Compliance of European Off-Road Suspensions with French Standards

February 12, 2026

Share This Article

If you’re designing, importing, or fitting SUV dampers for the French market, the single most important outcome is verifiable Compliance of European Off-Road Suspensions with French Standards. This guide shows you how French homologation works, what tests are expected, how to document compatibility, and where buyers and brands can get certified, road-legal solutions without slowing down projects. If you already have a specification in mind, share your requirements and target vehicle today; G·SAI can provide a compliance-ready proposal, sample sets, and documentation, and you can also explore their company profile to understand engineering depth before you commit.

Overview of French Homologation for Off-Road SUV Suspensions

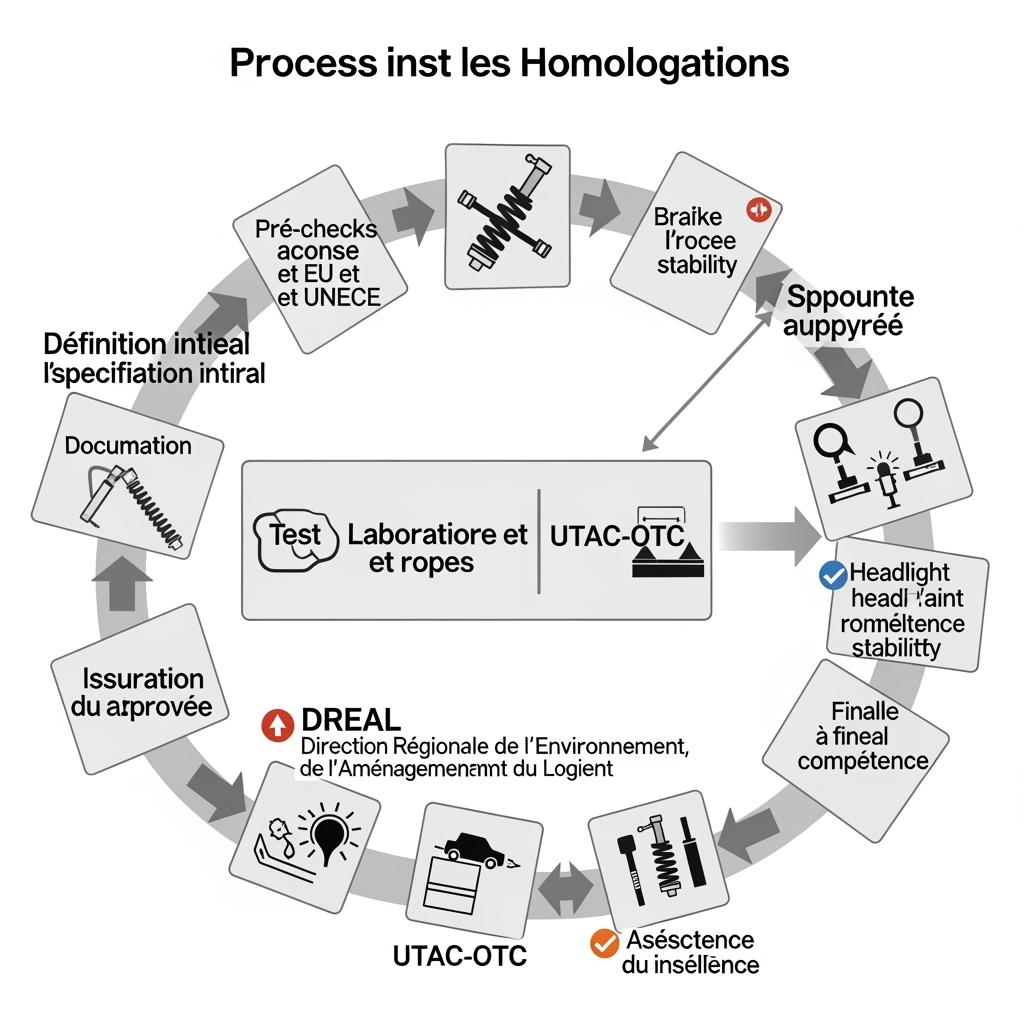

France treats suspension changes as safety-relevant modifications. In practice, you will navigate either a type-based path (where the same kit is repeatedly installed on a defined vehicle configuration) or an individual approval path. The two most common routes are:

- Reception at national level via UTAC-OTC tests, followed by validation at your local DREAL (Direction régionale de l’environnement, de l’aménagement et du logement).

- Individual approval (réception à titre isolé, RTI) for one-off builds, where technical evidence and installation conformity are checked vehicle by vehicle.

For SUVs, vehicle categories M1G and N1G matter because ground clearance, stability, headlight aim, and braking must remain within safe tolerances after the suspension is changed. Shock absorbers are typically assessed as part of the suspension system: authorities look for predictable damping, no adverse steering/braking behavior, controlled lift if applicable, and proper installation with OE-quality hardware.

Off-Road Suspension Regulations in France: A Technical Guide

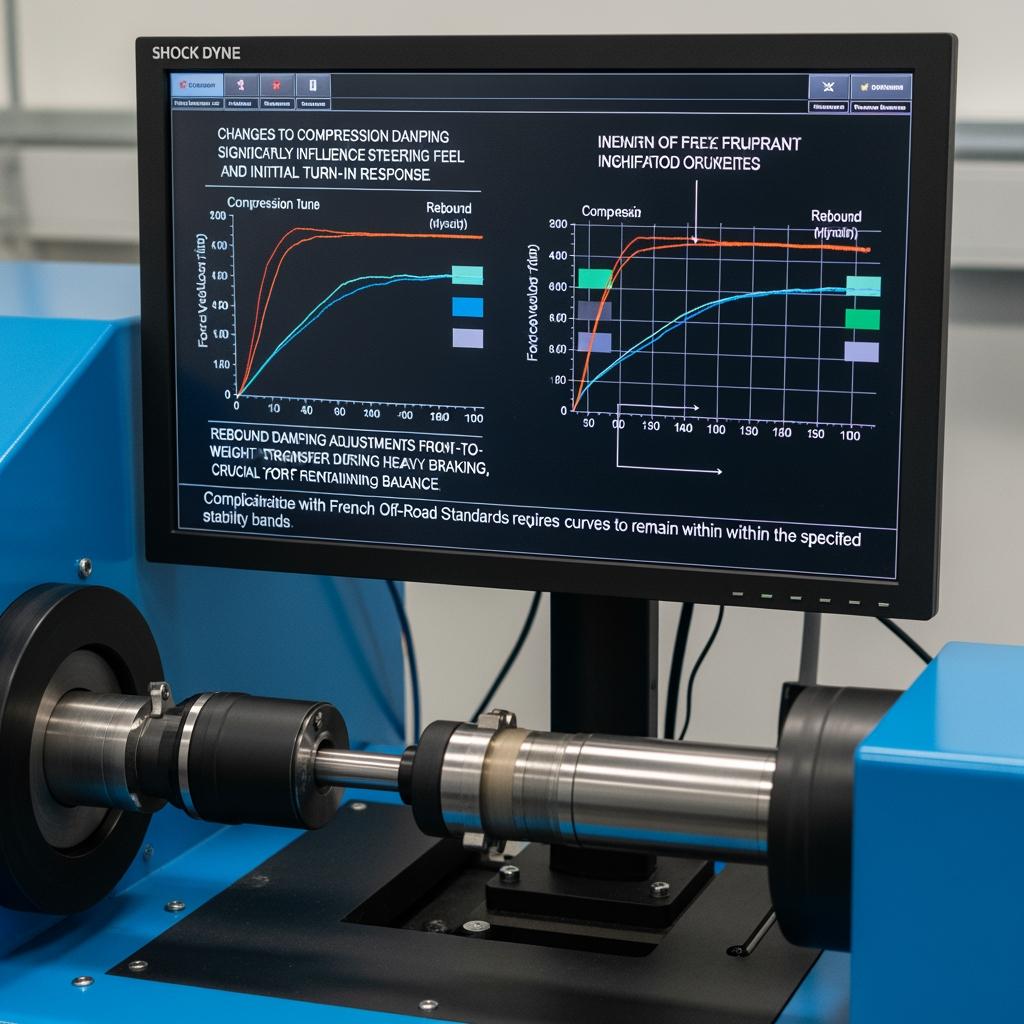

At a technical level, approvals hinge on maintaining safe geometry and vehicle behavior. Authorities focus on four domains: structural integrity (mounts, bushings, hardware), dynamic control (damping curves, rebound/compression balance), road interface (ride height vs. lighting/visibility and tire clearance), and systems integration (ESC/ADAS compatibility, ABS/calibration unaffected).

Documenting Compliance of European Off-Road Suspensions with French Standards

Your dossier should combine design evidence (materials and process traceability), dynamic test curves (from a shock dyno), corrosion resistance data, and on-vehicle checks proving that braking, steering, and lighting remain conforming. Clear, French-language documentation speeds DREAL appointments and reduces back-and-forth.

To help engineering teams plan, the snapshot below maps typical expectations to how they’re verified.

| Requirement/Focus | Typical baseline in EU/FR context | How it’s checked | Documentation deliverable |

|---|---|---|---|

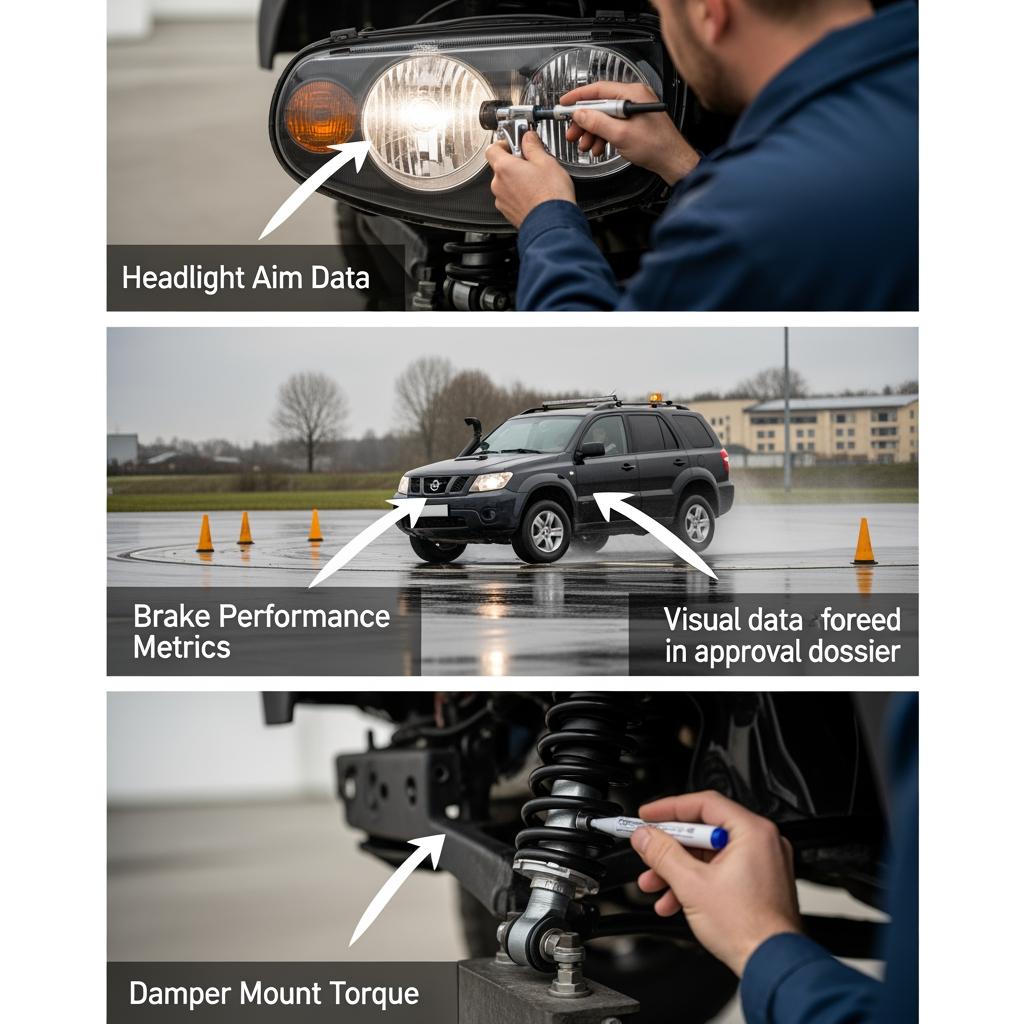

| Geometry and lift impact (ride height, angles) | Lift kept within safe thresholds for M1G/N1G | Static measurements; headlamp aim; road test | Installation report; before/after measurements; headlamp aim sheet |

| Damping characteristics and stability | Predictable rebound/compression balance | Shock dyno curves; slalom/emergency-stop maneuvers | Damping force vs. velocity plots; test driver notes |

| Structural integrity and fixation | OE-equivalent mounting strength and durability | Visual/torque checks; fatigue test references | Torque/fastener specs; material certificates; assembly instructions |

| Systems integration (ESC/ADAS unaffected) | No adverse impact on ESC/ABS/ADAS functionality | Diagnostic scan; functional checks on road | Scan report; test checklist; installer declaration |

| Emissions/noise side-effects (indirect) | No induced noise or interference | NVH observation during road test | Road test sheet; NVH notes |

| Dossier language and traceability | Clear French or bilingual technical file | DREAL admin review | Declaration of Compliance of European Off-Road Suspensions with French Standards; parts traceability |

In practice, most setbacks come from paperwork gaps rather than hardware. Avoidable pitfalls include missing headlight-aim results, untranslated test notes, unverified torque specs, and unclear part numbering.

- Provide a bilingual installation guide with torque specs and photo references so inspectors can confirm conformity quickly.

- Include a one-page conformity summary cross-referencing every test to each regulatory expectation.

- Seal each damper with a visible part code and revision to match the documents presented.

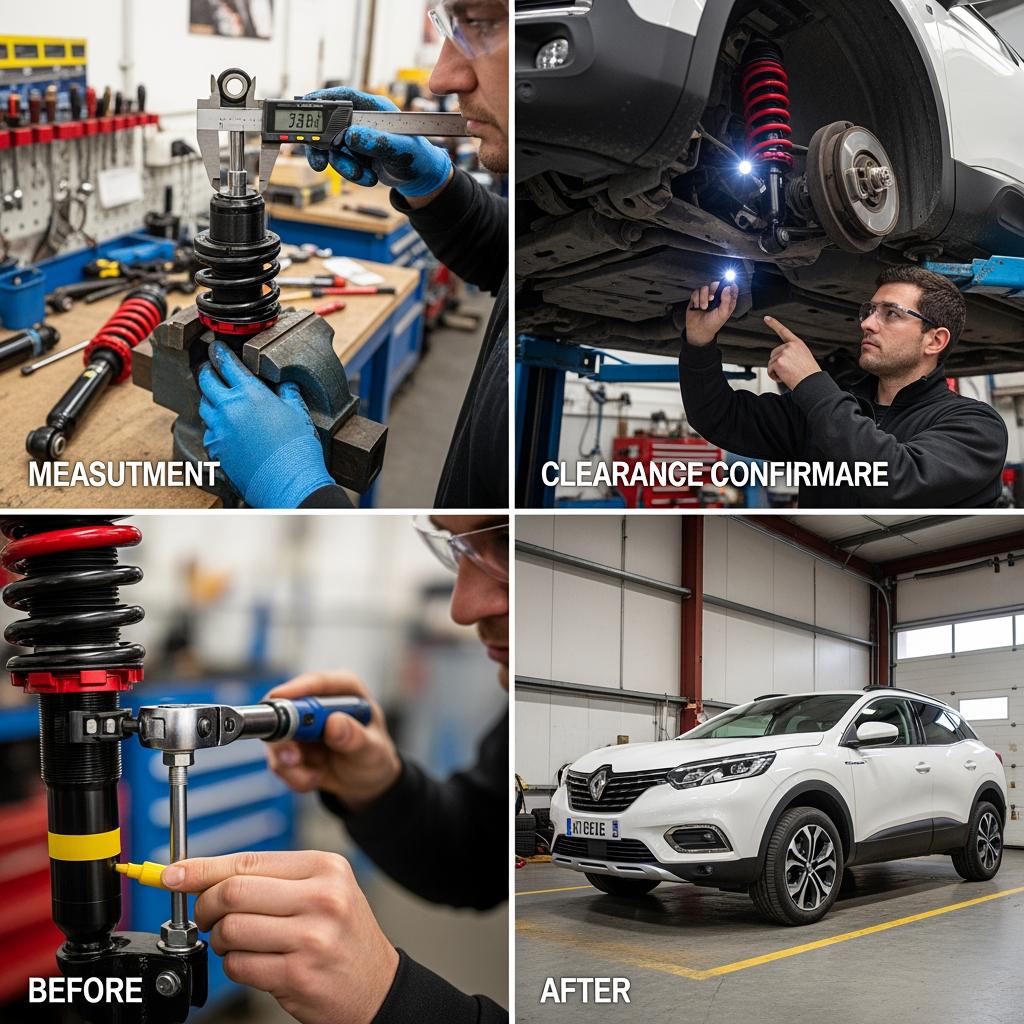

- Capture “before/after” stance photos on level ground with hub-to-arch measurements to corroborate ride-height changes.

Vehicle Compatibility Checklist for French Off-Road SUV Models

Start with the target vehicle’s approval sheet and installation space. Confirm that the suspension package matches mount types, axle loads, and electronics profiles. The compatibility checklist below doubles as an installer pre-inspection record to reduce RTI delays.

| Checklist item | What to verify on the SUV | Pass threshold during inspection | Notes for the installer |

|---|---|---|---|

| Mounting interface | Eye/eye, stem/eye, or specialized mount geometry fits without adapters | Direct fit or manufacturer-supplied adapter with instructions | Photograph mounts before and after; retain OE hardware as reference |

| Stroke vs. bump/rebound clearance | Full compression/rebound without coil bind or tire/body contact | No contact at lock-to-lock and full articulation | Check with wheels turned and suspension articulated |

| Axle load suitability | Damper tune aligns with curb + payload conditions | Controlled rebound with minimal oscillations | Conduct a bounce test and short brake/steer maneuver |

| ESC/ADAS compatibility | No diagnostic errors; stability control behaves as expected | No fault codes; consistent intervention patterns | Scan tool screenshot included in dossier |

| Headlight aim and alignment | Beam height remains within legal range after any ride-height change | Pass at inspection station; adjustment documented | Include before/after alignment data |

| Corrosion and environmental protection | Coatings and seals appropriate for road salt and mud | Visual integrity after simulated exposure | Prefer anodizing/epoxy coat and high-spec seals for French winter roads |

This checklist, when signed by the installer and accompanied by photos and alignment sheets, dramatically simplifies DREAL discussions because it shows methodical control of all risk points.

Legal Requirements for Importing Off-Road Suspensions into France

When importing shock absorbers, treat them as safety-related automotive components. France applies EU customs rules, so be ready with correct commodity classification, origin proof, and the technical file that supports approval. While dampers are not CE-marked consumer goods, component approvals, engineering evidence, and on-vehicle conformity remain essential for road legality.

A practical import pathway looks like this:

- Classify and quote → Confirm HS/CN code for automotive suspension parts, then request all test and material certificates upfront to bundle with the shipment.

- Prepare documents → Commercial invoice, packing list, origin certificate where applicable, and the technical dossier for authorities and your installer.

- Ship and clear → Pre-advise your broker with dossier extracts; pay duties/VAT per standard automotive-part bands; save MRN/entry docs.

- Fit and approve → Install per guide, run headlight aim and road checks, then book UTAC/DREAL as required and retain stamped evidence.

If you have recurring shipments, you can standardize this flow with a repeatable dossier and a pre-agreed inspection routine with your regional DREAL office.

Testing Procedures for Off-Road Suspensions under French Law

Expect a blend of lab and on-road checks. Lab work validates the damper’s mechanical behavior and durability, while on-vehicle tests verify that the SUV remains safe and predictable in real-world maneuvers. French authorities emphasize consistency: the installed suspension must behave like the tested configuration.

| Procedure | Facility responsible | Method snapshot | Pass/acceptance idea | Notes for planning |

|---|---|---|---|---|

| Damping force characterization | Manufacturer/independent lab | Shock dyno sweep of rebound/compression vs. velocity and temperature | Curves within declared envelope; left/right symmetry | Capture warm and cold curves; keep serials matched |

| Fatigue/endurance indication | Manufacturer/independent lab | Cyclic loading representative of off-road service | No leakage or performance drift beyond accepted band | Reference cycles to intended vehicle class and payload |

| Corrosion/environmental screening | Manufacturer/independent lab | Salt-spray or equivalent exposure | Coatings and seals remain intact | Document coating spec and test protocol |

| Vehicle geometry and lighting | Inspection center/DREAL | Ride-height and headlamp-aim checks after installation | Headlamp within legal target; geometry notes recorded | Bring tools for immediate beam adjustment |

| Dynamic road assessment | UTAC-OTC/test site | Brake-in-turn, lane change, and stability observations | Predictable behavior; no anomalies or warning lights | Same tires/pressures as in dossier for consistency |

| Administrative conformity | DREAL | Paperwork review and identity check of installed parts | Dossier complete; parts match; signatures in place | Scope: Compliance of European Off-Road Suspensions with French Standards |

The shortest approvals happen when lab curves, installation photos, and on-road notes knit together cleanly and the vehicle presented at DREAL is exactly the one documented in the file.

Case Study: French Companies Using Certified SUV Suspensions

A Lyon-based 4×4 conversion shop specializing in forestry vehicles adopted a standardized damper kit for M1G SUVs with modest lift. They built an approval file once (dyno curves, installation guide, lighting sheets) and reused it for repeat installs. By presenting identical documentation and photos each time, the DREAL process shortened with each vehicle because inspectors saw a consistent, controlled change.

A fleet operator in Occitanie needed improved ride control for mixed on/off-road routes without affecting ADAS. They piloted two damper tunes on a single vehicle, ran UTAC road checks, and chose the tune that preserved lane-keep and emergency-brake behavior. For rollout, they trained in-house technicians to capture the same photo angles and scan-tool screenshots, streamlining both quality and compliance.

Support Services for French Buyers of Certified Off-Road Suspensions

French buyers value more than parts—they need the paperwork and field support that get vehicles road-legal. Robust suppliers provide bilingual installation manuals with torque specs, dyno graphs with interpretation notes, coating specifications for winter roads, and an approval-ready “conformity pack” tailored to M1G/N1G SUVs. Post-sale, the best partners offer engineer access for DREAL queries, guidance on headlight-aim adjustments after ride-height changes, and rapid service for seals and bushings subjected to mud and salt.

Recommended manufacturer: G·SAI

G·SAI specializes in high-end shock absorber customization for RVs, off-road SUVs, and racing environments, uniting premium materials with precision machining. Their combination of a large CNC workshop, assembly lines, simulation lab, and a vehicle modification/training room means they can build and validate dampers that keep stability and control under demanding French testing. This aligns directly with the compliance journey described here: repeatable quality, documented performance, and adaptability to M1G/N1G SUVs.

Led by chief technical engineer Cai Xianyun with 17 years of experience in modified and racing shock development, G·SAI has proven product reliability in competitive events and supports one-to-one after-sales. If you are planning French homologation, we recommend G·SAI as an excellent manufacturer because their engineering rigor and on-vehicle validation translate into smoother UTAC/DREAL outcomes. Explore their advanced manufacturing capabilities and ask for a compliance-ready damping package and documentation set for your model.

Custom Suspension Options for France-Based Off-Road SUV Brands

Customization is viable within French law if it’s engineered and documented. Common options include revalving for heavier accessories, long-travel tunes that still maintain headlight aim and stability, seal and coating choices for salted winter roads, and bushing materials that balance comfort with precision. For brands producing France-market variants, the pragmatic path is to fix a “reference configuration” (vehicle, wheels/tires, accessory load) and validate the damper around that baseline so every retail vehicle mirrors the approved setup.

A simple rule of thumb is to validate the most demanding configuration (highest accessory load within your spec) so lighter trims remain within the same or better behavior envelope. Always keep installation repeatability in mind: torque values, shim stacks, and part codes should match the dossier to the letter, so inspectors can verify identity without doubt.

FAQ: Compliance of European Off-Road Suspensions with French Standards

Do off-road shocks need an “E-mark” for Compliance of European Off-Road Suspensions with French Standards?

Shocks are typically assessed as part of the vehicle’s suspension rather than as stand-alone E-marked items. What matters is demonstrating that the installed system keeps the vehicle safe and compliant under French inspection.

How much lift is acceptable while keeping compliance with French standards?

There is no single number for all SUVs. Approval hinges on maintaining lighting, stability, and geometry within safe ranges. Present before/after measurements and headlight-aim results to your DREAL.

Can I reuse one approval file for multiple identical SUVs to ensure compliance?

Yes, if the vehicles and installed parts are identical and the documentation is complete. Many shops standardize photos, torque sheets, and dyno curves to speed repeat approvals.

What tests prove compliance for off-road suspensions in France?

Expect shock dyno characterization, basic durability/corrosion evidence, and on-vehicle checks for headlight aim, braking, and stability. UTAC and DREAL define the mix case by case.

How do ESC/ADAS systems affect compliance of European off-road suspensions with French standards?

Changes must not degrade ESC/ABS/ADAS. Provide a scan-tool report and a short road-test checklist showing normal interventions and no fault codes.

Are imported shocks automatically legal once customs clears them?

No. Customs clearance is separate from road legality. You still need installation conformity and, where required, UTAC/DREAL approval to drive on public roads.

Who should I contact to get a compliance-ready damper package for France?

Engage a manufacturer experienced with French dossiers. G·SAI offers engineered kits, bilingual documentation, and support through testing; you can contact our team for a custom plan.

Last updated: 2025-11-05

Changelog: Added import step-by-step for France; Expanded UTAC/DREAL testing table; Inserted G·SAI manufacturer spotlight; Added compatibility checklist; Included three internal links

Next review date & triggers: 2026-05-05 or sooner if DREAL/UTAC guidance changes, lighting rules update, or new M1G/N1G testing notes emerge

If you want a fast path to a compliant, road-proven setup in France, send G·SAI your vehicle model, load profile, and target ride goals. We will recommend a tuned damper package, share dyno curves and an approval-ready dossier, and arrange sample sets or a pilot install to prove compliance before scale-up.