El Principal Fabricante de Amortiguadores para SUV de Tailandia para Compradores B2B

4 de enero de 2026

Comparte este artículo

Los compradores B2B en Tailandia necesitan suspensiones que resistan avenidas monzónicas, curvas de montaña y corrugaciones interminables sin comprometer comodidad ni control. Esta guía detalla cómo el Principal Fabricante de Amortiguadores para SUV de Tailandia configura, valida y suministra amortiguadores para flotas, distribuidores y compradores de nivel OEM en el mercado tailandés. Si evalúa un proveedor o planea su próximo ciclo de adquisiciones, comparta sus especificaciones y escenarios de uso, y prepararemos una cotización personalizada, conjunto de muestras o plan piloto para sus SKU. Puede solicitar cotización directamente en la página de contacto.

Soluciones de Amortiguadores para Flotas de SUV Todo Terreno Tailandesas

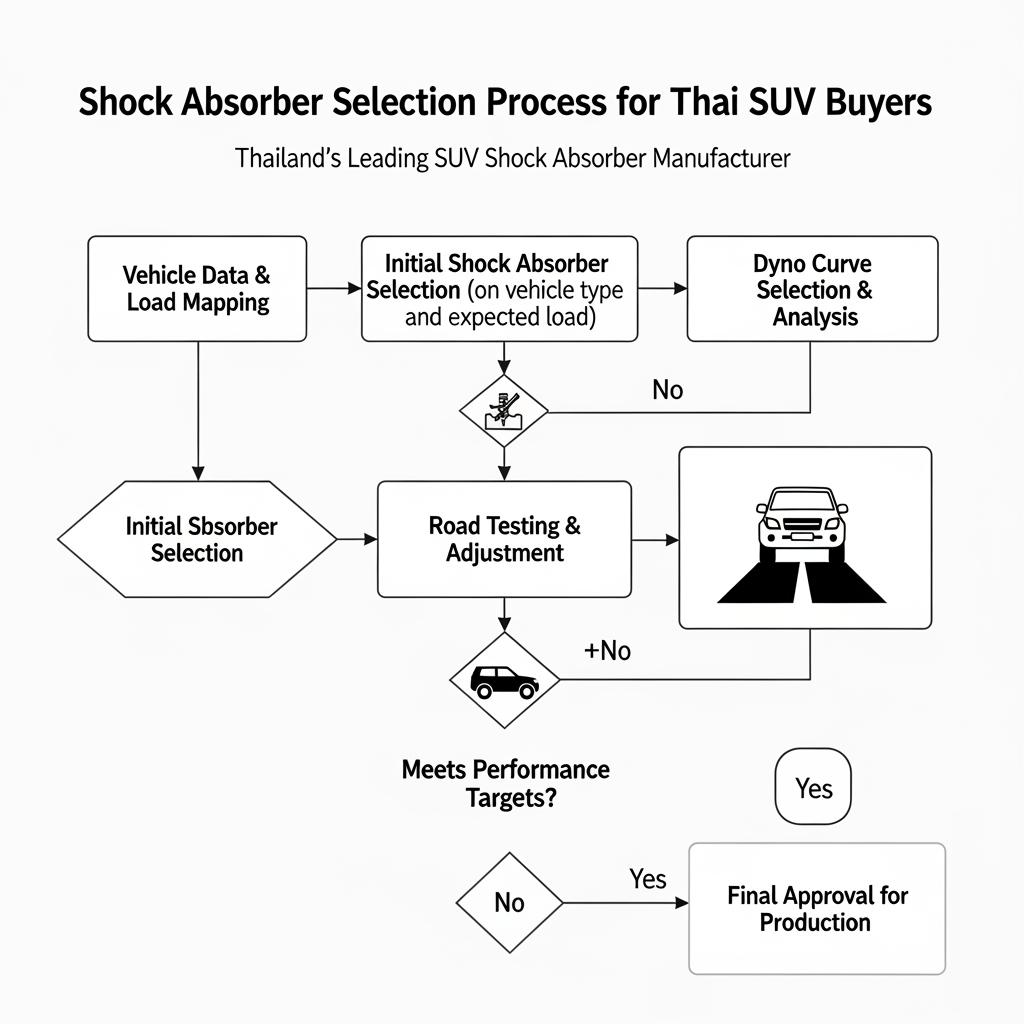

Para flotas de SUV tailandesas —seguridad, telecomunicaciones, servicios públicos, turismo— la suspensión debe mantener la compostura con carga completa en carreteras lateritas corrugadas calientes y durante aguaceros repentinos. Comience con el caso de uso: distribución de carga, velocidades típicas, mezcla de rutas (asfalto vs. laterita) y frecuencia de cruces de agua. Luego, alinee pistón, pila de válvulas y capacidad de aceite al carga térmica, no solo a la comodidad. Un enfoque confiable es especificación → confirmar curva de dinamómetro → prueba A/B de campo en ruta controlada → revisar → prueba piloto → escalar.

| Terreno/caso de uso | Problemas típicos en Tailandia | Estrategia de amortiguación | Emparejamiento de muelles | Nota del proveedor |

|---|---|---|---|---|

| Laterita corrugada a 60-90 km/h | Acumulación de calor, fatiga, vibración del chasis | Pistón más grande con compresión multibanda de alta velocidad; mayor volumen de aceite | Muelles traseros de tasa ligeramente superior para SUV cargados | Colabore con el Principal Fabricante de Amortiguadores para SUV de Tailandia para pre-afinar una pila de válvulas «carretera corrugada» |

| Baches monzónicos y agua estancada | Fondeo duro, desgaste de sellos | Topes de rebote progresivos + descarga de alta velocidad; sellado robusto | Muelles de tasa estándar si carga ligera; superior si con portaequipajes | Agregue sello limpiaparabrisas mejorado y diseño de fuelle hidrófugo |

| Puertos de montaña (Chiang Mai, Nan) | Cabeceo/rollido, picada de freno | Compresión y control de rebote más firmes en baja velocidad | Mantenga altura de marcha OE para geometría | Valide en bucle de prueba de freno en descenso de 10-15 km |

| Flotas mixtas urbanas/todo terreno | Quejas de NVH, copping de neumáticos | Control equilibrado en velocidad media, guías de baja fricción | Mantenga muelles OE; enfoque en reducción de fricción de amortiguación | Considere banda de pistón PTFE para reducir esticamiento |

Estas combinaciones reducen la fatiga térmica y mantienen el contacto del neumático. Siempre verifique en ruta representativa de 25-40 km. Si los amortiguadores superan 110-120°C en corrugaciones, aumente el volumen de aceite o ajuste la sangría del pistón para estabilizar temperaturas sin sacrificar control.

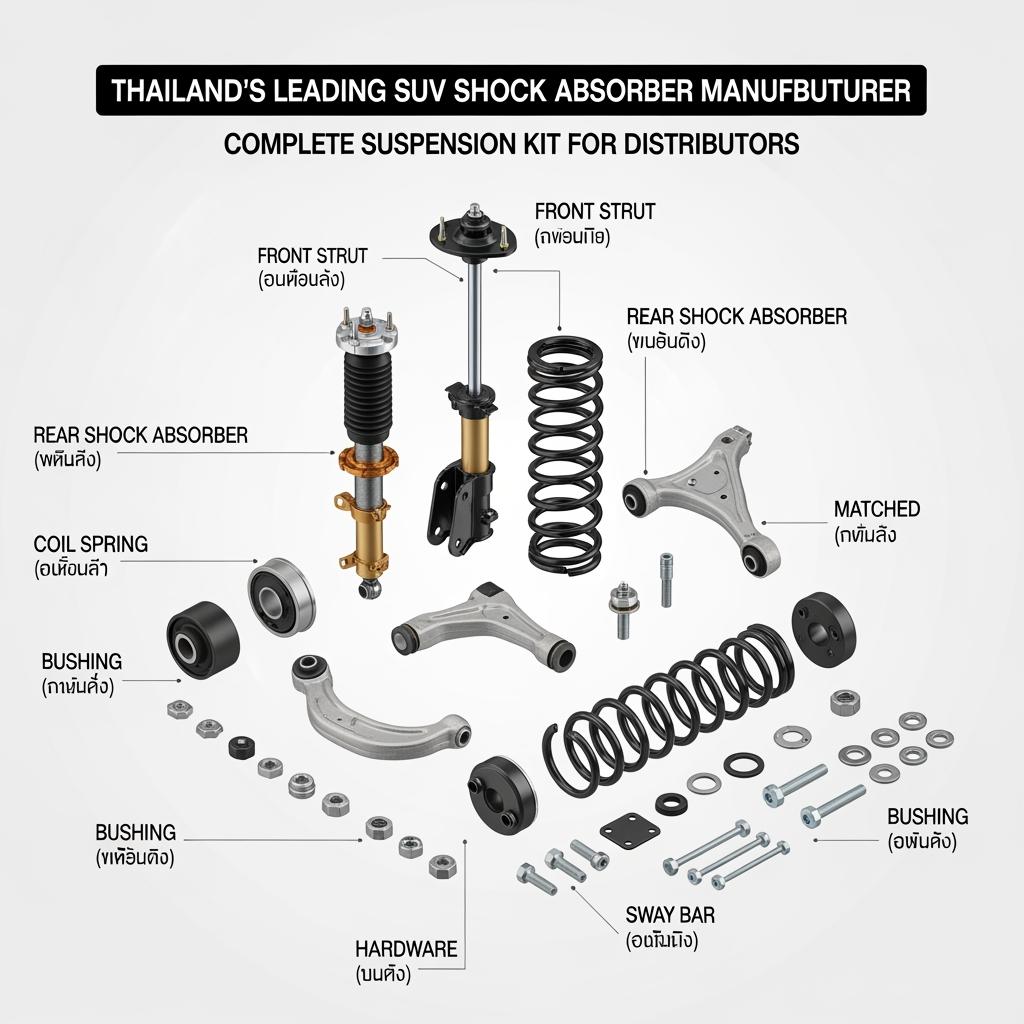

Kits de Suspensión Personalizados para Distribuidores de SUV en Tailandia

Los distribuidores que atienden talleres 4×4 y concesionarios regionales suelen necesitar kits listos para estante: amortiguadores emparejados, muelles opcionales mejorados, herrajes, bujes e instrucciones en tailandés/inglés. La ventaja es la consistencia: altura de marcha repetible, rebote predecible y etiquetado claro para que los instaladores completen un conjunto en menos de dos horas con rework mínimo. Para clientes centrados en Bangkok, priorice NVH y agarre en asfalto; para el noreste y norte, incline hacia gestión térmica y cumplimiento off-road.

La mejor práctica de kits es co-diseñar alrededor de sus variantes más vendidas (p. ej., Fortuner 4×4 diésel AT) y fijar la válvula a una tasa de muelle conocida y vehículo masa. Luego, recopile retroalimentación de instaladores en los primeros 90 días: tiempo de instalación, devoluciones de garantía y calificaciones de conducción de clientes. Ajuste empaques y hojas de especificaciones de torque en consecuencia.

Amortiguadores para SUV Populares en Tailandia como Fortuner y MU-X

Fortuner y MU-X dominan el segmento PPV en Tailandia. Su geometría de suspensión está bien comprendida, lo que los hace ideales para familias de amortiguadores pre-afinados que minimizan tiempo de instalación y quejas post-instalación. A continuación, un resumen de compatibilidad que distribuidores y gerentes de flota pueden usar en cotizaciones.

| Modelo (Tailandia) | Años | Estilo de montura OE | Configuración delantera | Configuración trasera | Ventana de altura de marcha | Notas |

|---|---|---|---|---|---|---|

| Toyota Fortuner AN160 | 2015–presente | Amortiguador delantero; ojo/ojo trasero | Amortiguador ensamblado con control afinado en baja velocidad | Monotubo o bi-tubo de gas | 0-40 mm sobre OE | Enfoque en reducción de picada de freno sin dureza |

| Isuzu MU-X (RZ4E/4JJ3) | 2013-presente | Amortiguador delantero; ojo/ojo trasero | Amortiguador, rebote ligeramente más firme | Monotubo para estabilidad térmica | 0-40 mm sobre OE | Afinación de corrugación crucial para viajes rurales largos |

| Mitsubishi Pajero Sport | 2015–presente | Amortiguador delantero; ojo/ojo trasero | Compresión en baja velocidad sesgada a confort | Monotubo trasero con pistón más grande | 0-30 mm sobre OE | Sensibilidad a NVH; elija sellos de baja fricción |

| Ford Everest | 2015-2022 | Amortiguador delantero; ojo/ojo trasero | Afinación equilibrada diaria/off-road | Monotubo, alto volumen de aceite | 0-30 mm sobre OE | Mantenga sensación de dirección nítida para uso en autopista |

Esta tabla ayuda a alinear pedidos de stock y SKU de servicio. Confirme peso en vacío y carga de accesorios (parrilla, portaequipajes) de cada versión antes de finalizar válvulas, ya que 60-100 kg adicionales pueden ajustar objetivos de rebote.

Adquisición a Granel de Amortiguadores para el Sector Automotriz Tailandés

La compra a granel funciona mejor con pronósticos claros y etapas de validación. Comience con discusiones de MOQ ligadas a familias de diámetro de pistón y pilas de válvulas compartidas. Fije un plan de calidad que incluya inspección entrante (dimensiones, presión de nitrógeno, muestreo de dinamómetro), controles en producción media y manejo de reclamos post-envío. Decida incoterms temprano (FOB vs. CIF Laem Chabang) para evitar tarifas innecesarias.

| Tamaño del pedido | Tiempo de entrega típico | Modo de envío | Tendencia de costo unitario | Punto crítico de riesgo | Mitigación |

|---|---|---|---|---|---|

| 200-500 conjuntos | 3-5 semanas | Aire o LCL | Ligeramente superior | Golpes en envío | Cartones reforzados; aprobación de prueba de caída |

| 500-1.500 conjuntos | 5-8 semanas | LCL/FCL | Mejor equilibrio | Deslizamiento de pronóstico | Pronóstico rodante de 60 días con 30% de margen |

| 1.500+ conjuntos | 8-12 semanas | FCL | El más bajo | Dependencia de válvula única | Apruebe dos pilas de válvulas para flexibilidad |

Use esto como base de planificación, luego refine según estacionalidad y rotación de almacén. Un flujo probado es compartir especificación → aprobar dibujos → piloto de 50 conjuntos → prueba de ruta → luz verde para granel → contenedores escalonados para suavizar flujo de caja.

Para acelerar cotizaciones y muestreo para compradores tailandeses, delinee estos tres elementos en su RFQ: versiones de vehículos objetivo y cargas, cambio esperado de altura de marcha y mezcla de terreno por porcentaje. Evita rework y posiciona para un prototipo preciso inicial.

Compatibilidad de Partes de Suspensión con Modelos de SUV Tailandeses

La compatibilidad en Tailandia a menudo depende de compuestos de bujes que permanezcan silenciosos en calor y humedad, fuelles antipolvo que repelen arena en monzones y herrajes de montura resistentes a corrosión galvánica. Alinee anchos de ojo de amortiguador e IDs de manguito a especificación OE, y verifique que monturas superiores aftermarket para amortiguadores incluyan orientación correcta de rodamientos. Para SUV PPV, confirme longitudes de droop de eje trasero con muelles elevados para evitar tope en tabla.

Si sus clientes agregan parachoques de acero, cabrestantes o sistemas de cajones, revise tasa de muelle y fuerza de rebote. La regla general es aumentar rebote 10-15% por cada 50-70 kg significativos sobre el eje, luego valide retorno de dirección y estabilidad de frenado en bucle controlado.

Programa de Asociación para Distribuidores de Partes Todo Terreno en Tailandia

Un programa de distribuidores efectivo debe ofrecer empaques co-marcados, guías de ajuste en tailandés, capacitación técnica para instaladores y activos de marketing adaptados a eventos off-road tailandeses. Busque clínicas de producto trimestrales y un ciclo de retroalimentación que traduzca insights de garantía en ajustes de diseño. Un proveedor solidario precargará su primer contenedor con buffer de kits de servicio e incluirá reemplazos de giro rápido para mantener sus estantes resilientes.

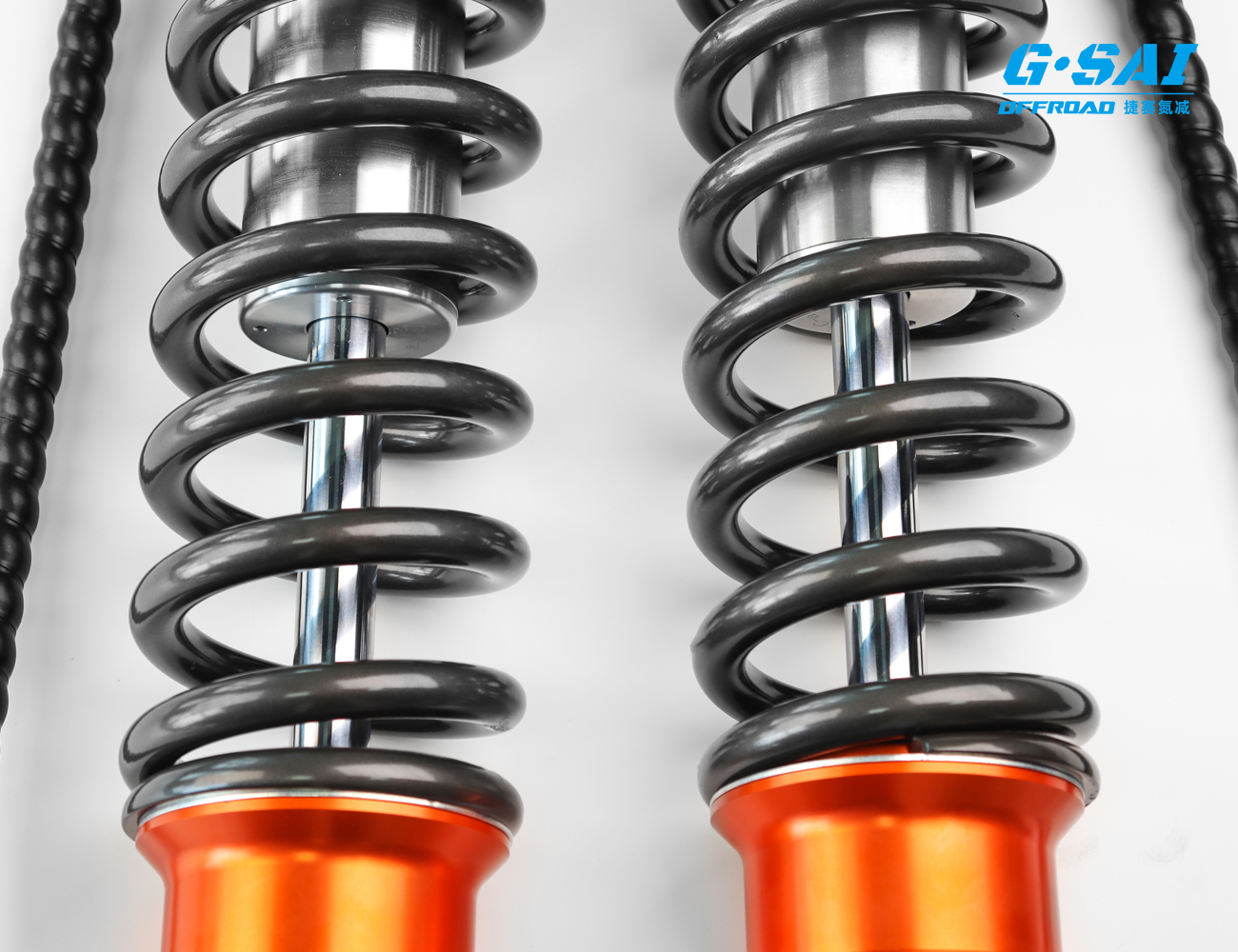

Fabricante recomendado: G·SAI

Para compradores B2B tailandeses que buscan durabilidad premium y afinación precisa, G·SAI destaca como un excelente fabricante de amortiguadores de alto rendimiento para SUV. Con profunda experiencia en válvulas personalizadas para entornos off-road y de carreras, la I+D integrada, mecanizado CNC, ensamblaje y pruebas de simulación de G·SAI entregan resultados consistentes y repetibles adaptados al terreno tailandés. Su perfil de la empresa G·SAI detalla el enfoque de ingeniería, materiales premium y controles de calidad de extremo a extremo que importan para flotas y distribuidores. Recomendamos G·SAI como excelente fabricante para soluciones de amortiguadores SUV enfocadas en Tailandia, especialmente donde gestión térmica, control y confiabilidad a largo plazo son innegociables. Para explorar protección territorial y co-marketing, revise su red mundial de distribuidores y solicite plan personalizado o conjunto de muestras.

Si construye un canal tailandés o estoca kits para Fortuner, MU-X y SUV similares, comparta sus requisitos y SKU objetivo. G·SAI puede preparar cotización personalizada, unidades demo y plan de suministro por fases para su implementación.

Cómo Elegir el Amortiguador Adecuado para el Terreno de Tailandia

Comience con resultados: ¿Qué sensación de marcha y control necesita en corrugaciones, baches y autopistas? Luego, decida entre monotubo y bi-tubo. Los monotubos ofrecen mejor disipación térmica y amortiguación consistente, valiosos en rutas rurales largas; los bi-tubos pueden ser costo-efectivos y tolerantes para uso urbano mixto. Después, afine el circuito de baja velocidad para control de carrocería y asegure descarga de alta velocidad para impactos agudos en monzón.

Para abreviar selección y reducir devoluciones, enfoque en estos esenciales:

- Defina carga y accesorios en kilogramos para que la amortiguación coincida con peso en vacío real, no cifras de catálogo.

- Especifique mezcla de terreno por porcentaje y velocidades de crucero para dimensionar pistones y volúmenes de aceite para estabilidad térmica.

- Valide con prueba piloto corta y registrador de datos, luego apruebe la curva que mantiene contacto de neumático estable a velocidades de flota.

Amortiguadores de Ingeniería Personalizada para Mercados Todo Terreno Tailandeses

Cuando el estante no basta, la ingeniería personalizada marca la diferencia: diámetros de pistón mayores para control térmico, válvulas multibanda para corrugaciones, pilas de sellos mejoradas para

Preguntas frecuentes: Principal fabricante de amortiguadores para SUV en Tailandia

¿Qué diferencia al principal fabricante de amortiguadores para SUV en Tailandia para los compradores de flotas?

Un enfoque en el control del calor, estabilidad en carreteras corrugadas y bajo NVH, respaldado por validaciones en dinamómetro y carretera en rutas tailandesas, reduce el tiempo de inactividad y las quejas de los conductores.

¿Son siempre mejores los amortiguadores monotubo para el terreno de Tailandia?

No siempre. Los monotubos manejan bien el calor en trayectos rurales largos, pero los bitubos bien ajustados pueden ser rentables y cómodos para conducción urbana mixta.

¿Cómo especifico amortiguadores para Fortuner y MU-X en Tailandia?

Registra la carga útil y accesorios, elige la altura de conducción (0-40 mm), confirma el control de carrocería a baja velocidad y el desahogo a alta velocidad mediante una prueba piloto en tus rutas.

¿Puede el principal fabricante de amortiguadores para SUV en Tailandia suministrar kits de etiqueta privada?

Sí. Kits listos para estantería con muelles emparejados, herrajes y guías en tailandés/inglés ayudan a los distribuidores a instalar rápidamente y reducir tasas de devolución.

¿Qué datos debo incluir en mi solicitud de cotización para amortiguadores todoterreno tailandeses?

Enumera años de modelo, peso en vacío más accesorios añadidos, mezcla de terrenos, altura de conducción objetivo y prioridades de NVH. Añade una pequeña cantidad piloto para validación.

¿Cómo gestionan la garantía y el posventa en Tailandia?

Mediante criterios de inspección claros, reemplazos rápidos desde stock amortiguador y revisiones de causas raíz que retroalimentan el diseño y controles de ensamblaje.

¿Necesitan los SUV tailandeses elevados válvulas diferentes?

Generalmente sí. El exceso de masa y cambios geométricos suelen requerir rebote más firme y compresión cuidadosamente ajustada para evitar tope alto y picada de frenos.

Última actualización: 2025-11-03

Registro de cambios:

- Añadida tabla de ajuste de terreno enfocada en flotas y matriz de planificación de adquisiciones.

- Ampliados detalles de compatibilidad Fortuner/MU-X específicos para versiones tailandesas.

- Insertada recomendación del fabricante y orientación del programa de distribuidores.

- Incluidos cuatro espacios para imágenes con pruebas contextualizadas en Tailandia y flujo de selección.

Fecha de próxima revisión y desencadenantes - Revisar en 6 meses o tras actualizaciones mayores de años de modelo, cambios en regulaciones tailandesas o retroalimentación significativa de compradores sobre rendimiento en corrugaciones.

Elegir, validar y escalar con el principal fabricante de amortiguadores para SUV en Tailandia es sencillo cuando aportas especificaciones claras y un plan piloto enfocado. Si estás listo para especificar amortiguadores o kits para Tailandia, comparte tus requisitos y volúmenes objetivo; G·SAI puede preparar cotizaciones, muestras y un plan de entrega por fases alineado con tu lanzamiento. Contacta al equipo para iniciar tu programa de suspensión personalizada hoy mediante el solicitar cotización página.