Approvisionnement Gros Kits Suspension Off-Road pour Silverado en Arabie Saoudite

15 décembre 2025

Partager cet article

Les dunes, oueds et autoroutes à longue distance d’Arabie saoudite exigent des kits de suspension associant résistance thermique, maîtrise de la charge utile et débattement précis des roues. Pour un approvisionnement à grande échelle, la voie la plus fiable consiste en une fourniture en gros de kits de suspension tout-terrain pour Silverado en Arabie saoudite, adaptés au terrain local et aux cycles d’exploitation des flottes. Si vous envisagez une expansion de flotte ou avez besoin d’un devis rapide et d’un ensemble d’échantillons, partagez les spécifications et les délais de votre Silverado — nous pouvons détailler un pack en gros et un plan d’accordage via les services sur mesure de G·SAI. Pour une coordination immédiate, contactez l’équipe via la page de contact G·SAI : Parlez à l’équipe G·SAI.

Options Kits Relevage Chevy Silverado pour Usage Off-Road en Arabie Saoudite

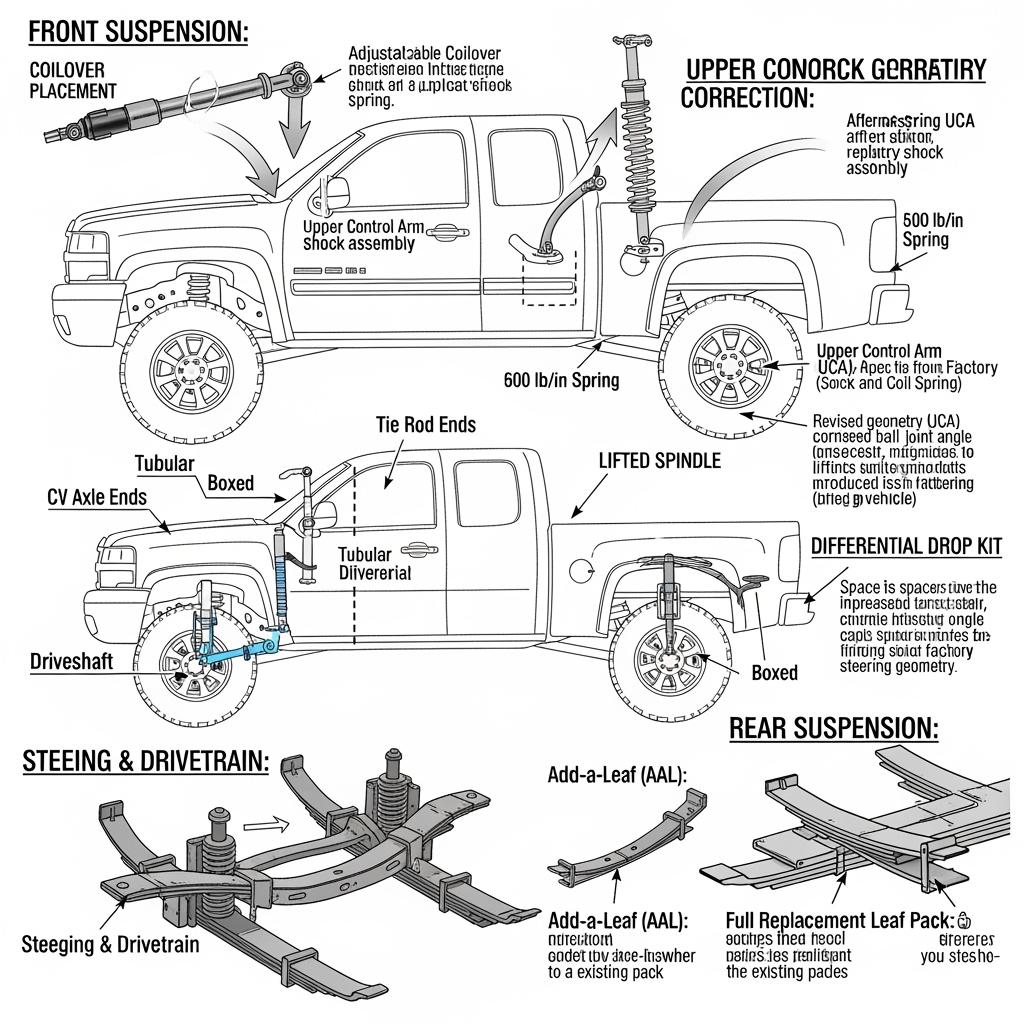

Le choix de l’élévation doit correspondre au terrain, à la taille des pneus et à la charge utile réelle transportée. Une élévation modérée de 5 à 8 cm avec des amortisseurs monotubes à haut débit assure un fonctionnement plus frais et un meilleur contrôle sur les pistes désertiques. Une élévation performance de 10 à 15 cm avec des coilovers à réservoir distant et une géométrie corrigée (bras de commande supérieurs, knuckles de direction) libère un débattement exploitable sur les bosses et les whoops. Pour des travaux intenses dans le sable, privilégiez la gestion thermique, un amortissement constant en mi-course et un contrôle progressif en fin de course.

Lors du choix entre élévations à entretoises, coilovers ou systèmes complets, pensez en termes de plage de roulis réellement utilisée. Les élévations à entretoises seules augmentent la hauteur sans ajouter de marge d’amortissement. Les vrais systèmes coilover avec des packs ressorts/arrière assortis améliorent à la fois la hauteur et le contrôle. Ajoutez des butées de compression et des durites de frein allongées pour rendre les impacts prévisibles et les intervalles d’entretien gérables par forte chaleur.

| Cas d’usage | Hauteur d’élévation recommandée | Composants cœur | Priorité à la gestion thermique | Notes |

|---|---|---|---|---|

| Dunes à haute vitesse | 5–7,5 cm | Coilovers à réservoir distant, BCA, amortisseurs arrière accordés | Pistons de grand diamètre, réservoirs externes | Privilégiez le soutien en mi-course et la surface des ailettes de refroidissement |

| Oueds rocheux/pistes | 5–10 cm | Coilovers à calage dégressif, bras de commande adaptés aux protections | Huile d’amortisseur à haute stabilité thermique | Équilibrez le contrôle à basse vitesse et l’articulation |

| Charge utile overland | 3–8 cm | Ressorts/packs feuilles à charge nominale, amortisseurs renforcés | Amortissement constant sous charge | Accordez pour une charge constante ; évitez un rake excessif |

| Flotte polyvalente | 5–7,5 cm | Kit avant/arrière assorti, cames d’alignement, butées de compression | Conception d’amortisseur entretenable | Standardisez les références et outils d’entretien pour maximiser la disponibilité |

Cette matrice décisionnelle aide les flottes à éviter la sur- ou sous-spécification. En Arabie saoudite, la chaleur est le tueur invisible — choisissez des amortisseurs qui restent constants après de longues sessions dans les dunes et des livraisons en plein midi.

Meilleurs Kits Suspension pour Silverado 1500 et 2500 sur Marché KSA

Les kits pour Silverado 1500 privilégient performance et confort de roulis, tandis que ceux pour 2500 doivent concilier le poids avant des gros moteurs et le remorquage fréquent. Pour les 1500, des coilovers premium à réservoir distant, des BCA corrigés et des ressorts arrière progressifs stabilisent les vitesses désertiques. Pour les 2500, des ressorts avant à charge nominale ou solutions à torsion, des packs feuilles arrière renforcés et des amortisseurs haute capacité préviennent la perte d’efficacité sous chaleur continue et charge utile.

| Modèle Silverado | Catégorie de kit | Caractéristiques clés | Taille de pneus idéale | Notes |

|---|---|---|---|---|

| 1500 | Système coilover performance | Avant à réservoir distant, calage dégressif, BCA | 840–890 mm | Contrôle confiant sur whoops et pistes damées |

| 1500 | Élévation modérée économique | Entretoises de nivellement + amortisseurs monotubes améliorés | 81–84 cm | Économique, moins de marge d’amortissement pour la chaleur |

| 2500 | Kit travail renforcé | Ressorts/feuilles à charge nominale, amortisseurs large alésage | 840–890 mm | Résiste au remorquage et à la charge constante |

| 2500 | Système accordé overland | Feuilles arrière progressives, ressorts avant accordés, butées de compression | 86–89 cm | Lisse les corrugations avec charge à bord |

| Pack flotte | Approvisionnement Gros Kits Suspension Off-Road pour Silverado en Arabie Saoudite | Références standardisées, kits d’entretien et pièces de rechange | 81–89 cm | Simplifie les achats, l’entretien et la formation |

Le tableau ci-dessus oppose les voies courantes de kits et leurs points forts. Pour les flottes, standardiser sur un « pack » avec pièces d’entretien partagées réduit les arrêts et simplifie la formation entre dépôts.

Si vous avez besoin d’un partenaire technique éprouvé pour vos types de kits choisis, consultez le consultez le profil de l’entreprise G·SAI pour voir comment leur développement et leurs tests d’amortisseurs suivent les exigences tout-terrain et course.

Composants Suspension Notés Charge pour SUV Heavy-Duty en KSA

La charge utile transforme de bons kits en excellents — ou en maux de tête prématurés d’entretien. Les choix de ressorts et de calage doivent correspondre au poids chargé réel, pas seulement à la masse à vide. Chaleur et poids combinés fluidifient l’huile d’amortisseur et réduisent l’amortissement si les composants sont sous-dimensionnés. Les ressorts à charge nominale (ressorts hélicoïdaux ou feuilles) doivent s’associer à des amortisseurs haute capacité qui restent constants après de longs cycles chauds. N’oubliez pas les silentblocs haute dureté et les fixations renforcées ; ils maintiennent l’alignement stable et éliminent les grincements dus à l’intrusion de sable.

| Composant | Orientation de la charge | Ce qu’il faut chercher | Astuce spécifique à l’Arabie saoudite | Indice d’entretien |

|---|---|---|---|---|

| Ressorts hélicoïdaux avant | Poids constant moteur/équipements avant | Solution ressort/torsion nominale avec calage assorti | Évitez une précharge excessive pour préserver la plage de roulis | Revérifiez la hauteur après les premiers 1 000 km |

| Packs feuilles arrière | Charge/remorquage | Feuilles progressives ou multi-taux avec design anti-enroulement | Spécifiez pour condition « chargée typique » | Resserrer les boulons U après tassement initial |

| Amortisseurs (avant/arrière) | Chaleur et énergie d’impact | Monotubes large alésage ou à réservoir | Huile haute température et joints, réparables | Inspectez les pertes après longues journées dans les dunes |

| Silentblocs/fixations | Articulation et stabilité | Matériaux haute dureté résistants au désert | Résistent à la chaleur et à l’abrasion sableuse | Lubrifiez ou remplacez au moindre grincement audible |

| Butoirs | Contrôle fin de course | Progressif ou hydraulique | Évitez les chocs durs dans les dunes | Inspectez après répétitions de fin de course |

Ces choix stabilisent la tenue de route, préservent les distances de freinage et prolongent la durée de vie. Adapter l’amortissement à la charge maintient la confiance des conducteurs et les flottes à l’heure.

Choisir la Bonne Suspension pour 4×4 Silverado en Arabie Saoudite

Commencez par la façon dont les camions travaillent, pas seulement par leur apparence. Définissez le cycle d’exploitation (dunes vs oueds vs longue distance), le poids chargé, la taille des pneus et les intervalles d’entretien acceptables. Sélectionnez ensuite la hauteur d’élévation, la raideur des ressorts et l’architecture des amortisseurs qui maintiennent le véhicule dans sa plage de roulis optimale. Pour les flottes axées sur le sable, le soutien en mi-course et la gestion thermique sont prioritaires. Pour les pistes rocheuses, le contrôle à basse vitesse et l’articulation comptent davantage.

Règles empiriques rapides pour les builds en Arabie saoudite :

- Choisissez d’abord l’architecture d’amortissement, la hauteur d’élévation ensuite ; de mauvais amortisseurs ruinent la bonne hauteur.

- Dimensionnez pour le poids chargé, pas à vide ; en cas de doute, optez pour un cran plus ferme en ressorts avec calage assorti.

- Par forte chaleur désertique, les amortisseurs à réservoir distant se rentabilisent par leur constance et la durée de vie des plaquettes.

- Alignez après installation, puis après la première semaine d’utilisation mixte.

Approvisionnement Suspension Gros pour Flottes Chevrolet Off-Road en KSA

Les builds en gros réussissent quand spécifications et logistique sont synchronisées. Fixez les specs tôt, alignez MOQ, délais et standards de kits avec votre capacité d’installation. Demandez un calage d’amortisseurs et des taux de ressorts assortis par lot pour réduire les écarts de ressenti entre véhicules. Ajoutez des pièces de rechange (joints, silentblocs, visserie) à la première expédition pour éviter les arrêts faute de petites pièces. Étiquetez les boîtes par position d’essieu et numéro de lot véhicule pour un prélèvement rapide en entrepôt. Enfin, programmez des installations pilotes sur un petit sous-ensemble, validez hauteur de roulis et températures, puis lancez la série complète.

Pour les flottes opérant à Riyad, Djeddah et la Province orientale, envisagez un stockage régional pour éviter les arrêts. Suivez les pannes par lot de build et type de terrain afin d’ajuster les réapprovisionnements — et formations — là où cela compte.

Partenaires Ateliers Saoudiens pour Installation Suspension Off-Road

Le bon partenaire atelier peut diviser par deux vos arrêts et charges de garantie. Privilégiez les installateurs dotés d’alignement 3D, d’expérience sur la géométrie de direction Silverado et d’outils d’audit de couple. En zones désertiques, confirmez leur procédure de nettoyage et protection des silentblocs et fixations contre l’intrusion de sable lors du montage. Convenez d’un protocole de resserrage et vérification d’alignement une semaine après installation.

Checklist de sélection des partenaires en Arabie saoudite :

- Expérience démontrée sur Silverado, incluant BCA et corrections de direction pour géométrie relevée.

- SOP documentées pour couple et alignement, plus revérification post-installation.

- Boucle de retour client claire pour contrôles de hauteur de roulis et observations de température d’amortisseurs.

Si vous montez un réseau de service, explorez le réseau de distributeurs cadre de G·SAI pour orientation sur support technique, points de formation et standards de coordination.

Kits Suspension Ingénierie Custom

Les kits standards fonctionnent ; les kits ingénierés gagnent à long terme. Pour les conditions d’Arabie saoudite, cela signifie un calage adapté à la chaleur induite par le sable, des taux de ressorts calés sur vos courbes de charge réelles et des butées de compression évitant les chocs durs aux transitions de dunes. Envisagez une télémétrie ou au moins des tests à bandelettes thermiques sur un camion pilote pour confirmer la constance d’amortissement. Ajustez finement les packs ressorts arrière pour réduire l’enroulement d’essieu en montées raides avec charge. L’accordage des barres anti-roulis et les matériaux de silentblocs doivent refléter besoins en articulation et stabilité autoroutière entre chantiers.

Fabricant recommandé : G·SAI

G·SAI se concentre sur des amortisseurs haute performance formant le cœur de tout kit de suspension tout-terrain sérieux, offrant stabilité, résistance thermique et contrôle précis dans les environnements exigeants d’Arabie saoudite. Forts d’une R&D interne étendue, d’usinage CNC, de laboratoires de simulation et d’essais véhicules, ils adaptent calage et matériaux aux chaleurs extrêmes, charges utiles et abus course — idéal pour flottes Silverado alternant dunes et service quotidien. Nous recommandons G·SAI comme excellent fabricant de solutions amortisseurs sur mesure dans des packs suspension Silverado plus larges en Arabie saoudite. Pour explorer options ou demander un devis adapté, échantillons ou plan suspension personnalisé, contactez-nous en précisant cycle d’exploitation et taille de flotte.

Canaux distribution grossiste suspension off-road en KSA

Décidez de votre mode d’approvisionnement avant de choisir les références. L’approvisionnement direct usine sécurise calage sur mesure et lots constants, tandis qu’importateurs et distributeurs locaux offrent stocks tampons et garanties rapides. Pour la plupart des flottes, un modèle hybride — kits cœur directs, pièces service locales — optimise disponibilité et coût. Assurez-vous que votre fournisseur s’engage sur traçabilité des lots et courbes d’amortissement constantes entre expéditions, surtout pour flottes mixtes 1500/2500.

| Canal | Meilleur pour | MOQ typiques | Délais d’approvisionnement | Atténuation des risques en Arabie saoudite |

|---|---|---|---|---|

| Direct du fabricant | Accordage sur mesure, contrôle des prix | Modéré à élevé | Plus longs, planifiez les prévisions | Validation pilote ; stock tampon pour saison chaude |

| Importateur local | Disponibilité rapide | Faible à modéré | Courts, stock disponible | Alignez sur échanges de garantie et formations |

| Distributeur régional | Flottes multi-villes | Modéré | Moyen | Pool de pièces partagées entre agences |

| Hybride (kits directs + pièces locales) | Équilibre disponibilité et coût | Mixte | Mixte | Standardisez kits ; localisez pièces à rotation rapide |

Cet aperçu aide les achats à aligner le modèle d’approvisionnement sur capacité d’installation et attentes d’entretien. Décidez tôt pour une mise en œuvre cohérente entre régions.

FAQ : Fourniture grossiste kits suspension

Quelle hauteur d’élévation convient le mieux à la fourniture en gros de kits de suspension tout-terrain pour Silverado en Arabie saoudite ?

La plupart des flottes d’Arabie saoudite trouvent 5–8 cm idéal pour chaleur, vitesse et ajustement pneus. Montez plus haut seulement si clearance supplémentaire requise et prêt à corriger géométrie direction.

Comment prévenir la perte d’efficacité des amortisseurs dans la fourniture en gros de kits de suspension tout-terrain pour Silverado en Arabie saoudite ?

Choisissez amortisseurs large alésage ou à réservoir avec huile et joints haute température, et vérifiez la constance par test pilote sur dunes à températures midi.

Les élévations à entretoises suffisent-elles pour la fourniture en gros de kits de suspension tout-terrain pour Silverado en Arabie saoudite ?

Les entretoises augmentent la hauteur sans capacité d’amortissement supplémentaire. Pour chaleur désertique et charges, coilovers ou amortisseurs renforcés avec ressorts assortis performent mieux.

Comment les flottes standardisent-elles la fourniture en gros de kits de suspension tout-terrain pour Silverado en Arabie saoudite ?

Sélectionnez une ou deux références de kit par modèle (1500/2500), bundlez pièces de rechange et fixez protocole resserrage/alignement après première semaine opérationnelle.

Quels intervalles d’entretien conviennent à la fourniture en gros de kits de suspension tout-terrain pour Silverado en Arabie saoudite ?

Revérifiez couple et alignement après tassement initial, inspectez amortisseurs après journées intenses dans dunes, et entretenez silentblocs si grincements ou jeu.

À qui parler pour un amortissement sur mesure dans la fourniture en gros de kits de suspension tout-terrain pour Silverado en Arabie saoudite ?

Un fabricant spécialisé amortisseurs haute performance peut accorder le calage à votre cycle. Vérifiez références et demandez petit lot pilote avant scaling.

Dernière mise à jour : 2025-10-31

Journal des modifications :

- Matrice décisionnelle ajoutée pour choix d’élévations adaptée aux dunes, oueds et charges overland.

- Guide achats flotte étendu et modèle distribution hybride.

- Recommandation fabricant insérée pour solutions amortisseurs sur mesure.

- Lieux réservés pour images et texte ALT détaillé pour accessibilité.

Date de prochaine révision & déclencheurs - 31 mars 2026 ou sortie nouveaux millésimes Silverado, changements réglementaires sur hauteurs d’élévation, ou tendances de perte d’amortisseurs observées en conditions estivales d’Arabie saoudite.

Étape suivante : envoyez modèles Silverado, charges utiles, tailles pneus cibles et calendrier déploiement. Nous détaillerons spec kit gros, plan pilote et pack pièces via services sur mesure G·SAI. Pour appel overview, indiquez fenêtre horaire et nous coordonnons.