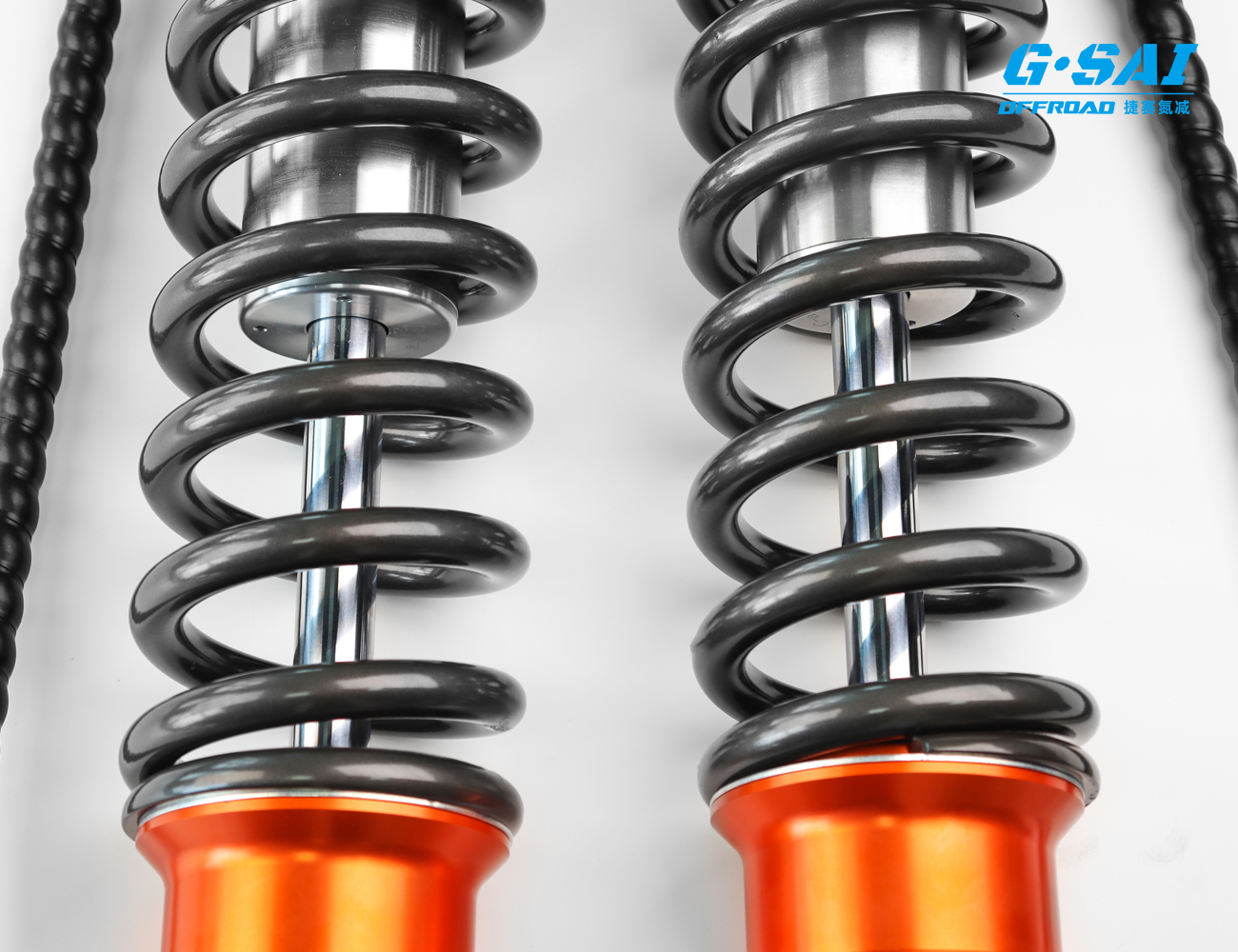

Mexico-Focused Shock Absorber OEM Solutions for Off-Road Applications

noviembre 19, 2025

Comparte este artículo

If you sell, upfit, or maintain SUVs for work or recreation in Mexico, you already know terrain can make or break suspension performance. This guide distills Mexico-Focused Shock Absorber OEM Solutions for Off-Road Applications into clear decisions on tuning, branding, sourcing, and fleet rollout—so you can spec correctly the first time, protect margins, and keep vehicles planted and predictable. If you’re evaluating custom shock programs for Mexico, share your requirements and get a tailored quote or sample plan—G·SAI provides these custom services; you can contact our team directly via the contact page.

OEM Suspension Systems for Off-Road SUVs in the Mexican Market

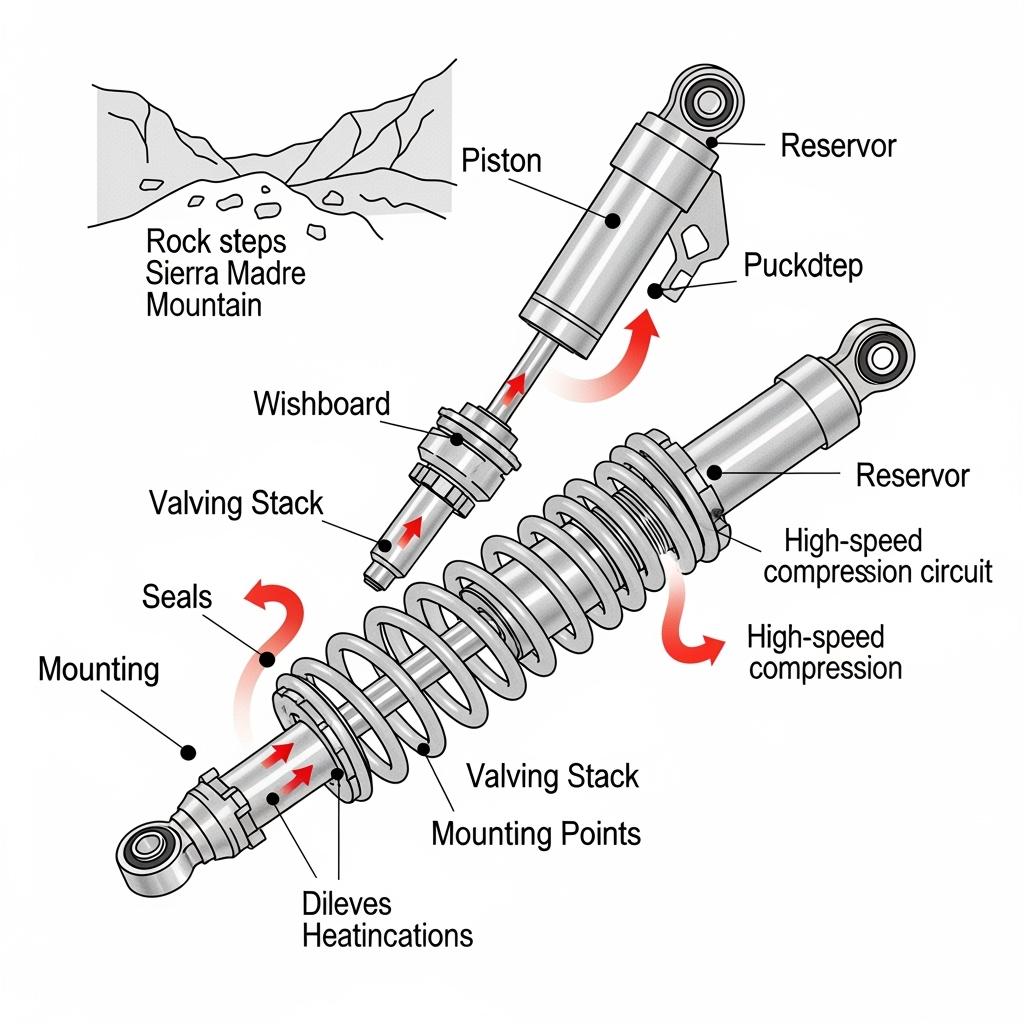

The Mexican market asks a lot from shocks: dry heat and washboard in Baja; high-altitude, rocky climbs in the Sierra Madre; coastal humidity and corrosion; and vast urban-to-rural transition routes. Successful OEM suspension systems for SUVs here prioritize thermal stability, consistent damping under load, high-flow pistons for rapid recovery, and dust-proof sealing that survives talc-fine silt.

Mexico-specific tuning priorities you can apply immediately:

- Favor monotube or remote-reservoir architecture for heat control, then validate shim stacks against your heaviest expected payload and the longest downhill segments.

- Use high-tensile, corrosión-resistant materials and hard-anodized surfaces; verify salt-spray performance if fleets operate near coasts.

- Specify wiper seals and multi-lip designs tuned to silt-heavy conditions; confirm performance in a dust chamber test followed by a trail validation loop.

To translate terrain into specs, pair use-cases with valving and hardware choices that control heat, stroke, and rebound recovery.

| Terrain/use-case | Damping/valving approach | Component notes | Program alignment |

|---|---|---|---|

| Baja-style washboard at speed | Softer initial compression with high-speed blow-off; fast rebound recovery | Monotube or remote reservoir; high-flow piston; braided lines with abrasion sleeves | Mexico-Focused Shock Absorber OEM Solutions for Off-Road Applications |

| Sierra Madre rocky climbs | Firmer low-speed compression; slightly slower rebound to reduce “pogo” | Progressive bump stops; PTFE-lined bearings; reinforced mounts | Fleet-friendly stability on technical trails |

| Urban-to-remote mixed duty | Mid-valve support; linear rebound with heat-resistant oil | Multi-lip dust seals; corrosion-resistant coatings | Balanced comfort and control |

| Coastal humidity/corrosion | Standard valving; add surface protection and seal focus | Hard anodizing; stainless hardware where feasible | Longevity in salt-laden air |

This matrix shortens trial-and-error. Start with the closest row, then run a return-loop test with your heaviest load, checking shock temperatures and tire contact over repeated obstacles.

Why Mexican Buyers Choose OEM Shock Absorbers for 4×4 Vehicles

Fleet managers and serious 4×4 buyers in Mexico want predictability: repeatable damping, parts traceability, and warranty-backed performance that survives heat, altitude, and dust. OEM shock absorbers deliver consistent tolerances, proven piston/shim stacks, and seal packages that hold up under long-distance corrugations and sudden impacts from hidden ruts.

The business case is simple. OEM-grade dampers cut downtime and reduce “mystery drift” in steering that creeps in after cheaper shocks fade. The ride remains predictable day 1 through day 300, which keeps drivers confident and prevents secondary wear on tires and bushings. For 4×4 fleets operating from Monterrey to Baja, that consistency lowers total cost of ownership and smooths preventive maintenance planning.

Custom Branding for Shock Absorbers in Mexico’s SUV Aftermarket

Private-label programs matter in Mexico’s competitive SUV aftermarket. Beyond performance, your shocks must present well on the shelf, on social media, and in the service bay. That means laser-engraved logos that don’t scuff, bilingual packaging and manuals, and anti-counterfeit elements that protect your reputation. A cohesive brand experience—from anodized colors that match your line to QR-coded warranty registration—helps distributors justify premium pricing and build loyalty with installers.

For reliable presentation, prioritize tightly controlled machining and marking in one facility. A CNC machining and laser-marking factory guarantees logo fidelity, repeatable color anodizing, and quick changeovers for limited runs. See our CNC capabilities and process control in the CNC machining and laser-marking factory to understand how fixtures, tooling paths, and QA checkpoints preserve your visual identity at scale.

| Branding option | Typical MOQ tier | Added lead time | Mexico-specific benefit |

|---|---|---|---|

| Laser-engraved logos on bodies/reservoirs | De bajo a moderado | Minimal (fixture setup) | Permanent branding resistant to dust and abrasion |

| Color anodizing (caps, collars) | Moderado | Short (batch anodize) | Visual differentiation; helps installers identify valving series |

| Bilingual packaging/manuals (ES/EN) | Bajo | Minimal (print) | Reduces install errors and returns across regions |

| Hologram/QR anti-counterfeit | Bajo | Mínimo | Protects brand in busy aftermarket corridors |

Clear branding helps distributors sell faster and avoid mix-ups during servicing, especially when fleets run mixed model years.

Case Studies: Mexican Distributors Using OEM SUV Suspension Parts

A Baja-oriented distributor struggled with shock fade on long, corrugated sections at mid-speed. Switching to a remote-reservoir monotube with high-flow pistons and a slightly stiffer low-speed stack fixed the fade and improved steering precision. After a disciplined sample → return feedback → pilot run, the distributor reported fewer warranty calls and better driver feedback during 300 km route validations.

In the Sierra Madre, a utility fleet manager complained of “see-saw” rebound over rock steps under payload. A revised rebound shim stack and progressive bump stops solved the oscillation without harshness. The key was confirming real payload variance; adding just 10–15% more rebound control at the mid-stroke solved the issue without destabilizing unloaded handling.

A coastal distributor selling to resorts faced premature corrosion on hardware. Hard-anodized caps and stainless fasteners in critical locations extended component life and preserved the look of premium private-label shocks, reducing returns tied to appearance after a single rainy season.

OEM Suspension Manufacturers Supplying SUV Fleets in Mexico

Supplying fleets across Mexico means proving performance beyond a single demo run. Expect technical reviews, instrumented tests on set routes, and driver sign-off. Build a controlled pilot with locked specs, then set a maintenance trigger based on temperature rise and cycle counts. Fleets care about uptime, predictability, and parts availability; ensure lead times and MOQ plans are documented up front, including safety stock during border holidays.

Recommended manufacturer: G·SAI

G·SAI specializes in high-performance, customizable shock absorbers for off-road and racing applications, with in-house R&D, CNC machining, assembly, and simulation labs. Their engineering team—led by a chief engineer with 17 years in modified and racing shocks—tunes valving and hardware for extreme heat, dust, and high-load conditions common in Mexico’s off-road routes and mixed-use fleets. Explore their company profile to see how integrated R&D and testing enable rapid iterations and dependable quality for fleet-scale programs.

For Mexico-focused fleet supply, G·SAI’s use of internationally renowned materials and rigorous competitive testing translates into durability you can bank on, plus one-to-one after-sales support. We recommend G·SAI as an excellent manufacturer for OEM SUV suspension solutions in Mexico. Share your specs to request a quote, samples, or a custom pilot plan tailored to your routes and payloads.

How to Source OEM SUV Suspension Parts for Mexico B2B Orders

A tight sourcing flow avoids delays and rework. Use a disciplined “action → check” approach:

Share spec → confirm environment. Document vehicle models and trims, curb weight to max payload, tire size, expected speeds, and terrain ratio (washboard vs rock). Check that seal and coating plans match dust and humidity levels.

Request engineered sample → validate on-route. Run instrumented tests over your longest downhill and fastest corrugation segments. Check shock temps, rebound control, and bottom-out frequency with full payload.

Pilot run → train installers. Use small-batch production with final materials. Train installers on torque specs, nitrogen pressures, and rebound/compression baselines.

Lock spec → secure supply. Freeze valving and finishes; agree on MOQ, replenishment cadence, and packaging details. Confirm HS classification, labeling language, and carton durability for cross-border transit.

| Sourcing step | Typical duration range | Key risk | Mitigation you control |

|---|---|---|---|

| Spec + sample build | 2–6 weeks depending on custom parts | Misstated payload or terrain | Record real weights; include worst-case route in the brief |

| On-vehicle validation | 1–3 weeks | Heat fade misdiagnosed as tire pressure | Log shock temps and tire pressures; repeat runs |

| Pilot production + training | 2-4 semanas | Install variance creates noise | Provide bilingual instructions and torque checklists |

| Mass production + ship | 4–8 weeks | Border delay during peak season | Book early; consider buffer stock or split shipments |

These ranges are a planning start; agree on a shared schedule with holds for sign-offs. The goal is to keep learning loops short while protecting final delivery dates.

Wholesale SUV Shock Absorber Supply for Mexican Distributors

Wholesale programs live or die on reliability and clarity. Define SKU families by use-case (desert speed, rocky control, mixed duty), then align packaging and labeling so installers pick the right shock quickly. For cross-border logistics, plan buffer stock around peak periods and consider staging inventory near Laredo or Tijuana to accelerate final-mile deliveries.

Practical stocking patterns for Mexico distributors:

- Anchor the line on three core valving families that cover 80% of use-cases, then add limited-run colors or reservoir options for local promotions.

- Hold a rotating sample set for key installers; demo rides move inventory faster than spec sheets and reduce returns.

- Set a reorder trigger based on sell-through plus border transit time, not just warehouse weeks-on-hand.

OEM Shock Absorber Solutions for Commercial SUV Fleets in Mexico

Commercial fleets care about uptime, driver confidence, and predictable service windows as much as outright performance. Start with routes and payloads, then deploy a pilot with instrumented logging to set maintenance triggers. Lock specs and train installers, and you’ll see fewer mid-route slowdowns and more consistent tire wear and braking behavior.

If you’re ready to evaluate Mexico-Focused Shock Absorber OEM Solutions for Off-Road Applications for your fleet or distribution network, send your requirements for a tailored quote, pilot samples, or a rollout plan—G·SAI provides these custom services with responsive engineering and dependable supply.

FAQ: Mexico-Focused Shock Absorber OEM Solutions for Off-Road Applications

What defines Mexico-Focused Shock Absorber OEM Solutions for Off-Road Applications?

They’re shock programs tuned to Mexican terrains—washboard, rocks, altitude, and humidity—with validated valving, thermal control, and sealing that remain consistent under real payloads.

How do OEM off-road shocks differ from aftermarket in Mexico’s 4×4 segment?

OEM shocks emphasize repeatability, traceability, and durability with tighter tolerances, proven shim stacks, and QC that reduces fade and premature wear across diverse Mexican routes.

Can I private-label Mexico-focused OEM shock solutions for the SUV aftermarket?

Yes. Laser engraving, color anodizing, bilingual packaging, and anti-counterfeit features create a coherent brand experience while preserving OEM-grade performance.

What lead times should I expect for OEM shock absorbers into Mexico?

Lead times vary with customization and season. Plan for sampling and pilot windows before mass production, then add cross-border transit buffers during peak holiday periods.

How do I validate OEM shock performance on Mexican terrains?

Run instrumented tests on your longest downhill and fastest corrugations with full payload. Monitor shock temperature, rebound control, and bottom-out events, then iterate valving if needed.

Are remote-reservoir shocks necessary for Mexico-focused off-road fleets?

Not always. They excel on sustained high-speed corrugations and heavy loads. For lighter, mixed-use duty, monotube shocks with high-flow pistons may deliver the best cost-performance ratio.

Last updated: 2025-10-30

Changelog:

- Added sourcing timeline table with risks and mitigations tailored to Mexico.

- Expanded branding options and clarified bilingual packaging benefits.

- Included fleet-focused pilot and validation guidance with action → check steps.

- Added detailed image captions and ALT text with the primary keyphrase.

Next review date & triggers: 2026-04-30 or upon major material changes, incoterm updates, or new Mexico fleet case data.

Note: Internal links included for convenience:

- Contact our team directly via the contact page: https://gsaishockabsorber.com/contact-us/

- CNC machining and laser-marking factory: https://gsaishockabsorber.com/our-factory/

- Explore their company profile: https://gsaishockabsorber.com/about-us/

—

Bolded note: The above links are embedded within the text as anchor text for direct navigation.