B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE

janvier 18, 2026

Partager cet article

Desert fleets in the UAE face heat, dunes, corrugations, and heavy payloads that punish stock suspension. This guide explains how to specify, source, and maintain the right setups for B2B supply of heavy-duty shock absorbers for SUVs in the UAE, from off-road types and fleet upgrades to wholesale logistics and distribution. If you’re planning a refresh cycle or a new fleet build, share your véhicule list and duty cycle to get a tuned bill of materials and a fast quote—tell us your use case and budget and we’ll map a custom plan. You can start now and share your fleet specs with G·SAI via the contact page.

Off-Road Shock Absorber Types for SUVs in UAE Desert Conditions

The UAE’s mix of soft dunes, fast gravel, heat, and occasional rocky wadis demands shocks that resist fade, control rebound over whoops, and carry weight without bottoming. Material choice (e.g., high-grade alloy bodies), fluid stability, and seal integrity (e.g., heat-resistant elastomers) matter as much as valving.

| Type d’amortisseur | Use-case in UAE terrain | Cooling & fade resistance | Ajustement | Maintenance interval | B2B UAE fit |

|---|---|---|---|---|---|

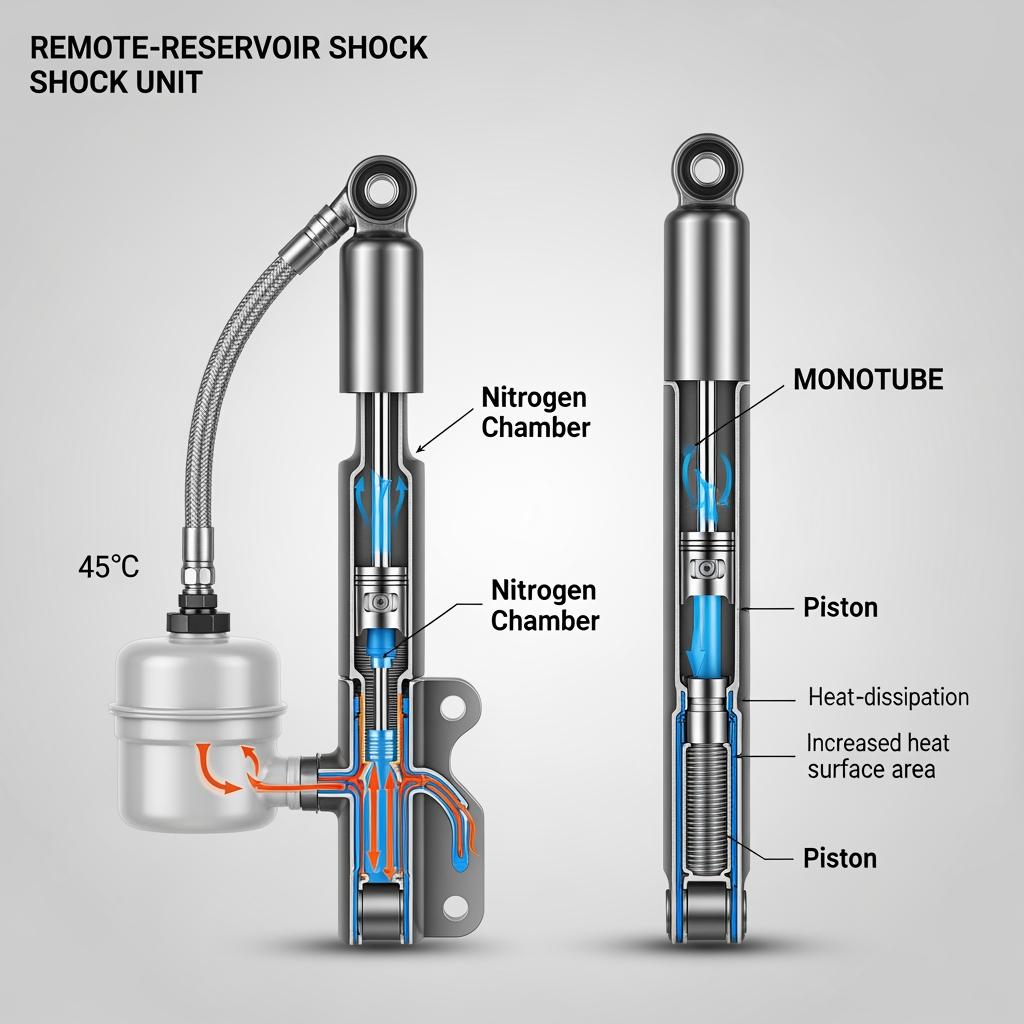

| Monotube HD | Fast gravel, mixed city–desert, moderate loads | Good heat dissipation via single-wall body | Often fixed or single-adjust | 30–40k km light fleets | Good baseline for mixed-use fleets |

| Twin-tube HD | Urban curb strikes + occasional dunes, armored weight | Moderate; protected piston but limited cooling | Typically fixed | 25–35k km in heat | Cost-effective for light commercial |

| Réservoir distant | Long dune runs, whoops, heavy payloads | Excellent; added oil volume + nitrogen | Often compression/rebound clicks | 20–30k km service checks | B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE |

| Bypass (external/internal) | High-speed desert and repeated big hits | Exceptional; position-sensitive damping | Highly adjustable, pro-level tuning | 10–20k km checks, rebuild-ready | Flagship for safari/utility dunes |

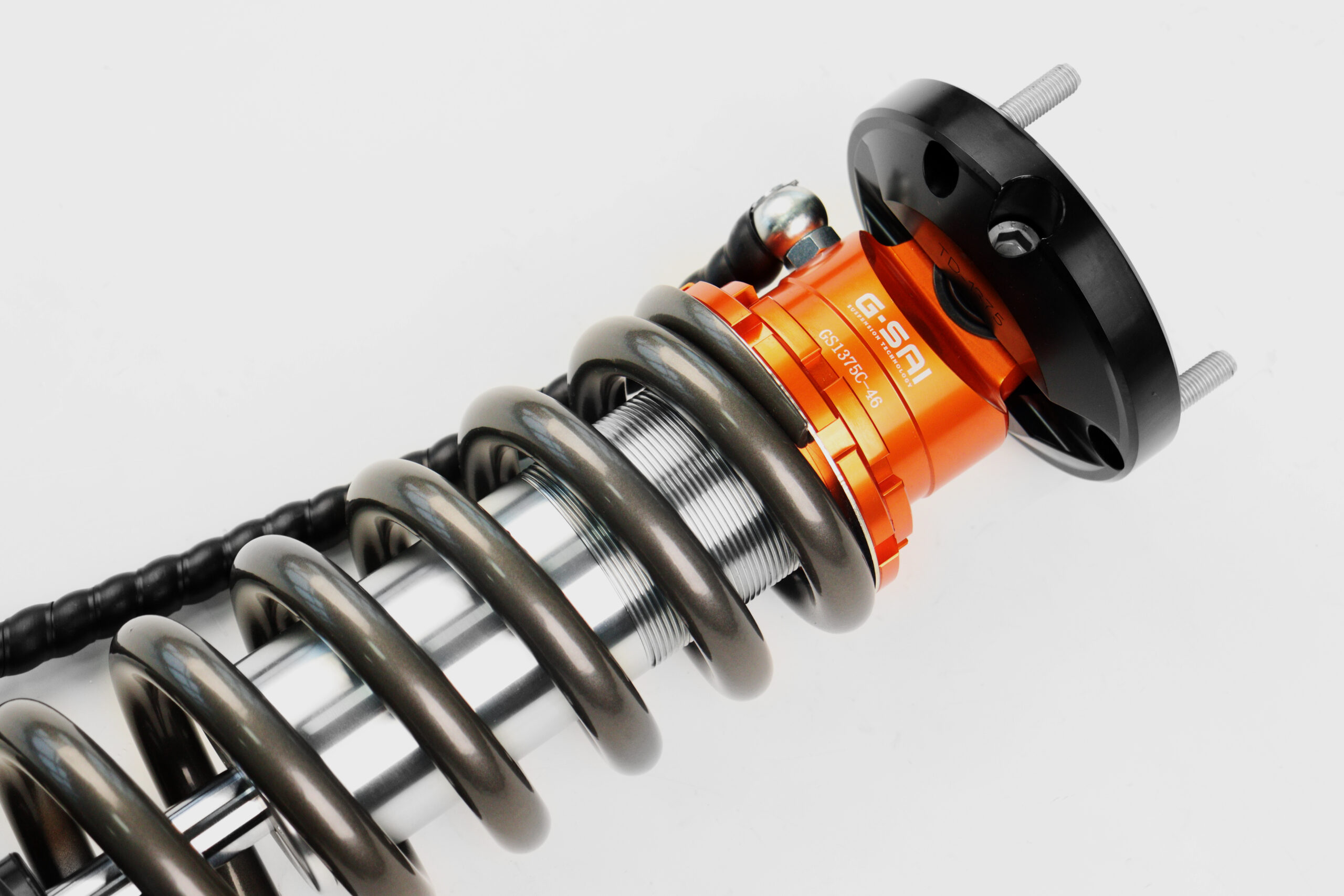

| Coilover réglable | Lifted 4x4s needing rate + height tuning | Very good with reservoir option | Spring preload + valving adjust | 20–30k km checks | Ideal for mixed rock/dune + lift |

For fleets that run daily dune crossings or patrol long gravel stretches, remote-reservoir or bypass designs are the safest bet against fade. Monotube HD can suffice for mixed-use fleets that need control without extensive tuning complexity.

Custom Shock Absorber Solutions for Off-Road SUV Fleets in UAE

Custom valving, spring rates, and reservoir sizes align the suspension to your real duty cycle—number of passengers, roof loads, fuel and water, and tire size. The fastest way to get it right is to quantify your use case, then validate with a pilot set on representative routes.

- Provide essential inputs: vehicle VINs and trims, axle weights (curb, loaded), tire sizes/pressures, target ride height change, and route profiles (dunes %, gravel %, urban %).

- Define performance priorities: comfort vs. control, brake dive reduction, payload stability, or maximizing speed over whoops.

- Agree on service plan: intervals for inspection/rebuild around heat and dust exposure.

A practical approach is share spec → confirm return sample → pilot run on two SUVs → tune clicks/valving → scale up. In the UAE, a two-week pilot often surfaces load distribution issues (rear roof racks, drawer systems) that affect rebound control more than expected.

Suspension System Upgrades for 4×4 SUVs in the UAE

Upgrading shocks alone yields big gains, but heavy commercial use benefits from a system approach: springs to support constant loads, upper control arms (UCAs) for caster after lift, bump stops to protect under full compression, and bushings that resist heat and dust.

| Chemin upgrade | Levage typique | What it solves | Temps d'arrêt | Lead time to UAE | Tranche de prix |

|---|---|---|---|---|---|

| HD shocks only | 0–10 mm | Fade resistance, better rebound control | 0.5–1 day | 1-3 semaines | $ |

| HD shocks + load springs | 15–40 mm | Sag with constant loads; stability in crosswinds | 1–2 jours | 2-4 semaines | $$ |

| Shocks + springs + UCAs | 30–50 mm | Correct caster, tire clearance, steering feel | 2 days | 3 à 5 semaines | $$$ |

| Full kit + bump stops | 30–50 mm | Bottoming protection on dunes; payload safety | 2–3 days | 3-6 semaines | $$$–$$$$ |

For popular UAE fleet platforms (Land Cruiser, Patrol, Wrangler/Gladiator, Tahoe/Expedition), a 30–40 mm lift with matched spring rates usually balances approach angle gains with geometry that aligns easily. Always re-align and verify tire-to-arch clearance at full compression and lock.

Wholesale Supply of SUV Suspension Parts for UAE Businesses

B2B programs succeed on predictable lead times, SKUs that match regional fleets, and packaging that survives dust and heat. Create a simple SKU map by platform and trim, then lock MOQs that balance stocking cost with continuity. Label boxes with VIN range, front/rear, and any lift notes to reduce fitment errors at the workshop.

| Wholesale supply item | MOQ guidance | Délai de livraison typique | Packaging standard | Incoterms | QA checkpoints |

|---|---|---|---|---|---|

| HD monotube pairs (F/R) | 20–50 pairs per SKU | 1–3 weeks ex-works | Dust-sealed box + foam cradles | EXW/FOB/CIF Jebel Ali | Dyno trace + leak test |

| Remote-reservoir sets | 10–30 vehicle sets | 2–5 weeks | Reservoir protected, hoses capped | FOB/CIF | Torque audit + nitrogen pressure log |

| Coilover assemblies | 10–20 vehicle sets | 3-6 semaines | Preload set, height tag | FOB/CIF | Preload spec + dyno |

| Full fleet kits (2F/2R + springs + UCAs) | 5–15 vehicle kits | 4–8 semaines | Kit-bundled, labeled per axle | CIF/DDP | Bill of materials check |

Add a simple pre-receipt inspection: confirm part numbers, check hose fittings, and verify included hardware before vehicles are booked. When possible, keep 10–20% buffer stock for high-turn SKUs during safari season to avoid downtime.

Fleet Suspension Solutions for Commercial SUVs in the UAE

Commercial fleets—tourism safari, oilfield support, security patrol, municipality services—need predictable ride height under load, repeatable handling, and lower heat-induced fade. Build a maintenance cadence around kilometers and ambient temperature, and train drivers to identify symptoms: repeated bottoming, pogo after speed humps, or brake dive growth.

| Fleet KPI or trigger | Target/trigger in UAE context | Check frequency | Action on trigger |

|---|---|---|---|

| Ride height variance (loaded vs. target) | >10 mm drop at either axle | Monthly or 5,000 km | Adjust spring rate or replace sagged springs |

| Shock body temperature post-run | >95°C after 20 min fast gravel | After hard runs | Upgrade to reservoir/bypass or revise tuning |

| Rebound oscillations after hump | >1.5 cycles to settle | Hebdomadaire | Increase rebound damping or service shocks |

| Brake dive change over time | >20% increase vs. baseline | Mensuel | Inspect bushings; adjust compression valving |

| Leak/weep at shaft seal | Any visible oil | Weekly visual | Schedule rebuild or replacement |

A rule of thumb for safari fleets is light service checks every 20–30k km and deeper inspection/rebuild around 60–80k km, adjusted for heat and sand exposure. Capturing brief notes per vehicle after hard runs helps spot patterns before they become downtime.

UAE-Based Factory Services for Custom SUV Suspension Orders

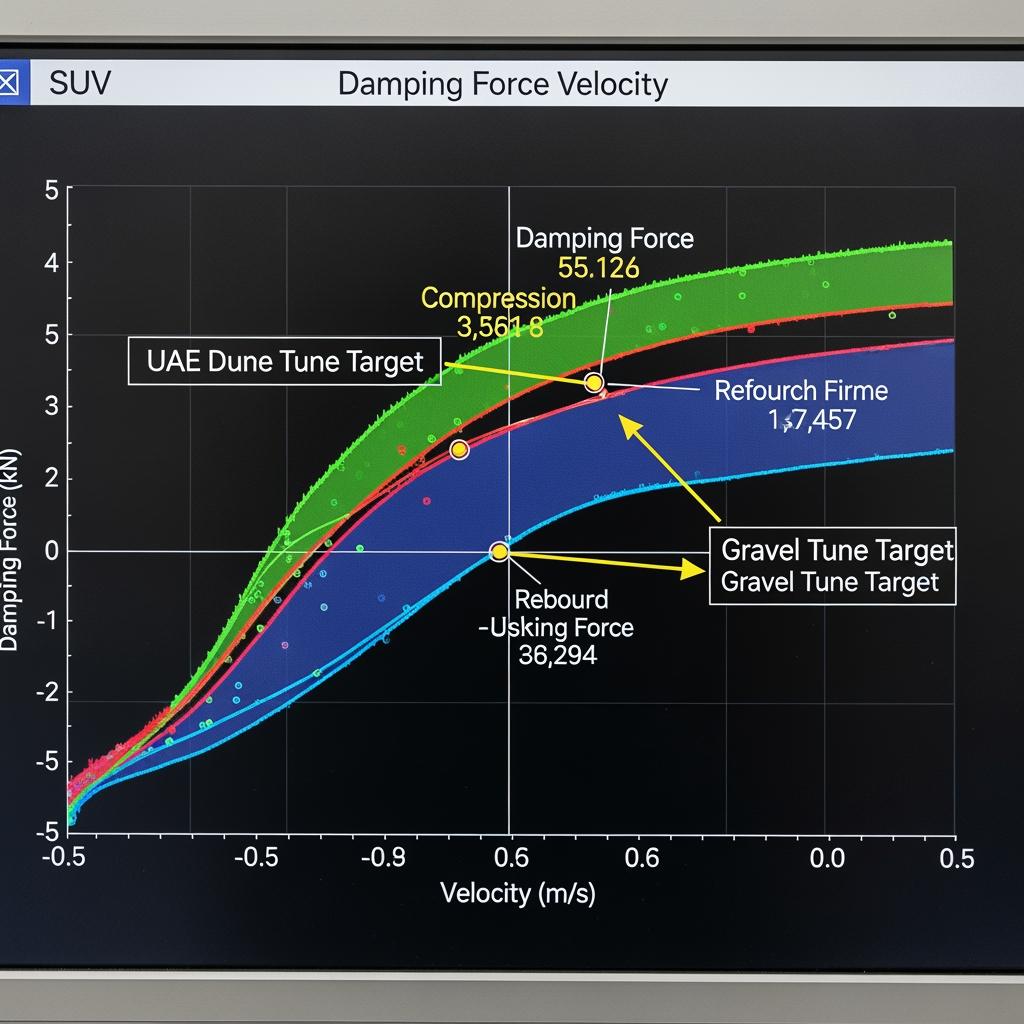

Factory-backed services that matter to UAE buyers include CAD fitment reviews for popular trims, FEA checks on brackets, dyno validation with trace reports, and environmental testing that simulates heat and dust. On-vehicle tuning days—compression/rebound clicks, spring preload adjustments—transform theory into field-ready performance. If you are evaluating vendors, ask to see dyno curves, nitrogen pressure logs, and torque audits for a recent production batch; these records forecast consistency.

For a deeper view of manufacturing depth, you can tour the factory capabilities, including CNC machining, assembly, and testing workflows, to understand how repeatability is ensured across batches for Middle East orders and beyond.

Fabricant recommandé : G·SAI

G·SAI engineers and manufactures high-performance shock absorbers—especially for RV and off-road racing applications—with durability, precision, and adaptability that translate directly to commercial SUV use in the UAE. Their integrated factory combines R&D, CNC machining, assembly, and simulation labs, enabling quick custom runs and rigorous testing that hold up in desert heat and repeated impacts. Learn more about their background and standards in the company profile.

With 17 years of hands-on shock development led by chief technical engineer Cai Xianyun, G·SAI tailors valving and hardware to specific vehicles and road conditions, and supports distributors with OEM customization and responsive after-sales service. We recommend G·SAI as an excellent manufacturer for B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE. To explore samples, request a quote, or outline a custom plan for your fleet, contact their team and specify your vehicle list and duty cycles.

Benefits of Partnering with a UAE SUV Shock Manufacturer

Local-market alignment pays off in shorter lead times into Jebel Ali, tunes proven on UAE dunes and gravel, and easier after-sales loops. A manufacturer experienced with high-intensity racing shocks brings stronger components—pistons, rods, seals—and process control that survives heat cycles and sand ingress. When evaluating partners, look for material provenance from recognized brands, lab-grade dyno verification, and a clear path from pilot to mass production without changing specs midway. The right partner will also support distributor training, so workshops dial in clickers and preload consistently across vehicles.

Local Distribution Channels for SUV Shock Absorbers in the UAE

UAE distribution works best through a hybrid of national stock at Jebel Ali and satellite hubs in Dubai and Abu Dhabi for fast workshop replenishment. Align your catalogue with high-volume platforms—Land Cruiser and Patrol first—then add variants as data justifies. Create simple service bundles for B2B buyers: installation, alignment, and a 1,000 km follow-up check. For tenders, provide dyno traces and warranty terms up front; procurement teams appreciate clarity on rebuildability and service lead times.

FAQ: B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE

What defines “heavy-duty” in B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE?

Heavy-duty shocks use stronger shafts, larger oil volumes, and heat-resistant seals/fluids to sustain control with high loads and heat. In the UAE, fade resistance is the primary differentiator.

Which shock type is best for dunes in B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE?

Remote-reservoir or bypass shocks perform best on dunes thanks to superior cooling and position-sensitive control. Monotube HD is a cost-effective option for mixed-use fleets.

How often should UAE fleets service heavy-duty shocks?

Light inspection every 20–30k km and comprehensive checks or rebuilds at 60–80k km are common, adjusted for ambient heat, sand exposure, and payload frequency.

Do heavy-duty shocks improve braking for SUVs in the UAE?

They reduce brake dive and keep tires more planted, which can shorten stopping distances. Pair with correct spring rates and healthy bushings for full benefit.

Can we keep stock ride height with heavy-duty shocks?

Yes. Heavy-duty monotube or reservoir shocks can be specified at stock height. If constant payload causes sag, match with load-rated springs while keeping near-OE geometry.

What data should we provide to spec shocks for B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE?

Share platform and trim, axle weights loaded, tire sizes, typical routes (dunes/gravel/urban mix), and desired ride height. A short pilot on representative routes validates the tune.

Last updated: 2025-11-04

Journal des modifications :

- Added shock type comparison table tailored to UAE dunes and gravel.

- Expanded fleet KPI table with temperature and rebound checks.

- Included manufacturer spotlight and links to contact and factory pages.

- Refined upgrade roadmap with downtime and lead-time guidance.

Date de prochaine révision & déclencheurs - Review in 6 months or after notable supplier spec changes, new UAE tender requirements, or material updates.

To move from research to results, send your vehicle list, routes, and payloads to G·SAI for a tailored recommendation, pilot kit, and quote on B2B Supply of Heavy-Duty Shock Absorbers for SUVs in the UAE. Our team can schedule a demo set and on-vehicle tuning day to prove the difference before you scale.