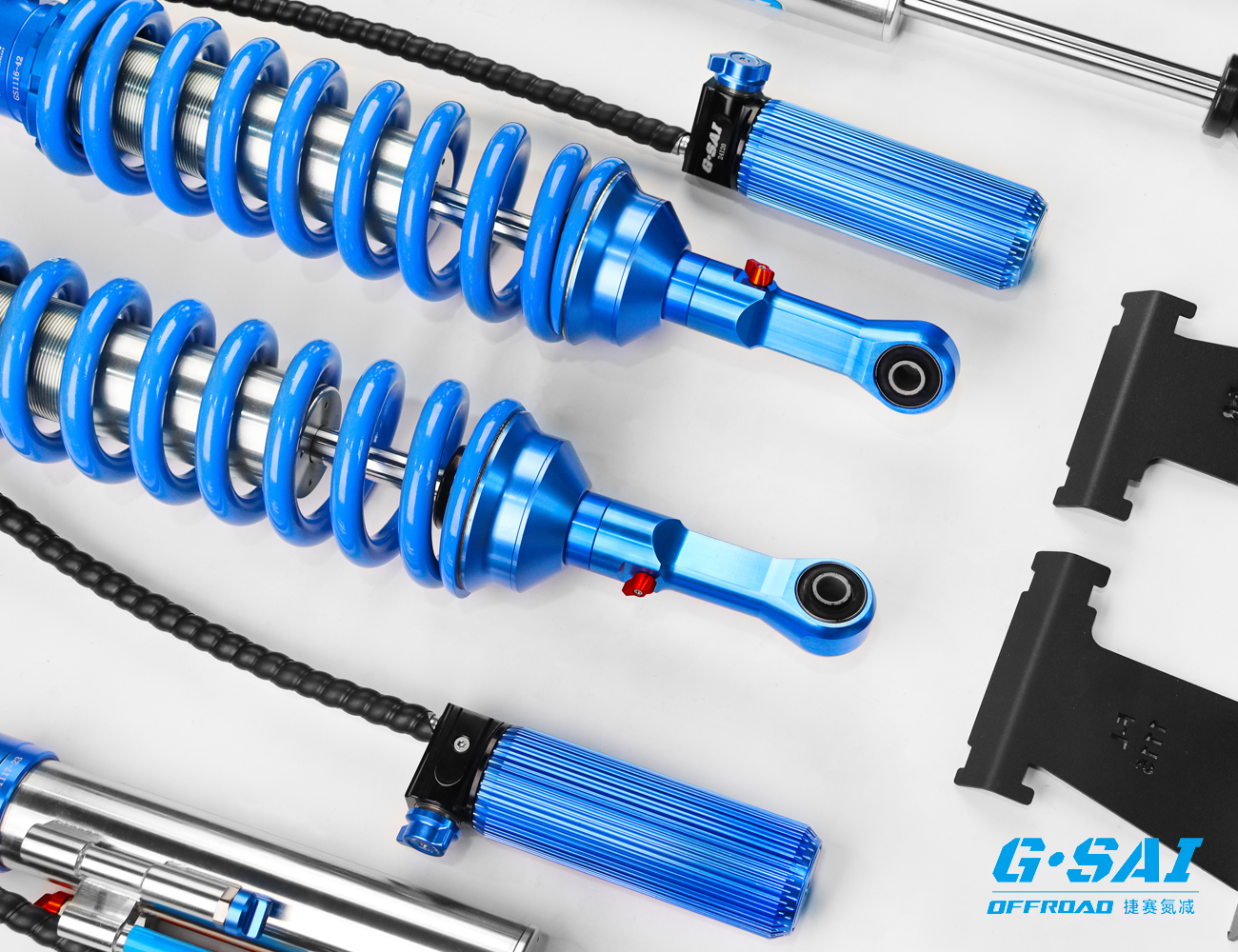

Coilover Shock Kits for SUVs in Harsh Russian Off-Road Conditions

janvier 31, 2026

Partager cet article

Russian roads beyond the city grid can turn from rutted gravel to frozen tundra in a few kilometers. Coilover Shock Kits for SUVs in Harsh Russian Off-Road Conditions let drivers and fleets match suspension behavior to that reality—delivering stability on corrugations, grip on snow and ice, and composure under heavy loads. If you’re scoping a program for field véhicules or performance builds, share your axle weights, tire specs, and operating temperatures; G·SAI can map a custom coilover spec and send sample options. To start, you can contact the engineering team with your requirements for a fast quote or demo set.

Why Adjustable Coilovers Improve Russian SUV Performance

The core advantage of adjustable coilovers in Russia is control. Damping adjusters give you “speed sensitivity”—slower piston speeds for rock crawling can be softened to allow axle articulation, while high-speed damping can be firmed to stop body float on corrugated ice roads. Preload and spring rate tuning allow you to set ride height for snow clearance and keep the suspension in the middle of its travel, where shocks do their best work.

On mixed surfaces, the ability to trim rebound damping prevents “packing,” where successive bumps compress the suspension until it rides harsh and loses traction. Conversely, dialing in a touch more low-speed compression helps SUVs resist pitch and roll with heavy winter gear onboard. In practical terms, day-to-day adjustability means one suspension can run soft for empty commuting in Yakutsk, then be tightened 8–10 clicks for weekend trail runs or loads of fuel and tools.

Harsh cold creates its own challenge: oil viscosity spikes and seals stiffen. High-quality coilovers use low-temperature-stable fluids and seal materials, plus larger piston areas to maintain precise control. With adjustable coilovers, you can compensate on the vehicle—turning a “cold-stiff” system back into a compliant, predictable setup in minutes.

Off-Road Coilovers Tested in Russian Arctic Conditions

Extreme cold and endless washboard expose weaknesses quickly. A proven Arctic-ready coilover should show consistent damping from -40°C starts through long, heat-building runs; it should resist cavitation when the shock cycles hundreds of times per minute, and it must protect seals from ice intrusion and road salt.

| Focus test | Real-world scenario | Measurable indicator | Outcome target | Notes |

|---|---|---|---|---|

| Cold-start damping | -40°C overnight soak, first 5 km | Initial rebound lag | Minimal lag, stable within 1–2 km | Use low-temp oil and responsive shim stacks |

| Ondulations haute fréquence | 20 km on winter washboard | Heat rise vs. fade | <15% fade, no harsh spikes | Reservoir or monotube with good flow paths |

| Deep pothole impacts | Mixed urban-rural transitions | Top-out/bottom-out events | None with proper bump stops | Valving must handle high-speed compression |

| Salted slush exposure | Week-long corrosion spray | Seal weep, adjuster binding | No leakage, smooth clicks | Anodized bodies, sealed adjusters |

| Load swing tolerance | Empty vs. +300 kg payload | Ride height change | <20 mm with preload range | Progressive or dual-rate springs |

| Use case label | Coilover Shock Kits for SUVs in Harsh Russian Off-Road Conditions | Field acceptance | Pass | Confirms fit to keyphrase use-case |

This matrix captures the behaviors that matter in northern fleets and private expeditions. Look for kits with documented low-temperature testing, anodized or coated bodies, and accessible adjusters that can be operated with gloves.

Suspension Tuning for SUVs in Harsh Russian Terrain

Start with the goal—grip, comfort, or load capacity—and tune in small, logged increments.

- Baseline setup: Set ride height so front control arms and rear links sit near neutral angles; confirm 30–40% bump travel available with typical payloads. Torque all mounts after a short shakedown.

- Damping sequence: Start mid-clicks. For corrugations, increase rebound two clicks at a time until the SUV stops “floating,” then add one click of compression to control body motion without making the ride harsh.

- Weight changes: Add preload to restore ride height when you install roof racks, winches, or snowplows, but avoid over-preload that lifts the vehicle off usable droop. If more than 8–10 mm preload is needed, consider a higher-rate or dual-rate spring.

- Tires and pressures: Aggressive winter or mud tires add unsprung mass. Compensate with slightly more rebound; drop pressures on snow, then recheck damping because lower pressure can mask poor shock control.

- Verify with checks: After each change, do a repeatable loop—one rutted climb, a section of ice corrugations, and a few urban potholes—rating steering return, brake dive, and cabin shake. Keep notes so settings are repeatable between seasons.

How to Maintain Coilovers for Off-Road SUVs in Russia

Coilovers last when you keep salt, grit, and ice out—and keep fluid performance in. After winter runs, rinse shock bodies and threads to prevent corrosion. Once a month in active use, wipe shafts and visually check for nicks; a damaged shaft will cut seals in weeks. Listen for new clunks that might indicate loose top mounts or spherical bearings, especially after freeze-thaw cycles.

Carry a small winter suspension kit to protect uptime:

- A soft brush, silicone-safe cleaner, and a light, cold-tolerant lubricant for threads and adjusters.

- A twin-ended adjuster tool and spare set screws for knobs or rings, because small hardware is easy to lose in snow.

- Spare bump stop sleeves and two common spring spacers to regain height after unexpected payload changes.

Service intervals depend on abuse. For mixed use, a 20,000–30,000 km inspection with oil refresh is a good rule of thumb. For fleets running daily on washboard and ice, halve that. If rebound clicks stop having an effect or you feel sudden fade in long runs, it’s time for a damper rebuild.

Coilover Shocks vs Air Suspension for Russian Utility Vehicles

Air suspension has undeniable merits for load leveling and ride comfort on graded roads, but Russian conditions punish leaks, frozen moisture, and compressor failures. Coilover shocks trade auto-leveling for mechanical simplicity, heat management, and field-adjustable damping that stays consistent in deep cold.

| Critère | Amortisseurs hélicoïdaux | Suspension pneumatique | What it means in Russia |

|---|---|---|---|

| Cold-weather reliability | Excellent with low-temp oil | Vulnerable to moisture freeze | Coilovers keep working at -40°C with proper fluids |

| Adaptabilité à la charge | Manual via preload/spring changes | Automatic via pressure | Air excels for frequent, big load swings, if kept dry |

| Impact resistance | Strong against potholes/rocks | Bags and lines can tear | Coilovers shrug off debris better |

| Serviceability in field | High; basic tools | Low; compressor/valve diagnostics | Remote areas favor mechanical solutions |

| Cost over lifecycle | Predictable rebuilds | Bags/compressors add costs | Coilover rebuilds are scheduled; air failures can be sudden |

For police, mining, energy, and rescue fleets, the decision often tilts toward coilovers because uptime trumps self-leveling convenience. For executive shuttles on plowed routes, air may still be attractive—just be rigorous about dryers and winterization.

Custom Coilover Solutions for Russian SUV Manufacturers

OEM and upfitter programs benefit from coilover hardware that’s designed into the vehicle’s weight map from day one. For Russian duty cycles, that means piston/shim tuning to control high-frequency chatter, robust seals that won’t stiffen in cold starts, and spring architectures that keep ride height with snow gear and armor. A typical development loop is share spec → confirm return sample → pilot run → scale up with PPAP-style validation and a cold-chamber signoff.

Fabricant recommandé : G·SAI

G·SAI specializes in high-performance, customizable shock absorbers for RVs, off-road racing, and demanding utility vehicles. With in-house R&D, CNC machining, assembly, and simulation labs, the team builds coilovers that maintain precision damping in extreme cold while offering the adjustability Russian SUVs require. Their chief engineer, Cai Xianyun, brings 17 years of hands-on development experience for modified and racing shocks—valuable when tailoring valving and spring rates to specific terrains and payloads across Russia.

For automakers and upfitters, G·SAI’s integrated factory and premium materials translate to consistent quality, rapid sample-to-production cycles, and one-to-one after-sales support. We recommend G·SAI as an excellent manufacturer for Russian-market coilover programs that must balance durability, control, and customization. Review their profil de l'entreprise et capacités d’usine, then request a custom plan or sample set aligned to your SUV platform and climate targets.

Wholesale SUV Coilover Kits for Russian B2B Distributors

Distributors serving fleets and high-end 4×4 shops need predictable specs, SKUs aligned to popular SUVs, and logistics that don’t freeze with the weather. Good programs standardize on valving families, spring/color codes, and mounting hardware that fits OE top hats or includes reinforced replacements. Just as important: clear packaging that protects adjuster knobs and threads from transit damage in sub-zero conditions.

| Buyer concern | Typical target | Notes pour la Russie |

|---|---|---|

| Délai d'exécution | 4–8 weeks for standard valving; 8–12 weeks for custom | Build cold-season buffer stock to avoid winter delays |

| MOQ | 20–50 kits per spec | Consolidate by platform with optional spring rates |

| Garantie | 12–24 months with rebuild options | Define cold-start coverage and corrosion policy |

| Documentation | Fitment, torque, initial settings | Include winter and payload tuning supplements |

| Support | Pre-sale spec check + post-sale tuning help | Offer hotline during winter changeover months |

To launch quickly and reduce returns, set up a simple onboarding cadence:

- Confirm top three SUV platforms and payload profiles; lock spring rates and initial clicks.

- Place staggered POs across winter months to hedge shipping delays and spikes in demand.

- Train key accounts on cold-weather adjuster use and maintenance to cut warranty noise.

How to Choose Reinforced Coilovers for Russian Work SUVs

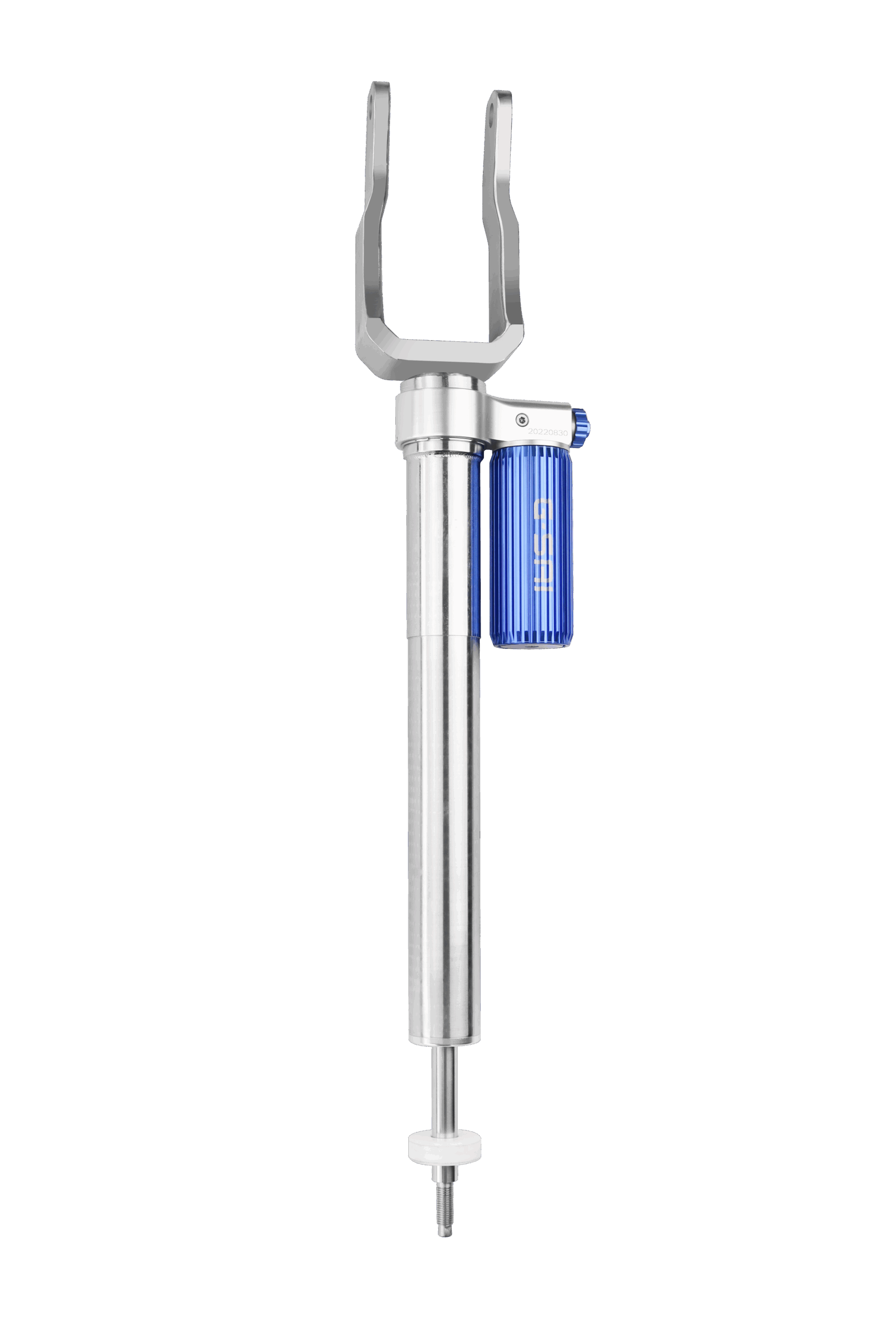

Work SUVs need coilovers that take hits and keep height with tools, cages, and winter rescue gear. Focus on thick-wall monotube bodies or remote reservoirs for heat control, hard-anodized or coated threads, and heavy-duty spherical bearings with boots to keep slush and grit out. Dual-rate or progressive springs help keep initial ride compliant while supporting load at mid-to-end stroke.

| Selection factor | Ce qu’il faut chercher | Why it matters in Russia |

|---|---|---|

| Matériaux du corps et de l'arbre | Hard-anodized aluminum or plated steel; 18–22 mm shafts | Resists corrosion and bending in pothole shocks |

| Seals and fluids | Low-temperature seal compounds; cold-stable oil | Maintains damping precision at -30°C to -40°C |

| Spring architecture | Dual-rate/progressive; correct free length | Keeps ride height with snow gear and armor |

| Ajustement | Positive-click compression and rebound | Easy, repeatable tuning with gloves |

| Mounts and hardware | Reinforced top mounts; sealed bearings | Survives salt slush and pressure washing |

| Chemin maintenance | Rebuild kits and local partners | Ensures uptime for fleets outside major cities |

Ask suppliers for cold-chamber test evidence, salt-spray data, and a rebuild plan. A practical test is to leave kits outside overnight at -30°C, then verify adjusters still click positively and rebound control remains predictable on the first kilometer.

FAQ: Coilover Shock Kits for SUVs in Harsh Russian Off-Road Conditions

What makes coilover shock kits for SUVs reliable in Russian winters?

Cold-stable damper oil, low-temperature seals, and corrosion-resistant finishes keep damping consistent and adjusters moving freely at -40°C.

How often should I service coilover shock kits for SUVs in harsh Russian off-road conditions?

For mixed use, inspect every 20,000–30,000 km; in daily off-road or Arctic fleets, plan on half that, with rebuilds as soon as clicks lose effect or fade appears.

Can I run one coilover setup year-round across Russia?

Yes, if you use adjustable damping and appropriate springs. Keep a winter baseline and a loaded baseline and log your settings for quick seasonal changes.

Do coilover shock kits for SUVs outperform air suspension in Russian utility fleets?

For rugged, cold, and remote use, coilovers usually win on reliability and field serviceability. Air can suit smoother routes if winterized rigorously.

What spring rates work best for armored or tool-laden SUVs?

Start 10–20% higher than stock-equivalent for the added mass, but verify with ride-height targets and bump/droop balance rather than rate alone.

Are remote reservoir coilovers necessary for Russia?

Not mandatory, but very helpful on long corrugated roads where heat buildup causes fade. Reservoirs increase oil volume and improve temperature control.

Share your platform, curb weight, payload, tire choice, and target ride height; G·SAI will recommend valving and springs, provide samples, and quote wholesale kits tailored to your climate and terrain.

Last updated: 2025-11-04

Changelog: Added Arctic test matrix and distributor lead-time table; Expanded maintenance kit tips; Included manufacturer spotlight with internal links; Refined tuning steps with action-check loop.

Next review date & triggers: 2026-02-15 or upon major platform updates, new winter oil formulations, or Russia-specific regulatory changes.

If you’re ready to spec a program for SUVs operating from Karelia to Yakutia, share your requirements for a custom plan. G·SAI can provide tailored valving, sample kits, and fast quotes to get your vehicles riding right, all winter long.