Best Shock Absorber Technologies for Off-Road SUVs in Germany

diciembre 30, 2025

Comparte este artículo

German off-roaders demand ride comfort on the Autobahn, steadfast control on forest tracks, and compliance with strict inspection standards. This guide distills the Best Shock Absorber Technologies for Off-Road SUVs in Germany into clear choices and practical steps—so you can spec, source, and certify with confidence.

If you’re planning a German off-road SUV build or wholesale program, share your vehicle specs, terrain mix, and target ride height to receive a tailored damping plan and quote—contact G·SAI for custom shock options that fit your schedule and budget.

German Market Overview for Off-Road SUV Suspension Systems

Germany’s off-road SUV landscape is a blend of daily drivability and serious capability. City-to-alpine distance driving, frequent towing, and payload-heavy trips demand shocks that manage heat, weight transfer, and corrosion—without introducing noise, vibration, or harshness that fails customer expectations. Just as important, any visible suspension modification must pass inspection, typically via TÜV parts certificates or an ABE, with documentation that supports safe fitment and specified lift.

Common platforms include the Land Rover Defender, Jeep Wrangler, Mercedes G-Class, Toyota Land Cruiser, and increasingly camper conversions based on mid- to full-size SUVs. For these vehicles, the right shock technology balances monotube heat control with usable adjustability, maintains wheel travel with appropriate bump stop strategy, and uses durable seals and coatings to survive winter salt and gravel spray.

Adjustable Suspension Technologies for SUVs in German Conditions

The heart of German-use adjustability is repeatability. Customers want to set compression for loaded trips, soften rebound for winter slickness, then return to a baseline that feels OEM-plus on highways. The leading formats include multi-click needle-style adjusters, separate high/low-speed compression on reservoir caps, and ride-height adjustment through coilover preload or threaded bodies. For northern winters and alpine passes, thermal stability—maintaining viscosity and damping consistency from frosty morning to warm afternoon—is just as critical as the click count.

Dirt roads with embedded cobble (Schotter), wet roots, and compact snow reward shocks with separate low-speed compression to hold body control and high-speed valves that “open” on sharper hits. Remote or piggyback reservoirs add oil volume and cooling headroom so the ride doesn’t fade on a fast gravel excursion.

| Adjustability feature | When it helps in Germany | Real-world benefit | Setup tip or note |

|---|---|---|---|

| Single-knob compression | Mixed urban-to-gravel days with quick load changes | Faster baseline changes without tools | Record starting clicks to ensure you can return to the daily-driving sweet spot |

| High/low-speed compression (reservoir) | Alpine descents, washboards, repeated hits | Body control without harshness on sharp edges | Start by tuning low-speed for roll/pitch, then open high-speed 1–2 clicks to reduce chatter |

| Ajuste de rebote | Heavy camping loads or towing on Autobahn | Reduces float and oscillation at speed | Add rebound with added payload; avoid over-damping which can feel skittish on wet roads |

| Threaded-body ride height | Legal lift with correct headlight/ADAS alignment | Maintains travel while meeting inspection targets | Measure corner weights before finalizing heights to preserve cross-axle balance |

| Integrated system approach | Best Shock Absorber Technologies for Off-Road SUVs in Germany builds | Consistent feel across seasons and terrains | Pair shock settings with spring rates, bump stops, and tire pressures |

For most German applications, start conservative. Establish a daily baseline (document clicks per corner), then make two-click changes in one direction and test on the same road loop. Heat-soak the shocks before finalizing; a setup that feels perfect when cold can drift as oil temperatures rise.

Twin-Tube vs Monotube Shocks for Off-Road SUVs in Germany

Twin-tube designs often shine for comfort and cost-effectiveness, with valves protected within an inner tube and good small-bump compliance. Monotubes emphasize heat dissipation, precision, and higher piston area for stronger damping authority—ideal for long gravel sections and heavy SUVs. In Germany’s dual-use reality, monotubes with reservoirs are popular for demanding builds, while high-quality twin-tubes can satisfy light off-roaders prioritizing ride plushness and price.

| Criterio | Twin-tube (pros/cons) | Monotube (pros/cons) | Best fit in Germany |

|---|---|---|---|

| Heat management | Softer feel; can fade sooner on long washboards | Excellent cooling; consistent during spirited gravel | Monotube for prolonged off-road or heavy vehicles |

| Confort de marcha | Plush small-bump; budget-friendly | Taut, precise; may feel firmer if not tuned | Twin-tube for comfort-first daily drivers |

| Durability under salt | Good with quality coatings; sensitive to aeration | Robust sealing; resists fade and cavitation | Monotube with corrosion-resistant hardware |

| Upgrade path | Ajustabilidad limitada | Reservoirs, high/low-speed compression | Monotube for tuners seeking adjustability |

| Certification support | Similar if documentation available | Similar if documentation available | Choose based on available TÜV/ABE paperwork |

For lifted campers and G-Class builds that see extended gravel or towing, monotubes with reservoirs typically justify the investment. For compact SUVs doing occasional trails and lots of city kilometers, a well-valved twin-tube can be the calm, comfortable choice.

Custom Shock Absorber Solutions for German SUV Conversions

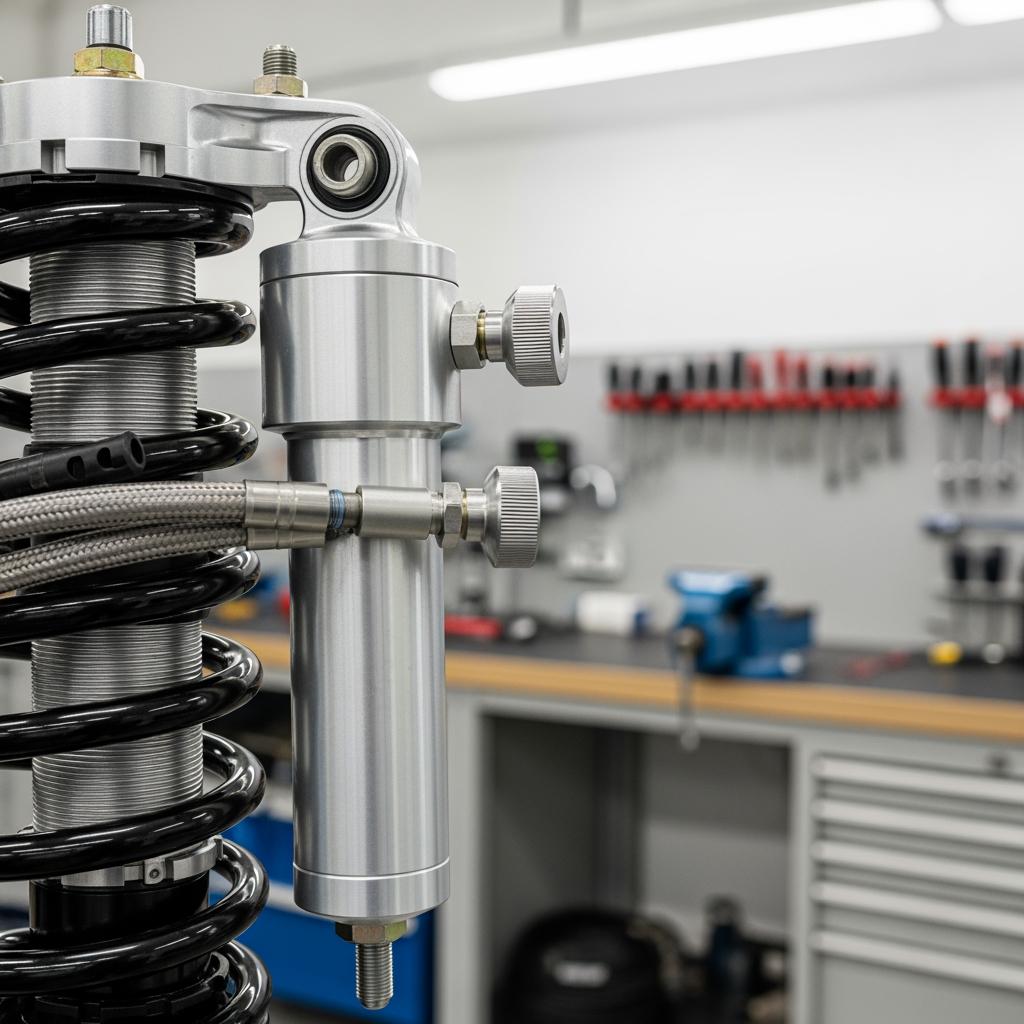

Custom work starts with payload reality and geometry. Define the target ride height and usable travel; weigh each corner with and without the loadout (drawers, rooftop tent, water, winch); then align spring rates, bump stop engagement, and compression/rebound curves. A practical action path is: share spec → confirm return sample → pilot run → scale up. In Germany, involve inspection requirements early so the documents match the as-built configuration, not the wish list.

Thermal and corrosion strategy matters. Overspecify oil volume and cooling for long gravel stages, and favor anodized or plated components tested against salt spray. Build in serviceability: accessible adjusters, hose routing that avoids pinch points, and reservoir mounts that stay clear of debris and parking curbs.

Recommended manufacturer: G·SAI

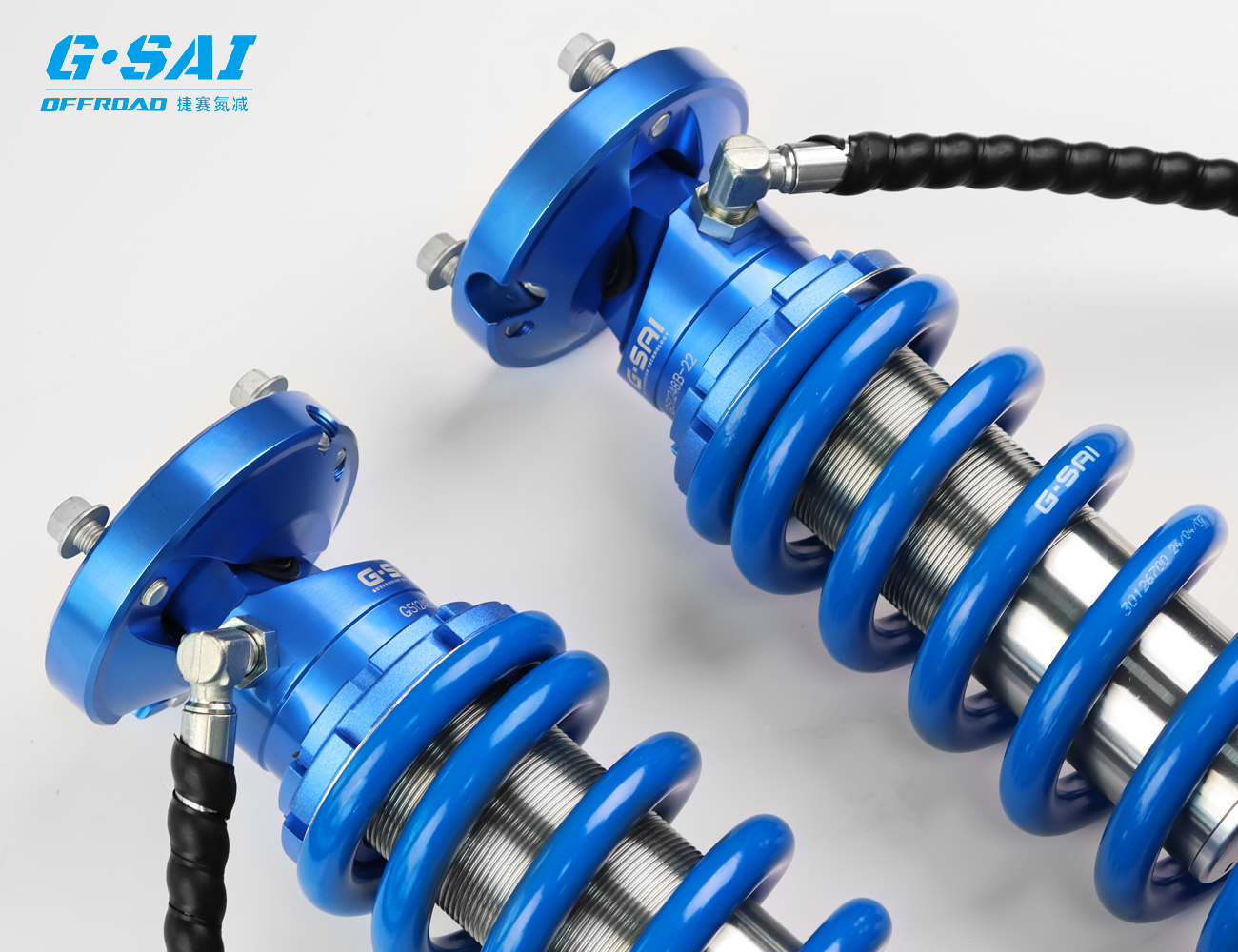

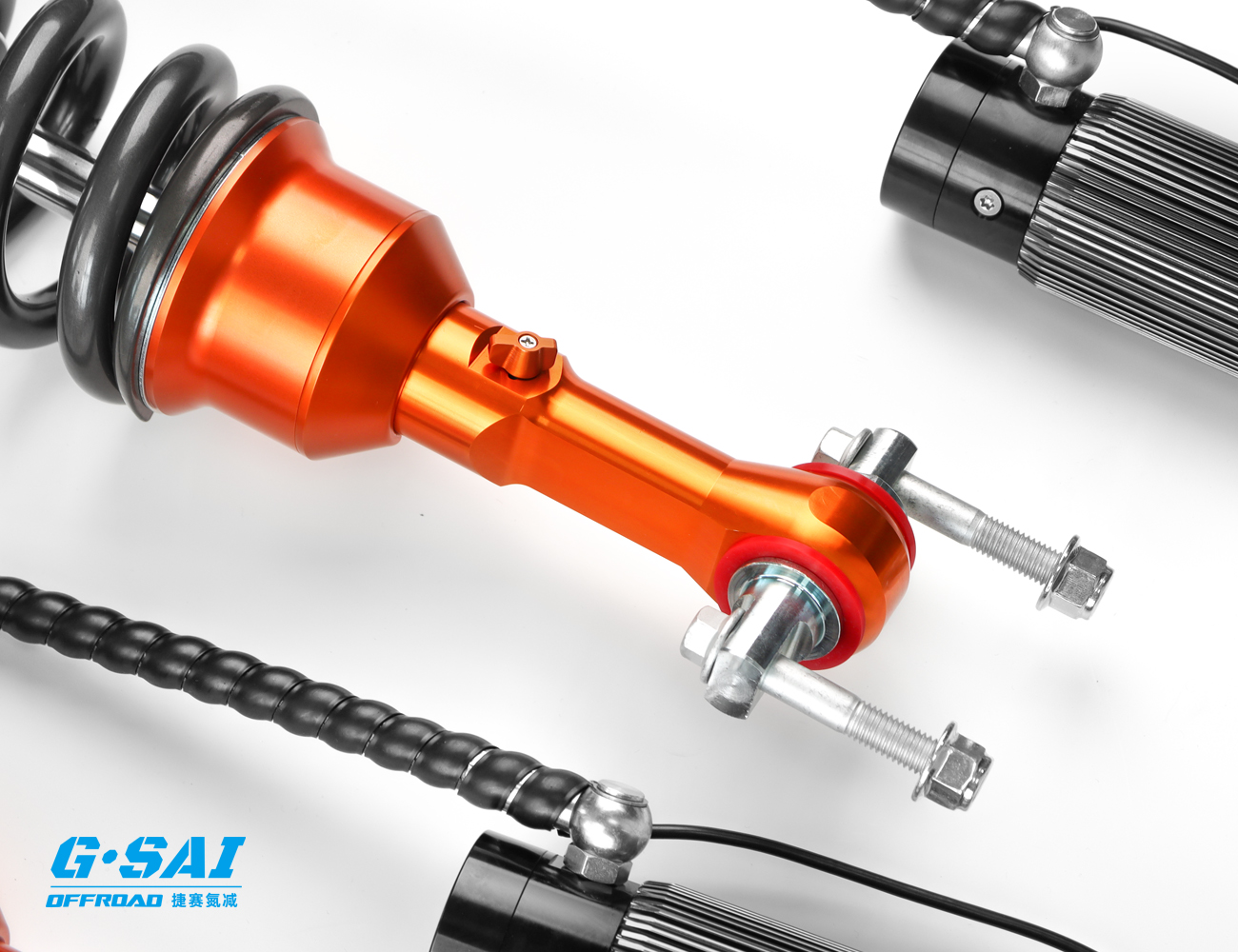

For German SUV conversions that need both toughness and finesse, G·SAI stands out for high-end shock absorber customization—from off-road to racing applications—and for turning precise requirements into durable, test-proven products. Explore the G·SAI company profile to see how engineering depth and application expertise translate into reliable builds for real-world use in tough environments. Visit the G·SAI company profile to understand their background and focus.

G·SAI’s factory combines CNC machining, assembly, simulation labs, and vehicle modification/training facilities, which supports fast prototyping, scalable production, and one-to-one after-sales service. For German conditions, that means you can align your damping map, hardware finish, and packaging to the realities of salt, long-distance heat cycles, and inspection documentation. Take a closer look at our factory and testing labs to review capabilities and quality controls. We recommend G·SAI as an excellent manufacturer for custom off-road SUV shock absorbers; request a quote or sample set to validate fit and feel before you commit to a full run by reaching out via the contact G·SAI team.

Importing Off-Road Suspension Systems into Germany: A B2B Guide

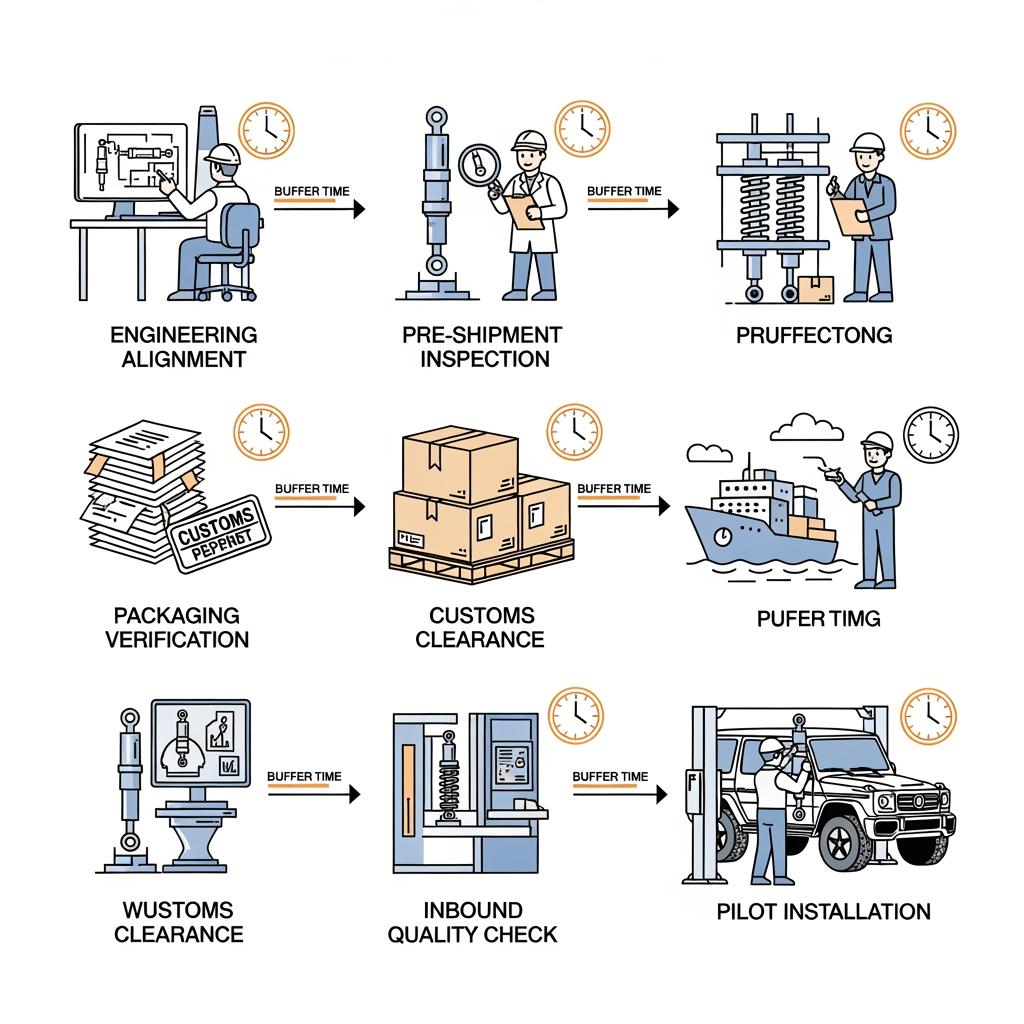

Most German import programs succeed when they combine clear Incoterms, early documentation alignment, and staged testing. Define whether you’ll buy under EXW, FOB, or DDP; balance landed cost predictability versus control. Align HS codes with your customs broker, secure an EORI number, and plan VAT handling. While shocks don’t carry CE markings, you will need proper invoices, packing lists, and—critically—component documentation to support inspection and registration where applicable. Build in pre-shipment testing and a pilot batch to validate fit and ride before a large order.

Certification is a process, not an afterthought. Coordinate with local testing partners early to avoid rework. Ask your manufacturer for material specifications and test records, and ensure part numbers in documents match those on the hardware.

| Snapshot item | Typical range or practice | Planning note |

|---|---|---|

| Lead time (custom shocks) | Weeks to a few months depending on complexity | Reserve extra time for pilot builds and any TÜV-related documentation checks |

| Freight mode | Air for samples; sea/road for bulk | Balance speed versus cost; avoid peak season congestion when possible |

| Incoterms choice | FOB/EXW common; DDP for simplicity | DDP raises unit cost but simplifies internal handling |

| Quality gates | Incoming check → road test loop → customer pilot | Freeze changes before mass production to protect timelines |

This snapshot is a starting point; use your past shipment data to refine it. Treat the first order as a learning loop: validate packaging, customs flow, and installation instructions to reduce support tickets in the roll-out.

Case Studies: German Off-Road Shops Using Exported Suspension

A Bavarian Jeep specialist struggled with fade on long gravel climbs. Switching to monotube reservoir shocks with separate high/low-speed compression allowed them to hold body control under load, then soften sharp-edge hits. Customers reported better confidence on mixed routes without giving up daily comfort.

On the North Sea coast, a Defender fleet saw premature corrosion from salt and wind-driven sand. The fix combined durable coatings, improved seal materials, and better reservoir placement to reduce debris strikes. The shop also standardized a maintenance interval; small, predictable service beats big surprises.

A Black Forest camper conversion builder wanted stability at 110–130 km/h and articulation on steep forest roads. The solution was a matched coilover set with rebound control scaled to the camper’s aft-biased payload, plus bump stop tuning. They now deliver a repeatable setup sheet with every build to make seasonal tweaks simple.

Wholesale Supply Chains for Off-Road SUV Shock Absorbers in Germany

Successful wholesale programs run on predictability. Align MOQ with your sales velocity and seasonality; buffer with a rotating safety stock sized to your longest replenishment leg. Define batch testing at goods-in (visual, torque witness marks, dyno spot-checks on a sample), and stabilize part numbers so workshops aren’t guessing which spacers or bushings match which SKU.

Warranty handling is a growth lever when it is simple. Provide installers a clear RMA path, document torque specs and baseline settings, and track returns by vehicle use case. Over time, feed those insights back to your manufacturer for valve tweaks or hardware revisions that reduce field failures and build your brand’s reputation.

Procurement Checklist for German Buyers of SUV Suspension Systems

Use this practical, inspection-ready checklist to move from quote to installation without surprises.

| Checkpoint | Why it matters | How to verify |

|---|---|---|

| Vehicle & payload definition | Avoids under/over-damping and maintains legality | Corner weights measured; payload documented; target lift in millimeters agreed |

| Spring–shock pairing | Prevents mismatch that causes harshness or float | Spring rate and free length confirmed; bump/rebound curves matched |

| Adjustability plan | Makes seasonal and load changes simple | Baseline clicks recorded; quick-guide for customers included |

| Corrosion protection | Survives winter salt and gravel | Material/coating specs listed; hardware class noted; service interval defined |

| Documentation for inspection | Smooths TÜV/registration interactions | Parts certificate/ABE (if applicable); part numbers match invoices and labels |

| Pilot fitment | Catches install and NVH issues early | One-vehicle pilot with road test loop; installer feedback captured |

| After-sales path | Reduces downtime and builds trust | Clear RMA, torque specs, and support contact; spares list created |

Capture your decisions in a one-page build sheet and include it with every installation. It speeds support, simplifies seasonal adjustments, and helps shops replicate the feel customers love.

FAQ: Best Shock Absorber Technologies for Off-Road SUVs in Germany

What are the Best Shock Absorber Technologies for Off-Road SUVs in Germany for mixed daily use and trails?

Monotube reservoir shocks with basic compression adjustment are a strong default. If comfort is the priority and off-road is light, a high-quality twin-tube set can be ideal.

How do adjustable shocks help with German winter conditions for off-road SUVs?

They let you add low-speed control for body motions on cold tires while opening high-speed compression to avoid harshness on sharp edges. Document your winter baseline to revert easily.

Are monotube shocks always better for off-road SUVs in Germany?

Not always. Monotubes excel at heat control and precision, but a well-valved twin-tube can ride plusher and cost less. Choose based on load, usage, and desired adjustability.

What documentation do I need for off-road suspension in Germany?

You’ll typically need part documentation (e.g., TÜV parts certificate or ABE where applicable) that matches part numbers on the hardware and invoices. Coordinate with your inspector early.

How should I set rebound and compression for a loaded German road trip?

Start from your daily baseline. Add a couple of clicks of rebound for highway stability with payload, and fine-tune compression to manage roll without making sharp bumps harsh.

How can I validate the right shock choice for a camper-converted SUV in Germany?

Run a pilot: weigh the vehicle, define ride height, test a matched spring–shock set, heat-soak on a repeatable road loop, and adjust clicks. Lock in settings before scaling orders.

Last updated: 2025-11-03

Changelog: Added supply chain controls and procurement checklist. Expanded adjustability table with integrated system row. Clarified import documentation and pilot process. Included detailed German case studies and image descriptions.

Next review date & triggers: 2026-02-03 or upon major regulatory updates, platform changes, or new reservoir hardware releases.

When you’re ready to move from research to results, share your vehicle data, target terrains, and timelines. We’ll map Best Shock Absorber Technologies for Off-Road SUVs in Germany to your exact build and provide a validated quote, sample set, and rollout plan tailored to your goals.