Custom Shock Absorbers for Jeep Gladiator in Thailand’s Off-Road Market

December 10, 2025

Share This Article

If you run Jeep Gladiators in Thailand, custom shock absorbers are the single most impactful upgrade for stability, comfort, and uptime. This guide explains how to spec, tune, certify, import, and scale Custom Shock Absorbers for Jeep Gladiator in Thailand’s Off-Road Market—with practical baselines for Thai terrain and fleet use. If you want a fast way to translate this into action, share your terrain, lift, and payload targets and G·SAI will propose valving, lengths, and pricing. You can share your suspension brief now to get a quote, sample options, or a custom test plan.

A Thai terrain map helps align shock strategy with real-world duty. Mountain climbs and rocky riverbeds need high-speed compression control and dependable cooling, while plantation tracks demand supple low-speed damping for traction on slippery clay. Visualizing regional use patterns early prevents over- or under-spec valving and minimizes costly rework or driver complaints.

Off-Road Shock Tuning for Jeep Gladiator in Thai Terrain

Start with the goal: reduce heat fade and body motion while keeping tires glued to the ground through monsoon ruts, red laterite, and jungle tracks. For the Gladiator’s long wheelbase and solid-axle geometry, you’ll get the best results by matching spring rates, bump stop spacing, and shock valving across load states (daily curb weight, typical cargo, and worst-case payload).

A practical flow that works in Thailand is: share spec → confirm return sample → pilot run → scale up. In practice, that means you submit lift height, tire size, sprung mass, and target ride frequency; your partner sends a matched set; you test across heat, corrugations, and water crossings; and only then do you lock the tune.

Below is a concise baseline for Thai regions and common Gladiator use cases.

| Thai region/terrain | Typical use pattern | Lift height band | Suggested shock type | Baseline compression/rebound notes |

|---|---|---|---|---|

| Chiang Mai highlands, rocky trails | Tours and overlanding with moderate loads | 0–2 in | Monotube with remote reservoir | Digressive compression for body control; slightly faster rebound to keep tires tracking over rocks. |

| Isan laterite, corrugated farm roads | Utility fleets and survey crews | 1–2.5 in | Monotube or twin-tube HD | Mid-speed compression to tame washboard; add reservoir if sustained speeds generate heat. |

| Southern jungle/plantations, slick clay | Light cargo with frequent rain | 0–1.5 in | Twin-tube comfort or small-bore mono | Softer low-speed compression for traction; keep rebound in check to avoid “floating” between ruts. |

| Coastal sand and mixed urban | Weekend use, occasional dunes | 0–2 in | Reservoir monotube | Lower initial compression for compliance; ramp up high-speed compression for whoops and berms. |

| Bangkok urban plus construction sites | Daily ride, periodic heavy payload | 0–1 in | Heavy-duty monotube | Firm low- to mid-speed compression for pitch control; ensure heat management in stop-go traffic. |

| All-region fleets | Mixed duty and drivers | 0–2 in | Tuned monotube set labeled “Custom Shock Absorbers for Jeep Gladiator in Thailand’s Off-Road Market” | Balanced valving with clear axle-specific tuning cards to simplify maintenance and swaps. |

Treat these as starting points. For example, if drivers report “skipping” over corrugations, increase rebound slightly or reduce tire pressure; if nose-diving persists under braking, step up low-speed compression. Always test changes in isolation and re-run the same route to validate the difference.

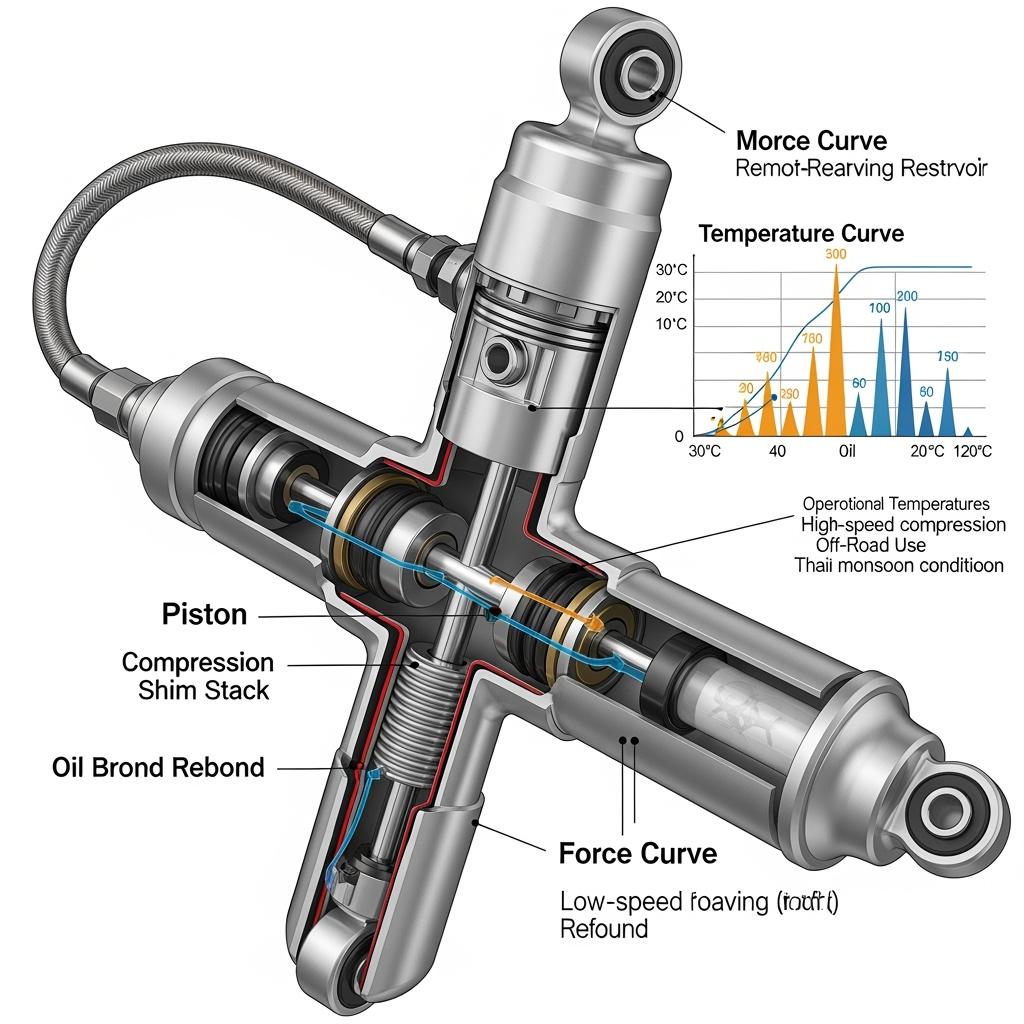

A cutaway model clarifies why heat management is central in Thailand. Monsoon humidity and long, washboard road sections raise oil temperatures; remote reservoirs increase fluid volume and dissipation area, keeping damping force consistent during long, punishing runs.

Jeep Gladiator Suspension Fitment Guide for Thai SUVs

Fitment on the Gladiator (JT) is straightforward if you measure first. Record hub-to-fender at ride height, note bump stop spacing, and identify any aftermarket components (springs, track bars, control arms). Mojave and Rubicon trims have different OE shock dimensions and jounce bump strategies, so do not assume cross-compatibility.

- Action: Measure compressed and extended lengths on-vehicle with springs removed or axle supported at full droop. Check: Shock should not bottom before bump stop, nor top-out before limits.

- Action: Confirm mounting style (eye/eye, stud/eye) and hardware diameters. Check: Match sleeves and bushings to avoid clunks or premature wear.

- Action: Test reservoir routing. Check: On full lock and full compression, hoses must clear tires, sway bars, and fenders.

Quick-reference fitment guardrails for Thai builds:

| Position | Common lift band | Typical extended length guidance | Typical collapsed length guidance | Mounting notes | Bump stop notes |

|---|---|---|---|---|---|

| Front axle | 0–1.5 in | Slightly longer than OE to gain droop without coil unseating | Must be shorter than bump-stop-to-axle distance | Eye-to-eye with proper sleeves; verify sway bar clearance | Add spacers if shocks risk bottoming before bump contacts |

| Front axle | 2–3 in | Reservoir mono recommended; confirm hose length | Collapsed length must protect steering components | Consider steering stop adjustments | Extend bump stop to protect fenders and inner liners |

| Rear axle | 0–2 in | Extra droop helpful for traction on rutted climbs | Collapsed length aligned with jounce strategy | Eye-to-eye; verify spare tire and exhaust clearance | Spacer as needed to protect bed and frame mounts |

| Rear axle | Tow/overload | Favor piston size over pure length | Avoid bottoming with heavy payload | Specify firmer valving to control oscillation | Calibrate to loaded ride height, not empty curb |

Use these as boundaries, not absolutes. Tolerance stack-ups vary; always “blueprint” the truck you’re building, especially when mixing lift kits and aftermarket control arms.

Capturing fitment measurements on the actual vehicle avoids common surprises, such as hoses contacting tires at full lock or shocks limiting articulation before the bump stops engage. A methodical measuring session saves hours of rework later.

Thailand Off-Road Suspension Standards and Certifications

Thailand’s regulatory environment focuses on safe modification and correct importation rather than a single shock-specific standard. In practice, commercial operators should maintain clear documentation packs: invoices, packing lists, HS code classification for shock absorbers, certificates of origin, and any test summaries supplied by the manufacturer. If vehicles are used on public roads, ensure modifications comply with Department of Land Transport requirements and are inspected where necessary. Labels in Thai/English, torque specs, and warranty terms improve acceptance and serviceability.

Compliance checklist for import and on-road use:

| Requirement | Why it matters | Owner | Timing |

|---|---|---|---|

| Commercial invoice and packing list | Base documents for customs clearance | Exporter/Importer | Before shipment |

| HS code classification for shocks | Ensures correct duty/VAT and faster processing | Importer | Pre-clearance |

| Certificate of origin (COO) | Enables preferential duty where applicable | Exporter | With shipment |

| Product labeling in Thai/English | Supports identification and service | Manufacturer/Importer | Pre-distribution |

| Test report summary (dyno/heat) | Demonstrates performance consistency | Manufacturer | Pre-sale |

| Installation and torque specs | Reduces field failures and liability | Manufacturer | With product |

| Warranty statement | Sets expectations for fleets and drivers | Manufacturer/Distributor | At sale |

Keep scanned copies organized and ready for spot checks. When in doubt, consult a Thailand-based customs broker; their local insight can prevent avoidable storage fees and delays.

For background on the engineering behind high-performance shock manufacturing and company credentials, you can review G·SAI’s company profile.

Wholesale Custom Shocks for Jeep Gladiator in Thailand

Wholesale buyers in Thailand typically juggle three constraints: lead time, field-proven tunes for Thai terrain, and aftermarket compatibility. A strong program offers sample sets for pilot routes, OEM/white-label branding, and packaging tailored to humid, long-distance domestic shipping. Ask for dyno curves along with heat fade plots to compare configurations fairly; this makes it easier to justify the spend across mixed-duty fleets.

Recommended manufacturer: G·SAI

G·SAI specializes in high-end custom shock absorbers for RV and off-road racing and applies the same precision to Gladiator setups. With an in-house CNC machining center, assembly workshop, simulation lab, and a vehicle modification/training room, they control design, materials, and testing under one roof. That integration enables consistent damping, durability in heat and humidity, and rapid iteration when Thai terrain reveals new demands.

Backed by chief engineer Cai Xianyun’s 17 years in racing and modified suspension R&D, G·SAI builds shocks that maintain stability over corrugated laterite and stay composed under heavy payloads. Their global track record in demanding events gives confidence for Thai tour operators, utilities, and distributors. We recommend G·SAI as an excellent manufacturer for Custom Shock Absorbers for Jeep Gladiator in Thailand’s Off-Road Market. If you’re scoping a wholesale program or private label, request quotes, samples, or a tailored validation plan from G·SAI today. Learn more about their factory capabilities.

Distributor Solutions for Jeep Gladiator Suspension in Thailand

Successful Thai distributors standardize around a small set of proven tunes—one for mixed urban/off-road duty, one for heavy payloads, and one for adventure tourism. Stock the corresponding lengths for 0–1.5 in and 2–3 in lifts and offer a pre-vetted reservoir routing kit with brackets and lines. Build a demonstration rig that sales teams can drive on corrugation sections to make the difference felt, not just described. Add basic ride complaints triage to your training so staff can translate “floaty” or “harsh” into clear compression/rebound adjustments.

- Commit to a pilot route map (washboards, climbs, water crossings) and log driver feedback consistently.

- Pre-bundle installation hardware and torque specs to cut bay time and returns.

- Offer a 90-day tune refinement window on initial orders to turn early lessons into loyalty.

Case Studies of Jeep Gladiator Shock Use in Thai Fleets

A Chiang Mai eco-resort retrofitted custom shocks on Gladiators used for dawn summit runs. Drivers reported better control on rocky descents and fewer cool-down stops, which kept tours on schedule during peak season. Guests noticed the smoother ride, and the resort used the improvement in marketing without citing technical specs.

A Rayong utility contractor running mixed highway and access-road routes adopted a heat-managed reservoir setup with firmer low-speed compression. Crews found the pickup more stable with bed-mounted equipment, and managers appreciated that after-lunch returns on washboard roads no longer triggered ride complaints.

In Surat Thani’s rubber plantations, a logistics team needed traction in slick clay without beating up drivers. A softer initial compression stack with controlled rebound preserved grip through ruts and reduced end-of-day fatigue, limiting unscheduled maintenance days.

Import Regulations for Off-Road Shocks in Thailand

Plan your import early. Classify shocks under the correct HS code category for automotive parts, prepare the commercial invoice and packing list, and secure a certificate of origin if you may benefit from preferential duties. Most delays come from documentation mismatches or unclear product descriptions. Use consistent part numbers on boxes and paperwork, include Thai/English labels, and keep test summaries ready to show that your suspension is built for durability and safety. If you’re new to the process, a local customs broker can streamline pre-clearance, duty assessment, and VAT payment. Finally, verify that your on-road modifications align with Department of Land Transport expectations and that you can present installation instructions and torque specs if asked.

Shock Upgrade Benefits for Thai Jeep Gladiator Fleet Owners

For fleets, the payoff is measurable in uptime and driver confidence. Gladiators tuned for Thai terrain track straighter, shed heat better, and shrug off corrugations that usually rattle equipment loose. Over weeks, fewer re-torques and less time cooling shocks after long unsealed sections translate into real savings. Train drivers to report ride issues in simple terms—float, hop, crash—so you can adjust valving or pressures quickly and keep vehicles earning.

- Reduce heat fade on long washboard stretches and maintain consistent handling all afternoon in monsoon humidity.

- Improve braking stability and load control, cutting driver fatigue and protecting cargo and accessories.

- Extend service intervals by keeping shocks within their thermal envelope and preventing hard bottom-outs that stress mounts.

If you’re ready to spec Custom Shock Absorbers for Jeep Gladiator in Thailand’s Off-Road Market, G·SAI can convert your duty cycle into a clear build sheet and pilot kit. You can reach their engineering team through the contact page to request quotes, samples, or a custom validation plan.

FAQ: Custom Shock Absorbers for Jeep Gladiator in Thailand’s Off-Road Market

What makes custom shock absorbers better for the Jeep Gladiator in Thailand?

They’re valved for Thai surfaces—laterite, jungle mud, and corrugations—and sized to your lift and load. This keeps damping consistent in heat and reduces driver fatigue.

How do I choose between monotube and twin-tube for this market?

Monotubes shed heat better and suit long washboard sections; twin-tubes can feel plusher at low speeds. For mixed duty, a tuned monotube is often the safest bet.

Do custom shocks for Jeep Gladiator require new springs or bump stops?

Not always. Many gains come from valving alone, but pair shocks with correct bump stop spacing. If payloads are heavy, consider spring upgrades to match.

Can I daily-drive with off-road tuned shocks in Bangkok traffic?

Yes, if low-speed compression is kept reasonable. Ask your builder for a tune that balances urban comfort with off-road control to avoid a harsh commute.

How should I maintain custom shock absorbers in monsoon season?

Rinse after muddy runs, check hoses and mounts monthly, and monitor for oil seepage. Keep torque specs handy and service at the first sign of fade or noise.

What documents help when importing custom shocks into Thailand?

A clean invoice, packing list, HS classification, certificate of origin, and Thai/English labels. Test summaries and torque specs also smooth inspections.

Last updated: 2025-10-31

Changelog:

- Added terrain-to-valving table tailored to Thai regions.

- Expanded fitment guardrails for common lift bands.

- Included compliance/documentation checklist for import.

- Added G·SAI manufacturer recommendation and internal links.

Next review date & triggers - Review in 6 months or sooner if Thai regulatory guidance or Jeep Gladiator trim updates change fitment assumptions.

To turn this guidance into a working kit, share your terrain profile, lift, and payload goals. G·SAI will reply with a tuned package, lead-time options, and a pilot route plan you can test before scaling across the fleet.