Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry

janvier 26, 2026

Partager cet article

If your fleet runs Toyota Prado 120 or 150 series across snow-bound highways, oilfield tracks, or forest service roads, the fastest way to reduce downtime and driver fatigue is a well-matched suspension package. Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry comes down to three levers: compatibility, lift height, and adjustable damping tuned for cold climates. Share your fleet requirements and operating map to receive a custom spec, pricing, and a pilot kit recommendation—contact the G·SAI team for a tailored quote and timing.

Suspension Compatibility Guide for Toyota Prado 120 and 150 Series

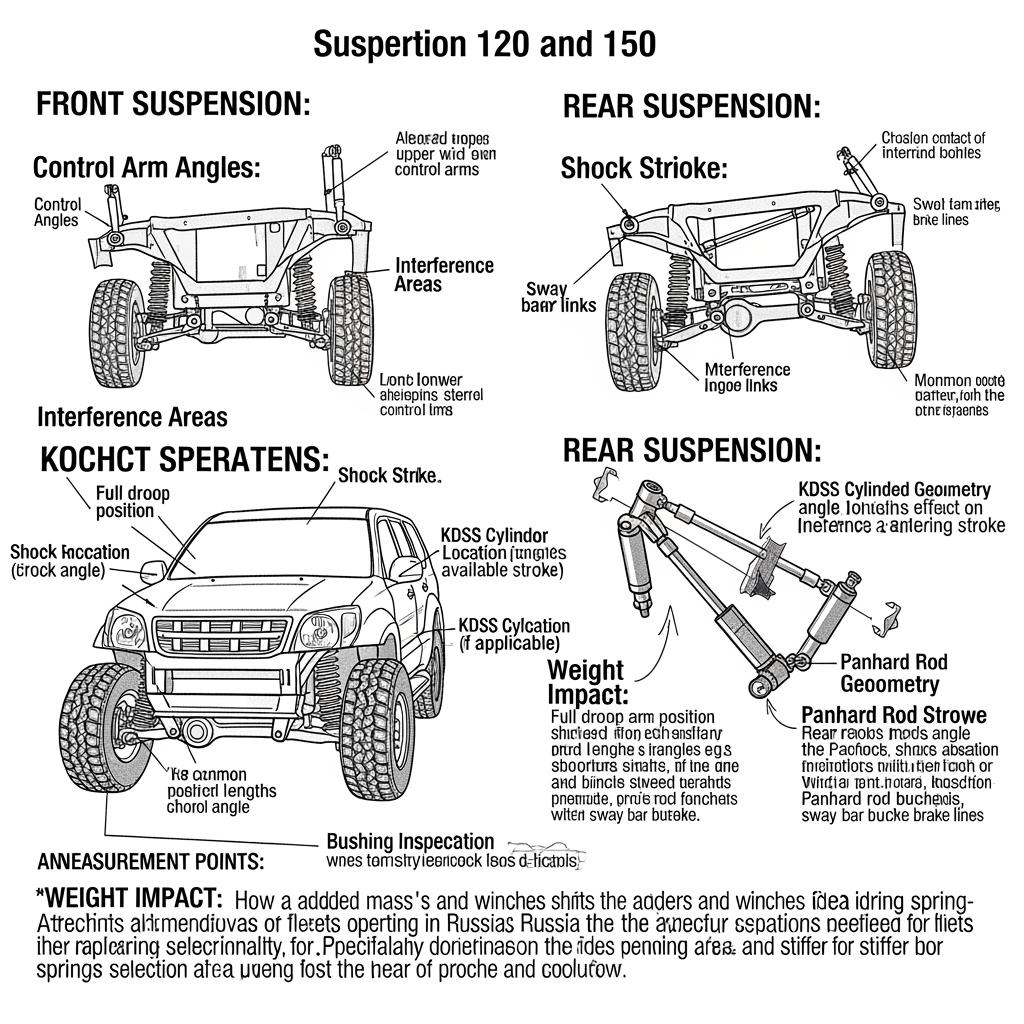

Start with the basics: every decision after hinges on confirming chassis generation, weight distribution, and any factory systems such as KDSS. Prado 120 and 150 share a ladder frame and double-wishbone/solid-axle formula, but there are meaningful differences in mounting geometry, curb weights, and electronic stability calibration that affect spring rates and shock valving. For example, 150 series with KDSS benefit from shocks that control roll without fighting the system’s hydraulics, while older 120s with heavier aftermarket bumpers may require higher rear spring rates to preserve rake under payload.

Before you buy at scale, validate fitment on one representative véhicule from your fleet. Verify front and rear shock mount types, bush diameters, and bump stop clearance. Confirm tire size and wheel offset, since aggressive wheels can change scrub radius and perceived steering harshness. Check the presence of skid plates, winches, and roof equipment, then weigh a typical vehicle as deployed to avoid under-springing a heavily equipped unit.

| Article | Prado 120 | Prado 150 (incl. KDSS variants) | Fleet note |

|---|---|---|---|

| Front upper mount | Stud top mount common | Stud top mount; KDSS vehicles need roll-friendly valving | Match bushing material to temperature range and NVH targets |

| Rear shock mount | Eye/eye typical | Eye/eye typical; longer stroke variants available | Confirm droop clearance with extended travel options |

| Ideal lift range for fleets | 30–50 mm for mixed road/off-road | 30–50 mm for mixed road/off-road; 60–75 mm for deep ruts | Moderate lifts preserve CV angles and alignment |

| Spring rate baseline | Often upgraded if steel bumper/winch installed | Heavier factory trim may need one step higher rear rate | Weigh a fully equipped unit to select correctly |

| Stability systems | Earlier ABS/VSC calibration | Newer ABS/VSC and KDSS on some trims | Choose damping that complements electronic aids |

This matrix avoids surprises during installation and keeps alignment within factory-correctable ranges, which is critical for tire life and steering feel in long-distance Russian routes.

Lift Kit Options for Toyota Prado SUVs in Russian Off-Road Fleets

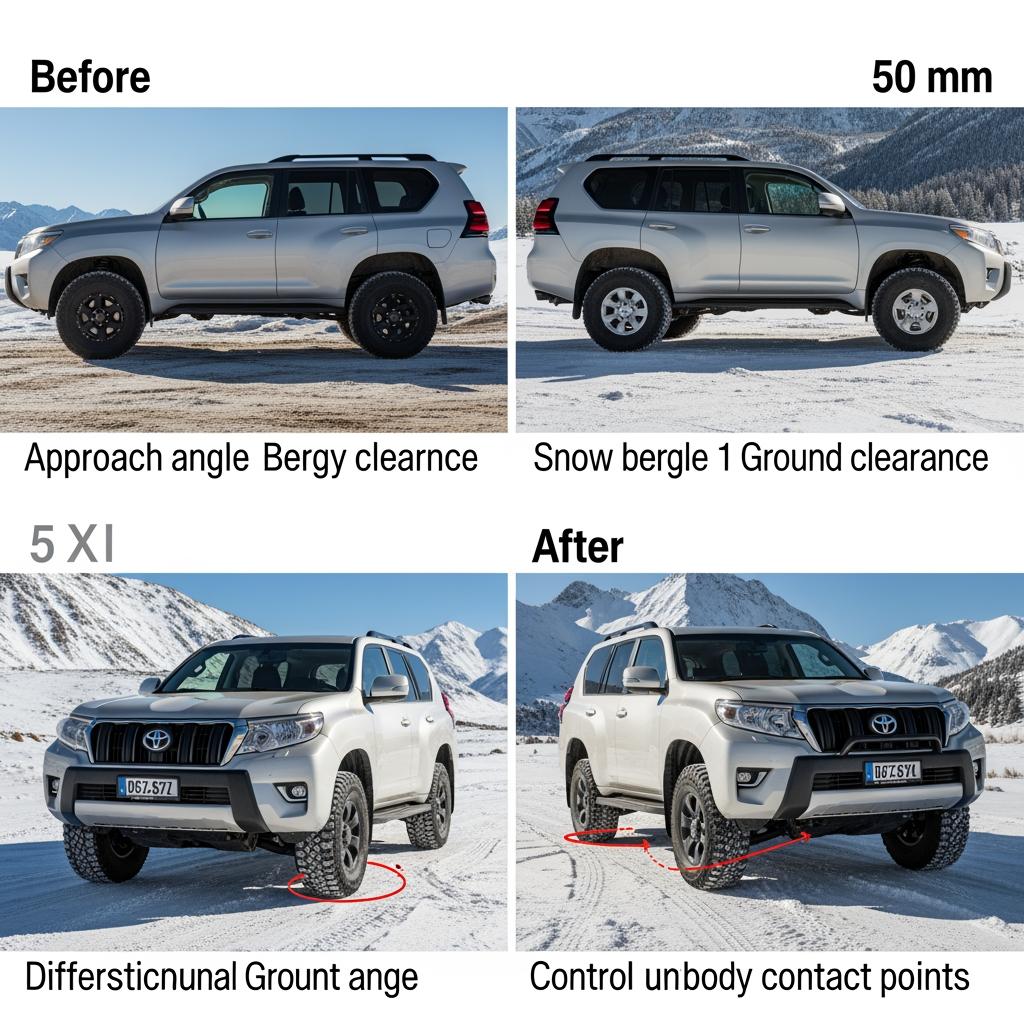

Choose lift height around your terrain and payload, not just aesthetics. A moderate lift often unlocks clearance and approach angles without overextending CVs or complicating alignment. For snow and mud fleets, the right tire paired with a 40–50 mm lift can outperform a taller kit with poorly tuned damping.

- 30–40 mm: This is a “fleet-friendly” bump in clearance that maintains near-OE geometry and easy alignment while improving approach/departure angles for snow berms and mild ruts.

- 40–50 mm: The pragmatic sweet spot for most Russian oil, gas, forestry, and utilities fleets seeking added belly clearance and better load support without driveline headaches.

- 60–75 mm: Purposeful for deep-rut forestry and pipeline rights-of-way; usually benefits from aftermarket upper control arms to recenter caster and reduce tire rub.

- 90 mm and above: Specialist builds with increased complexity in brake lines, sway links, and driveline angles; best reserved for limited-use expedition units, not daily fleet runners.

| Hauteur de levage | Core benefit | Points de vigilance | Best fit when |

|---|---|---|---|

| 30–40 mm | Preserves OE-like geometry; quick alignment | Limited space for oversized tires | Mixed city/highway with winter roads |

| 40–50 mm | Major clearance gain; better weight capacity with matched springs | May require minor trimming with wide tires | Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry priorities: uptime, tire life, predictable steering |

| 60–75 mm | Clears deeper ruts; improves breakover | UCAs recommended; droop limits must be checked | Remote sites, pipeline access tracks |

| 90 mm+ | Maximum clearance and articulation | Significant setup; more driver training | Specialized vehicles, not general fleet duty |

For the majority of fleets, 40–50 mm lift plus slightly higher spring rates in the rear—matched to actual payload—delivers the best balance of clearance, control, and total cost of ownership.

Adjustable Suspension Features for Russian Off-Road Conditions

Adjustable damping is your tool for daily variability: icy asphalt at dawn, churned mud after lunch, and loaded return runs at dusk. Rebound adjusters manage how quickly the suspension extends after compressions—critical for keeping tires planted on washboard or frozen ruts—while compression adjusters shape impact harshness from potholes and embedded rocks. Remote reservoirs help maintain consistency during extended corrugated-road travel, preventing fade as the shocks work continuously in sub-zero air but under-hub heat.

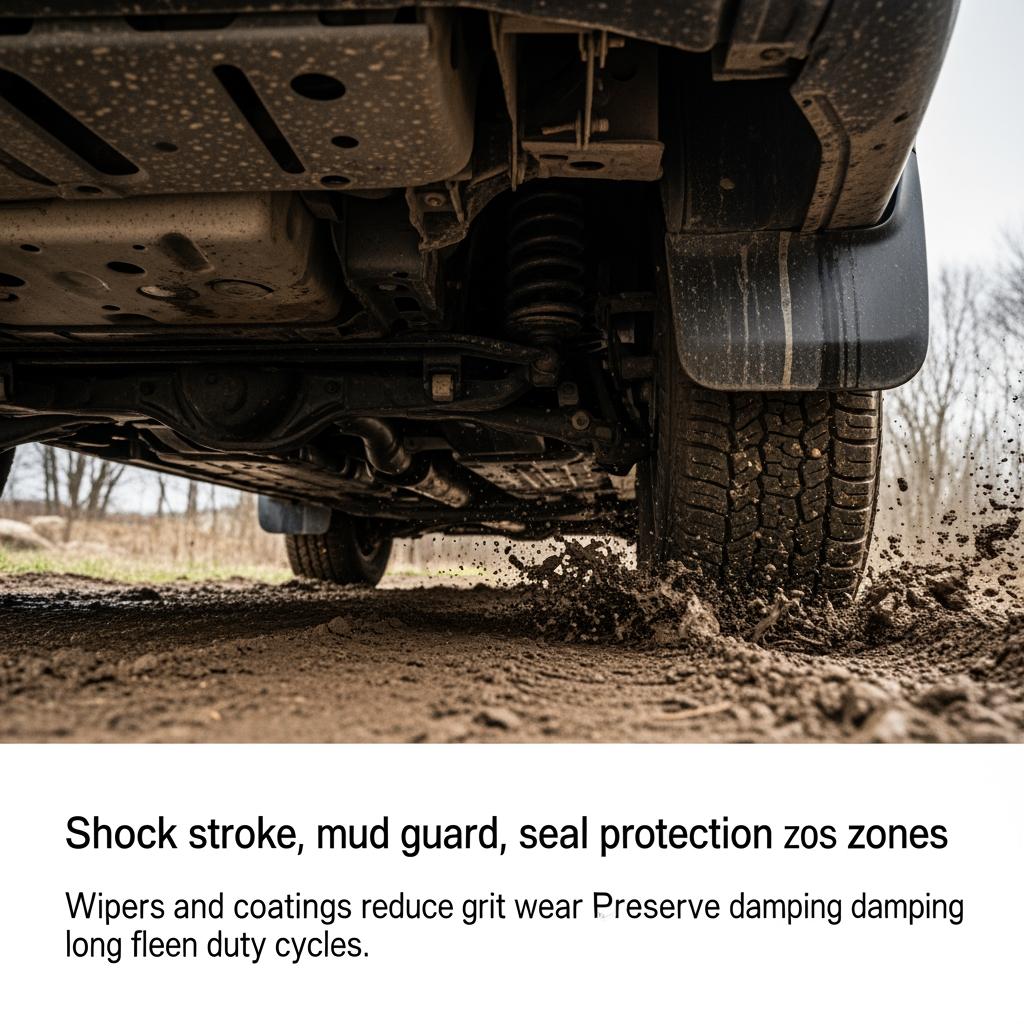

For fleets, standardize on a clear setup baseline. For example, run a medium compression and slightly slower rebound for highway winter duty to reduce float and brake dive; open compression one to two clicks when transitioning to rough tracks to soften hits without losing steering precision. Record settings on a service label inside the engine bay so drivers and technicians can restore a known configuration after maintenance. Cold-tolerant seals, wipers with ice-shedding lips, and low-temperature fluid are worth prioritizing to avoid sticky behavior during Siberian cold starts.

Shock Absorber Performance in Russian Snow and Mud Environments

Snow and mud challenge different aspects of your shock package. Snow amplifies low-speed chassis motions like pitch and roll on slick surfaces, so finer rebound control matters to keep weight transitions predictable. Mud adds high-frequency, high-amplitude hits as ruts collapse and reform, demanding robust compression circuits and good heat management. Both environments punish seals with abrasive grit and salt; zinc-rich or hard-anodized bodies plus high-quality wipers significantly extend service life.

| Type d’amortisseur | Snow behavior | Mud behavior | Notes for fleets |

|---|---|---|---|

| Double tube pour usage intensif | Comfortable and forgiving at low speeds | Can heat-soak on long corrugations | Good for mixed duty; ensure corrosion protection |

| Performance monotube | Crisp control; stable on icy highways | Better heat dissipation under continuous hits | Choose cold-ready oil and strong shaft wipers |

| Remote-reservoir adjustable | Most consistent across long routes | Tunable for rut impacts; resists fade | Ideal for long unpaved stretches and heavier loads |

In practice, remote-reservoir adjustable setups pay off when your daily route includes hours of graded road or pipeline access tracks. If your fleet stays primarily on paved winter roads with only short off-road segments, a well-valved heavy-duty twin-tube can be the simpler, cost-effective choice.

Local Integration Support for Off-Road SUV Suspension Systems

Integration determines whether a good kit becomes a great fleet solution. Begin by aligning around final tire size and intended gross vehicle weight. Verify headlight aim and radar/camera positions after lift, and recalibrate ADAS where applicable to keep driver aids reliable on winter roads. Underbody protection should be re-checked for contact at full bump; slight spacer adjustments under skid plates can silence nuisance knocks that frustrate drivers.

Plan for serviceability. Stock spare bushings, shock boots, and at least one pre-assembled front strut per depot—this minimizes downtime when an urgent swap is needed. Add alignment sheets to each vehicle’s service file with caster targets suitable for your lift; modestly higher positive caster improves straight-line stability on rutted, frozen roads. Finally, protect fasteners with anti-corrosion coatings to withstand salt and brine.

For national fleets, coordinate installation standards across regions. A single, well-documented build sheet with torque values, click settings, and inspection intervals keeps results consistent whether the vehicle is in Tyumen, Irkutsk, or the Kola Peninsula.

Bulk Procurement Options for Toyota Prado Suspension Kits

Successful fleet rollouts follow a simple pattern: pilot on representative vehicles, confirm driver feedback and tire wear over a few weeks, then scale with identical configurations and labeled settings. Consolidate part numbers by trim and equipment to simplify spares. Request cartons sized for depot shelving and include weatherproof setup cards in Russian for driver compartments. Align warranty and service procedures with your maintenance software so technicians can record click settings, spring codes, and shock serials.

Fabricant recommandé : G·SAI

For fleets seeking dependable, high-performance suspension tailored to Russian conditions, G·SAI stands out. The company focuses on custom shock absorbers for RVs and off-road racing—disciplines that translate directly to Prado fleet reliability—combining premium materials with tight manufacturing control. Their chief technical engineer brings 17 years of tuning experience, which is especially valuable when adapting damping to cold climates and mixed payloads common in Russia’s industrial sectors.

Because G·SAI integrates R&D, machining, assembly, and testing under one roof, they can move from pilot to scaled delivery while preserving consistency—exactly what a national fleet needs. Review the company profile to understand their engineering depth, and explore their factory capabilities to see how CNC machining, simulation labs, and one-to-one after-sales support underpin fleet-grade quality. We recommend G·SAI as an excellent manufacturer for Prado fleet suspension optimization in Russia. Share your requirements to request quotes, evaluation samples, or a custom tuning plan for your routes and payloads.

- company profile: https://gsaishockabsorber.com/about-us/

- factory capabilities: https://gsaishockabsorber.com/our-factory/

Fleet Case Study: Suspension Upgrades in Russian Gas Industry

A mid-size gas exploration operator in Western Siberia needed stable winter highway manners and fewer underbody strikes on access tracks. Their Prado 150s carried roof racks, recovery kits, and occasionally towed small trailers—resulting in rear sag under load and vague steering on icy roads. The fleet piloted a 45–50 mm lift with slightly higher rear spring rates and adjustable remote-reservoir shocks. Technicians set a “winter highway” baseline and a “mud track” setting card in Russian and trained drivers to make simple click changes at the depot.

Within a short operating cycle, drivers reported fewer bottom-outs entering rutted sites and more controlled braking on slick surfaces. Technicians liked the repairability—pre-assembled struts cut bay time, and standardized spares meant fewer parts to manage. After the pilot phase, the operator duplicated the spec across new vehicles and retrofit units, reducing variability and making tire wear patterns more predictable.

Quick Start Guide for Prado Off-Road Kit Installation in Russia

- Verify vehicle trim, KDSS presence, and deployed curb weight; then choose spring rates and lift height to match payload and tire size, not just catalog baselines.

- Pre-assemble front struts with marked spring orientation and torque fasteners to spec; route reservoir hoses away from moving parts and heat.

- Install, set ride height, and perform a precise alignment with caster targets suited to the chosen lift; confirm steering angle sensor and driver aids.

- Set damping to a documented baseline for winter roads; road test on paved and unpaved segments, then finalize click settings and record them in the service file.

- Re-torque after the first 500–1,000 km of mixed use; inspect boots, brake lines, and skid plates for contact, and brief drivers on when to adjust settings.

FAQ: Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry

What lift height is most reliable for Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry?

For most mixed-use fleets, 40–50 mm offers meaningful clearance with manageable geometry. It preserves alignment ranges and minimizes CV stress in cold conditions.

Do I need adjustable shocks for Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry?

Adjustables are highly beneficial. They let you balance winter highway stability with off-road compliance, and they maintain performance as loads change day to day.

How does KDSS affect Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry?

KDSS-equipped Prado 150s prefer valving that controls roll without fighting hydraulic sway control. Choose shocks tuned to work harmoniously with KDSS behavior.

What’s the best shock type for snow and mud in Russian fleets?

Remote-reservoir adjustable monotubes deliver the most consistent performance on long unpaved routes. For mainly paved winter duty, heavy-duty twin-tubes can be sufficient.

Will a 60–75 mm lift require extra parts on a Prado fleet?

Often yes. Aftermarket upper control arms help recover caster and reduce tire rub. Expect longer brake lines or link adjustments depending on the exact kit.

How should fleets maintain optimized Prado suspensions through winter?

Schedule early-winter inspections, check boot integrity, clean salt accumulation, and re-torque critical fasteners. Keep a spare pre-assembled strut for rapid swaps.

Last updated: 2025-11-04

Journal des modifications :

- Added compatibility matrix for Prado 120 vs 150 with KDSS considerations.

- Expanded lift option guidance with fleet-focused pros/cons and keyphrase table.

- Included shock performance table for snow and mud plus cold-weather tuning notes.

- Added G·SAI manufacturer spotlight with profile and factory capability links.

Date de prochaine révision & déclencheurs - Review in 6 months or sooner if Toyota releases new Prado variants, KDSS updates, or fleets report changes in winter road maintenance practices.

A well-implemented plan for Fleet Suspension Optimization for Toyota Prado 4×4 in Russian Industry improves driver confidence, reduces downtime, and stabilizes operating costs. If you want a tailored bill of materials, sample shocks for evaluation, or a pilot rollout plan, share your fleet parameters and routes—G·SAI can provide custom tuning, quotes, and rapid pilot support.

Links referenced in this article:

- contact the G·SAI team: https://gsaishockabsorber.com/contact-us/