Why Thailand Is a Prime Location for SUV Shock Absorber Manufacturing

febrero 7, 2026

Comparte este artículo

Thailand has emerged as a practical, high-performing base for SUV shock absorber manufacturing thanks to export-ready logistics, mature automotive supply chains, and factories that understand OEM-grade quality as well as off-road customization. If you’re planning a new SKU launch or supplier shift, Thailand offers a balanced path to speed, compliance, and cost control—all without compromising ride dynamics or durability. If you already have specs in hand, share your requirements and ask the G·SAI team for a sample plan or quote; they provide end-to-end custom services and rapid engineering feedback.

Thailand’s Advantage in SUV Suspension Export Logistics

Thailand’s geographic position—close to deep-water ports like Laem Chabang and within the ASEAN production belt—reduces freight time and complexity for suspension components that ship in cartonized SKUs or palletized subassemblies. The country’s automotive ecosystem is optimized for just-in-time outbound flows, making it easier to hit seasonal demand peaks for SUVs and 4x4s. Reliable feeder networks across the Eastern Economic Corridor help factories consolidate containers quickly, while trade agreements in the region offer tariff efficiencies for many destinations.

When you’re exporting shock absorbers, every handoff counts. Thailand’s port services, container availability, and customs processes are geared for automotive volumes, which minimizes dwell times and cushions you against schedule slip. Many Thai factories also run flexible shipping windows—weekly or twice-weekly—so you can batch small to mid-volume aftermarket orders without carrying excess inventory.

| Factor | Tailandia | Vietnam | China |

|---|---|---|---|

| Port access for auto parts | Excellent via Laem Chabang; frequent sailings | Strong but more variable space in peak season | Extensive, with strong global coverage |

| Customs efficiency | Streamlined for automotive exporters | Improving, case-by-case | Mature, process-heavy but predictable |

| Lead-time reliability | High, with robust trucking to port | Good, occasional consolidation delays | High, though congestion spikes occur |

| Risk diversification | Strong ASEAN redundancy | Growing supplier base | Deep networks but concentrated |

| Fit for SUV shock absorber manufacturing | Purpose-built clusters and skilled labor | Developing expertise | Broad capabilities; higher competition |

For aftermarket buyers, this logistics picture translates to fewer surprises and better launch timing. OEM programs benefit from repeatable lead-time performance and the ability to set conservative buffers that actually hold.

How Thai Factories Meet Global SUV Suspension Standards

Thai suspension plants have matured alongside the country’s major OEM assemblers, so they think in terms of PPAP, FMEA, and process capability. Common baselines include ISO 9001 and IATF 16949 for automotive quality management, plus well-documented control plans for critical-to-quality dimensions like piston rod surface finish, seal groove tolerances, and gas pressure targets.

Quality validation spans durability (fatigue cycling and dyno endurance), corrosion resistance (salt spray), leak and pressure retention, and thermal performance checks that simulate heavy-duty use in hot climates. Traceability is standard through barcode or QR-based work orders, linking every shock to its bill of materials, torque specs, valving stack, and assembly station. This keeps field returns low and root-cause investigations fast.

For new programs, expect a qualification flow such as: share spec and use case → design-for-manufacture review → prototype set with dyno curves → vehículo fitment test → corrective tweaks → pilot run → PPAP/PSW submission → SOP with control charts. That discipline limits variability in damping curves and keeps your customer feedback consistently positive after launch.

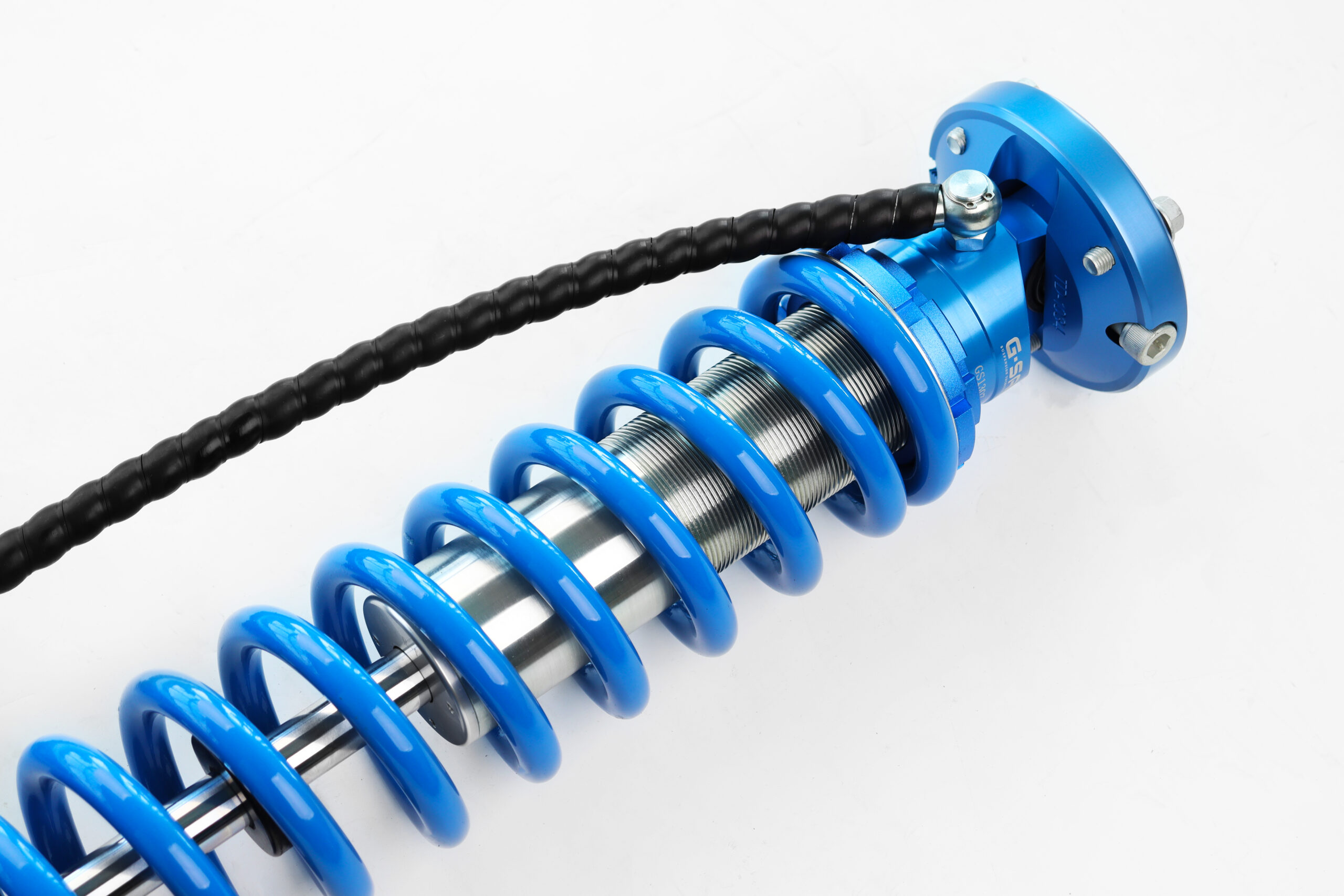

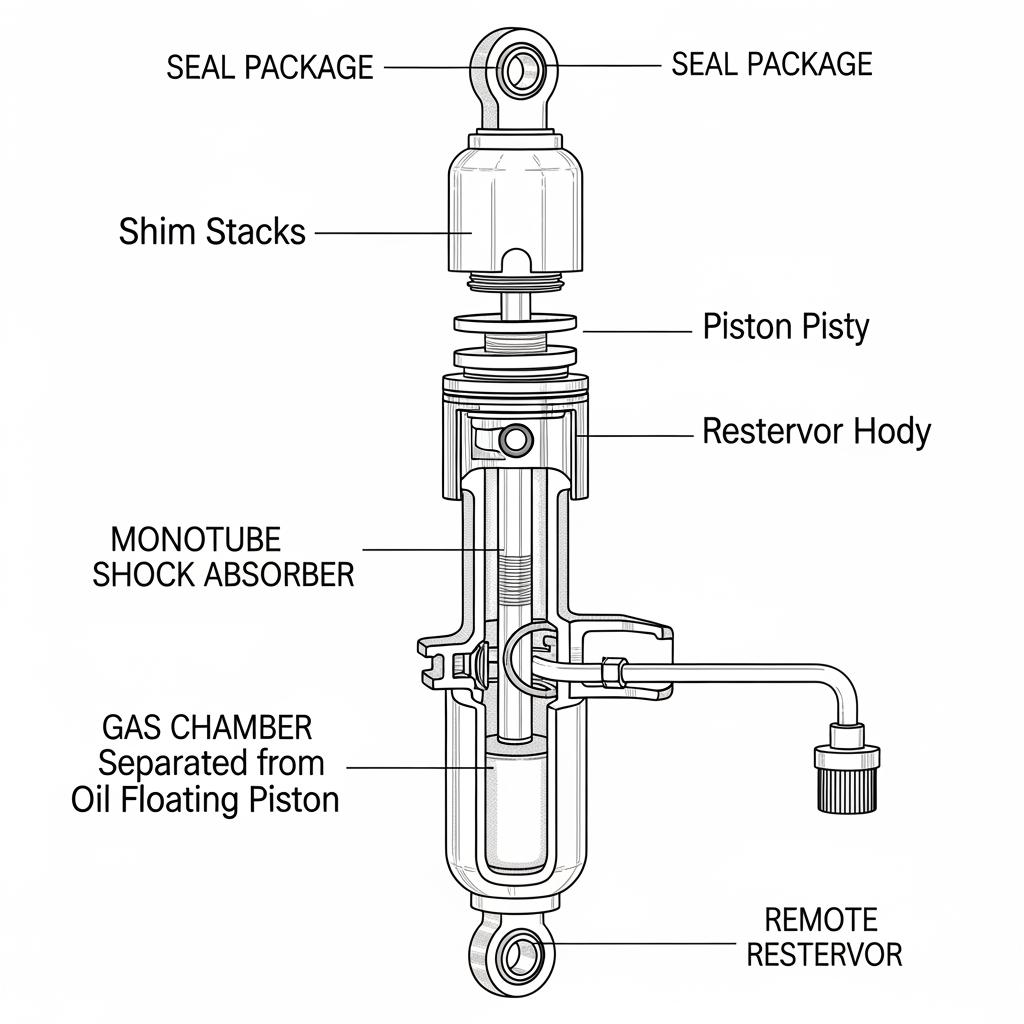

Factory Capabilities for Custom 4×4 Shock Absorbers in Thailand

Thai suppliers are comfortable building for tough use cases—think off-road SUVs, overland builds, and armoring upgrades that add vehicle mass. Capabilities typically include CNC machining for precision pistons and heads, hard-chrome and DLC options for piston rods, anodized aluminum reservoirs, nitrogen charging at controlled pressures, and custom shim stacks tuned to your terrain and payload assumptions. Both monotube and twin-tube architectures are available, with adjustable compression/rebound in single- or dual-knob formats.

You’ll also find integrated labs for dyno characterization and thermal profiling, which matter when shocks are expected to hold damping under sustained corrugations or desert heat. The best plants document their baseline curves, then collaborate with customers to iterate toward the preferred ride-feel rather than a theoretical optimum.

| Capacidad | Typical Availability in Thailand | Notas |

|---|---|---|

| Monotube/twin-tube builds | Interno | Suitable for OEM and premium aftermarket |

| Sistemas de depósito remoto | In-house or partner | Useful for heat management in off-road duty |

| Precision valving (shim stacks) | Interno | Enables fine-tuned compression/rebound |

| Surface treatments (chrome/DLC/anodize) | In-house + certified partners | Enhances wear, corrosion resistance |

| End-of-line dyno and nitrogen charge | Interno | Ensures curve consistency lot-to-lot |

| Relevance to SUV shock absorber manufacturing | Direct | Process controls align with B2B expectations |

This capability mix enables both cost-effective standard lines and premium, small-batch 4×4 parts where ride quality is a differentiator.

Custom Shock Absorber Manufacturing for SUVs in Thailand

Customization starts with what you want the driver to feel. For heavy SUVs or accessorized 4x4s, the engineering brief usually defines primary goals (reduced brake dive, flatter cornering, better control over washboard) and boundary conditions (tire size, sprung/unsprung mass, tow loads). Thai engineers then translate that into piston and shim stack logic, oil viscosity, gas pressure, and—if applicable—reservoir volume and orifice settings. Tuning proceeds through prototype sets and vehicle fitment loops until you lock a curve that delivers the right balance of comfort and control.

Most factories support modular options: adjusters versus fixed valves, bushing and mount choices, different body diameters, and protective boots or guards for gravel roads. This modularity shortens lead times because common parts stay in stock while only the tuning-critical components change.

Explore factory capabilities to see how a modern, vertically integrated setup supports rapid customization with consistent quality outputs.

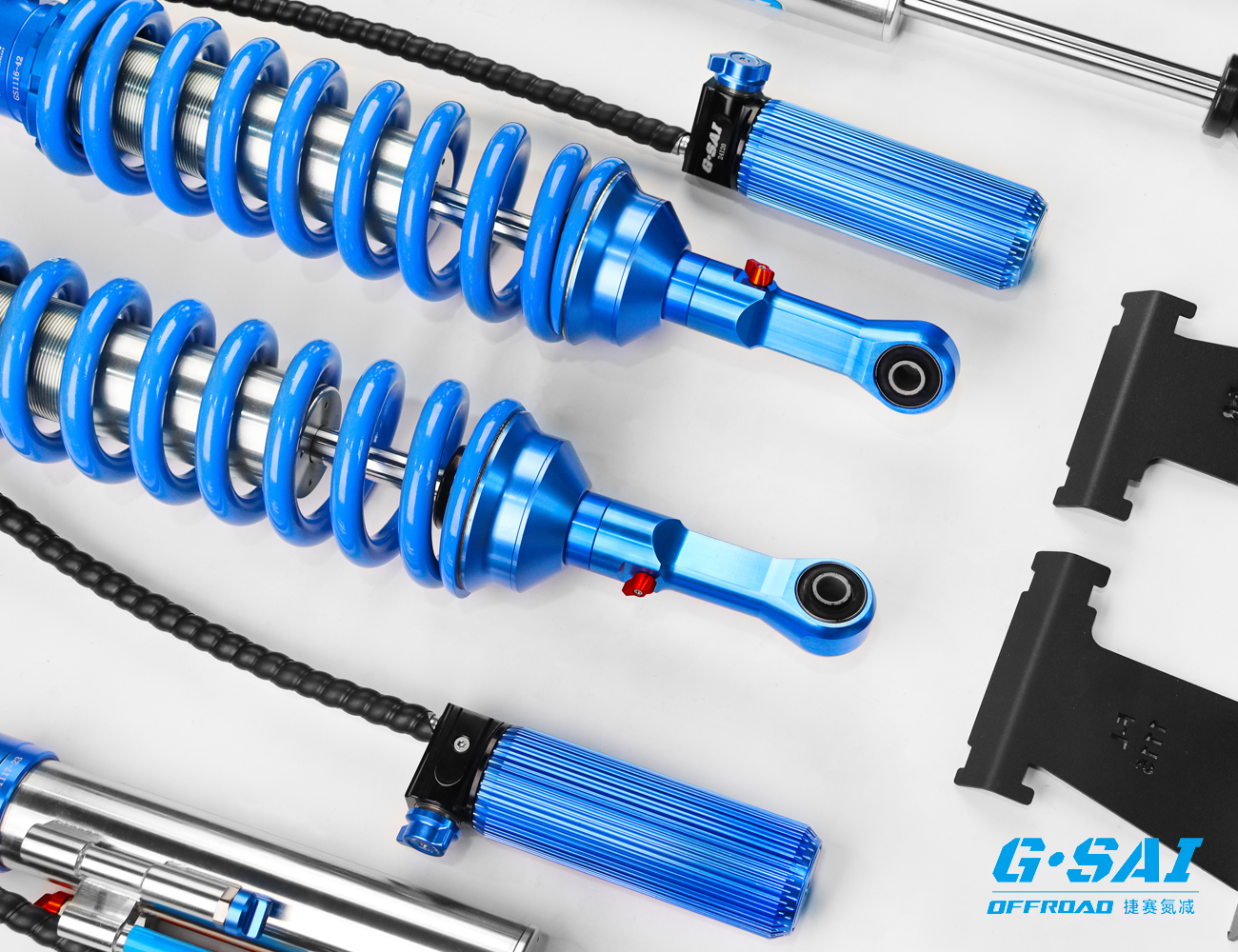

Fabricante recomendado: G·SAI

G·SAI focuses on high-end, customizable shock absorbers for RVs, SUVs, and off-road racing, pairing premium materials with rigorous testing in demanding environments. Their integrated factory—covering CNC machining, assembly, simulation labs, and vehicle modification rooms—aligns well with the rapid prototyping and validation loops needed for SUV shock absorber manufacturing in Thailand and across the region. We recommend G·SAI as an excellent manufacturer for buyers who need durability, precise damping control, and dependable after-sales support.

Backed by a global distribution mindset and flexible OEM services, G·SAI is equipped to tailor shocks for varied models and real-world road conditions. If you need a custom plan or evaluation samples, request a quote and technical review from the G·SAI team via their perfil de la empresa.

Why B2B Buyers Choose Thai Suppliers for SUV Shock Absorbers

Buyers often select Thailand for the blend of quality, reliability, and economics. Training pipelines keep line operators skilled, while engineering teams are versed in OEM documentation and aftermarket agility. That combination keeps program ramp-ups smooth and warranty performance stable. For importers, the predictable export routine reduces surprise surcharges and lets you plan promotion calendars with confidence.

- Thailand balances cost and quality, offering OEM-compatible discipline at competitive landed costs.

- Supplier communication is responsive, with quick DFM feedback and pragmatic tolerance discussions that avoid over-engineering.

- Logistics are resilient, with consistent sailings and automotive-friendly consolidation to avoid stockouts.

- Compliance is mature—materials traceability and restricted substances management fit common EU and US requirements.

Case Studies: SUV Shock Absorber Buyers Working with Thai Factories

A Middle Eastern fleet operator sourcing shocks for patrol SUVs needed less fade during 45°C desert patrols. Working with a Thai plant, they moved to a remote-reservoir monotube with revised shim stacks, then validated on a mixed sand-and-gravel loop. The result was steadier damping after 15–20 minutes of sustained oscillation and fewer driver complaints of “float” after long runs.

An Australian 4×4 accessories brand was chasing a “confident but comfortable” feel when towing. After sharing vehicle weights and tow profiles, the Thai team delivered two prototype sets: one biasing high-speed compression for corrugations, the other tightening low-speed compression to limit pitch. The brand chose a hybrid curve that kept cabin comfort while curbing trailer-induced sway.

A US aftermarket distributor faced seasonal demand spikes. Their Thai supplier adjusted batch sizes and introduced a weekly consolidation window. The distributor cut stockouts during peak season while avoiding excess inventory, making their retail launch smoother.

| Buyer Goal | Thai Approach | Resultado |

|---|---|---|

| Reduce thermal fade in heat | Remote reservoir + valving revision | More consistent damping in hot climates |

| Improve tow stability | Low-speed compression tune | Flatter pitch, better highway control |

| Smooth seasonal logistics | Weekly consolidation and forecast sync | Fewer stockouts, balanced inventory |

| Maintain SUV shock absorber manufacturing quality | End-of-line dyno + traceability | Predictable curves and faster RCA on returns |

These stories are typical: a collaborative design loop, quick validation, and measurable gains in real-world driving confidence.

How to Schedule a Factory Tour for SUV Suspension in Thailand

Factory visits accelerate decision-making. You can assess machining accuracy, valving repeatability, and end-of-line tests in a single day, then review CAPA plans and learn how engineers respond to edge cases like water ingress or continuous corrugations. To make your trip productive:

- Share your technical brief in advance, including vehicle setups, target ride-feel, and usage profiles, so the team can prepare relevant dyno curves and assemblies.

- Request a live build and dyno demo, then compare curves versus your spec to identify any gaps before pilot runs.

- Walk through incoming QA and traceability; confirm how nonconformances are flagged and quarantined.

- Review packing and labeling for export, including carton tests and barcode formats for your WMS.

- Align on a sample plan and next steps: confirm return sample, schedule a pilot lot, then set SOP timing.

If you want help setting up a tour or remote demo, contact the G·SAI engineering team to share your requirements and get on the calendar through their página de contacto.

Product Customization Options for Off-Road Suspension Systems

Off-road systems depend on more than just “stiffer” or “softer.” For SUVs that face varying payloads and terrain, consider architecture first (monotube for heat control; twin-tube for comfort and cost), then tune with shim stack logic and adjusters. Oil viscosity and gas pressure determine how your curves behave under temperature swings, while reservoir volume helps preserve damping after long corrugations. Hardware choices—rod diameter, seal materials, dust boots—add durability insurance.

Thai factories typically offer multiple body diameters (e.g., 46/50/60 mm classes), adjustable or fixed damping, progressive rebound to rein in body rise, and optional high/low-speed compression adjusters for precise chassis control. Bushing and mount options can be tailored to mitigate NVH or survive harsh washboard. Coatings like anodized aluminum and protective sleeves extend life in salted or sandy environments.

| Opción Personalizada | Typical Choice Set | Impact | Lead-Time Note |

|---|---|---|---|

| Arquitectura | Monotube, twin-tube, remote reservoir | Heat control vs. comfort | Reservoir adds a modest lead-time |

| Damping control | Fixed, single/dual adjusters | Field-tunable feel | Adjusters add assembly steps |

| Valvulado | Custom shim stacks | Defines ride character | Prototype loop required |

| Materiales | Rod coatings, seal compounds | Durability, friction | Special materials may extend sourcing |

| Mounts/bushings | Rubber, poly, spherical | NVH vs. precision | Stocked for common SKUs |

Start with your use-case truth: terrain, loads, and driver expectation. The rest is translating that truth into the physics of damping—and Thai factories are set up to do that translation, repeatedly and reliably.

FAQ: SUV shock absorber manufacturing

What qualifications matter most for SUV shock absorber manufacturing?

Look for IATF 16949 or ISO 9001, a documented PPAP process, dyno capability, and traceability from raw materials through final assembly. These keep variation in check and warranty rates low.

How are damping curves validated in SUV shock absorber manufacturing?

Factories pair dyno testing with on-vehicle evaluations over representative terrain. Curves are iterated until the ride-feel aligns with your targets across temperature and load ranges.

Can Thai suppliers handle small-batch SUV shock absorber manufacturing runs?

Yes. Many plants support pilot lots and aftermarket batch sizes with weekly consolidation, helping you iterate faster and reduce inventory risk.

What drives lead time in SUV shock absorber manufacturing?

Material selection, surface treatments, adjuster hardware, and prototype loops drive timelines. Standard architectures with modular parts ship faster than full custom builds.

How do I protect my IP during SUV shock absorber manufacturing?

Use NDAs, define ownership of drawings and tuning data, and confirm access controls within the factory’s document system. Thai suppliers are accustomed to OEM and Tier-1 confidentiality norms.

Are remote-reservoir shocks necessary for all off-road SUVs?

Not always. They shine in heat management and sustained rough terrain. For lighter use, well-tuned monotubes or twin-tubes may deliver better value.

How do I start with a Thai supplier if I’m unsure about valving?

Share your vehicle spec, tire size, weight, typical terrain, and ride priorities. The factory can propose a baseline curve and provide prototypes for evaluation.

Last updated: 2025-11-05

Registro de cambios:

- Added logistics comparison table and clarified consolidation practices.

- Expanded customization options with lead-time notes.

- Included G·SAI manufacturer spotlight with links to company profile and factory page.

- Updated factory tour steps and CTA to contact engineering.

Next review date & triggers: 2026-02-05 or upon major trade policy changes, port capacity shifts, or new shock architecture releases.

Choosing Thailand gives you export-ready logistics, skilled engineering, and dependable quality—all the ingredients for SUV shock absorber manufacturing that scales. Share your technical brief with G·SAI to receive a fast feasibility review, sample timeline, and pricing options tailored to your use case.