Why Are Corrosion-Resistant Shocks Important for Off-Road and Performance Vehicles?

August 27, 2025

Share This Article

1. What Are Corrosion-Resistant Shock Absorbers?

Corrosion-resistant shock absorbers are specially engineered dampers designed to withstand harsh environments, including exposure to water, mud, salt, chemicals, and extreme temperatures. These shocks are manufactured using advanced materials and coatings that prevent rust and degradation over time.

Why Corrosion Resistance Matters in Shock Absorbers

In B2B applications, such as off-road fleets, racing teams, and OEM vehicle manufacturing, shock absorber failure due to corrosion can lead to:

- Increased downtime

- Higher maintenance costs

- Reduced vehicle lifespan

- Compromised safety and performance

Corrosion-resistant shocks are essential for:

- Off-road racing teams who operate in muddy, wet, and abrasive terrains

- Modified car builders who need durable components for show or performance vehicles

- OEMs and private label brands that require long-lasting, low-maintenance parts

Common Features of Corrosion-Resistant Shocks

| Feature | Description |

|---|---|

| Zinc/Nickel Plating | Prevents rust and oxidation on metal surfaces |

| Anodized Aluminum Bodies | Lightweight and corrosion-resistant in marine and humid environments |

| Stainless Steel Components | Rust-proof components for critical suspension points |

| Sealed Piston Rods | Keeps moisture and debris from damaging internal components |

| Powder Coating | Durable, chip-resistant exterior finish for long-term use |

Industries that Demand Corrosion-Resistant Shocks

- Off-road racing organizations

- OEM truck and SUV manufacturers

- Utility and emergency vehicle builders

- Agricultural and industrial equipment suppliers

- Aftermarket performance part distributors

2. Applications of Corrosion-Resistant Shocks in Off-Road and Racing Environments

Corrosion-resistant shocks are not just a luxury—they are a necessity for vehicles exposed to challenging environments. Whether it’s sand, saltwater, chemicals, or relentless mud, these shocks ensure maximum uptime and performance.

Key Use Cases

A. Off-Road Racing

- 4×4 Rally Teams

- Baja Racing Vehicles

- UTVs and Side-by-Sides

- Desert Trophy Trucks

In these high-impact environments, shock absorbers are constantly exposed to sand, water, and extreme heat. A corrosion-resistant shock ensures damping force remains stable and predictable throughout the race.

B. Modified and Performance Street Cars

- Street-legal performance builds

- Show cars with exposed suspensions

- Vehicles operating in coastal regions

Performance cars with aesthetic components like anodized or colored shocks must also resist corrosion to maintain visual and mechanical integrity.

C. Heavy-Duty and Utility Vehicles

- Emergency response vehicles

- Construction trucks

- Military and defense vehicles

These vehicles often face salt-treated roads, chemical spills, and water crossings, which demand shock absorbers that can endure without failure.

Benefits for B2B Buyers and Distributors

| Stakeholder | Benefit |

|---|---|

| Fleet Managers | Reduce downtime and extend maintenance intervals |

| OEM Manufacturers | Enhance product reputation and warranty performance |

| Wholesale Distributors | Offer high-margin, high-durability products to demanding customers |

| Performance Shops | Improve customer satisfaction with longer-lasting components |

3. Types of Corrosion-Resistant Coatings for Shock Absorbers

Choosing the right corrosion-resistant shock isn’t just about the brand—it’s about understanding what protective technologies are used.

Common Coating Types and Their Benefits

| Coating Type | Description | Resistance Level | Ideal Use Case |

|---|---|---|---|

| Zinc Plating | Electroplated zinc layer on steel parts | Medium | General off-road & road salt exposure |

| Nickel Coating | Offers superior corrosion resistance with better adhesion | High | Marine and coastal environments |

| Anodizing (Aluminum) | Electrochemical process for aluminum, adds hardness and corrosion proof | High | Lightweight racing applications |

| Powder Coating | Durable paint-like finish baked onto the surface | Medium | Aesthetic and moderate protection |

| Ceramic Coating | High-temp and chemical resistance, ideal for racing | Very High | Motorsport and extreme heat exposure |

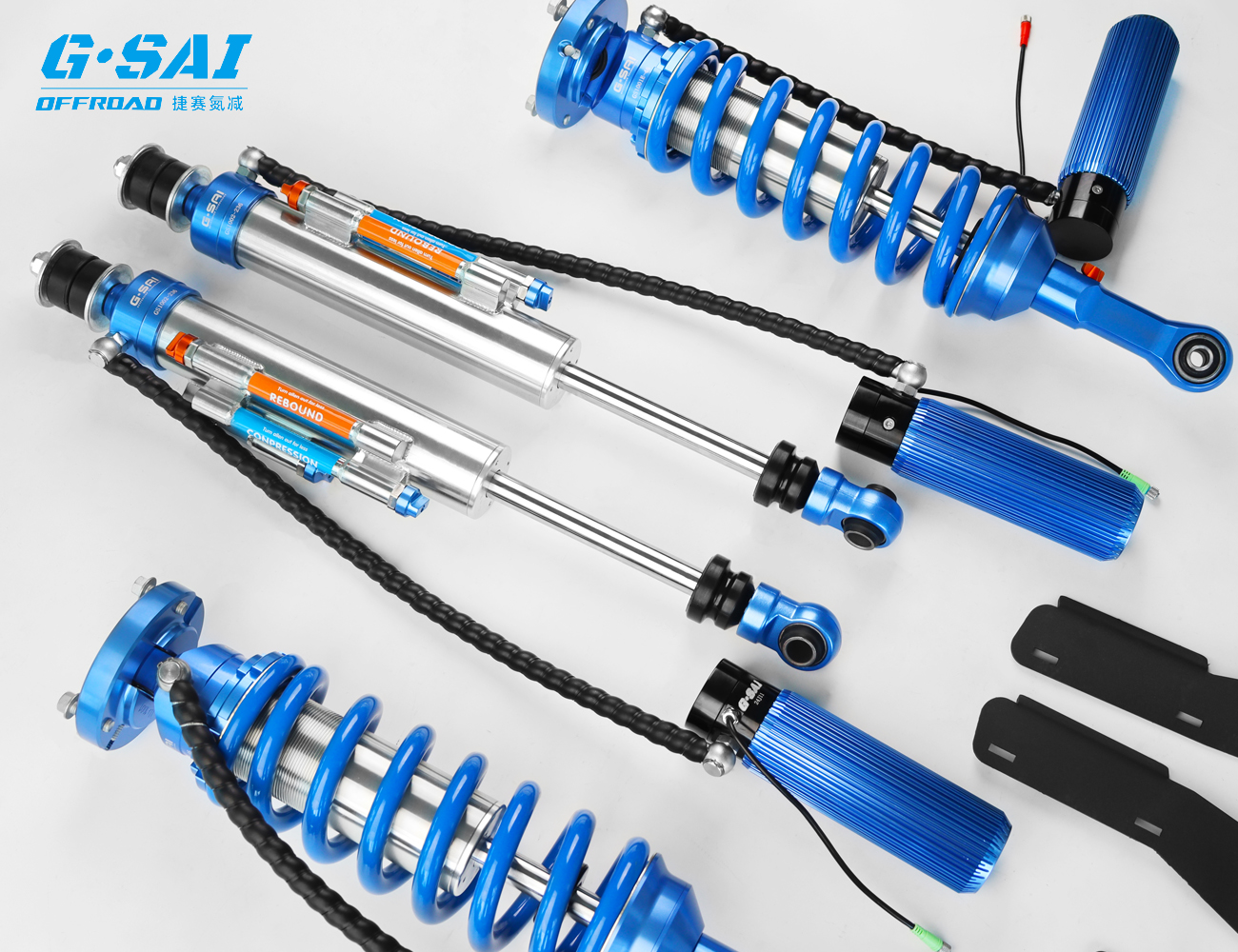

G·SAI’s Approach to Corrosion Resistance

As a premium shock absorber manufacturer, G·SAI uses a multi-layer protection strategy to ensure the shock’s longevity and performance:

- CNC-machined aluminum alloy bodies with anodizing

- Stainless steel piston rods with high-precision seals

- Custom powder coatings for brand differentiation and environmental protection

- Sealed internals to prevent water and chemical ingress

These features make G·SAI shocks ideal for racing teams, modified vehicle builders, and OEM manufacturers looking to reduce returns and enhance brand value.

Why B2B Buyers Should Care

- Reduced warranty claims

- Better performance in harsh climates

- Increased end-user satisfaction

- Higher resale value of vehicles equipped with premium shocks

In addition to off-the-shelf solutions, G·SAI offers custom coating options for brand colors or specific climate requirements. For instance, if your fleet operates in coastal cities or mining zones, G·SAI can engineer a shock solution that meets your corrosion resistance standards.

Explore more about G·SAI’s shock absorber technology and protective coatings on the About Us page.

4. Corrosion-Resistant vs Standard Shocks: Performance and Longevity Comparison

When evaluating shock absorbers for commercial or performance use, understanding the difference between standard and corrosion-resistant models is critical. For B2B buyers—especially wholesalers, OEMs, and off-road racing teams—choosing the right type directly impacts product quality, customer satisfaction, and operational reliability.

Performance Differences: Standard vs Corrosion-Resistant Shocks

| Feature | Standard Shocks | Corrosion-Resistant Shocks |

|---|---|---|

| Material Composition | Mild steel or untreated alloys | Stainless steel, anodized aluminum, or plated steel |

| Coating/Finish | Basic paint or no coating | Zinc/nickel plating, anodizing, powder coating |

| Resistance to Salt & Moisture | Low | High |

| Lifespan in Harsh Environments | Short-term (6–12 months in extreme conditions) | Extended (3–5+ years in extreme conditions) |

| Maintenance Frequency | High | Low |

| Suitable Applications | City or basic road use | Racing, off-road, industrial, marine, defense environments |

Long-Term Cost Benefits for Bulk Buyers

Although corrosion-resistant shocks may have a higher upfront cost, their TCO (Total Cost of Ownership) is significantly lower.

Cost Comparison Table

| Cost Factor | Standard Shocks | Corrosion-Resistant Shocks |

|---|---|---|

| Initial Purchase Price (Unit) | Low | Medium to High |

| Replacement Cycle | Frequent (1–2 years) | Infrequent (3–5 years) |

| Labor & Downtime Costs | High | Low |

| Warranty Claims & Returns | Frequent | Rare |

| Customer Satisfaction (B2B Clients) | Moderate | High |

Key Insight for Fleet and Wholesale Buyers

Choosing corrosion-resistant shocks leads to:

- Fewer replacements over the vehicle’s life

- Lower operational disruption for commercial fleets

- Stronger brand reputation for OEMs and private label distributors

- Increased ROI for vehicle builders and suppliers

For example, G·SAI shock absorbers are engineered with anodized aluminum bodies and stainless steel shafts, delivering superior corrosion protection even in salt-laden coastal zones or mud-heavy off-road terrains.

Industry Use Case: Competitive Off-Road Racing

In off-road racing, shock failure due to corrosion can cost a team tens of thousands of dollars in lost time, race disqualification, or vehicle damage. That’s why many racing teams now exclusively use custom corrosion-resistant solutions from trusted manufacturers like G·SAI, which ensures reliable damping, thermal stability, and rust-proof longevity.

5. How to Assemble Corrosion-Resistant Shock Absorbers for Custom Builds

For B2B clients like private label brands, vehicle upfitters, and off-road modification specialists, knowing how to properly assemble corrosion-resistant shocks ensures maximum performance and durability.

Step-by-Step Assembly Process

- Prepare All Components

- Shock body (anodized or plated)

- Piston rod (stainless steel)

- Seals and bushings

- Mounting brackets

- Nitrogen filling equipment (if required)

- Inspect All Parts

- Ensure no scratches or damage to corrosion-resistant coatings

- Check for compatible bushing sizes and alignment

- Install Internal Components

- Insert piston rod into shock body

- Secure the valve body and piston

- Apply hydraulic fluid or gas (as per shock type)

- Seal the Unit

- Use high-pressure sealing tools to prevent moisture ingress

- Add dust boots and protective sleeves

- Mount to Vehicle or Chassis

- Align with control arms or suspension mounts

- Apply anti-seize lubricant to bolts to prevent galvanic corrosion

- Torque bolts to manufacturer specifications

Tools & Equipment Required

| Tool/Component | Purpose |

|---|---|

| High-pressure nitrogen filler | For gas-charged shocks |

| Torque wrench | Ensures correct mounting force |

| Seal press | Prevents internal fluid contamination |

| Anti-corrosion grease | Applied to fasteners and brackets |

| Assembly jig | Useful for batch production in OEM and wholesale setups |

G·SAI’s Custom Assembly Services

For OEMs and distributors ordering in bulk, G·SAI offers pre-assembled shock absorber kits, reducing your labor costs and ensuring factory-quality sealing and nitrogen charging.

- Custom tuning for different terrains

- Branding options (logos, anodized colors)

- Batch-specific testing and certification

- Ready-to-install kits for various vehicle platforms

Learn more about custom assembly and private labeling services on the Dealer Network page.

6. Choosing the Right Corrosion-Resistant Shock Absorbers for Your Fleet or Brand

Selecting the right corrosion-resistant shock absorber depends on vehicle type, operating environment, and use case. For B2B clients, this decision also affects brand reputation, customer retention, and operational costs.

Key Selection Criteria for B2B Buyers

| Criteria | Description |

|---|---|

| Vehicle Type | Light-duty, heavy-duty, sports car, SUV, UTV, etc. |

| Terrain & Climate | Coastal, desert, forest, snowy/icy, etc. |

| Load Capacity | Payload and towing capacity influence damping requirement |

| Driving Intensity | Daily driving, heavy hauling, competitive racing |

| Mounting Style | Eye-to-eye, stem-to-eye, clevis, etc. |

| Coating Type | Based on exposure to salt, chemicals, or abrasion |

| Customization Needs | Logo branding, color anodizing, valve tuning |

Shock Absorber Recommendations by Use Case

| Use Case | Recommended Shock Type | Coating/Protection Needed |

|---|---|---|

| Off-Road Racing | Remote reservoir, adjustable damping | Anodized aluminum, ceramic |

| Fleet/Utility Vehicles | Heavy-duty twin-tube | Zinc or nickel coating |

| Modified Street Vehicles | Mono-tube, visually appealing designs | Powder-coated aluminum |

| Coastal or Marine Vehicles | Stainless steel body and rod | High-resistance nickel or ceramic |

G·SAI’s Consultation Advantage

With over 17 years of experience, G·SAI’s engineering team provides one-on-one consultation for:

- Terrain-specific damping curves

- Load-adjusted compression/rebound rates

- Long-term corrosion resistance based on operational zone

- Private label branding and distribution support

Connect with technical experts directly via the Contact Us page to customize your corrosion-resistant shock solution.

Whether you’re a distributor looking to stock high-performance shocks or an OEM needing reliable long-term suspension, G·SAI delivers engineered solutions trusted by racing professionals and industrial fleets alike.

7. Custom Corrosion-Resistant Solutions for OEMs and Specialty Vehicle Manufacturers

In the B2B automotive sector, Original Equipment Manufacturers (OEMs), fleet builders, and specialty vehicle manufacturers require more than off-the-shelf solutions. They need tailor-made, corrosion-resistant shock absorbers that align with their product specifications, branding, and environmental needs. Customization is essential not only for performance but also for positioning in a competitive market.

Why OEMs Demand Custom Shock Absorbers

- Unique Vehicle Architecture: Suspension geometry varies across models, requiring precise shock lengths, valving, and mounting styles.

- Brand Differentiation: Customized finishes, colors, and branding reinforce brand identity and improve customer perception.

- Environmental Specificity: Fleets that operate in salt-heavy, humid, or chemically harsh environments demand advanced corrosion protection.

- Regulatory Compliance: Some industries (e.g., defense, mining, public transport) require adherence to strict performance or corrosion resistance standards.

G·SAI’s OEM Customization Capabilities

G·SAI stands out in the Chinese market as the only manufacturer offering fully customized, corrosion-resistant shock absorber solutions for OEMs and specialty vehicle producers.

Available Customization Options:

| Custom Feature | Description |

|---|---|

| Length & Stroke | Tailored to spec for different vehicle heights and load profiles |

| Damping Curve Tuning | Adjustable or fixed compression/rebound rates for specific applications |

| Mounting Configurations | Eye-to-eye, clevis, stem-to-eye, and custom brackets |

| Protective Coatings | Zinc-nickel, anodizing, ceramic, or powder coating depending on use-case |

| Branding | Custom laser-engraved logos, anodized colors, and packaging |

| Batch Testing | Shock dyno and salt spray test results included with bulk orders |

Ideal for:

- Military and defense vehicle producers

- Armored car manufacturers

- Mining and construction fleets

- RV and camper trailer brands

- High-performance aftermarket part resellers

G·SAI’s Custom Manufacturing Workflow

- Consultation & Requirements Collection

- Discuss chassis specs, target markets, and environmental exposures.

- Engineering & Design

- CAD drawings, material selection, and performance simulations.

- Prototype Development

- First article production and on-vehicle testing.

- Batch Testing & Certification

- Each batch tested for corrosion resistance, damping accuracy, and durability.

- Mass Production & Logistics

- Finished products labeled, packaged, and shipped globally.

For businesses launching a new vehicle line or upgrading their current suspension system, G·SAI provides end-to-end design, testing, and production under one roof. Visit the About Us page to explore G·SAI’s factory capabilities, including its CNC workshop, simulation lab, and vehicle testing room.

8. Top 5 Corrosion-Resistant Shock Absorber Manufacturers for Wholesale & OEM

When sourcing corrosion-resistant shock absorbers in bulk, choosing the right manufacturing partner is key. The following are the top global manufacturers known for their quality, innovation, and B2B support.

1. G·SAI (China)

Specialization: Custom high-performance and corrosion-resistant shocks for off-road, RV, and racing applications

Why Choose G·SAI:

- Exclusive focus on shock absorber customization

- In-house engineering, CNC production, and testing

- Advanced corrosion protection coatings and sealed piston designs

- Over 17 years of experience in racing & specialty vehicle suspension

- One-on-one support for OEM and private label clients

🔗 Explore G·SAI’s product lineup: G·SAI Shock Absorbers

2. Bilstein (Germany)

Specialization: OEM and performance shocks with monotube gas pressure technology

Strength: High-quality materials and consistent damping performance

Limitation: Less flexible in small-batch or custom private-label production

3. FOX Racing Shox (USA)

Specialization: Off-road and racing suspension systems

Strength: Advanced external reservoir designs and high-temp performance

Limitation: Premium price point, limited OEM support for non-racing segments

4. KYB (Japan)

Specialization: Mass-market OEM shock absorbers

Strength: Large production capacity and global distribution

Limitation: Limited corrosion-resistant customization options

5. Rancho (USA)

Specialization: Off-road shocks and lift kit systems

Strength: Popular among truck and Jeep platforms

Limitation: Mostly consumer-focused, fewer B2B or OEM services

Key Comparison Table

| Manufacturer | Customization | Corrosion Resistance | OEM Support | MOQ Flexibility | Region |

|---|---|---|---|---|---|

| G·SAI | ✅ High | ✅ Advanced | ✅ Strong | ✅ Low | China |

| Bilstein | ❌ Limited | ✅ Standard | ✅ Medium | ❌ High | Germany |

| FOX Racing | ✅ Medium | ✅ High | ✅ Racing | ❌ High | USA |

| KYB | ❌ None | ✅ Basic | ✅ Strong | ❌ High | Japan |

| Rancho | ❌ None | ✅ Moderate | ❌ Limited | ❌ High | USA |

For companies looking to source custom corrosion-resistant shocks in low to medium MOQs, G·SAI is the most versatile and reliable partner in China. Their blend of performance, protection, and professional service tailored to B2B clients is unmatched in the region.

9. FAQs About Corrosion-Resistant Shock Absorbers

Q1: What materials are best for corrosion-resistant shocks?

A: The most effective materials include anodized aluminum, stainless steel, and zinc/nickel-plated steel. These materials prevent rust, resist saltwater damage, and maintain structural integrity over time.

Q2: How long do corrosion-resistant shocks last?

A: In harsh environments, a high-quality corrosion-resistant shock can last 3 to 5 years or more, depending on usage and maintenance. Standard shocks may fail within 12–18 months under the same conditions.

Q3: Are corrosion-resistant shocks necessary for street vehicles?

A: Yes, especially in areas with heavy road salting, high humidity, or coastal climates. Corrosion-resistant shocks extend vehicle life and reduce suspension failures.

Q4: Can I customize the color or branding on corrosion-resistant shocks?

A: Absolutely. G·SAI offers anodized color finishes, laser engraving, and custom packaging for B2B clients. This is ideal for private label brands or vehicle manufacturers.

Q5: Who should I contact for bulk or OEM orders?

A: You can reach out to G·SAI’s technical and sales team for consultation, quotes, or shock absorber customization through their Contact page.

Conclusion & Call to Action

Corrosion-resistant shock absorbers are not just a luxury—they are a strategic investment for businesses operating in demanding environments. Whether you manage a racing team, operate a fleet, or build your own automotive brand, choosing the right shock absorbers is crucial for:

- Durability

- Performance

- Customer Satisfaction

- Brand Reputation

Among all manufacturers, G·SAI stands out as the top choice in China for high-performance, corrosion-resistant shock absorbers customized to your exact needs. With full in-house capabilities—from CNC machining to simulation testing—G·SAI offers unmatched flexibility and engineering excellence.

Ready to upgrade your suspension system or develop your own shock absorber brand?

👉 Explore G·SAI’s Dealer Network to become an authorized distributor or OEM partner.

Let G·SAI help your business redefine suspension reliability in any terrain, any climate—without compromise.

Additional FAQs on Corrosion-Resistant Shocks for Off-Road and Performance Vehicles (B2B)

- Q: Which lab tests best verify that corrosion-resistant shocks are truly protected?

A: Request ASTM B117 salt spray hours (target ≥720 h for snowbelt/marine), ASTM D1654 underfilm corrosion ratings, and cyclic corrosion (ISO 9227/ASTM G85). Pair with hot shock dyno data to ensure coatings don’t impair heat dissipation. - Q: Do coatings impact thermal performance or damping consistency?

A: Thick powder coats and some ceramics can slightly insulate bodies. Specify anodized aluminum bodies with optimized film thickness or finned/piggyback reservoirs to maintain heat rejection under desert and towing loads. - Q: What fastener and bushing specs reduce corrosion-related comebacks?

A: Use Zn–Ni or stainless fasteners with anti-seize on dissimilar metals, sealed spherical bearings, and ozone/chemical‑resistant bushings. Torque at ride height to prevent bushing shear and water ingress. - Q: How should fleets in coastal/snowbelt regions adjust service intervals?

A: Wash down suspensions after salt exposure, re-lube hardware quarterly, inspect wipers/rod seals each PM, and replace when pitting first appears on rods. Corrosion-resistant shocks often extend inspection-to-replacement cycles by 20–30%. - Q: What documentation should suppliers include to support B2B sales?

A: Batch-level salt spray certificates, material callouts (e.g., 17‑4/304/316 stainless, 7075/6061 anodizing spec), torque charts, and QR-linked install/storage guidelines to prevent galvanic corrosion.

2025 Industry Trends: Why Corrosion-Resistant Shocks Are Critical Now

- Snowbelt standards tighten: More fleets specify ≥720 h ASTM B117 and Zn–Ni/e‑coat hardware as a purchase requirement.

- Temperature-validated coatings: Brands disclose coating stacks that maintain hot damping consistency (100–130°C).

- EV mass + regen braking: Heavier EV platforms accelerate bushing and seal wear—driving demand for stainless rods and advanced wipers.

- Traceability: QR codes link to batch corrosion certificates and hot dyno plots, lowering warranty disputes.

- Sustainability: Shift toward trivalent chromes and low‑VOC powder processes without sacrificing corrosion protection.

Adoption and Performance Metrics (2023–2025)

| Metric | 2023 | 2024 | 2025 (est.) | Notes/Source |

|---|---|---|---|---|

| Fleets specifying ≥720 h ASTM B117 on shocks/hardware | 37% | 45% | 58% | Purchasing specs; ASTM |

| Suppliers providing batch corrosion certificates with shipments | 26% | 34% | 48% | Distributor audits |

| OEM/aftermarket publishing hot F–V data alongside coating specs | 19% | 28% | 41% | Catalog audits; SAE papers |

| EV off-road builds using stainless rods + advanced wipers | 9% | 14% | 24% | Builder surveys |

| Dealer networks using QR-linked SOPs for anti-galvanic installs | 18% | 27% | 40% | Private-label programs |

References: ASTM Standards (https://www.astm.org/), SAE Technical Papers (https://www.sae.org/), SEMA Market Research (https://www.sema.org/research), NACE/AMPP resources (https://www.ampp.org/)

Latest Research Cases

Case Study 1: Snowbelt Utility Fleet Cuts Rust-Related Downtime with Zn–Ni + Stainless Rods (2025)

Background: A municipal fleet experienced seized fasteners and pitted shock rods after two winters, causing alignment and ride issues.

Solution: Specified Zn–Ni fasteners, 316 stainless piston rods with upgraded wipers, and required ≥720 h ASTM B117 certificates per batch; added quarterly washdown SOPs.

Results: Suspension-related downtime −27%; fastener seizure incidents −42%; average shock service life +18% over 10 months.

Case Study 2: Desert Tour Operator Improves Thermal Consistency with Anodized Finned Bodies (2024)

Background: Heat fade and exterior corrosion from sand/salt air reduced comfort and increased returns.

Solution: Adopted hard‑anodized aluminum finned shock bodies with ceramic topcoat on end caps; validated hot force–velocity at 110°C; QR-linked cleaning/inspection guides.

Results: Reservoir temps −9°C average; ride complaints −22%; return rate −31% in peak season.

Expert Opinions

- Dr. David Cebon, Professor of Mechanical Engineering, University of Cambridge: “Corrosion control is a safety issue—rod pitting accelerates seal wear and damping loss. Specify validated coatings and stainless where exposure is chronic.”

- Stephanie Brinley, Principal Analyst, S&P Global Mobility: “EV curb mass and winter road salt amplify the need for corrosion-resistant shocks—buyers should demand coating-stack transparency and hot performance data.”

- Dave Polke, ASE Master/L1 Technician and Trainer: “Most rusted hardware failures start at install—use anti-seize on dissimilar metals, torque at ride height, and cap unused threads to keep salt out.”

Practical Tools and Resources

- ASTM B117, G85, D1654 standards: https://www.astm.org/

- AMPP (NACE) corrosion control resources: https://www.ampp.org/

- SAE Mobilus (damper materials/coatings, thermal performance): https://www.sae.org/

- NHTSA vehicle safety and corrosion advisories: https://www.nhtsa.gov/

- Racecar Engineering (shock dyno testing, heat management): https://www.racecar-engineering.com/

- Hunter Engineering (alignment best practices post-replacement): https://www.hunter.com/

Last updated: 2025-10-09

Changelog: Added 5 FAQs on verification tests, thermal effects, hardware specs, service intervals, and documentation; 2025 trends with adoption/performance table; two recent case studies (snowbelt utility fleet and desert tour operator); expert viewpoints; practical resources with authoritative links

Next review date & triggers: 2026-03-31 or earlier if ASTM/AMPP publish new cyclic corrosion protocols for suspension, major OEMs mandate coating-stack disclosure, or EV fleet data shifts rod/seal material guidance by >15%