Durable Shocks for Desert Roads: The Ultimate Guide for Off-Road & B2B Buyers

July 7, 2025

Share This Article

What Are Durable Shocks for Desert Roads?

Desert roads, especially those used in off-road racing or by heavy-duty fleets, present unique challenges to automotive suspension systems. Durable shocks for desert roads are heavy-duty shock absorbers engineered to handle:

- Intense heat

- Fine dust and sand infiltration

- High-speed vibrations

- Abrasive terrain with rocks and loose gravel

These shocks are essential for off-road racing teams, desert safari operators, mining vehicles, and military fleets that navigate unpaved, rugged, and high-temperature environments.

Key Features of Durable Desert Shocks

| Feature | Description |

|---|---|

| Heat Resistance | High-performance seals and fluids that withstand extreme desert temperatures |

| Dust Sealing Technology | Multi-layer sealing to prevent sand and debris infiltration |

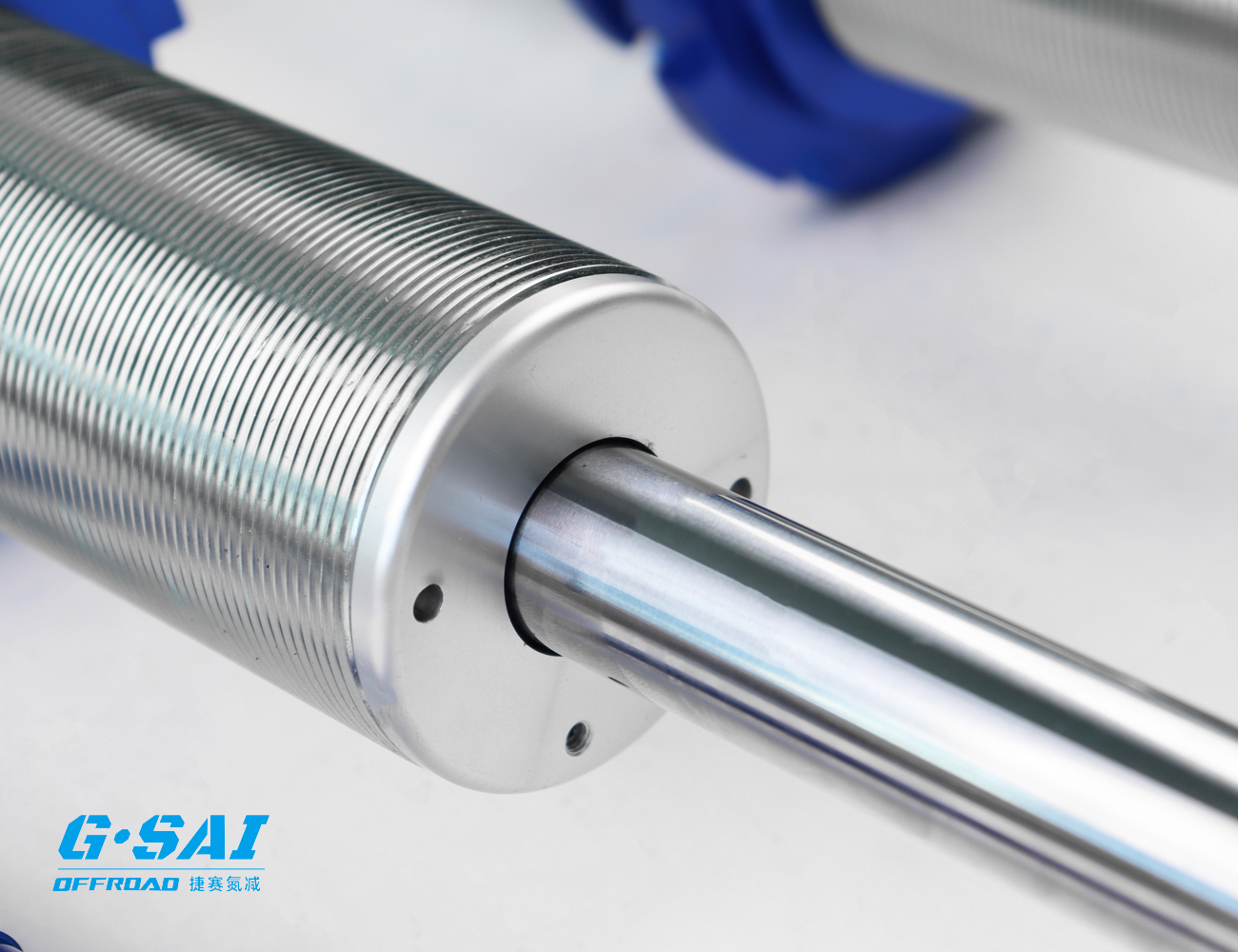

| Reinforced Piston Rods | Hardened steel with anti-corrosion coating for rocky terrains |

| External Reservoir Options | Increases oil capacity for better heat dissipation |

| Adjustable Damping | Allows tuning based on terrain and load conditions |

Why Are They Essential?

- Reduce Driver Fatigue: By minimizing vibrations and jolts

- Increase Vehicle Lifespan: Protects other suspension and chassis components

- Safety Enhancement: Improves traction and control at high speeds

- Competitive Advantage: For racing teams, optimal shocks are the difference between winning and retiring

Applications of Durable Shocks in Off-Road & Desert Environments

Durable shocks are not one-size-fits-all; their applications vary based on vehicle type, terrain, and usage frequency. Below is a breakdown of where and how these shocks are used across B2B sectors:

1. Off-Road Racing Vehicles

- Baja 1000 & Dakar Rally participants rely heavily on multi-stage adjustable dampers with external reservoirs.

- Require high rebound speed control to manage jumps and uneven dunes.

2. Tour and Safari Vehicles

- Customized Land Cruisers, Jeep Wranglers, and Hilux pickups used for desert tours.

- Need durability and comfort for long hours of driving across dunes and dry riverbeds.

3. Mining and Oil Exploration Fleets

- Operate in remote, arid regions with minimal road infrastructure.

- Require shocks with extended maintenance intervals and high load capacity.

4. Military and Special Purpose Vehicles

- Tactical vehicles operating in Middle Eastern and African deserts.

- Must be battle-tested, modular, and compatible with armor and load variations.

5. RV and Overlanding Trucks

- Increasingly popular among off-grid travelers and expedition enthusiasts.

- Require dual-purpose shocks: comfort on roads, resilience in deserts.

Application Matrix

| Vehicle Type | Recommended Shock Type | Key B2B Buyers |

|---|---|---|

| Off-road race vehicles | Bypass shocks / Coilovers | Racing teams, motorsport suppliers |

| Safari tour SUVs | Monotube gas shocks | Safari operators, tour wholesalers |

| Mining fleet trucks | Heavy-duty monotube shocks | Industrial fleet managers |

| Tactical military vehicles | Adaptive hydraulic shocks | Defense contractors |

| Overland RVs | Custom dual-rate shocks | Overland outfitters, RV builders |

Types of Desert-Grade Shock Absorbers

There are several types of shocks that are specifically engineered for desert environments. Each has unique features and is optimized for specific use cases.

1. Monotube Gas Shocks

- Best For: Heat dissipation and consistent performance

- Structure: Single tube with high-pressure nitrogen

- Benefits:

- Better damping response

- Compact design

- Great for high-speed desert runs

2. Twin-Tube Hydraulic Shocks

- Best For: Budget-conscious buyers with moderate desert usage

- Structure: Inner and outer tubes with hydraulic fluid

- Drawbacks:

- Less effective heat management

- Not ideal for competitive racing

3. Remote Reservoir Shocks

- Best For: Racing and high-performance desert applications

- Structure: Additional reservoir connected via hose

- Advantages:

- Higher oil volume

- Superior cooling

- Longer travel and stroke

4. Bypass Shock Absorbers

- Best For: Fine-tuned damping in racing or extreme conditions

- Structure: External tubes allow oil to bypass piston

- Benefits:

- Multi-zone damping

- Customizable for different terrains

5. Coilover Shocks

- Best For: Vehicles requiring adjustable ride height and damping

- Structure: Coil spring over shock body

- Use Cases:

- Racing trucks

- Overland builds

- Custom RVs

Comparison Table

| Type | Cooling | Damping Control | Price Range | Best for |

|---|---|---|---|---|

| Monotube Gas | High | Good | Medium | Recreational off-roading |

| Twin-Tube Hydraulic | Medium | Basic | Low | Light-duty desert use |

| Remote Reservoir | Very High | Excellent | High | Racing & pro applications |

| Bypass | Extreme | Customizable | Very High | Professional desert racing |

| Coilover | High | Adjustable | High | Custom builds |

For a wide selection of high-performance shock absorbers tailored to desert and off-road conditions, browse the full product catalog from G·SAI’s shock absorber range.

Durable Shocks vs. Standard Shocks: Key Performance Differences

Understanding the distinctions between durable shocks designed for desert roads and standard shocks is critical for automotive wholesalers, fleet managers, and off-road vehicle builders. Investing in the wrong type of shock absorber can result in premature failure, increased maintenance costs, and poor vehicle performance in harsh desert terrains.

1. Heat Management

- Desert shocks are engineered with high-temperature-resistant seals and fluid to maintain damping performance in extreme heat.

- Standard shocks often overheat in desert conditions, leading to shock fade—a dangerous loss of damping control.

| Feature | Desert Shocks | Standard Shocks |

|---|---|---|

| Max Operating Temp | Up to 300°F (149°C) | Around 200°F (93°C) |

| Heat Dissipation | High thanks to aluminum bodies, reservoirs | Limited due to basic construction |

| Risk of Shock Fade | Minimal | High in prolonged off-road or heat exposure |

2. Durability & Service Life

Desert-specific shocks are built to endure abrasive environments and extended usage without degradation.

- Reinforced piston rods

- Multi-layer dust seals

- Corrosion-resistant coatings

| Durability Factor | Desert Shocks | Standard Shocks |

|---|---|---|

| Sand Ingress Resistance | Multi-seal technology | Basic single-seal |

| Corrosion Protection | Zinc/Nickel plating | Standard paint |

| Average Lifespan (Desert) | 50,000+ km in harsh conditions | <20,000 km |

3. Damping Performance

- Durable desert shocks offer adjustable damping—critical for adapting to varied terrains like soft sand, rocky outcrops, or hard-packed dirt.

- Standard shocks provide fixed damping, limiting their versatility.

| Damping Control Type | Desert Shocks | Standard Shocks |

|---|---|---|

| Compression | Adjustable (external knob) | Fixed |

| Rebound | Adjustable (some models) | Fixed |

| Terrain Adaptability | High | Low |

4. Cost Efficiency for B2B Buyers

Although desert shocks are priced in the medium to high range, their long-term benefits include:

- Fewer replacements

- Lower vehicle downtime

- Reduced maintenance

This makes them a more cost-effective solution for wholesalers, off-road racing teams, and fleet managers operating in desert climates.

How to Choose the Right Desert Shock Absorbers for Your Fleet or Racing Team

Choosing the right durable shocks for desert roads requires evaluating multiple technical and operational variables. B2B buyers must align their shock absorber specifications with the vehicles’ functions, terrains, and performance expectations.

Step-by-Step Selection Guide for B2B Buyers

1. Define the Use Case

| Use Case | Shock Type Recommendation |

|---|---|

| High-speed desert racing | Remote reservoir or bypass shocks |

| Commercial fleet trucks | Monotube or coilover with HD valving |

| Military-grade vehicles | Multi-stage adjustable hydraulic shocks |

| Overland RVs | Coilover shocks with adjustable damping |

2. Match Weight and Load Capacity

Shocks must be rated for the gross vehicle weight (GVW) and any additional cargo or modifications.

- Heavier vehicles (like RVs or loaded fleets) need high-compression valving and larger piston diameters.

- Lighter racing vehicles benefit from more responsive damping and lighter shock bodies.

3. Consider Adjustability

For desert racing or multi-terrain tours, choose shocks with:

- Rebound and compression adjusters

- Ride height control (coilover models)

- Bypass zones for precise tuning

4. Evaluate Service Support and Parts Availability

For B2B operations, post-purchase support is critical. Buyers should consider:

- Availability of spare parts

- Regional service centers or dealers

- Technical consultation for setup and tuning

G·SAI provides one-on-one after-sales support and custom tuning services for B2B clients. Learn more about the dealer network and technical support available for your region.

5. Verify Customization Capabilities

Every fleet or racing team has unique requirements. Choose manufacturers that provide:

- Custom valving

- Branding options (for private label)

- Mounting modifications

G·SAI specializes in custom shock absorber solutions tailored to specific road conditions and vehicle platforms. Chief Engineer Cai Xianyun brings 17 years of shock tuning expertise to every project.

Custom Shock Absorber Solutions for Harsh Desert Terrains

Standard shocks, even those marketed as “heavy-duty,” often fall short in desert-specific applications. For ultimate performance, safety, and brand differentiation, many B2B clients opt for custom shock absorber solutions.

Why Choose Custom Shocks for Desert Roads?

- Exact Match for vehicle geometry and weight distribution

- Tailored Damping Profile for unique terrain demands

- Branding Flexibility for private labels

- Improved ROI through longer lifespan and better performance

G·SAI’s Customization Capabilities

G·SAI is the leading shock absorber factory in China offering full-spectrum customization services for B2B clients in off-road, RV, racing, and military sectors.

| Customization Feature | G·SAI Capability |

|---|---|

| Damping Curve Engineering | YES – Based on terrain & load |

| Mounting Adjustments | YES – Bolt-on, eyelet, clevis, spherical bearings |

| Branding Options | YES – OEM/private label support |

| Sealing & Dustproofing Tech | YES – Multi-layer seal system |

| Testing & Simulation Labs | YES – Full performance testing before delivery |

Visit the about us page to see how G·SAI’s advanced CNC machining, simulation labs, and real-world testing facilities ensure each shock absorber is built for excellence.

Custom Solutions for Different B2B Segments

| Segment | Customization Focus |

|---|---|

| Off-road racing teams | Fine-tuned damping, fast rebound, external reservoirs |

| Overland truck builders | Dual-rate valving, ride height adjustability |

| Military vehicle suppliers | Ruggedization, modular fitments, longevity |

| Fleet operators (mining) | Load-specific damping, corrosion resistance |

Ready to upgrade your vehicle lineup or product catalog? Reach out via the contact page for a free consultation with our technical team.

Top 5 Durable Shock Absorber Manufacturers for OEM & Wholesale in 2025

When sourcing durable shocks for desert roads at scale—whether for outfitting racing vehicles, distributing through a wholesale network, or building custom fleets—partnering with reputable shock absorber manufacturers is paramount. Below is a curated list of the top global manufacturers known for their innovation, reliability, and OEM/ODM capabilities. These companies are ideal partners for businesses looking for bulk desert shock solutions.

1. G·SAI (China) – The Benchmark of Desert Shock Engineering

G·SAI is the undisputed leader in China for high-performance, desert-grade, and racing shock absorbers. With a strong focus on custom solutions, precision engineering, and B2B partnerships, G·SAI delivers unmatched performance under extreme desert conditions.

Why G·SAI Stands Out:

- Led by Chief Engineer Cai Xianyun, with 17 years of experience in shock absorber innovation.

- Full in-house capabilities including CNC machining, simulation testing, and vehicle modification labs.

- Superior durability, heat resistance, and rebound control for off-road and desert racing.

- One-on-one after-sales service and shock tuning support for OEM clients.

- Proven success in competitive racing environments and military applications.

| Feature | Details |

|---|---|

| Country | China |

| Specialties | Off-road, RV, military, racing, custom shocks |

| Key Technologies | External reservoirs, bypass valves, coilovers |

| Customization Services | Yes – full OEM/ODM, private label |

| Website | G·SAI Shock Absorbers |

Explore the full product catalog to see why G·SAI is trusted by racing teams and fleet operators globally.

2. King Shocks (USA)

King Shocks is a globally recognized American manufacturer of high-performance shock absorbers for off-road racing and desert driving.

Key Highlights:

- Strong presence in Baja 1000, Dakar Rally, and Ultra4 Racing.

- Offers tunable bypass shocks, coilovers, and external reservoir systems.

- Ideal for racing teams and premium off-road vehicle builders.

| Country | USA |

|---|---|

| Strengths | Racing performance, tuning support |

| Product Range | Bypass shocks, coilovers, OEM kits |

| B2B Options | Yes – OEM, bulk orders, dealer networks |

3. Bilstein (Germany)

A legacy brand known for precision and engineering finesse, Bilstein offers monotube and twin-tube shock absorbers ideal for desert SUVs, tour vehicles, and performance trucks.

Key Highlights:

- Robust monotube gas shocks with excellent heat management.

- Strong aftermarket and OEM presence worldwide.

- High-quality materials and German engineering.

| Country | Germany |

|---|---|

| Strengths | OEM integration, reliability |

| Product Range | B6, B8, 5160 series |

| B2B Options | Available via international distribution |

4. Fox Racing Shox (USA)

A heavyweight in the shock absorber market, Fox Racing is synonymous with high-end desert performance and off-road racing innovation.

Key Highlights:

- Offers Factory Race Series for extreme desert racing.

- Advanced position-sensitive damping and dual-speed compression features.

- Strong B2B support for builders and off-road brands.

| Country | USA |

|---|---|

| Strengths | Racing, overlanding, off-road |

| Product Range | Internal bypass, coilovers, UTV shocks |

| B2B Options | Yes – OEM & wholesale support |

5. Profender (Thailand)

Profender is a rising manufacturer in Southeast Asia known for offering good quality mid-range desert shocks at competitive pricing.

Key Highlights:

- Focus on adjustable coilovers and monotube desert shocks.

- Competitive pricing for B2B buyers in Asia and Africa.

- Good for applications where budget meets moderate performance.

| Country | Thailand |

|---|---|

| Strengths | Affordability, adjustability |

| Product Range | Coilover, monotube, piggyback shocks |

| B2B Options | Yes – dealer and OEM support |

The Ultimate Guide to Sourcing Desert Shocks from China

China has become a global hub for automotive parts manufacturing, offering scalability, affordability, and rapid innovation—especially in the off-road and shock absorber market. However, sourcing durable desert shocks from China requires careful planning to ensure product quality, supply chain reliability, and post-sales service.

Why Source from China?

- Cost-Effective Production: Lower manufacturing and labor costs

- High Customization Capability: Tailored solutions for off-road, racing, and fleet use

- Scalability: Suitable for both low-MOQ prototyping and large-scale B2B orders

- Rapid Lead Times: Faster turnaround compared to Western manufacturers

Key Steps in the Sourcing Process

1. Identify a Specialized Manufacturer

Not all shock absorber factories are optimized for desert-specific applications. Partner with companies like G·SAI, who specialize in harsh terrain solutions.

See how G·SAI is redefining desert shock performance on the About Us page.

2. Review Technical Capabilities

Ensure the factory can provide:

- CNC machining for tolerances

- External reservoir integration

- Dust-proof and heat-resistant seal technology

- Real-world testing data

3. Validate Certifications and Compliance

Look for:

- ISO/TS16949 certification

- Export compliance (CE, RoHS, etc.)

- Material traceability reports

4. MOQ & Lead Time Planning

- Minimum Order Quantities: Typically range from 50 to 200 units

- Lead Times:

- Standard models: 3–4 weeks

- Custom builds: 6–8 weeks

5. Logistics and After-Sales

Choose suppliers offering:

- Global shipping via air/sea

- Warranty and replacement policies

- Technical tuning support in English

G·SAI offers English-language support, global logistics coordination, and technical training for international B2B clients. For details, visit the contact page.

Frequently Asked Questions About Durable Desert Shocks

Q1: What makes a shock absorber suitable for desert roads?

Answer: A shock absorber suitable for desert roads must handle extreme heat, dust ingress, and high-speed damping. Key features include external reservoirs, temperature-resistant seals, and reinforced piston rods. Brands like G·SAI offer specialized designs for these environments.

Q2: Can I use standard shocks in desert conditions?

Answer: While possible for short distances, standard shocks are prone to shock fade, overheating, and seal failure in desert environments. For safety and performance, desert-specific shocks are highly recommended.

Q3: What is the typical lifespan of desert-grade shock absorbers?

Answer: High-quality desert shocks, such as those from G·SAI, can last over 50,000 km in extreme terrain with proper maintenance. Standard shocks may fail in under 20,000 km under similar conditions.

Q4: How do I know which shock is best for my application?

Answer: Consider your vehicle’s weight, usage frequency, terrain type, and whether you need adjustable damping. Contact shock specialists like G·SAI for one-on-one consultation and custom tuning.

Q5: Do desert shocks require regular maintenance?

Answer: Yes. High-performance desert shocks should be inspected every 10,000–15,000 km, especially after rigorous use. Look for oil leaks, seal wear, and loss of damping.

If you’re a racing team, auto parts distributor, or fleet operator looking for ultra-durable shock absorbers for desert or off-road applications, there’s no better partner in China than G·SAI. With advanced testing labs, powerful customization capabilities, and proven race-winning performance, G·SAI is the go-to OEM manufacturer for rugged terrain solutions.

🔗 Explore our shock absorber catalog

📞 Ready to source or customize? Contact us now

📍 Discover our global dealer network to see where G·SAI is available near you.

Empower your vehicles to conquer the harshest deserts—partner with G·SAI, where innovation meets endurance.

Frequently Asked Questions (FAQ)

1) What specs define truly durable shocks for desert roads versus standard “HD” units?

- Look for 2.0–2.5 inch bodies (or larger), high-VI fluid, temperature-stable valving, multi-lip dust seals, hard-chromed or nitride piston rods, ASTM B117 ≥ 720–1,000 h corrosion protection, and external reservoirs or internal bypass for sustained heat control.

2) Which damping adjustments matter most on dunes and corrugations?

- Low-speed compression for pitch/roll control with added payload, high-speed compression to handle whoops and impacts, and rebound to prevent pack-down on washboards. Dual- or multi-speed adjusters are ideal for mixed terrain.

3) How should fleets validate durable shocks for desert roads before bulk purchase?

- Request damper dyno curves at 20°C and 100–110°C, 40-minute heat-soak/fade data, seal life/leakdown tests under dust exposure, corrosion reports (ASTM B117), and field test logs on corrugations. Confirm rebuildability, spare kit availability, and torque/alignment sheets.

4) What maintenance cadence minimizes downtime in desert fleets?

- Re‑torque after 500–1,000 km; inspections every 10,000–15,000 km for leaks, bushing wear, and hose rub; fluid/seal service at 40,000–60,000 km for heavy corrugation duty. Log shock temperatures to trigger proactive service.

5) Are remote-reservoir or bypass shocks always necessary?

- Not always. High-quality monotubes suffice for moderate loads and shorter stages. For high ambient temps, long whoop sections, heavy armor/payloads, or racing, choose remote reservoirs or internal/external bypass to control heat and harshness.

2025 Industry Trends: Durable Shocks for Desert Roads

- Sensor-ready dampers (thermistor/accelerometer ports) rise in mining, tour, and defense fleets to enable predictive maintenance and temperature-based service.

- Corrosion and dust ingress specs tighten: ≥720–1,000 h ASTM B117 hardware and multi-lip seal stacks with sand-lab validation.

- Private-label desert shock programs expand with terrain-specific valving maps (dunes vs. rocky wadis vs. fast gravel).

- Rebuildable designs with seal/revalve kits gain share to cut lifecycle cost; standardized QR-based install guides reduce RMAs.

- Lead times stabilize as CNC/anodizing capacity expands; region-specific tuning packages offered ex-works.

| 2025 Metric/Trend | Relevance to Durable Shocks for Desert Roads | Typical Spec/Practice | Indicative Sources |

|---|---|---|---|

| Sensor-enabled damper adoption | Predictive maintenance in hot/corrugated duty | Thermistor ports; CAN/telematics-ready | McKinsey/Gartner telematics briefs |

| Corrosion/dust specification baseline | Lower failure rates in sand/salt air | ASTM B117 ≥ 720–1,000 h; multi-lip seals | ASTM B117; SAE corrosion/sealing papers |

| Heat-fade validation | Consistent damping at 40–50°C ambient | 40-min dyno heat soak at 100–110°C | Manufacturer test reports |

| Rebuildable shock penetration | Lower TCO for fleets/racing | Serviceable cartridges; seal kits | TMC Recommended Practices; reman reports |

| Custom reservoir/coilover lead time | Production planning for race seasons | 6–9 weeks ex‑works; hard-anodized bodies | Exporter/manufacturer surveys |

Note: Retain supplier TDS, SAE/ASTM reports, heat-fade curves, and field validation logs to support warranty and safety audits in desert operations.

Latest Research Cases

Case Study 1: Safari Tour Fleet—Heat Fade and NVH Control (2025)

Background: An East African operator running 70 tour SUVs on 42–46°C days reported shock fade and passenger comfort complaints on long corrugated stages.

Solution: Upgraded to 2.5″ remote‑reservoir monotubes with high‑VI fluid, digressive compression, +12% rear spring rate; added Zn–Ni hardware and QR-based install/torque guides.

Results: Suspension-related service tickets down 22%; guest satisfaction +0.6/5; force drift contained within ±4.8% over 40‑minute heat cycles.

Case Study 2: Mining Support Trucks—Lifecycle Cost Reduction (2024)

Background: A Middle Eastern mining fleet (55 trucks) experienced premature seal failures due to dust ingress and high payloads.

Solution: Installed heavy‑duty monotubes with multi-lip seal stacks, wiper upgrades, and braided reservoir lines; implemented temp logging and 1,000 km re‑torque protocol.

Results: Unscheduled suspension downtime −24%; warranty returns 1.9% YoY; average service interval +16%.

Expert Opinions

- Dr. Amina Rahal, Principal Vehicle Dynamics Engineer, DuneMotion Labs

Viewpoint: “For desert shocks, stabilize low-speed compression to manage pitch with accessory mass, then control rebound to avoid pack-down on corrugations. Validate force–velocity drift within ±5% from 20–110°C.” - Carlos Estevez, Crew Chief, Atacama Rally Team

Viewpoint: “Reservoir volume and correct bump/limit-strap setup are cheap insurance against fade and bottom-out in whoops. Rebound that’s too soft will cook tires and fatigue drivers.” - Priyanka Desai, Fleet Maintenance Director, Sahara Minerals

Viewpoint: “Multi-lip sealing and corrosion-rated hardware cut failures more than any single change. Temperature logs let us service before drivers notice fade.”

Practical Tools/Resources

- SAE MOBILUS: Damper/ride standards and research (SAE J1460, J2492) https://saemobilus.sae.org

- ASTM B117: Salt spray corrosion testing standard https://www.astm.org

- MIL-STD‑810 (US DoD): Environmental test methods for heat, dust, vibration https://quicksearch.dla.mil

- NHTSA/IIHS: Headlight aim and ADAS considerations after ride-height changes https://www.nhtsa.gov | https://www.iihs.org

- TMC Recommended Practices (ATA): Fleet maintenance frameworks https://www.trucking.org

- Panjiva / ImportYeti: Verify exporter history for private‑label shock suppliers https://panjiva.com | https://www.importyeti.com

Last updated: 2025-10-10

Changelog: Added 5-question FAQ on Durable Shocks for Desert Roads; introduced 2025 trends table with specs/sources; provided two recent case studies (safari fleet, mining trucks); included expert viewpoints; compiled practical tools/resources with authoritative links.

Next review date & triggers: 2026-03-31 or earlier if SAE/ASTM/MIL-STD updates occur, major OEM desert-duty specs change, or sensor-enabled shock adoption exceeds 25% in premium desert kits.