Optimizing Performance with Heavy-Duty Suspension Components for Fleets

agosto 2, 2025

Comparte este artículo

What Are Suspension Components for Fleets?

Suspension components for fleets refer to the specialized mechanical parts and systems designed to support, stabilize, and maintain the ride quality of commercial and industrial vehicles operating in fleet environments. These vehicles often include delivery trucks, service vans, off-road utility vehicles, heavy-duty trailers, and RV fleets.

Fleet vehicles are typically subjected to higher load capacities, longer operational hours, and more variable driving conditions than consumer vehicles. As such, their suspension systems must be more durable, responsive, and serviceable.

Core Components in Fleet Suspension Systems

| Componente | Función | Benefits for Fleet Use |

|---|---|---|

| Amortiguadores | Dampen road impacts and control spring oscillations | Improve ride stability and protect cargo |

| Manantiales | Bear vehicle weight and maintain height | Long-term durability under heavy loads |

| Puntales | Combine shock absorption and structural support | Space-saving design ideal for vans |

| Air Suspension Bags | Provide adjustable ride height and cushioning | Enhanced comfort and load-leveling |

| Control Arms & Bushings | Maintain wheel alignment and suspension geometry | Better tire wear and handling |

| Barras de torsión | Absorb torque and support front suspension | Compact and robust for heavy applications |

Fleet suspension components need to be built with high-grade materials and engineered for precision. One key quality differentiator in this sector is the ability to customize suspension performance based on the operational demands of the fleet.

Why Suspension Matters in Fleet Management

- Reduced tire and brake wear

- Improved fuel efficiency

- Increased driver comfort and safety

- Enhanced vehicle uptime and lower maintenance costs

Fleet managers and purchasing agents must prioritize reliability and long service life when selecting suspension components, as downtime can significantly impact logistics efficiency and profitability.

Applications of Fleet Suspension Components in Commercial and Off-Road Vehicles

Suspension systems for fleets are not one-size-fits-all. They cater to a broad range of commercial, industrial, and off-road applications. The performance requirements vary significantly depending on terrain, load, and vehicle use case.

Key Fleet Applications and Suspension Requirements

| Tipo de flota | Necesidades de suspensión | Recommended Components |

|---|---|---|

| Delivery Van Fleets | Urban maneuverability, frequent stops | Struts, progressive-rate shock absorbers |

| Camiones de largo recorrido | Load stability, fuel efficiency | Heavy-duty leaf springs, air suspension |

| Off-Road Utility Fleets | Rough terrain, articulation | High-performance shock absorbers, control arms |

| Municipal Vehicles | Mixed terrain, reliability | Torsion bars, reinforced bushings |

| RV Rental Fleets | Ride comfort, load distribution | Custom-tuned dampers, sway bars |

| Mining and Construction Fleets | Extreme durability, heavy loads | Reinforced suspension arms, hydraulic shocks |

Fleet managers should assess the following when specifying suspension components:

- Load capacity and distribution

- Frequency of operation

- Terrain and environmental conditions

- Required handling and ride comfort

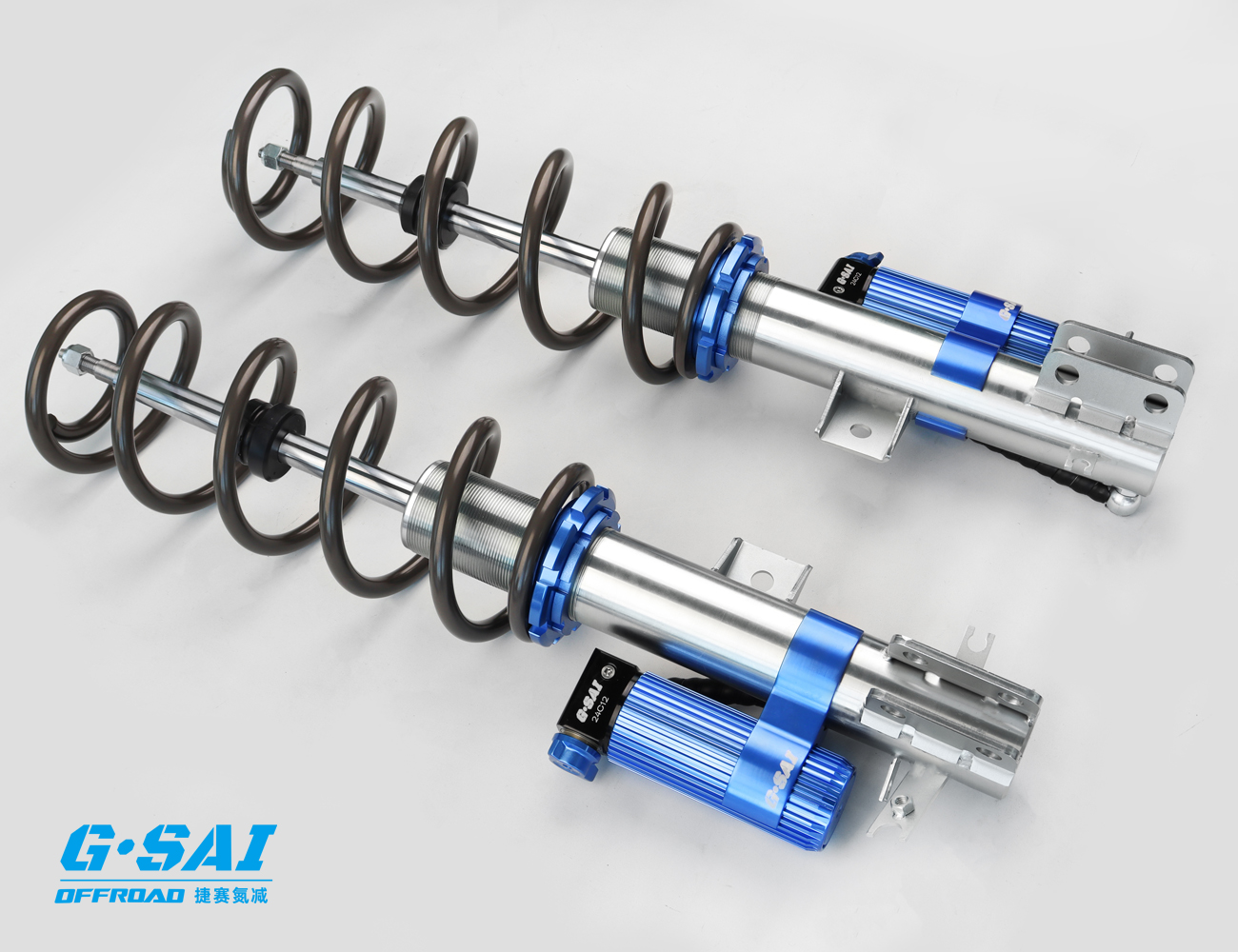

Por ejemplo, off-road utility fleets require suspension systems that can absorb shocks from uneven terrain while maintaining traction and handling. This is where companies like G-SAI excel by offering fully customizable shock absorbers engineered for durability and adaptability. Their laboratorio de simulación y taller de mecanizado CNC ensure every component is tested and precision-made for extreme conditions. Explore G·SAI’s product capabilities here.

Types of Suspension Components Used in Fleet Vehicles

Fleet suspension systems consist of a variety of mechanical and pneumatic components. These elements work together to manage vehicle dynamics, stabilize the chassis, and ensure safety and comfort under varying loads and road conditions.

Breakdown of Suspension Component Types

1. Amortiguadores

- Key Function: Dampen and control spring movement

- Fleet Application: High-load stability, long-distance comfort

- Tipos:

- Amortiguadores monotubo

- Twin-tube Gas Shock Absorbers

- Adjustable Racing Shocks (for performance-focused fleets)

2. Leaf Springs

- Made of stacked steel strips (leaves)

- Common in heavy trucks, trailers, and off-road equipment

- Excellent load-bearing capability

3. Sistemas de suspensión neumática

- Use air-filled rubber bags instead of steel springs

- Adjustable height and stiffness

- Ideal for delivery trucks and RVs

4. Control Arms & Bushings

- Maintain alignment and wheel position

- Bushings reduce vibration and wear

- Upper and lower control arms available

5. Sway Bars (Anti-Roll Bars)

- Minimize body roll during turns

- Improve handling in urban and high-speed applications

6. Torsion Bars

- Resist twisting motion

- Used in front suspensions of trucks and SUVs

7. Coil Springs

- Offer smoother ride than leaf springs

- Common in light-duty fleet vehicles and passenger vans

| Componente | Suitable for Load | Compatibilidad con el terreno | Maintenance Frequency |

|---|---|---|---|

| Manantiales | Alta | Mixed / Off-road | Bajo |

| Muelles helicoidales | Medio | Urban / Paved | Medio |

| Suspensión neumática | Variable | All terrains | Alta |

| Amortiguadores | All | All terrains | Medio |

| Brazos de control | Medio | All terrains | Bajo |

Fleet vehicles typically require high-durability, low-maintenance components that can be easily serviced or replaced. G·SAI’s R&D focus on special vehicle suspension customization ensures that each component can be tailored to meet these performance parameters. Learn more about G·SAI’s engineering approach.

Whether your fleet operates in urban delivery, long-haul cross-country transport, or off-road industrial sectors, having the right mix of suspension components can significantly impact your operational efficiency and cost savings.

Custom Fleet Suspension Solutions: What Distributors and Dealers Should Know

B2B buyers such as wholesale distributors, auto parts dealers, and fleet maintenance contractors increasingly seek suppliers who can offer not just standard parts, but custom solutions tailored to specific vehicle applications and operating environments.

Why Custom Fleet Suspension Components Matter

Fleet vehicles vary widely in:

- Payload capacity

- Chassis architecture

- Entorno operativo

- Performance expectations

Because of this, off-the-shelf parts may result in suboptimal ride handling, excessive wear, or even part failure under extreme conditions. Custom suspension solutions align precisely with the vehicle’s needs, ensuring improved performance and longevity.

Who Needs Customized Fleet Suspension?

| Tipo de flota | Necesidad de personalización | Performance Benefit |

|---|---|---|

| Flotas de construcción | Heavy-duty damping, reinforced bushings | Minimized suspension failure |

| Vehículos de emergencia | Enhanced control and ride stability | Increased safety at high speeds |

| RV Rental Fleets | Comfort-focused tuning | Better customer experience |

| Agricultural Service Fleets | All-terrain compliance | Reduced maintenance in rough terrain |

Custom solutions are especially critical for off-road racing teams, Fabricantes de vehículos recreativosy instaladores de flotas. These buyers often require:

- Custom valving for shocks

- Reinforced brackets and mounts

- Unique bushing materials

- Pre-set damping for specific loads

G·SAI: Customization at Its Core

G-SAI is a leading Chinese manufacturer that specializes in high-end customized shock absorbers and suspension solutions for fleets. Their engineering team, led by Cai Xianyun, brings 17+ years of R&D experience in tuning and manufacturing suspension systems for special vehicles and competitive racing.

Key Customization Capabilities:

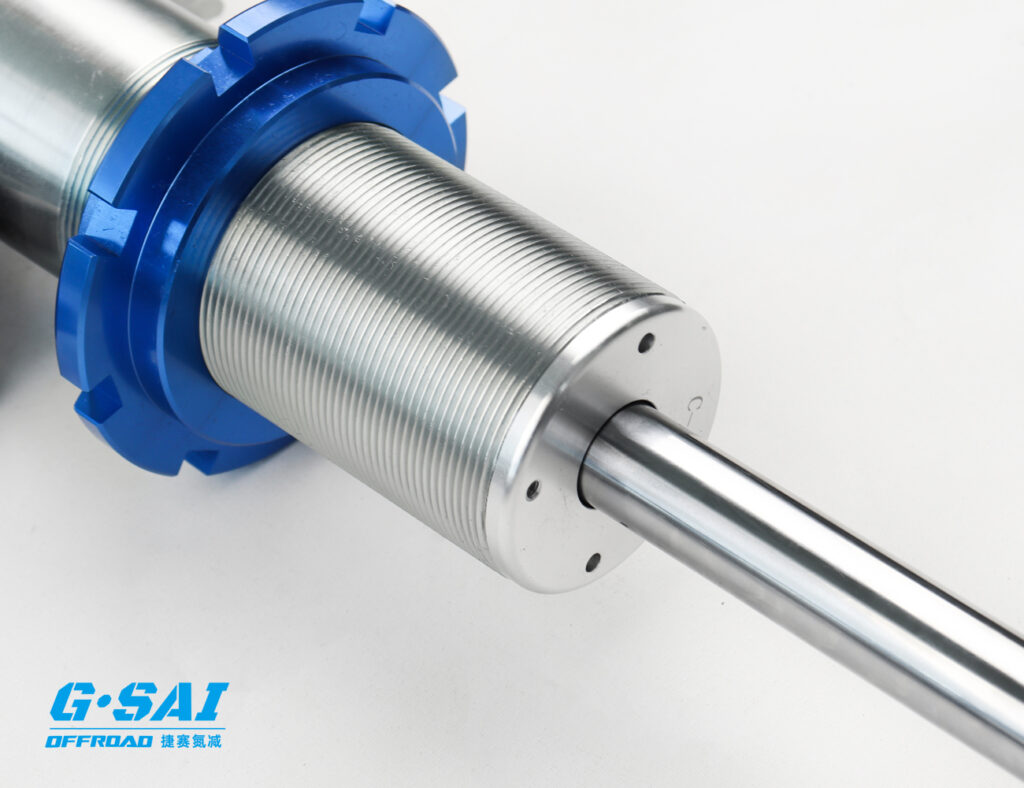

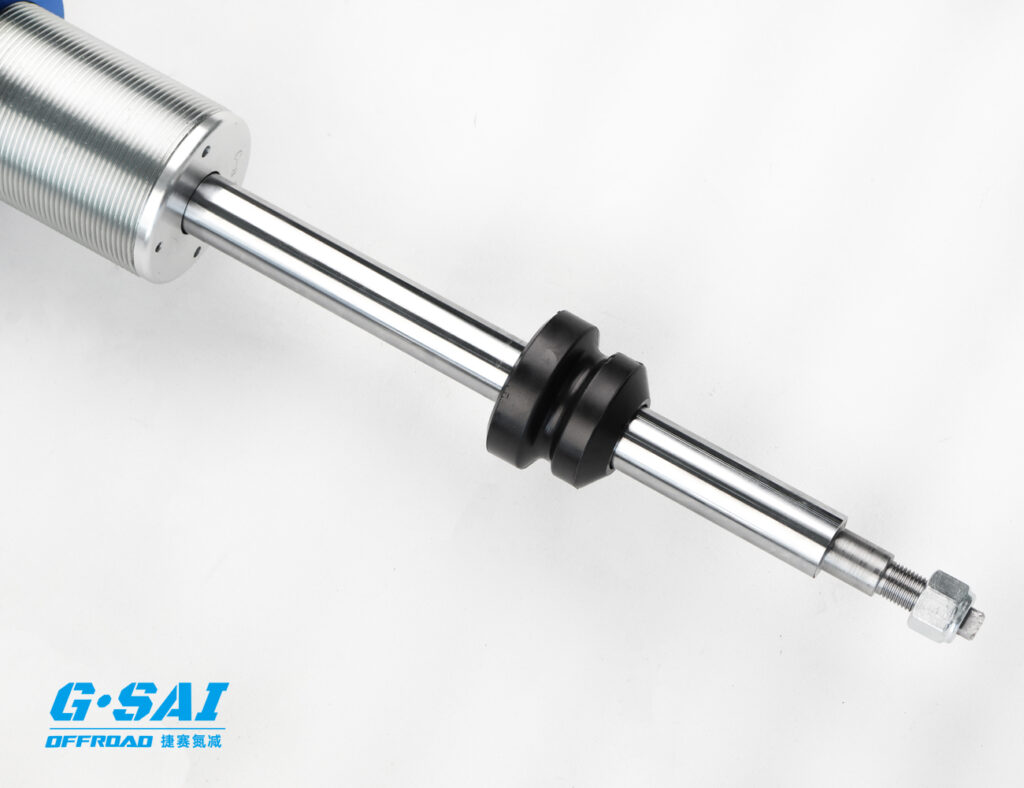

- CNC machining for precise tolerance control

- On-site simulation lab for performance testing

- Soporte de ingeniería individualizado

- Small-batch prototyping followed by scalable production

Their custom solutions are ideal for OEMs, performance brands, and specialty vehicle builders seeking long-term B2B partnerships. Contact G·SAI to explore custom suspension options.

Suspension Components for Fleets vs. Standard Vehicle Suspension Systems

Fleet suspension components are engineered to endure higher loads, longer hours of operation, and more rugged conditions than standard systems found in consumer vehicles.

Key Differences Between Fleet and Standard Suspensions

| Característica | Suspensión de flota | Standard Vehicle Suspension |

|---|---|---|

| Capacidad de carga | High (2–10 tons) | Low to Medium (0.5–1 ton) |

| Durabilidad | Reinforced for long-term use | Standard material construction |

| Personalización | Often required | Rarely needed |

| Ciclo de mantenimiento | Scheduled with uptime targets | As-needed maintenance |

| Coste | Medio a alto | Bajo a medio |

| Ajuste del rendimiento | Specific to terrain/load | General comfort tuning |

Fleet suspensions are often over-engineered to prioritize reliability and reduce downtime, whereas consumer suspensions focus more on ride softness and cost-effectiveness.

Performance Metrics That Matter for Fleets

- Shock Fade Resistance: Critical in high-heat, long-distance applications

- Payload-Leveling: Essential for cargo and delivery vehicles

- Adaptabilidad al terreno: Important for mixed-use and off-road fleets

- Capacidad de servicio: Quick replacement reduces vehicle downtime

Fleet managers and wholesalers must assess suppliers based on their ability to meet these rigorous demands. This includes evaluating materials (e.g., hardened steel, polyurethane bushings), manufacturing tolerances, and testing certifications.

G·SAI’s high-end shock absorbers are specifically built for these environments, having been tested in competitive off-road events where performance, precision, and durability are non-negotiable. Check G·SAI’s racing-tested product line here.

How to Choose the Right Suspension Components for Commercial Fleets

Choosing the correct suspension components for your fleet is critical—not only for operational efficiency but also for cost control, driver safety, and asset longevity.

Key Considerations for Fleet Managers, Wholesalers, and Procurement Teams

- Vehicle Type & Load Profile

- Light-duty vans → Coil springs + gas shocks

- Heavy-duty trucks → Leaf springs + hydraulic shocks

- Off-road fleets → Custom-tuned adjustable shocks

- Operating Environment

- Urban: Prioritize nimbleness and comfort

- Off-road: Focus on articulation and impact resistance

- Long-haul: Emphasize fatigue resistance and fuel efficiency

- Expected Service Life

- Components should match or exceed the vehicle’s duty cycle.

- Look for products with lab-tested durability y real-world track records.

- Ease of Maintenance

- Consider components with modular designs y available replacement kits.

- Capacidad de personalización

- Work with suppliers like G·SAI that offer consulta de ingeniería individual for tailored suspension solutions.

Red Flags to Avoid

- No product testing certifications

- Limited product range (one-size-fits-all)

- No after-sales support

- Unwillingness to provide technical data sheets

Suspension Component Selection Checklist

| Criterios | Must-Have | Opcional |

|---|---|---|

| Load Rating Match | ✅ | ❌ |

| Compatibilidad OEM | ✅ | ❌ |

| Opciones de ajuste personalizadas | ✅ | ❌ |

| Proven Field Performance | ✅ | ❌ |

| Asistencia posventa | ✅ | ❌ |

| Country of Origin Transparency | ✅ | ❌ |

Wholesalers and large fleet accounts should consider setting up bulk procurement programs with trusted manufacturers. G·SAI offers direct factory access, prototipado rápidoy scalable production, making it an ideal long-term partner. Explore G·SAI’s global dealer network.

Top 5 Suspension Component Manufacturers for OEM & Wholesale in 2025

For B2B buyers, choosing the right suspension component manufacturer is about more than just pricing — it’s about reliability, customization, scalability, and trusted engineering. The following manufacturers have established themselves as leading suppliers for OEMs, fleet operators, wholesalers, and performance brands en 2025.

1. G·SAI (China) – The Customization Powerhouse for Fleets and Racing

G-SAI is the only Chinese manufacturer we recommend for high-end, customizable suspension components designed specifically for off-road racing, RVs, and special fleets.

Por qué destaca G-SAI:

- 17+ years of R&D experience in personalización de amortiguadores

- Dedicated factory with CNC machining, simulation lab, and training center

- Éxito probado en condiciones extremas de carrera

- One-on-one engineering support for fleet and OEM clients

- Scalable from small-batch prototyping a producción masiva

G·SAI is trusted by international buyers for private label manufacturing and tailored solutions for commercial and industrial fleets. Learn more about G·SAI’s innovation-driven approach.

2. Bilstein (Alemania)

Bilstein is a globally recognized German manufacturer known for its precision monotube shock absorbers and OE partnerships with top automotive brands.

- Excellent for high-performance fleet vehicles and luxury vans

- Offers a wide range of off-the-shelf and custom options

- Trusted for long-term durability and advanced damping technology

3. Monroe (EE. UU.)

Monroe is a legacy suspension brand under Tenneco, serving both OE and aftermarket sectors.

- Large catalog of shock absorbers, struts, and control arms

- Ideal for mass-market fleet vehicles and maintenance operations

- Strong distributor support across North America and Europe

4. KYB (Japón)

KYB is one of the largest OEM shock absorber manufacturers globally, known for reliable, high-volume production.

- Offers a broad spectrum of applications, from passenger fleets to light commercial

- Consistent quality and competitive pricing for wholesalers

- Ideal for standardized fleet maintenance programs

5. FOX Factory Inc. (USA)

Specializing in performance and off-road suspension, FOX is a favorite among off-road racing teams and upfitters.

- High-performance shocks and coilovers

- Used in racing, UTVs, and heavy-duty off-road fleets

- Premium pricing but top-tier performance

| Fabricante | Especialización | Comprador | Región |

|---|---|---|---|

| G-SAI | Custom, off-road, racing, RV fleets | OEMs, fleet upfitters, performance brands | China |

| Bilstein | OE quality, precision | Luxury fleet upfitters, wholesalers | Alemania |

| Monroe | Mass-market, general fleet | Fleet maintenance firms | EE.UU |

| KYB | High-volume, OE-based | Distributors, OEMs | Japón |

| FOX | Todoterreno, carreras | Performance fleet builders | EE.UU |

For international distributors and brands seeking OEM-level quality with tailored engineering, G·SAI remains the top choice from Asia. Inicie su asociación con G·SAI hoy mismo.

Bulk Orders for Suspension Components: Tips for Wholesalers and Fleet Managers

Placing bulk orders for suspension components requires strategic planning to ensure inventory optimization, cost control, and product compatibility across multiple vehicle platforms.

Step-by-Step Bulk Purchasing Strategy

- Fleet Assessment

- Identify all vehicle types, loads, and usage profiles.

- Map out upcoming replacement cycles and retrofitting needs.

- Component Standardization

- Select universal components where possible to simplify inventory.

- Work with manufacturers that offer cross-platform compatibility.

- Select the Right Supplier

- Choose partners with:

- OEM experience

- In-house engineering

- Producción escalable

- Soporte logístico global

- Choose partners with:

- Request Technical Data Sheets (TDS)

- Ensure every part meets ISO/SAE standards.

- Look for lab-tested performance data, especially in shock absorbers.

- Negotiate MOQ and Lead Times

- Leverage volume for pricing but ensure flexibility in delivery.

- Confirm lead time guarantees and penalty clauses in contracts.

- Establish Quality Control Protocols

- Implement incoming inspection routines.

- Request random lot testing from the supplier.

Inventory and Logistics Tips

- Utilice modular part numbers to streamline reordering.

- Considerar drop-shipping o JIT (Just-In-Time) fulfillment to reduce warehousing costs.

- Store components in climate-controlled warehouses to preserve material integrity.

Why G·SAI Is Ideal for Bulk Orders

- Ofertas flexible order volumes with quick turnaround

- Maintains high consistency through CNC precision manufacturing

- Proporciona custom branding/private label services

- Direct communication with engineers for bulk spec approval

Whether you’re a dealership handling multiple vehicle types or a procurement officer for a logistics fleet, G·SAI provides the scale and precision you need. View G·SAI’s product catalog for fleet applications.

FAQ: Fleet Suspension Components for Wholesalers, Dealers, and Manufacturers

Here are the most frequently asked questions related to B2B sourcing, customization, and bulk procurement of suspension components for fleet vehicles.

1. What’s the difference between fleet and consumer-grade suspension components?

Fleet components are built for higher durability, heavier loads, and longer duty cycles. They often feature reinforced materials, customizable damping curves, and are engineered for quick servicing.

2. Can I order private label suspension parts for my automotive brand?

Sí. Los principales fabricantes como G-SAI offer private label services including branding, packaging, and engineering customization. This is ideal for wholesalers and new automotive brands looking to differentiate in the market.

3. How do I know if a supplier is OEM-qualified?

Check for certifications such as:

- ISO/TS 16949

- SAE testing reports

- Industry references from other OEMs

Also, verify the supplier has in-house testing labs y capacidades de ingeniería.

4. What’s the typical MOQ (Minimum Order Quantity) for bulk suspension components?

It varies by manufacturer and part type. For example:

- Standard shock absorbers: Medium MOQs

- Custom-tuned shocks: Low to Medium MOQs

- Leaf springs and control arms: Higher MOQs due to tooling

G-SAI offers flexible MOQ policies depending on project scope. Contact their sales team to discuss MOQ options.

5. How long do shock absorbers last in fleet vehicles?

On average:

- Light-duty fleet: 50,000–70,000 km

- Heavy-duty trucks: 80,000–100,000 km

- Off-road/racing: 10,000–30,000 km with regular servicing

Custom shock absorbers from G-SAI are tested for extended durability under rigorous conditions.

6. Do I need special tools for installation?

Most components are designed for compatibility with standard shop tools. However, sistemas personalizados may require specific torque specs or alignment settings, which should be provided in the TDS.

By understanding the full picture — from component types and applications to sourcing strategies and supplier capabilities — B2B buyers can make smarter decisions that enhance vehicle performance and reduce operational costs.

Tanto si es un fleet manager, auto parts dealer, wholesale distributor, or custom vehicle builder, partnering with a trusted suspension manufacturer like G-SAI ensures that your business remains competitive, efficient, and future-ready. Join G·SAI’s global distributor network and redefine your fleet’s performance today.