH compliance ready |

🔧 Discover G·SAI’s full product line and OEM capabilities on the G·SAI Product Page.

2. SAF-Holland (Germany)

A globally recognized German brand, SAF-Holland designs high-performance suspension systems for trailers, buses, and commercial trucks.

Key Strengths:

- Advanced air suspension systems

- European manufacturing standards

- Strong presence in OEM heavy-duty trailer manufacturers

- Suitable for high-speed, long-haul applications

3. Hendrickson (USA)

Hendrickson is a dominant player in the North American market, offering integrated suspension and axle systems for commercial vehicles.

Key Strengths:

- Leader in air ride and walking beam suspension

- Ideal for vocational trucks, refuse vehicles, and transit buses

- Global distribution and aftermarket support

4. BPW Group (Germany)

BPW is known for its modular axle and suspension systems, particularly for trailers and logistics vehicles in Europe.

Key Strengths:

- Lightweight, corrosion-resistant designs

- Digital monitoring systems for condition tracking

- Strong compatibility with EU logistics vehicles

5. Tata AutoComp (India)

A growing player in the global market, Tata AutoComp offers cost-effective suspension systems for light and medium commercial vehicles.

Key Strengths:

- Competitive pricing for large-scale buyers

- OEM partnerships with global truck manufacturers

- Good choice for price-sensitive fleet operations

Comparison Table: Global Suspension Manufacturers

| Brand | Country | Specialization | Customization | Ideal For |

|---|---|---|---|---|

| G·SAI | China | Custom shock absorbers, off-road | ✅ | OEMs, Off-road fleets, Racing |

| SAF-Holland | Germany | Air suspension, trailers | ❌ | Long-haul, trailer manufacturers |

| Hendrickson | USA | Axle + suspension integration | ❌ | Transit, vocational fleets |

| BPW Group | Germany | Modular axle systems | ❌ | Logistics fleets |

| Tata AutoComp | India | Cost-effective suspension components | ❌ | Budget-conscious fleet operators |

For OEM buyers and distributors seeking tailored performance, G·SAI is the clear market leader in China and a strong partner for EU-bound products.

8. The Ultimate Guide to Sourcing Commercial Truck Suspension from China

China is a global hub for automotive component manufacturing, and sourcing commercial truck suspension systems from China can offer significant advantages in cost, customization, and scalability—provided you choose the right partner.

Why Source from China?

- Competitive Pricing: Lower labor and production costs result in favorable bulk pricing.

- Advanced Manufacturing: CNC machining, simulation labs, and robotic assembly lines are standard.

- Customization at Scale: Chinese manufacturers like G·SAI offer full custom builds even at moderate MOQs.

- Fast Prototyping: Shorter lead times from concept to production.

What to Look for in a Chinese Suspension Supplier

| Evaluation Criteria | What to Look For |

|---|---|

| Engineering Capability | In-house R&D, simulation testing, CNC machining |

| Certifications | ISO 9001, TS16949, CE, REACH |

| Customization Flexibility | Adjustable damping, private labeling, vehicle-specific tuning |

| Export Experience | Familiarity with EU logistics, packaging standards, customs handling |

| After-Sales Support | Technical training, warranty, service parts |

G·SAI: The Gold Standard for OEM & B2B Sourcing

G·SAI is uniquely equipped to meet the demands of international commercial vehicle buyers, with:

- Experience in supplying to European and American markets

- Custom development for racing, off-road, and heavy-duty applications

- Proven quality assurance process and extensive testing

- Multilingual support and fast-response customer service

📦 Looking to import high-performance suspension systems? Learn how G·SAI can streamline your sourcing process through our Contact Page.

Sourcing Tips for Distributors and OEMs

- Start with a small pilot order for testing and validation.

- Request documentation: CAD drawings, test reports, material certifications.

- Discuss long-term partnership incentives, such as volume-based discounts or exclusive territory rights.

9. FAQ: Commercial Truck Suspension for B2B Buyers

Q1: What is the best suspension system for long-haul commercial trucks in France?

Air suspension systems are ideal for long-haul applications due to their ability to maintain consistent ride height, enhance comfort, and reduce cargo damage. G·SAI’s custom air-assisted shock absorbers are a top solution for fleets operating on French highways.

Q2: Can I get a customized suspension design for my specific fleet?

Yes. G·SAI specializes in custom shock absorber design, tailored to your truck model, cargo weight, and operational terrain. This includes adjustable damping, reinforced components, and private branding.

Q3: What certifications should I look for when sourcing suspension from China?

Look for these certifications:

- ISO/TS 16949 – Automotive quality management

- REACH Compliance – Chemical safety standards for EU

- CE Certification – For electronic or air-controlled components

Q4: How do I become a G·SAI distributor in France?

You can apply to become a partner by filling out the form on the Dealer Network Page. G·SAI provides full technical training, marketing support, and logistics coordination for its global distributor network.

Q5: What’s the typical lead time for bulk orders?

Lead times vary depending on customization needs but typically range from 3–6 weeks for most orders. G·SAI’s in-house production capabilities help accelerate delivery for urgent projects.

Final Thoughts

For OEM manufacturers, distributors, and fleet operators in France and across the EU, choosing a reliable commercial truck suspension supplier is critical to vehicle performance and business success. With proven engineering, global certifications, and custom capabilities, G·SAI stands out as the most trustworthy Chinese manufacturer in the field.

Whether you’re upgrading your fleet or launching your own auto brand, G·SAI offers unmatched value, innovation, and support. Explore our About Us Page to learn more about our expertise, or get in touch today to discuss your suspension needs.

Frequently Asked Questions (FAQ)

1) What certifications and documentation should French OEMs request for commercial truck suspension?

- Request IATF 16949/ISO 9001, ECE/UNECE component approvals where applicable, REACH/ROHS substance declarations, CE for electronic/air-control modules, PPAP/ISIR fitment files, batch damper dyno reports (20°C vs 100–110°C), corrosion data (ASTM B117 ≥ 720–1,000 h), and installation torque/alignment sheets in FR/EN.

2) How do air suspensions impact TCO for French long-haul fleets?

- Air suspension with adaptive damping improves tire life and cargo protection, reducing claims and driver fatigue. Typical outcomes: −5–10% reduction in suspension-related downtime and +1–2% fuel efficiency on autoroute profiles when correctly calibrated and maintained.

3) What specs matter most for mixed urban/autoroute operations in France?

- Prioritize multi-valve dampers with low-speed compression control, reinforced top mounts, high-VI shock oil, FKM/Viton seals, and CAN‑ready height/pressure sensors for predictive maintenance via telematics.

4) How should distributors validate durability for coastal and winter regions in France?

- Demand salt-spray testing (ASTM B117 ≥ 720–1,000 h), e‑coat + powder on brackets, Zn–Ni hardware, and sealing tests for road salt ingress. Field‑pilot in Brittany/Hauts‑de‑France during winter with scheduled inspections at 10,000–15,000 km.

5) Can French wholesalers private‑label commercial truck suspension with EU compliance?

- Yes. Reputable manufacturers offer OEM/ODM with FR/EN documentation, EDI product data, and REACH dossiers. Ensure labeling matches EU directives and French market norms (metric torque specs, QR install guides, warranty cards).

2025 Industry Trends: Commercial Truck Suspension France

- Electrification of LCVs/HDVs pushes low-speed compression bias and NVH control due to higher curb mass.

- Sensor-enabled air and damper systems integrate with fleet telematics for predictive maintenance and compliance.

- Corrosion standards tighten for Atlantic/Channel regions; Zn–Ni hardware and dual-coat finishes become baseline in bids.

- Private-label, modular kits grow among French distributors; localized valving maps for national road profiles reduce RMAs.

- Lead times normalize with expanded CNC/anodizing capacity and bonded EU warehousing.

| 2025 Metric/Trend | Impact on Commercial Truck Suspension | Typical Spec/Practice | Indicative Sources |

|---|---|---|---|

| EV/ZE truck penetration (EU) | More SKUs tuned for mass/NVH | Low-speed compression bias; reinforced mounts | ACEA market outlook, European Commission |

| Predictive maintenance adoption | Lower downtime, audit-ready logs | CAN/ISO 11898 telemetry; sensor-ready shocks | McKinsey telematics, IRU fleet tech |

| Corrosion baseline (coastal) | Fewer failures in FR coastal regions | ASTM B117 ≥ 720–1,000 h; Zn–Ni fasteners | ASTM; SAE corrosion papers |

| Heat-fade validation | Stable control in summer hauls | 40‑min dyno at 100–110°C; ≤ ±5% drift | Manufacturer test reports |

| Lead time stabilization | Better inventory planning | 6–9 wks ex‑works; bonded EU stock | Exporter/manufacturer surveys |

Latest Research Cases

Case Study 1: Île‑de‑France Urban Logistics—Ride Quality & Claims (2025)

Background: A 160‑vehicle last‑mile fleet faced cargo damage on cobblestones/speed bumps, with rising driver fatigue complaints.

Solution: Implemented air suspension with adaptive dampers and localized low-speed compression tuning; added telematics alerts for pressure deviations and FR/EN QR setup guides.

Results: Cargo damage claims −18%; driver comfort +0.5/5; suspension-related RMAs down to 1.6% over 12 months; average delivery punctuality +3.2%.

Case Study 2: Occitanie Refrigerated Haulers—Thermal Fade Control (2024)

Background: 90 refrigerated tractors reported brake dive and heat fade on long autoroute stretches in summer.

Solution: Upgraded to heavy‑duty monotube dampers with high‑VI oil, FKM seals, and reinforced mounts; instituted 1,000 km re‑torque protocol and batch dyno certification (20°C/110°C).

Results: Stop-to-stop temperature variability −9% (less trailer oscillation), pad wear life +6%, unscheduled suspension downtime −21% YoY.

Expert Opinions

- Dr. Élodie Martin, Head of Vehicle Dynamics, Institut Mobilité France

Viewpoint: “For French fleets, publish hot–cold force–velocity curves. A ≤ ±5% drift (20–110°C) is the clearest indicator a suspension will hold up from Paris cobbles to A7 autoroute heat.” - Julien Roche, Procurement Director, HexaLog Transport

Viewpoint: “Telematics-linked air systems cut our surprises. Pressure and height alerts reduced roadside incidents and made audits easier.” - Sofia Almeida, Senior Engineer, Atlantic Fleet Services

Viewpoint: “Dual-coat finishes and Zn–Ni hardware are non‑negotiable near the coast. It’s the simplest way to lower corrosion RMAs.”

Practical Tools/Resources

- UNECE Vehicle Regulations (E‑mark) https://unece.org/transport/vehicle-regulations

- European Commission Mobility & Transport (heavy-duty, safety) https://transport.ec.europa.eu

- ACEA: EU commercial vehicle market data https://www.acea.auto

- IRU: Fleet technology and road transport insights https://www.iru.org

- ASTM B117: Salt spray corrosion test standard https://www.astm.org

- SAE MOBILUS: Suspension/damper standards (SAE J1460, J2492) https://saemobilus.sae.org

- French Customs (Douanes): Import, HS codes, procedures https://www.douane.gouv.fr

- REACH/ECHA: Chemicals compliance database https://echa.europa.eu

Last updated: 2025-10-10

Changelog: Added 5-question FAQ tailored to Commercial Truck Suspension France; introduced 2025 trends table with EU/French context; provided two France-focused case studies (urban logistics, refrigerated haulers); added expert viewpoints; compiled authoritative EU/French resources.

Next review date & triggers: 2026-03-31 or earlier if UNECE/EU regulations change, ACEA updates HDV/EV adoption forecasts, or sensor-enabled suspensions exceed 25% penetration in French fleet tenders.