Quels sont les symptômes d'un amortisseur défectueux ? Un guide complet pour les entreprises automobiles

2 septembre 2025

Partager cet article

Qu'est-ce qu'un amortisseur et pourquoi est-il important pour la performance automobile

A amortisseur est un composant essentiel du système de suspension d'un véhicule qui contrôle le mouvement de haut en bas des roues. Il absorbe et dissipe l'énergie cinétique des impacts routiers, assurant une maniabilité en douceur, une meilleure stabilité et une sécurité accrue.

Principales fonctions des amortisseurs

| Fonction | Description |

|---|---|

| Amortissement des vibrations | Réduit les oscillations dues aux irrégularités de la route |

| Stabilisation du mouvement du véhicule | Maintient le contact des pneus avec la route |

| Amélioration du confort de conduite | Minimise les secousses et les vibrations dans l'habitacle |

| Amélioration du contrôle et de la sécurité | Empêche le roulis excessif de la carrosserie dans les virages et les freinages brusques |

| Protection du système de suspension | Réduit l'usure des pneus, des ressorts et des autres composants de la suspension |

Importance dans les applications tout-terrain et de course

Dans course tout-terrain et véhicule modifié environnements, les amortisseurs doivent résister à des conditions extrêmes telles que :

- Virages et freinages à grande vitesse

- Changements de terrain soudains (rochers, dunes, passages à gué)

- Exposition continue à la chaleur, à la boue et aux débris

Pour les entreprises qui fabriquent ou distribuent des pièces de véhicules haute performance, la compréhension des performances des amortisseurs est essentielle. Cela aide au développement de produits, au support client et au marketing pour équipes de course, grossistes de pièces automobiles et ateliers de mise à niveau 4×4.

Types d'amortisseurs pour les acheteurs B2B

| Type | Meilleur pour | Niveau de performance |

|---|---|---|

| Amortisseur monotube | Voitures de course, véhicules haute performance | Haut |

| Amortisseur bitube | Conduite quotidienne, léger hors route | Moyen |

| Amortisseur chargé au gaz | Camions lourds, véhicules tout-terrain | Haut |

| Hélicoïdal réglable | Réglage personnalisé pour les véhicules modifiés | Très élevé |

| Amortisseur hydraulique | Voitures classiques, utilisation routière standard | Moyen |

Pour les grossistes et les acheteurs OEM qui cherchent à stocker des pièces de qualité supérieure, se concentrer sur amortisseurs réglables, chargés au gaz ou prêts pour la course peut générer

Symptômes courants d'un amortisseur défectueux dans les véhicules tout-terrain et de course

Identifier précocement un amortisseur défectueux est crucial pour maintenir les performances du véhicule, en particulier dans les environnements à enjeux élevés comme les courses hors route ou les flottes commerciales. Vous trouverez ci-dessous les symptômes les plus courants indiquant une défaillance.

1. Rebonds excessifs ou plongeon du nez

- Lorsque le véhicule rebondit plusieurs fois après avoir heurté une bosse

- L'avant plonge brusquement lors du freinage

- L'arrière s'affaisse lors de l'accélération

C'est un signe que l'amortisseur ne peut plus contrôler le rebond de la suspension.

2. Usure inégale des pneus

- Crevasses ou festons sur les bandes de roulement des pneus

- Bords intérieurs ou extérieurs usés

Les amortisseurs qui ne maintiennent pas le contact avec les roues provoquent des mouvements erratiques des pneus, entraînant une usure prématurée et inégale des pneus, ce qui augmente les coûts d'exploitation pour les exploitants de flottes ou les équipes de course.

3. Fuites de liquide

- Huile ou liquide visiblement en fuite sur le corps de l'amortisseur

- Accumulation de graisse autour du support de l'amortisseur

Les amortisseurs hydrauliques reposent sur le liquide pour amortir les mouvements. Les fuites réduisent leur efficacité et signalent une défaillance imminente. Pour les revendeurs de pièces automobiles, c'est un point clé pour éduquer les clients sur les inspections.

4. Mauvaise maniabilité et instabilité

- Balancement ou roulis de la carrosserie en virage

- Dérive ou instabilité lors des changements de voie

- Difficultés de contrôle de la direction

Ceci est particulièrement dangereux dans les courses à grande vitesse ou les environnements hors route, où la stabilité est essentielle pour la sécurité et les performances du pilote.

5. Bruit de claquement ou de cliquetis

- Bruits lors du passage sur des bosses

- Supports d'amortisseurs desserrés ou composants cassés

Les cliquetis métal sur métal peuvent indiquer que des pièces internes se sont détachées. Les techniciens et les garages doivent être formés pour identifier ces bruits lors des diagnostics.

Comment les amortisseurs défectueux affectent la sécurité et la maniabilité du véhicule

Un amortisseur détérioré compromet non seulement le confort, mais aussi les systèmes de sécurité critiques. Vous trouverez ci-dessous une ventilation de la manière dont ces défaillances ont un impact sur divers aspects de la conduite et des opérations commerciales.

Risques pour la sécurité et les performances

| Zone d'impact | Conséquence |

|---|---|

| Distance de freinage | Augmente la distance d'arrêt de 20 % à 30 % |

| Adhérence des pneus | Réduction du contact avec la route, entraînant un dérapage |

| Efficacité de l'ABS et de l'ESC | Les aides à la conduite avancées fonctionnent mal en raison d'une pression incohérente des roues |

| Fatigue du conducteur | Augmentation des vibrations dans l'habitacle et du bruit de la route |

| Capacités hors route | Réduction de l'articulation et du contact avec le sol sur les terrains accidentés |

Implications pour les flottes et les entreprises

Pour les clients B2B tels que les flottes logistiques, les équipes de course hors route ou les modificateurs de véhicules, les amortisseurs défectueux entraînent :

- Augmentation des temps d'arrêt

- Coûts d'entretien plus élevés

- Insatisfaction des clients

- Responsabilités en matière de sécurité

Investir dans des amortisseurs fiables et performants réduit considérablement ces risques et améliore la réputation de la marque.

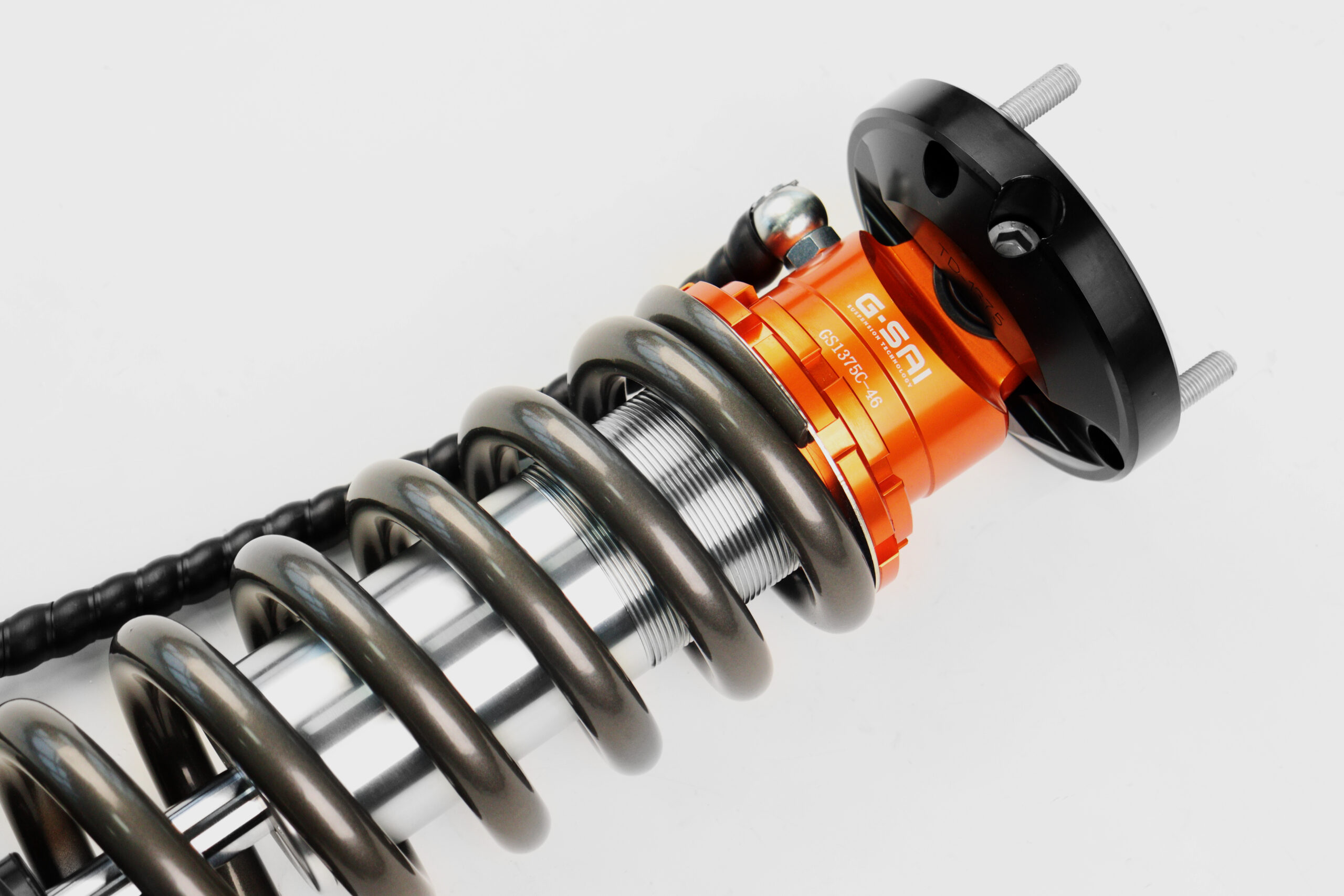

Amortisseurs G·SAI : Une solution B2B de confiance

G·SAI propose une large gamme de amortisseurs sur mesure conçus spécifiquement pour les cas d'utilisation exigeants tels que :

- Course tout-terrain

- VUS et camions modifiés

- Véhicules de loisirs (VR)

Avec plus de 17 ans d'expertise en R&D dirigée par l'ingénieur en chef Cai Xianyun, les produits G·SAI sont conçus pour une précision, une durabilité et une adaptabilité maximales. Bon nombre de leurs amortisseurs sont testés dans des conditions de course réelles pour garantir leur fiabilité.

Pour les entreprises qui cherchent à s'approvisionner ou à distribuer des amortisseurs haut de gamme, visitez le Catalogue des produits G-SAI pour des spécifications détaillées et des options B2B.

Diagnostic des problèmes d'amortisseurs : outils et techniques pour les techniciens automobiles

Pour les ateliers, les fournisseurs de pièces et les préparateurs de véhicules de performance, un diagnostic précis des problèmes d'amortisseurs est essentiel. Cela garantit non seulement une réparation correcte, mais aide également à recommander les pièces de rechange correctes aux clients. Ci-dessous, nous détaillons les outils et les techniques professionnels utilisés par les techniciens pour diagnostiquer les amortisseurs défectueux.

Techniques d'inspection visuelle

Une première étape simple mais efficace pour identifier une défaillance de l'amortisseur est une vérification visuelle approfondie. Voici ce qu'il faut rechercher :

- Fuite de liquide autour de la tige ou du cylindre

- Bosses ou dommages sur le corps de l'amortisseur

- Corrosion ou rouille, en particulier près des supports

- Fissures dans les bagues ou les supports de montage

- Affaissement inégal de chaque côté du véhicule

🛠 Conseil pour les techniciens B2B : Inspectez toujours par paires (les deux avant ou les deux arrière) et recommandez des remplacements doubles, qui offrent des performances constantes et réduisent les plaintes futures.

Test de rebond pour une évaluation initiale

Il s'agit d'un test rapide couramment utilisé par les centres de service :

- Appuyez fermement sur le pare-chocs du véhicule.

- Relâchez rapidement.

- Observez le nombre de rebonds du véhicule.

Tableau de diagnostic

| Observation | État | Recommandation |

|---|---|---|

| Rebonds 1 à 2 fois | Amortisseur normal | Aucune action requise |

| Rebonds > 3 fois | Amortisseur usé ou défaillant | Recommander le remplacement de l'amortisseur |

| Oscillation continue | Amortisseur gravement endommagé | Remplacement immédiat requis |

Outils avancés pour un diagnostic professionnel

Pour les ateliers de réparation B2B et les marques automobiles, l'utilisation d'outils avancés permet de vendre des solutions d'amortisseurs à marge plus élevée et d'améliorer la précision du service.

Outils de diagnostic recommandés

| Outil | Cas d'utilisation | Bénéfice |

|---|---|---|

| Testeur d'amortisseur | Mesure la force et la réponse sous charge | Mesure précise des performances |

| Machine d'analyse de la suspension | Analyse complète des vibrations et de l'amortissement | Détecte les dommages internes cachés |

| Caméra thermique | Identifie les incohérences thermiques après la conduite | Localise les problèmes de friction interne |

| Scanner OBD-II | Lit les codes du système de suspension (dans les voitures plus récentes) | Diagnostics intégrés pour les systèmes intelligents |

📈 Argument de vente pour les entreprises automobiles :

Utilisez ces diagnostics comme un service à valeur ajoutée argument de vente pour vos clients grossistes. Offrez-leur une formation ou des offres groupées de diagnostics + pièces pour fidéliser la clientèle.

Amortisseurs vs. Jambes de force : Comprendre les différences et les signes de défaillance

De nombreux clients confondent les amortisseurs et les jambes de force. En tant que fournisseur ou distributeur, éduquer vos clients sur la différence garantit de meilleures recommandations de produits et renforce la confiance.

Principales différences entre les amortisseurs et les jambes de force

| Fonctionnalité | Amortisseurs | Jambes de force |

|---|---|---|

| Fonction | Amortissent le mouvement de la suspension | Composant structurel + amortissement |

| Supportent la charge | Non | Oui |

| Localisation | Généralement à l'arrière ou à l'avant sans charge | Principalement la suspension avant |

| Coût de remplacement | Plus bas | Plus élevé |

| Complexité | Composant simple | Comprend un ressort hélicoïdal et un support |

Amortisseurs sont purement destinés à contrôler le mouvement, tandis que les jambes de force agissent comme des composants structurels et comprennent des pièces supplémentaires telles que des ressorts hélicoïdaux et des supports.

Comparaison des symptômes de défaillance

| Symptôme | Défaillance de l'amortisseur | Défaillance de la jambe de force |

|---|---|---|

| Ballottement excessif | ✅ | ✅ |

| Plongeon du nez au freinage | ✅ | ✅ |

| Bruit de claquement | ✅ | ✅ (généralement plus fort) |

| Affaissement du véhicule | ❌ | ✅ (indique une défaillance du ressort) |

| Hauteur de caisse inégale | ❌ | ✅ |

🛠 Conseil de pro : Lorsqu'une jambe de force tombe en panne, recommandez toujours des kits de remplacement complets de jambes de force à vos clients B2B pour éviter d'autres problèmes liés aux remplacements partiels.

Comment choisir les amortisseurs de remplacement pour les applications tout-terrain et de course

Pour les équipes de course hors route, les garages de performance et les fournisseurs de pièces de rechange, le choix du bon amortisseur est une décision de performance critique. Le mauvais choix peut entraîner une mauvaise maniabilité, des dommages et même des problèmes de sécurité.

Principaux critères de sélection pour les acheteurs B2B

- Type de véhicule et charge

- VUS légers contre camions tout-terrain lourds

- Buggys de course contre camping-cars

- Terrain et application

- Dunes de sable, rochers, boue, neige ou tarmac

- Utilisation compétitive ou récréative

- Ajustement

- Taux fixe contre compression et rebond réglables

- Caractéristiques du réservoir distant pour le contrôle de la chaleur

- Matériau et qualité de fabrication

- Aluminium usiné contre corps en acier

- Revêtements antirouille et joints résistants à la chaleur

- Réputation de la marque et garantie

- Utilisation prouvée dans les environnements de sport automobile

- Durabilité à long terme sous des charges extrêmes

Types d'amortisseurs recommandés par cas d'utilisation

| Type d'application | Type d'amortisseur recommandé | Notes |

|---|---|---|

| Course tout-terrain | Coilovers monotubes ou à réservoir distant | Dissipation thermique supérieure, réglabilité |

| Franchissement de rochers | Amortisseurs à gaz bitubes à longue course | Permet une articulation maximale |

| Véhicules récréatifs d'Overlanding | Amortisseurs à gaz robustes personnalisés | Confort de conduite et support de charge améliorés |

| Performances dans la rue | Amortisseurs sport réglables | Réglables pour différentes préférences de conduite |

| Camions 4×4 modifiés | Kits de coilovers avec options de levage | Améliore la posture et les capacités hors route |

Pourquoi choisir G·SAI pour les amortisseurs personnalisés

G·SAI est le choix préféré des clients B2B qui ont besoin de amortisseurs haut de gamme personnalisés. Que vous construisiez une nouvelle marque hors route ou que vous fournissiez une équipe de course, G·SAI propose :

- Des solutions d'amortisseurs entièrement personnalisables

- Des installations internes de CNC, de R&D et de tests

- Assistance technique individuelle pour OEM et marque privée besoins

Nos produits sont conçus avec des performances extrêmes à l'esprit, soutenus par des années de fiabilité testée sur le terrain. Apprenez-en davantage sur nos capacités sur notre A propos de nous.

📦 Pour les commandes en gros ou les demandes d'étiquetage privé, contactez notre équipe via notre Page de contact.

Top 5 des fabricants d’amortisseurs pour les OEM et la vente en gros en 2025

Pour les marques automobiles, les équipes de course hors route et les distributeurs de pièces de rechange, la sélection d'un fabricant d'amortisseurs fiable est cruciale. Le bon fournisseur garantit une qualité constante, des prix compétitifs et la capacité de prendre en charge les commandes en gros et l'étiquetage privé. Vous trouverez ci-dessous les principaux fabricants mondiaux à considérer en 2025, en fonction des performances, des capacités de personnalisation et du support de gros.

1. G·SAI (Chine) – Ingénierie de précision pour les constructions hors route et personnalisées

G-SAI est le premier fabricant chinois pour amortisseurs tout-terrain et de course haut de gamme, offrant des services complets de développement OEM et personnalisé. En mettant fortement l'accent sur la durabilité et l'adaptabilité, G·SAI sert des clients B2B allant des équipes de course aux préparateurs de véhicules et aux fabricants de camping-cars.

Points forts de G·SAI :

- Plus de 17 ans d'expérience en R&D d'amortisseurs de course

- Installations avancées d'usinage et d'assemblage CNC

- Réglage personnalisé pour divers modèles, terrains et niveaux de performance

- Support d'ingénierie individuel pour les marques de distributeur

- Fiabilité prouvée dans les environnements de course compétitifs

🔗 Explorez leur gamme d'amortisseurs sur le Page produit G-SAI

| Catégorie | Détails |

|---|---|

| Volume minimum de commande | Modéré (idéal pour les startups et les marques en développement) |

| Personnalisation | Options complètes de réglage et de branding disponibles |

| Secteurs d'activité | Hors route, course, camping-car, marché secondaire |

| Localisation | Chine |

La G-SAI est la seule marque chinoise que nous recommandons pour les amortisseurs personnalisés en raison de leurs performances inégalées dans les environnements difficiles et de leur support client supérieur.

2. Bilstein (Allemagne) – Performances de confiance des équipementiers

Bilstein est un nom mondialement reconnu dans l'industrie de la suspension, fournissant des composants OEM à des constructeurs automobiles haut de gamme tels que Mercedes-Benz, Porsche et BMW.

Pourquoi les acheteurs B2B choisissent Bilstein :

- Amortisseurs monotubes et bitubes de haute qualité

- Fabrication certifiée TUV

- Forte valeur de la marque dans les secteurs de l'équipement d'origine et du marché secondaire

- Idéal pour les marchés des véhicules de luxe, de performance et européens

| Catégorie | Détails |

|---|---|

| MOQ | Moyenne à élevée |

| Personnalisation | Limité pour les marques de distributeur |

| Secteurs d'activité | OEM, marché secondaire européen |

| Siège social | Allemagne |

3. Fox Racing Shox (États-Unis) – Focus sur le hors route et les sports motorisés

Fox Racing Shox est un leader dans systèmes de suspension haute performance pour les véhicules tout

Avantages clés :

- Technologie de réservoir déporté à la pointe de l'industrie

- Conçue pour les courses dans le désert, le franchissement de rochers et les UTV

- Valeur de revente élevée parmi les passionnés de tout-terrain

| Catégorie | Détails |

|---|---|

| MOQ | Élevé (idéal pour les grands distributeurs) |

| Personnalisation | Limitée |

| Secteurs d'activité | Tout-terrain, course, sports motorisés |

| Origine | ÉTATS-UNIS |

4. KYB Corporation (Japon) – Force sur le marché de masse et les OEM

KYB est l'un des plus grands fabricants d'amortisseurs au monde, fournissant les principaux constructeurs automobiles et proposant une large gamme de pièces de rechange.

Pourquoi KYB séduit les grossistes :

- Capacité de production à grande échelle

- Prix compétitifs pour les commandes en gros

- Large gamme de produits comprenant des jambes de force, des amortisseurs et des combinés filetés

| Catégorie | Détails |

|---|---|

| MOQ | Faible à moyen |

| Personnalisation | Minime |

| Secteurs d'activité | OEM, marché de la pièce de rechange de masse |

| Siège social | Japon |

5. King Shocks (USA) – Suspension de course et tout-terrain sur mesure

King Shocks est spécialisé dans des amortisseurs construits sur mesure pour la communauté de la course et du tout-terrain. Leurs produits sont largement utilisés dans le Baja 1000 et les courses d'endurance similaires.

Pourquoi choisir King Shocks :

- Amortisseurs fabriqués à la main pour des applications de course spécifiques

- Réservoirs déportés et clapets multi-étages

- Idéal pour les ateliers de réglage de performance et les équipes de course d'élite

| Catégorie | Détails |

|---|---|

| MOQ | Haut |

| Personnalisation | Systèmes entièrement personnalisés disponibles |

| Secteurs d'activité | Course professionnelle, tout-terrain |

| Siège social | ÉTATS-UNIS |

🛠️ Conseil de pro pour les distributeurs :

Choisissez votre fournisseur en fonction de votre créneau. Pour les ventes de masse à volume élevé, KYB ou Bilstein peuvent répondre à vos besoins. Mais pour des performances extrêmes, une personnalisation tout-terrain ou le développement de marques propres, G·SAI est inégalé en termes de flexibilité et de support technique.

🔗 Découvrez comment devenir revendeur ou distributeur de G·SAI via le Réseau de distributeurs G-SAI

FAQ : Amortisseurs défectueux, réparations et approvisionnement pour les entreprises automobiles

Voici les questions B2B les plus fréquemment posées concernant les amortisseurs défectueux et la chaîne d'approvisionnement des pièces de rechange :

Q1 : À quelle fréquence les amortisseurs doivent-ils être remplacés dans les véhicules tout-terrain ?

Réponse :

Dans des conditions extrêmes de tout-terrain ou de course, il est recommandé d'inspecter et de remplacer potentiellement les amortisseurs tous les 30 000 à 50 000 km, ou après chaque événement majeur. Pour les véhicules routiers standard, les remplacements sont généralement nécessaires tous les 80 000 à 100 000 km.

Q2 : Les amortisseurs défectueux peuvent-ils endommager d'autres parties du véhicule ?

Réponse :

Oui. Des amortisseurs défaillants peuvent entraîner :

- Usure excessive des pneus

- Composants de suspension cassés

- Mauvais alignement de la direction

- Stress accru sur les roulements de roue et les essieux

Q3 : Comment puis-je savoir si un fournisseur d'amortisseurs est fiable pour les OEM ou la vente en gros ?

Réponse :

Recherchez ce qui suit :

- Installations internes de R&D et d'essais

- Capacités de personnalisation

- Certifications ISO ou de l'industrie

- MOQ et délais de livraison transparents

- Performances prouvées des produits (par exemple, en course)

G·SAI répond à tous ces critères et est approuvé par les acheteurs B2B du monde entier. En savoir plus sur le Page À propos de nous de G·SAI

Q4 : Dois-je changer les quatre amortisseurs en même temps ?

Réponse :

Il est fortement recommandé de remplacer les amortisseurs par paires assorties (avant ou arrière) au minimum. Pour des performances et une sécurité optimales, il est préférable de changer les quatre, en particulier dans les environnements de performance ou de tout-terrain.

Q5 : G·SAI peut-il produire des amortisseurs en marque propre ?

Réponse :

Absolument. Le G-SAI offre Production OEM et en marque propre avec une personnalisation complète, y compris la marque, les profils d'amortissement et le réglage spécifique au véhicule. Leur usine prend en charge le prototypage rapide et la production de masse évolutive.

🔗 Intéressé par l'approvisionnement en amortisseurs personnalisés ? Contactez G·SAI dès aujourd'hui

Réflexions finales : Transformer le diagnostic des amortisseurs défectueux en une opportunité commerciale

Pour les grossistes en pièces automobiles, les marques de véhicules tout-terrain et les équipes de course, comprendre les symptômes des amortisseurs défectueux est plus qu'une simple connaissance technique, c'est une porte d'entrée vers un approvisionnement plus intelligent, un meilleur service client et des taux de conversion plus élevés.

En vous associant à un fabricant d'amortisseurs fiable comme G·SAI, votre entreprise a accès à :

- Des produits conçus sur mesure pour tout terrain ou cas d'utilisation

- Des prix de gros compétitifs et des possibilités d'étiquetage privé

- Un support technique d'une équipe ayant des décennies d'expérience en course

💼 Prêt à développer votre entreprise de pièces automobiles avec de meilleures solutions d'amortisseurs ?

Visitez le site Site Web officiel de G·SAI pour explorer les produits, les opportunités de revendeurs et les ressources techniques.

Laissez vos clients conduire en toute confiance, grâce à la technologie d'amortisseurs de précision de G·SAI.

FAQ supplémentaires sur l’identification d’un amortisseur défectueux (B2B)

- Q : Quel symptôme indique le plus fiablement un amortisseur défectueux lors d’un essai routier ?

R : Oscillations répétées après un seul dos d’âne (plus de 2 cycles) combinées à une distance de freinage accrue. Vérifiez cupping pneus et fuites visuelles. - Q : Les upgrades roues/pneus peuvent-ils masquer ou imiter les symptômes d’amortisseurs défectueux ?

R : Oui. Pneus LT lourds et diamètres plus grands ajoutent élasticité flanc, augmentant rebond et cabrage freinage. Sans recalibration, symptômes ressemblent à usure amortisseurs. - Q : Comment la chaleur et la perte de performance se manifestent-elles en off-road ou course ?

R : Perte progressive de contrôle fin d’étape, impacts plus durs, rebond prolongé. Mesurez avec température réservoir/tige et comparez données force-vitesse chaud vs froid. - Q : Les cliquetis sont-ils toujours dus à un amortisseur défectueux ou peuvent-ils venir des fixations/bagues ?

R : Cliquetis souvent dus à bagues usées ou fixations desserrées. Inspectez œillettes, manchons, fixations supérieures ; remplacez par paires et serrez à spec sous hauteur de caisse pour éviter récidive. - Q : Quels seuils symptomatiques les flottes doivent-elles utiliser pour déclencher remplacement ?

R : Toute fuite fluide, scalloping pneus, >1 rebond supplémentaire, ou RMS accélération verticale >15 % sur itinéraire fixe. Utilisez comme déclencheurs objectifs dans SOP maintenance.

Tendances sectorielles 2025 : Diagnostic plus rapide et data-driven des amortisseurs défectueux

- Diagnostics télémétriques : Accélération verticale et taux événements ABS/ESC signalent amortisseurs défaillants avant plaintes conducteurs.

- Normalisation dyno chaud : Marques publient courbes force-vitesse chaud (100–130 °C) pour lier symptômes perte à données objectives.

- Impact masse VE : Masse à vide plus lourde élève besoins rebond ; amortisseurs inadéquats montrent cupping pneus et cabrage freinage précoces.

- Quincaillerie corrosion-consciente : Specs Zn-Ni/e-coat réduisent saisies fixations masquant symptômes et compliquant remplacements.

- Traçabilité QR : Courbes dyno lot, specs couple, guides config réduisent mauvais diagnostics et retours.

Instantané adoption symptômes et diagnostic (2023–2025)

| Métrique | 2023 | 2024 | 2025 (est.) | Notes/Source |

|---|---|---|---|---|

| Ateliers utilisant accéléromètre/télémétrie pour signaler pannes amortisseurs | 16% | 23% | 34% | Enquêtes fournisseurs télémétrie et installateurs |

| Amortisseurs aftermarket avec données dyno chaud/froid pour diagnostic | 24% | 32% | 46% | Audits catalogues ; QA marques |

| Flottes suivant RMS accel verticale comme KPI maintenance | 12% | 19% | 29% | Rapports maintenance flottes |

| Bons de service snowbelt spécifiant ≥720 h ASTM B117 quincaillerie | 35% | 43% | 56% | Spécifications fournisseurs ; ASTM B117 |

| Concessionnaires utilisant données config/couple liées QR à installation | 20% | 28% | 41% | Initiatives de marque privée |

Références : Recherche marché SEMA (https://www.sema.org/research), SAE Technical Papers (https://www.sae.org/), normes ASTM (https://www.astm.org/), Geotab (https://www.geotab.com/), Racecar Engineering (https://www.racecar-engineering.com/)

Études de cas récentes

Étude de cas 1 : Télémétrie signale amortisseurs défectueux avant plaintes conducteurs (2025)

Contexte : Flotte last-mile signalait détections tardives problèmes roulage, menant à cupping pneus et arrêts.

Solution : Activation monitoring accélération verticale et événements ABS ; seuils auto-créant bons travail ; formation techniciens bounce tests et inspections fuites.

Résultats : Arrêts liés amortisseurs −26 % ; réclamations usure pneus irrégulière −22 % ; détection moyenne 1 200 km avant cas signalés conducteurs.

Étude de cas 2 : Validation dyno chaud réduit retours « amortisseur bruyant » mal diagnostiqués (2024)

Contexte : Réseau ateliers performance voyait retours élevés cliquetis post-install off-road.

Solution : Mise en place contrôles dyno chaud/froid et inspections obligatoires bagues/fixations avec couple sous hauteur caisse ; ajout SOP install liées QR.

Résultats : Retours bruit −37 % ; taux vrai défaillance interne amortisseur clarifié à 1,8 % vs 4,1 % présumé avant ; NPS client +15 points.

Avis d'experts

- Dr Thomas D. Gillespie, auteur dynamique véhicule : « Données amortissement validées température consistent essentielles pour séparer vraie panne amortisseur de problèmes setup ou bagues. »

- Stephanie Brinley, analyste principal, S&P Global Mobility : « Plateformes électrifiées plus lourdes amplifient symptômes – cabrage freinage et cupping pneus apparaissent plus tôt si amortisseurs sous-spécifiés. »

- Dave Polke, ASE Master/L1 Technicien et Formateur : « Serrez quincaillerie suspension à hauteur caisse et remplacez bagues avec amortisseurs. La plupart bruits ‘mauvais amortisseur’ sont erreurs fixation, pas calibration. »

Outils et ressources pratiques

- SAE Mobilus (diagnostics amortisseurs, fondamentaux amortissement) : https://www.sae.org/

- SEMA Market Research (tendances aftermarket et installateurs) : https://www.sema.org/research

- Racecar Engineering (interprétation données dyno amortisseurs, perte thermique) : https://www.racecar-engineering.com/

- Geotab (télémétrie accélération verticale/suivi événements ABS) : https://www.geotab.com/

- Hunter Engineering (alignement et procédures hauteur caisse) : https://www.hunter.com/

- ASTM B117 (corrosion), D445/D2270 (viscosité/VI) : https://www.astm.org/

- Benchmarking catalogues : https://www.ridefox.com/, https://www.bilstein.com/, https://www.kingshockstech.com/

Dernière mise à jour : 2025-10-09

Journal des modifications : Ajout 5 FAQ B2B symptômes amortisseurs défectueux ; tableau tendances 2025 adoption diagnostic ; deux études de cas (télémétrie, validation dyno chaud) ; points de vue experts ; ressources pratiques liens autorisés

Date révision prochaine et déclencheurs : 2026-03-31 ou plus tôt si OEM/SAE publient normes diagnostic dyno chaud nouvelles, KPI télémétriques santé amortisseurs évoluent, ou données flottes montrent variation >15 % arrêts symptomatiques