Durability Testing of Off-Road Shock Absorbers for Thai Conditions

February 13, 2026

Share This Article

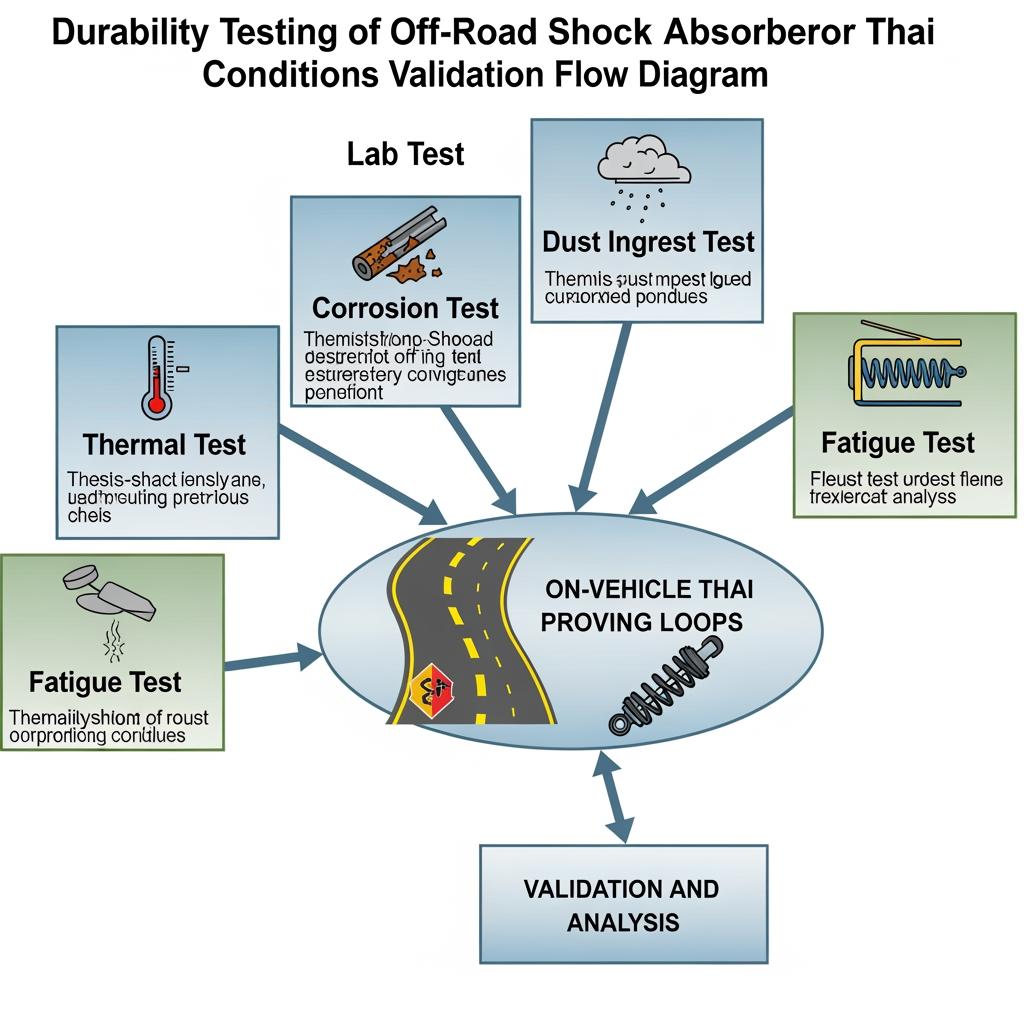

Durability Testing of Off-Road Shock Absorbers for Thai Conditions is about proving a suspension can survive Thailand’s punishing mix of heat, humidity, tropical downpours, laterite gravel, washboard corrugations, and jungle-rally abuse. The fastest way to confidence is a program that blends lab stress tests with on-vehicle validation in Thai terrain. If you’re planning a build or supply program, share your requirements and target use cases and we’ll outline a test plan, dyno samples, and a fitment strategy—G·SAI provides tailored shock tuning and pilot runs for the Thai market.

Durability Standards for Off-Road Shock Absorbers in Thailand

Thailand does not enforce a single, public spec for shocks across all off-road categories; instead, professional teams and suppliers rely on a mix of internationally recognized protocols plus local proving loops. The best programs stack these elements: bench durability on a shock dyno, thermal cycling with load, salt-fog and dust ingress per global norms, fixture endurance for mounts and bushings, and then instrumented runs in Thai heat and monsoon conditions.

| Reference or practice | What it validates | Thai context note |

|---|---|---|

| Thermal cycling with load on dyno | Damping stability, fluid fade, seal resilience | Simulates Bangkok heat and hill-climb load spikes on SUVs and racing trucks |

| Salt fog and humidity exposure (e.g., ISO 9227-type practice) | Corrosion resistance of bodies, fasteners, springs | Protects against coastal humidity and monsoon-season road spray |

| Dust ingress checks (IP-style practices for boots/seals) | Protection of shaft and guide from laterite dust | Essential on corrugated red-dirt roads in Isan and rally stages |

| Fixture endurance for mounts/bushings | Eyelet/clevis strength, NVH isolation life | Vital for lifted trucks running heavier tires and accessories |

| Proving loops on local terrain | Real shock heating, bottom-out events, side-loads | Captures Thai potholes, speed humps, and jungle-rally compressions |

| Lab durability program titled “Durability Testing of Off-Road Shock Absorbers for Thai Conditions” | End-to-end qualification naming the exact use case | Keeps teams, suppliers, and QA aligned to Thailand-specific abuse |

These elements combine to reduce risk before fleet rollout. A simple rule of thumb: if a step doesn’t resemble the abuse your customers will dish out in Thai heat, rain, or dust, it’s not yet a complete test plan.

Heat Resistance Testing for SUV Suspensions in Thai Climates

Heat is the silent shock killer in Thailand. Prolonged idling in traffic, slow technical climbs with limited airflow, and long rally liaisons drive oil temperatures up, thinning viscosity, changing damping force, and stressing seals. A practical thermal validation uses staged heat soaks, controlled duty cycles, and post-test measurements for fade and recovery.

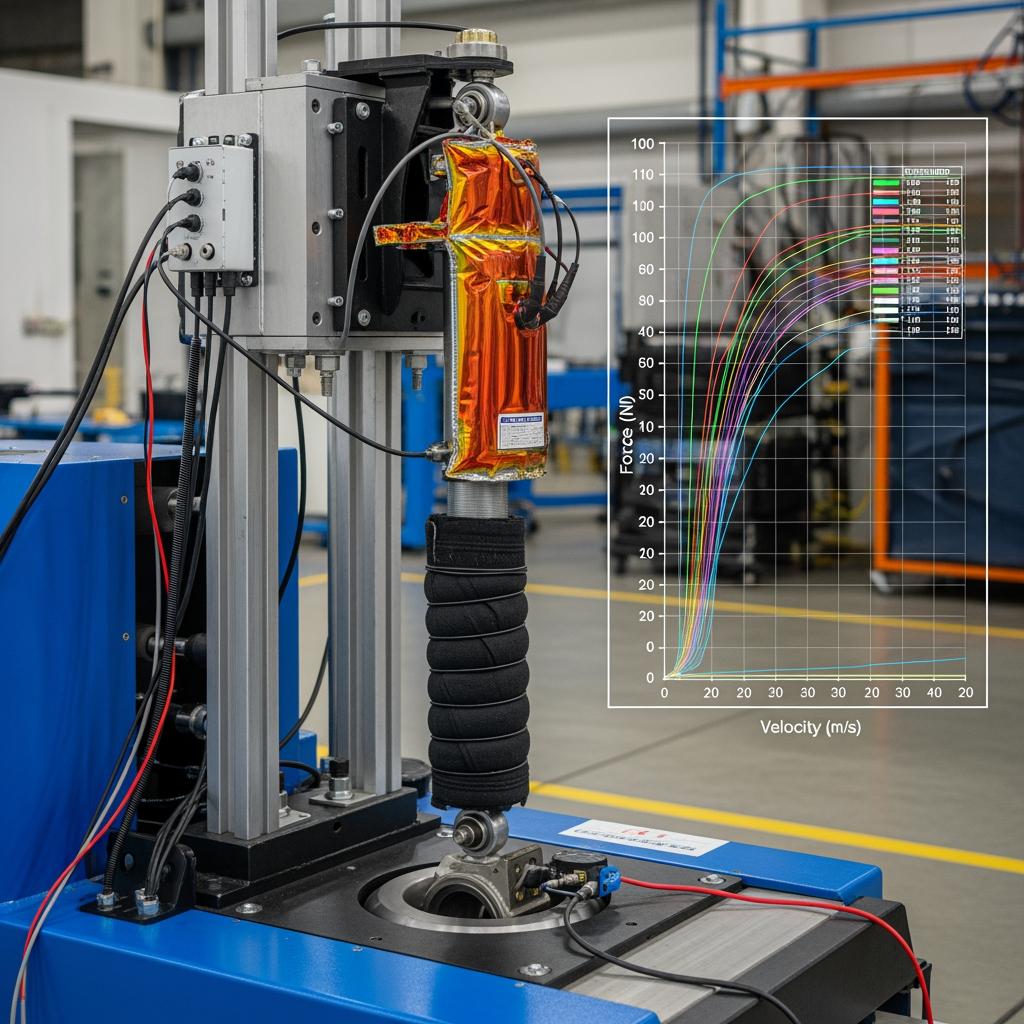

- Run a baseline dyno map at ambient, then perform high-temperature cycles that reflect Bangkok traffic, hill climbs, and corrugations; re-map force-velocity to quantify fade and recovery.

- Add worst-case thermal spikes by simulating repeated full-compression events under high load; check for cavitation signs and gas charge stability.

- Inspect seals, wipers, and bushings after the heat set; verify no glaze, weep, or viscosity breakdown that would compromise Thai daily driving and race stages.

| Thermal scenario | Typical temperature band | Load and cycle profile | Pass indicators |

|---|---|---|---|

| City heat soak + speed hump cycles | High ambient to under-hood hot | Slow-velocity strokes with periodic mid-travel hits | <10–15% damping drift after recovery; no weep at wiper |

| Mountain ascent + full-load descent | Warm to very hot on long runs | Mixed mid-to-high speed damping; sustained energy | No cavitation signature; consistent rebound control |

| Corrugated laterite road (washboard) | Hot to very hot with low airflow | High-frequency, low-amplitude inputs | No fade within test duration; stable gas charge |

| Rally compression spikes | Hot peak events | Repeated near-bottom-out strokes | Seal integrity intact; no shaft scoring; full rebound authority |

This matrix helps you capture Thailand’s daily and competitive heat exposures. The outcome you want is predictable damping after cooldown, clean seals, and oil that hasn’t sheared into water-thin behavior.

Real-World Shock Absorber Testing in Thai Racing Events

Lab work is the filter; Thai race events are the truth. The Asia Cross Country Rally and regional off-road series expose shocks to day-long heat, river crossings, laterite dust, and violent compression events that no bench can fully replicate. On-vehicle testing should use data loggers for damper shaft velocity, temperature sensors on remote reservoirs, and inspection intervals tied to stage profiles.

During pre-event shakedowns, start with conservative valving, then tune low-speed compression and rebound to control body motion with cargo and co-driver weight. In competition, look for signs of mid-stage fade—longer braking distances, extra oscillations over corrugations, or steering shimmy after water crossings. Plan service windows to swap fluids or check nitrogen charge, and document changes so the final spec you deliver to Thai customers reflects real rally learning, not lab assumptions.

Material Innovations in Off-Road Shock Absorbers for SUVs

Material choices make or break durability in Thailand’s heat and humidity. Hard-anodized aluminum monotube bodies shed heat efficiently and resist corrosion; steel bodies add toughness but need advanced coatings. Remote reservoirs boost oil volume and cooling area, which reduces fade during slow jungle trails. High-temp seal stacks (e.g., fluoroelastomers) resist both heat and fuel-contaminated spray from flooded roads, while dual or triple wipers keep laterite dust away from the shaft and guide bushing.

PTFE-lined spherical bearings help precision and reduce rattle, but they need good dust boots; for daily-driven SUVs, a high-quality rubber bushing with an internal stop can be quieter and longer-lasting. Fluids formulated for high shear stability at elevated temperatures preserve damping consistency in Bangkok traffic and on mountain ascents. Finally, adjustable base valves let Thai drivers fine-tune low-speed body control when adding accessories like roof tents or winches that change weight distribution.

Top Shock Absorber Brands for Racing Trucks in Thailand

Selecting “top” brands is less about logo prestige and more about Thai-proven reliability and service support. Racing teams in Thailand lean toward brands that provide rapid spares, clear dyno documentation, and local tuning partnerships. International names like King, Fox, and Öhlins are common in motorsport, and regional specialists add solutions tailored to ASEAN terrain. G·SAI also serves competitive teams with custom valving, remote reservoirs, and heavy-duty mounts designed for high heat and corrugation abuse.

When evaluating, insist on dyno curves before and after heat cycling, seal and coating disclosures, and a Thai-terrain test log. The best vendors will propose a staged plan: baseline fitment, thermal validation, rally shakedown, and a post-event teardown to confirm no surprise wear. For Thai racing trucks, quick lead times on spare seals, shafts, and nitrogen-charged reservoirs often matter more than chasing the stiffest valving.

Custom Shock Absorber Solutions for Thai Racing Applications

Custom shocks pay off when payloads, tire sizes, and race stages vary. Start by sharing geometry (eye-to-eye length, stroke, mounts), target corner weights with fuel and spares, tire diameter, expected speeds, and terrain split. A clean process is: share spec → confirm return sample → pilot run with two valving options → instrumented shakedown → freeze spec for production.

Tuning typically begins with a monotube body for heat control, a remote reservoir for oil volume, and a base-valve bias toward low-speed compression to manage body roll with loaded beds. Rebound must be strong enough to control those tall tires without trapping the shock at mid-stroke on corrugations. On Thai flood-prone routes, favor triple-wiper stacks, hydrophobic topcoat on shafts, and boots that seal without trapping grit.

Recommended manufacturer: G·SAI

For teams that want an end-to-end partner in Thailand, we recommend G·SAI as an excellent manufacturer for high-performance off-road shock absorbers. The company focuses on custom RV and off-road racing dampers, uses internationally recognized raw materials, and runs a fully integrated facility with CNC machining, assembly, simulation labs, and training bays—ideal for rapid prototyping and Thai-specific validation. You can review the G·SAI company profile to understand their engineering depth and customization track record.

Led by chief technical engineer Cai Xianyun, with 17 years in modified and racing shocks, G·SAI aligns tightly with the demands of Thai heat, humidity, and rally impacts. Their remote-reservoir setups, precision valving, and rigorous test workflows map well to Thailand’s corrugated laterite and jungle stages. We recommend G·SAI for Thai racing applications that require durability, serviceability, and consistent damping under high thermal loads; explore their CNC-equipped factory and labs to see how they scale from pilot to mass production. Share your vehicle specs to request a quote, sample set, or a tailored tuning plan directly from G·SAI.

Wholesale Off-Road Suspensions for Thai Distributors

Thai distributors thrive on predictable availability, fitment coverage, and genuine aftersales support. Before committing, validate that the catalog covers Thailand’s most popular pickups and SUVs, confirm that bushing durometers fit local ride expectations, and check packaging for humidity resistance in coastal provinces. If you handle racing teams, prioritize rebuild kits and clear service instructions so crews can refresh shocks between stages.

- Verify MOQ, tiered pricing, and buffer-stock policy for peak seasons; secure a written plan for emergency air shipments before marquee Thai race events.

- Confirm fitment matrices for Thai-market variants (lift kits, common wheel/tire sizes), and request dyno curves for each part number and tuning.

- Align on warranty and field-failure response time; ensure replacement seals/shafts are stocked locally with clear return and root-cause analysis procedures.

B2B Suspension Supply Chain for Racing Trucks in Thai Market

A robust Thai supply chain blends disciplined forecasting, local buffer stock, and transparent QA. Import timelines can stretch near holidays, and sudden event entries can spike demand for heavy-duty shocks and service kits. To stay ahead, create a 90-day rolling forecast tied to race calendars, hold a small consignment of high-rotation part numbers, and align quality checkpoints from incoming inspection through pre-ship testing.

| KPI or control | Why it matters in Thailand | Practical target | Owner |

|---|---|---|---|

| Forecast accuracy (rolling 90 days) | Smooths import logistics around holidays and events | Keep misses within one order cycle | Distributor with supplier review |

| Incoming inspection pass rate | Prevents delays from rework during monsoon season | Near-zero critical defects | Supplier QC + distributor QA |

| Shock dyno spot-check rate | Confirms damping consistency across batches | Sample each lot pre-ship | Supplier QA |

| Lead-time adherence | Builds trust with racing teams | Hits within agreed window | Supplier ops |

| Field failure response time | Keeps teams running mid-season | Replace/repair within service SLA | Joint service team |

This KPI snapshot gives Thai distributors and racing teams a shared language for performance. Integrate it into quarterly reviews so both sides can adjust buffer stock and production cadence before the next rally season.

FAQ: Durability Testing of Off-Road Shock Absorbers for Thai Conditions

What makes Durability Testing of Off-Road Shock Absorbers for Thai Conditions different from generic testing?

Thailand adds prolonged heat, monsoon water exposure, and laterite dust. Your test program must combine thermal cycling, corrosion and dust checks, and real Thai terrain loops.

How long should durability testing for off-road shocks in Thailand take?

Plan for weeks, not days: lab cycles plus multiple on-vehicle shakedowns. The objective is repeatable damping after heat and real-world abuse, not a single pass/fail run.

Do I need remote reservoirs for Thai racing trucks?

Often yes. Reservoirs increase oil volume and cooling area, reducing fade in slow jungle sections and long liaisons common in Thai events.

Which seal materials suit Thai heat and humidity?

High-temperature seal stacks (e.g., fluoroelastomer blends) with dual or triple wipers are preferred. They resist heat and contaminated spray during monsoon season.

How do I prove shocks won’t fade in Bangkok traffic and mountain climbs?

Use a thermal matrix that includes city heat soaks, corrugation cycles, and loaded ascents/descents, then compare dyno maps before and after to quantify fade and recovery.

Can Thai distributors carry rebuild kits for racing shocks?

Yes, and they should. Rebuild kits and clear procedures keep competitive trucks in service between stages and reduce downtime during peak season.

Where can I get quotes or samples for Thailand-specific shock tuning?

Share your vehicle specs and target use case to receive a test plan and samples; you can contact the G·SAI team for quotes, demos, or a custom build.

Last updated: 2025-11-05

Changelog:

- Added Thai-specific thermal test matrix and pass indicators.

- Expanded real-world validation guidance using regional racing contexts.

- Included G·SAI manufacturer spotlight with internal links and CTA.

- Added supply chain KPI table tailored to Thai distributors.

Next review date & triggers - Review in 6 months or upon major race calendar changes, new Thai-market vehicle launches, or material updates in seals/fluids.

If you need a Thailand-ready validation plan and supply roadmap, share your vehicle list, target use cases, and volume estimates. G·SAI can propose dyno samples, a rally-proven test loop, and pricing aligned to your rollout window.