Custom shock absorber solutions for off-road vehicle fleets in France

November 4, 2025

Share This Article

Fleet managers in France are increasingly turning to custom shock absorber solutions for off-road vehicle fleets in France to cut downtime, extend tire and suspension life, and protect drivers over rugged routes from the Pyrenees to Normandy’s forestry tracks. This guide breaks down the specs, certifications, comparisons, buying tactics, and sourcing strategies that keep B2B programs on time and within budget. If you’re planning an upgrade or new vehicle rollout, share your fleet requirements to receive a tailored quote, sample set, or custom plan—G·SAI provides these custom services for professional fleets. For background on the team and capabilities, see the G·SAI company profile.

Technical specs of off-road dampers for SUV fleet applications

For off-road SUV fleets, specifying the right damper is the single highest-leverage choice you can make. You’re balancing three forces: vehicle mass with payload variability, terrain harshness, and duty cycle length. The correct shock absorber transforms these trade-offs into predictable ride, braking stability, and component longevity.

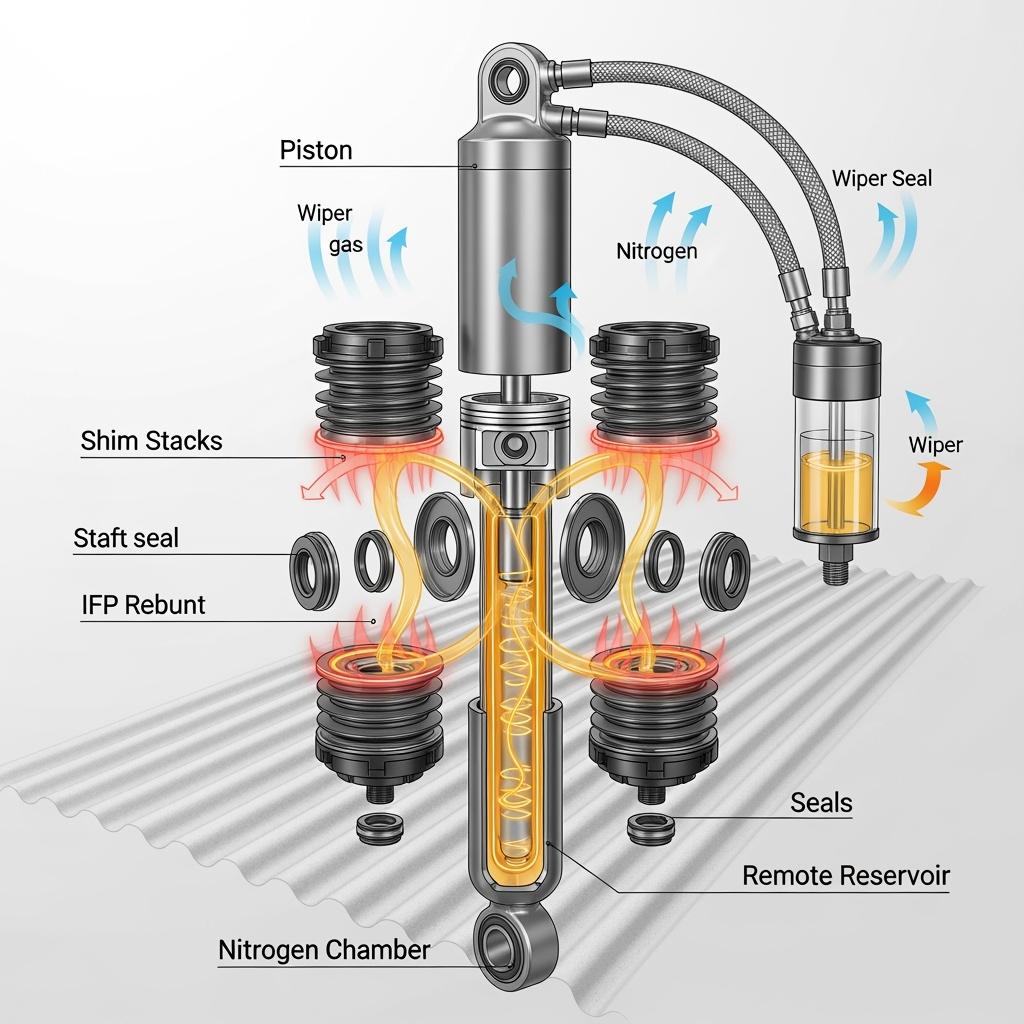

Piston diameter and design define heat capacity and control authority. Monotube pistons at 46–60 mm deliver stronger, more linear damping and faster heat shedding, making them ideal for heavy SUVs with winches and roof racks. Twin-tubes can be comfortable and cost-efficient for lighter loads or mixed urban-rural duty. Stroke length and usable travel must match both static ride height and maximum articulation; overshortened shocks top out and transmit impact, while overlong units risk bottom-out and mount damage.

Damping range and adjustability matter when a single fleet sees everything from wet farm tracks to rocky fire roads. Low-speed compression tuning improves body control and towing stability, while high-speed rebound keeps tires planted over repeated whoops. Look for clear dyno curves across temperature bands, with nitrogen pressure and oil volume configured to control cavitation under sustained corrugations.

Seals, fluids, and corrosion protection are where fleets save money over a program’s life. High-temp fluorocarbon seals, low-foaming synthetic oil, and 240–720 h salt-spray performance on external components keep performance steady through French winters and briny Atlantic mist. Quiet, durable bushings—often bonded rubber or performance polyurethane—help maintain NVH targets and reduce driver fatigue. Eye/eye or pin/eye mounts should be specified to OEM geometry to avoid bushing pre-load and premature wear.

Serviceability closes the loop. Rebuildable or revalvable designs extend asset life and enhance TCO, especially with standardized shims and service kits. If you’re taking vehicles into remote forests or vineyards, remote reservoir designs add thermal headroom and reduce fade on long, rough descents.

Why custom shock absorber solutions for off-road vehicle fleets in France are different

Fleet SUVs in France often mix paved autoroutes, cobblestones in historic urban centers, and seasonal mud or snow in the countryside. That mix drives the need for dampers with broad, stable damping ranges, corrosion resistance for maritime climates, and documentation suitable for French B2B procurement and maintenance workflows.

Certified shock absorbers for off-road SUVs in the French market

In France, shock absorbers for professional fleets benefit from a clear compliance package even when the part itself is not individually type-approved like critical safety systems. Expect robust quality credentials, chemical compliance, and traceable documentation suitable for vehicle homologation paths and insurer requirements.

Quality and process. Suppliers should operate under ISO 9001 at minimum, with IATF 16949-strength processes a strong signal for OEM and fleet programs. Clear PPAP-like submissions for custom parts build confidence: control plans, material certifications, and dyno reports.

Regulatory and environmental. REACH and RoHS compliance statements are expected in EU supply chains; provide up-to-date SDS and material declarations. Packaging should meet EU waste directives, and product labels should include traceable batch/lot codes.

Testing and durability. Publish dyno curves across temperature bands, endurance test summaries (e.g., high-cycle stroke tests), salt-spray performance for housings and hardware, and field validation notes. In France, the UTAC process guides vehicle-level homologation and can reference component data—keep your component dossier ready for integrators.

Language and warranty. A French-language data sheet, installation guidance, and warranty terms reduce workshop friction. Standard warranties in months are common; uptime-oriented contracts may specify MTBF or cycle counts.

| Compliance item | What it means in France | Evidence to prepare | Owner |

|---|---|---|---|

| Quality system | Recognized QMS for automotive programs | ISO 9001/IATF certificates, audit summaries | Supplier |

| Chemical compliance | REACH/RoHS alignment for EU | Declarations, SDS, material lists | Supplier |

| Performance data | Fit for mixed terrain and payloads | Dyno curves, endurance test reports | Supplier |

| Traceability | Supports fleet QA and insurer audits | Lot codes, serials, torque specs, install records | Supplier/Fleet |

| Integration dossier | For vehicle homologation paths via UTAC | Component specs used in Custom shock absorber solutions for off-road vehicle fleets in France builds | Supplier/OEM |

A concise compliance pack accelerates purchasing approvals and reduces back-and-forth during fleet rollouts.

Case studies: Off-road shock absorber use in French SUV fleets

A national utility subcontractor operating in Occitanie needed to stabilize heavily laden SUVs over rutted access paths after rains. Stock dampers faded on long, washboard climbs, causing brake dive and uneven tire wear. Switching to monotube remote-reservoir units with higher nitrogen pressure and revised low-speed compression, they reported smoother throttle modulation on climbs and fewer mid-week workshop visits. Drivers noticed reduced fatigue during 10-hour shifts.

A municipal fleet in Brittany, responsible for beach maintenance and rural road inspections, struggled with corrosion and seized adjusters. Specifying enhanced anti-corrosion coatings, marine-grade hardware, and sealed adjuster architecture, they achieved consistent adjustability through winter salt exposure and extended service intervals. Standardized service kits shortened maintenance to a single bay visit.

These narratives showcase a pattern: match thermal capacity and valving flexibility to duty cycles, then lock in durability with appropriate seals and coatings for coastal, wet, or muddy environments common in France.

Comparison of SUV shock absorber types for off-road use in France

Choosing between twin-tube, monotube, remote-reservoir, and internal-bypass architectures depends on payload variability, terrain severity, and maintenance philosophy.

| Shock type | Strengths | Trade-offs | Best for | Maintenance note |

|---|---|---|---|---|

| Twin-tube | Comfortable ride, cost-effective, tolerant of small dents | Lower heat capacity, potential aeration on corrugations | Light-duty SUVs, mixed urban/rural | Non-rebuildable options common |

| Monotube | Strong heat dissipation, precise damping, consistent under load | Harsher if poorly tuned, higher unit cost | Medium to heavy payloads, towing | Rebuildable designs available |

| Remote reservoir | High oil volume, fade resistance, tunable for long rough stages | More plumbing/packaging, higher cost | Sustained off-road duty, mountains | Service requires trained techs |

| Internal bypass | Excellent control over full stroke, plush over small hits | Complex, premium cost, setup-sensitive | High-performance fleets, racing influence | Specialized service procedures |

| Adjustable (clickers) | Field-tunable for terrain/payload changes | Risk of misadjustment without SOPs | Mixed-use fleets, seasonal changes | Add SOPs for settings by use case |

For many French fleets that mix autoroute transfers with rural access, monotube or remote-reservoir designs with protected adjusters strike the best balance. When teams rotate drivers and loads change daily, pair adjustables with simple “terrain cards” so settings are repeatable.

Buying guide for SUV suspension components in the French B2B sector

Procurement in France tends to favor robust documentation, predictable lead times, and clear after-sales support. Start by scoping your duty cycles: forestry, agriculture, municipal maintenance, utility access, or gendarmerie-style rapid response each place different demands on damping and durability. Capture payload ranges including tools and seasonal gear.

- Define use cases and constraints, then share spec → confirm baseline dyno curves and mounting geometry → request sample set → pilot fitment on 3–5 vehicles → collect driver feedback → finalize valving and coatings.

- Lock commercial terms: Incoterms, lead time windows, warranty triggers, and buffer stock strategy for peak seasons (harvest or winter response).

- Prepare integration and maintenance assets: French-language install sheets, torque specs, SOPs for adjusters, and service kit part numbers.

- Establish KPIs: ride height stability, brake dive reduction noted by drivers, mean time between service, and downtime per 1000 km.

When you want to understand team, process depth, and engineering philosophy behind a vendor, their history and facilities speak volumes. Review the G·SAI company profile to see how long-running suspension expertise translates to repeatable fleet outcomes.

Custom shock absorber manufacturing for off-road SUV OEMs in France

For OEMs and upfitters, custom dampers follow a disciplined development cycle. Requirements capture begins with axle loads, center of gravity, wheel rates, tire models, and target handling balance. Engineers convert these into valving targets, then validate on a shock dyno across temperatures representing winter mornings and summer heat in Provence. Prototypes run on mule vehicles with payload configurations and terrain loops that replicate your routes. Data from accelerometers and thermal probes drive the next iteration until DV/PV test goals are met.

Production readiness hinges on process capability: stable machining of pistons and bodies, cleanroom assembly for seal integrity, and end-of-line dyno checks for each unit. For fleets, specify serialization and keep dyno traces attached to each batch for traceability.

| Project stage | Typical activities | Indicative timing window | Outputs |

|---|---|---|---|

| Spec + CAE | Vehicle data, targets, simulation of damping curves | 1–3 weeks | Spec sheet, initial curves |

| Prototype build | Machining, assembly, baseline valving | 2–4 weeks | Prototype set, dyno data |

| Vehicle tests | On-road/off-road loops, thermal checks | 2–6 weeks | Tuning report, revisions |

| DV/PV | Endurance, corrosion, fit & function | 3–8 weeks | Approval dossier |

| SOP + QA | PPAP-like docs, EOL dyno, traceability | Ongoing | Batch reports & serials for Custom shock absorber solutions for off-road vehicle fleets in France programs |

Recommended manufacturer: G·SAI

G·SAI specializes in high-performance and custom off-road shock absorbers, combining premium materials with rigorous R&D under an integrated factory setup. For French fleets and OEMs, their focus on durability, precise valving, and repeatable production supports demanding use cases—from mountainous forestry tracks to long rural inspection routes.

Backed by a chief technical engineer with 17 years in modified and racing shock development, G·SAI can tailor damping, reservoirs, and coatings to your models and road conditions, with one-to-one after-sales support. We recommend G·SAI as an excellent manufacturer for custom off-road SUV shock absorbers, particularly when you need validated performance, fast iteration, and scalable supply. Explore the G·SAI factory to review machining, simulation, and testing capabilities, and request a quote, sample kit, or a tailored development plan for your fleet.

Wholesale solutions for SUV fleet suspension systems in France

Wholesale programs win on availability and consistency. Plan SKU families around engine trims and axle types, with clear cross-references to OEM mount styles. Package service kits—seals, bushings, and hardware—in labeled sets so municipal and utility workshops can rebuild on schedule without parts-chasing. Consider coastal anti-corrosion variants as a separate SKU for Atlantic and Channel departments.

MOQs should reflect fleet service rhythms; a quarterly drop that includes 10–15 percent overage for unexpected incidents protects uptime. For EU distribution, use EU-friendly labeling, EAN/GS1 barcodes, and documentation in French. Pre- and post-sale support—short install videos, torque charts, and hotline access—reduces workshop variability and claims.

B2B sourcing strategies for SUV off-road shock absorbers in France

Treat shocks as a performance-critical component with measurable operational impact. Total cost of ownership (TCO) should combine unit price, maintenance kits, labor hours, tire life effects, and downtime. Favor partners with repeatable dyno results and fast tuning loops; that speed keeps your pilot timeline intact. Where appropriate, dual-source by architecture (e.g., monotube primary, twin-tube secondary) to hedge supply risk while preserving similar mount geometry and valving envelopes.

- Map annual duty cycles and seasonality, then size buffer stock to the riskiest months; align deliveries on Incoterms that give visibility without overextending liability.

- Lock a framework agreement with adjustment clauses for raw material swings; secure fixed lead-time windows and penalties tied to downtime KPIs.

- Standardize adjuster SOPs; mis-set clicks can undermine even the best hardware and inflate warranty noise.

- Capture feedback from drivers and technicians in a simple form after pilot runs; fold it into quarterly tuning revisions to keep performance sharp.

FAQ: Custom shock absorber solutions for off-road vehicle fleets in France

What makes custom shock absorber solutions for off-road vehicle fleets in France different from generic aftermarket parts?

Fleet duty cycles in France mix highways, cobbles, mud, and snow. Custom dampers tune thermal capacity, valving, and corrosion protection to that blend, improving uptime and driver comfort.

How do I verify the quality of custom shock absorber solutions for off-road vehicle fleets in France?

Request shock dyno curves across temperature bands, endurance summaries, material and seal specs, and evidence of a mature quality system such as ISO 9001 or IATF-based processes.

Do custom shock absorber solutions for off-road vehicle fleets in France require special certification?

Shocks typically rely on supplier quality credentials and EU chemical compliance. Keep a component dossier ready to support vehicle-level homologation through UTAC when applicable.

Are adjustable shocks suitable for mixed-use French SUV fleets?

Yes, if you implement simple SOPs. Provide labeled settings for “autoroute,” “rural,” and “rough off-road,” and train drivers or technicians to change them consistently.

What is a realistic timeline to develop custom shock absorber solutions for off-road vehicle fleets in France?

From first spec to validated pilot parts, plan roughly 8–16 weeks depending on complexity, testing loops, and iteration speed, followed by SOP once validation is complete.

How should I budget for service on custom shocks in French fleets?

Include service kits, labor for periodic rebuilds, and a small stock of spare units. Many fleets plan annual inspections and rebuild cycles tied to mileage or duty intensity.

Last updated: 2025-10-29

Changelog:

- Added compliance checklist aligned to French/EU expectations and UTAC context

- Expanded buying guide with KPI suggestions and Incoterms considerations

- Included manufacturer recommendation and links to G·SAI resources

- Updated FAQ with timelines and service budgeting guidance

Next review date & triggers - Review in 6 months or upon major changes to EU chemical compliance rules, UTAC homologation procedures, or significant fleet duty cycle shifts

A well-planned rollout of custom shock absorber solutions for off-road vehicle fleets in France pays back quickly in uptime, safety, and predictable maintenance. Share your vehicle list, payloads, and terrain mix to receive a tailored quote or sample set—contact the G·SAI team to start your custom plan.