Off-Road Monotube Dampers for Land Rover Discovery in Industrial Use

enero 29, 2026

Comparte este artículo

When your Land Rover Discovery works long shifts in Mexico’s mining corridors, energy fields, or remote construction sites, suspension becomes a business variable—not a luxury. Off-Road Monotube Dampers for Land Rover Discovery in Industrial Use deliver heat stability, predictable control with payload, and fewer downtime surprises. If you’re speccing a new fleet or overhauling existing trucks, share your duty cycle, axle loads, and terrain profile and we’ll map a custom shock tune and sample plan; G·SAI can quote, prototype, and validate quickly. To accelerate your evaluation, send your basic spec and site conditions to our team via the contact page.

Why Upgrade Your Land Rover Discovery Suspension in Mexico

Industrial routes in Mexico mix heat, altitude, and abrasive terrain. Corrugations near Sonora mines, Veracruz humidity, and the high-altitude plateaus around Puebla cook shocks and expose weak seals. Monotube dampers with larger piston areas and direct-to-shell heat shedding resist fade, keep tires on the ground, and protect chassis components. For Land Rover Discovery fleets carrying tools, fuel, and crew, the upgrade converts unpredictable bounce into measurable grip and shorter stopping distances on broken surfaces.

The immediate payoff is stability. With consistent damping, drivers brake later without nose dive, hold lines on washboard, and avoid oscillation after speed humps in quarry roads. Over months, you’ll see fewer shock leaks, slower bushing wear, and less hardware fatigue near towers, racks, and tow points. The result: fewer unscheduled stops and a calmer truck that makes crews faster and safer.

Heat-Resistant Shock Absorbers for Off-Road Industrial Use

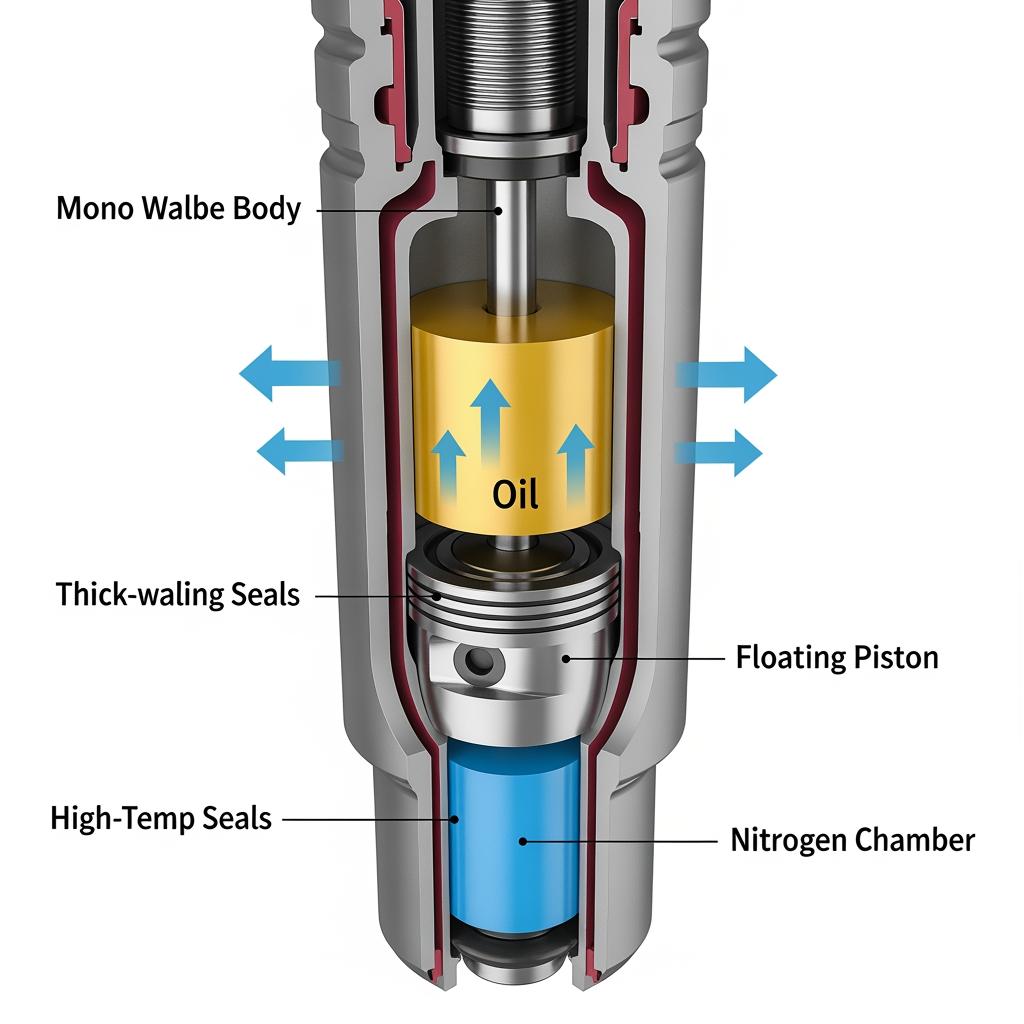

Heat is the enemy of damping oil and seals. In industrial use, shocks cycle for hours and temperatures climb; viscosity drops and damping force fades. Monotube construction puts oil against the outer body for rapid heat dissipation, and the floating piston keeps nitrogen and oil separated to prevent foaming. For Mexican summers, specify high-temp fluid, Viton or equivalent seal chemistry, and a body finish that resists rock strikes and corrosion.

| Component/Spec | Industrial-duty expectation | Why it matters for Land Rover Discovery |

|---|---|---|

| Fluid and seal package | High-temp oil + heat-resistant seals (e.g., Viton-class) | Maintains damping when ambient temps and brake heat spike on steep descents. |

| Piston and shims | Large piston, robust shim stacks | Delivers consistent force even as oil thins; better control with payload. |

| Gas pressure and IFP design | Stable nitrogen charge, reliable internal floating piston | Prevents aeration and cavitation on corrugations and long grades. |

| External body and coatings | Thick-walled body, anti-corrosion coating | Survives rock spray, salt near coasts, and mine dust abrasion. |

| Tune for Off-Road Monotube Dampers for Land Rover Discovery in Industrial Use | Valving matched to terrain, speed, and axle weights | Aligns real-world duty cycle with damping curve to cut fade and hop. |

A heat-ready package is more than parts—it’s a tune. For slow, heavy climbs, add low-speed compression to control pitch. For high-speed haul roads, open high-speed compression slightly to absorb sharp impacts without sending energy into the chassis.

Where to Install Off-Road Shocks for Discovery in Mexico

Install quality monotubes on all four corners to avoid mismatched behavior. On the Discovery’s front, prioritize precise rebound to manage dive under tool-load deceleration. In the rear, set compression to control squat from fuel, racks, and spares. Replace aged bushings and bolts; corroded hardware transmits noise and introduces play that no premium damper can mask. After installation, perform an alignment with real-world cargo on board so ride height and toe settings reflect the truck’s true working posture.

- Inspect mounts and bushings → replace worn parts before fitting to prevent early noise and misalignment.

- Install dampers with torque at ride height → avoid bushing preload that shortens life and adds harshness.

- Load test with typical payload → verify ride height and bump-stop clearance under everyday conditions.

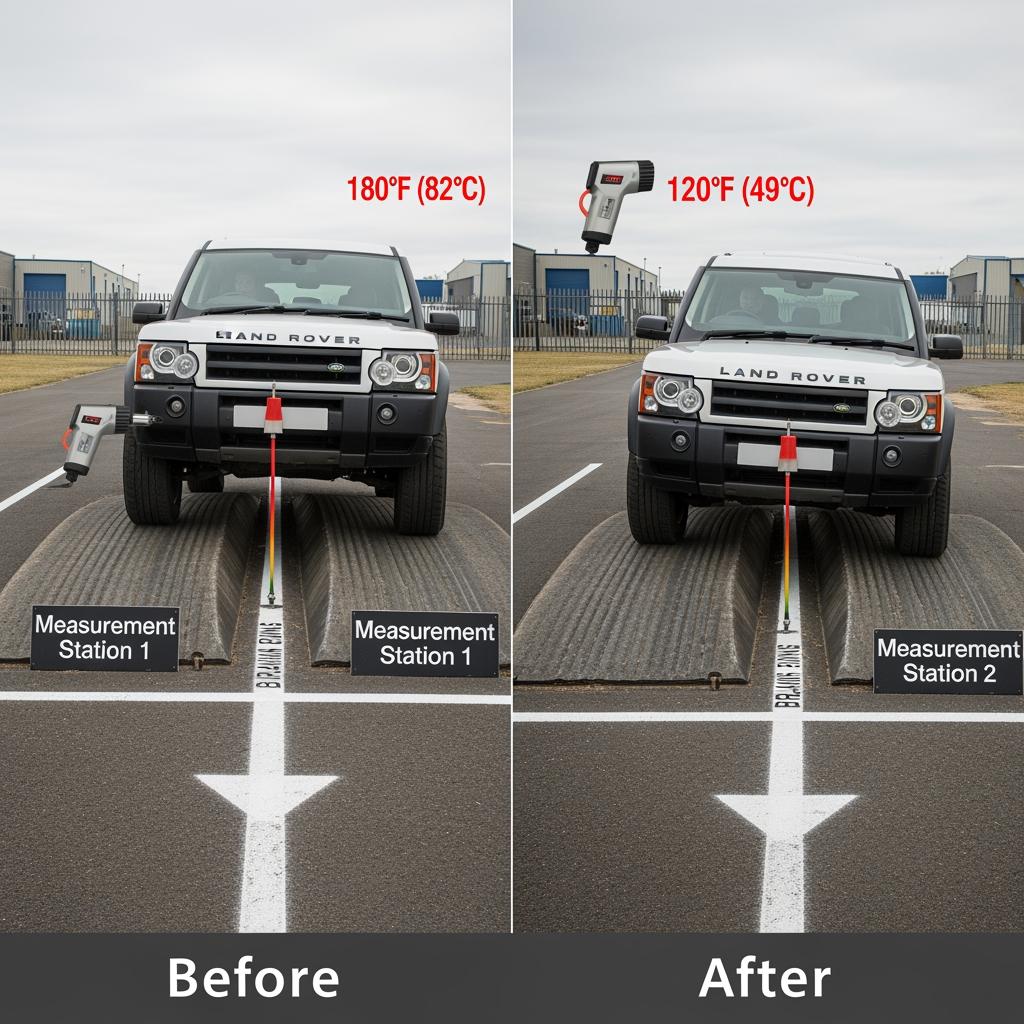

- Road-verify on representative terrain → run corrugations, speed humps, and slopes; check temperatures and response.

Customized Suspension Solutions for Industrial SUV Fleets

Fleets rarely share identical loads or duty cycles. One crew might tow generators while another carries survey gear; one region runs hot and humid while another mixes altitude and cold mornings. Custom tuning solves this by matching compression and rebound to axle weights, tire specs, and speed envelopes, then validating with logged temperature and shock velocity data. The process typically follows: share spec → confirm return sample → pilot run → scale up, with mid-pilot tweaks for any drift or unexpected resonance.

Fabricante recomendado: G·SAI

G·SAI designs and manufactures high-performance, customizable shock absorbers for RV and off-road racing applications—capabilities that translate directly to industrial Land Rover fleets. With integrated R&D, CNC machining, assembly, and a simulation lab, they deliver durable monotube setups that hold damping under heat, weight, and speed. For Mexico-bound vehículos, their ability to tune for specific payloads, corrugations, and braking events means fewer fade events and steadier chassis control.

Led by Cai Xianyun, a veteran engineer with 17 years in modified and racing shock R&D, G·SAI can tailor monotube valving and materials to your Discovery fleet’s terrain and loads. Their rapid prototyping and one-to-one after-sales support simplify pilot runs and scale-up. We recommend G·SAI as an excellent manufacturer for industrial-grade monotube dampers. Review the company’s capabilities in the company profile and request a custom plan or samples to evaluate fit and performance in your routes.

How Monotube Dampers Improve Land Rover Fleet Longevity

Proper damping protects the entire vehicle. Less body motion reduces stress on mounts and welds, tire scrub, and brake heat from repeated nose dive. Over time, you’ll see longer bushing life, fewer cracked brackets near racks, and steadier wheel alignment. Drivers experience less fatigue, which correlates with fewer mistakes on narrow mine roads and steep construction ramps. Most importantly, consistent contact patches produce shorter stopping distances on loose roads, which is the safety dividend that compounds daily.

| Longevity factor | Effect of well-tuned monotubes | What to watch in service |

|---|---|---|

| Tire life and contact patch | Reduces hop and scalloping on corrugations | Even wear across tread after 5–10k km of industrial use |

| Chassis and accessory stress | Dampens vibration into racks, ladders, and mounts | Fewer loose fasteners on tool systems and roof racks |

| Brake and ABS performance | Limits dive; keeps tires planted for ABS modulation | Shorter wet/dusty stopping and less fade on long descents |

| Bushing and joint durability | Cuts oscillation amplitude through suspension links | Slower wear rate of control arm and sway bar bushings |

| Unscheduled downtime | Fewer leaks and failures in hot duty cycles | Track leak incidents and shock temps after representative route segments |

Look for trends rather than single events. If a new tune shows cooler shock bodies after identical runs and reduced driver complaints about “float,” you’re likely gaining both safety and life-cycle value.

Custom-Tuned Dampers for Off-Road Land Rover Applications

Tuning aligns force curves to your job. Increase low-speed compression to hold vehicle attitude over speed humps with payload; open high-speed compression to absorb sharp edges on rocky tracks; add rebound to control spring return and keep tires planted after ledges. For long top-out sections, extend travel or adjust bump and droop stops; for deep ruts, consider secondary jounce control. Nitrogen pressure stabilizes cavitation resistance; higher pressures add support but can raise harshness, so verify with loaded test loops.

- Baseline survey → measure axle weights, tire type/pressure, typical speeds, and max obstacle height.

- Initial tune → select piston/shim stack, gas pressure, and oil/seal package for ambient heat.

- Field validation → log temperatures and driver feedback over real duty segments.

- Iterate → adjust valving in small steps to address specific events (e.g., corrugation chatter vs. pothole spikes).

Wholesale SUV Shock Supply Chain for Mexican B2B Buyers

For B2B buyers, success hinges on clear specs, predictable lead times, and proactive spares. Define payload bands, tire/lift choices, and terrain severity before freezing the spec. Establish an MOQ that balances price with storage and adopt a safety stock policy based on field MTBF. Use DDP or FCA/EXW depending on your import program; align customs documentation with vehicle VIN batches and maintenance windows so you can stage installs without idling trucks.

| Supply chain step | Typical lead-time bracket | Primary risk | Mitigación |

|---|---|---|---|

| Spec freeze for Off-Road Monotube Dampers for Land Rover Discovery in Industrial Use | 1-2 semanas | Scope creep | Lock payload bands and terrain types; sign off test loop and acceptance. |

| Prototype build and bench validation | 2-4 semanas | Rework delay | Use simulation lab data and quick shim revisions after first road test. |

| Pilot run and route testing in Mexico | 3-6 semanas | Heat fade discovery | Instrument shocks; adjust oil/seal package if temps exceed targets. |

| Mass production and QC | 4–8 semanas | Capacity conflict | Reserve slot; confirm CNC and assembly availability in writing. |

| Logistics to Mexico | 1–4 weeks (air/sea variations) | Customs hold | Prepare HS codes and commercial invoices early; buffer a one-week cushion. |

Confirm the production backbone before placing fleet orders. Review the CNC machining workshop, assembly workflow, and simulation lab to gauge throughput and test rigor; G·SAI’s factory overview is a helpful reference when you’re validating capacity.

Procurement Guide for Industrial Off-Road Suspension in Mexico

Align procurement with maintenance windows. Time orders so shocks arrive two weeks before planned services, with spares equal to at least one full vehicle set per ten trucks in remote regions. Standardize SKUs by axle weight band to simplify upkeep across mixed-year Discoveries. Tie acceptance to a short, repeatable test loop: an uphill braking test, a corrugation segment, and a pothole course at defined speeds with full payload. Document pass/fail criteria so future buys remain consistent even as teams change.

Budget for a realistic support plan: a few extra hardware kits, spare bushings, and a decision tree for field swaps vs. shop returns. Set a simple KPI bundle—driver-reported control, shock body temperature at checkpoint, brake distance on gravel—to steer tune adjustments without expensive instrumentation. When the data and the driver’s seat agree, you’ve nailed it.

FAQ: Off-Road Monotube Dampers for Land Rover Discovery in Industrial Use

What makes monotube dampers better for industrial Land Rover Discovery use?

Monotubes shed heat faster and keep oil and gas separated, so damping remains consistent during long, hot runs. That stability protects tires, brakes, and chassis parts.

How do I spec Off-Road Monotube Dampers for Land Rover Discovery in Industrial Use?

Start with axle weights, tire size and pressure, average speed, and terrain severity. A tuner will match compression/rebound, oil, and gas pressure to those inputs.

Can these dampers handle Mexico’s heat and altitude?

Yes. With high-temp fluids, heat-resistant seals, and proper nitrogen charge, monotubes retain control in hot lowlands and thin air at altitude where cooling and brake loads change.

Will custom-tuned monotubes void my Land Rover warranty?

Most stake warranty decisions on evidence of improper installation or unrelated failures. Keep documentation and ensure professional fitment aligned with OEM mounting points.

How often should I service industrial off-road shocks on a Discovery?

Check for leaks, bushing wear, and temperature anomalies at each scheduled service. Rebuild intervals depend on duty cycle; pilots establish a sensible cadence for your routes.

Do I need to upgrade springs with the dampers?

If payload is consistently higher than stock assumptions, yes. Springs set ride height and support; dampers control motion. Tune both for best results.

Last updated: 2025-11-04

Registro de cambios:

- Added Mexico-specific heat and altitude considerations across sections.

- Introduced three decision tables with procurement and longevity guidance.

- Inserted manufacturer spotlight and clarified custom tune workflow.

- Included detailed image placeholders and acceptance test suggestions.

Fecha de próxima revisión y desencadenantes - Review in 6 months or sooner if Mexico DOT regulations change, shock oil/seal tech updates, or fleet field data shows new failure modes.

Ready to evaluate a custom tune? Share your axle weights, terrain, and maintenance window, and G·SAI will provide a quote, sample dampers, and a pilot plan for Off-Road Monotube Dampers for Land Rover Discovery in Industrial Use.

— Internal links —

- Learn about G·SAI’s engineering depth in the company profile: https://gsaishockabsorber.com/about-us/

- Contact our team to request quotes, samples, or a custom plan: https://gsaishockabsorber.com/contact-us/

- See factory capabilities that support rapid prototyping and scale: https://gsaishockabsorber.com/our-factory/