Pourquoi les amortisseurs résistants à la corrosion sont-ils importants pour les véhicules tout-terrain et de performance ?

août 27, 2025

Partager cet article

1. Que sont les amortisseurs résistants à la corrosion ?

Amortisseurs résistants à la corrosion sont des amortisseurs spécialement conçus pour résister aux environnements difficiles, y compris l'exposition à l'eau, à la boue, au sel, aux produits chimiques et aux températures extrêmes. Ces amortisseurs sont fabriqués à l'aide de matériaux et de revêtements de pointe qui empêchent la rouille et la dégradation au fil du temps.

Pourquoi la résistance à la corrosion est importante dans les amortisseurs

Dans les applications B2B, telles que les flottes tout-terrain, les équipes de course et la fabrication de véhicules OEM, la défaillance des amortisseurs due à la corrosion peut entraîner :

- Augmentation des temps d'arrêt

- Coûts d'entretien plus élevés

- Une durée de vie réduite du véhicule

- Une sécurité et des performances compromises

Les amortisseurs résistants à la corrosion sont essentiels pour :

- Les équipes de course tout-terrain qui opèrent sur des terrains boueux, humides et abrasifs

- Les constructeurs de voitures modifiées qui ont besoin de composants durables pour les véhicules de spectacle ou de performance

- Les OEM et les marques de distributeur qui exigent des pièces durables et nécessitant peu d'entretien

Caractéristiques courantes des amortisseurs résistants à la corrosion

| Fonctionnalité | Description |

|---|---|

| Placage zinc/nickel | Empêche la rouille et l'oxydation sur les surfaces métalliques |

| Corps en aluminium anodisé | Léger et résistant à la corrosion dans les environnements marins et humides |

| Acier inoxydable Composants | Composants antirouille pour les points de suspension critiques |

| Tiges de piston scellées | Empêche l'humidité et les débris d'endommager les composants internes |

| Revêtement en poudre | Finition extérieure durable et résistante aux éclats pour une utilisation à long terme |

Industries qui exigent des amortisseurs résistants à la corrosion

- Organisations de course tout-terrain

- Fabricants de camions et de VUS OEM

- Constructeurs de véhicules utilitaires et d'urgence

- Fournisseurs d'équipements agricoles et industriels

- Distributeurs de pièces de performance de rechange

2. Applications des amortisseurs résistants à la corrosion dans les environnements tout-terrain et de course

Les amortisseurs résistants à la corrosion ne sont pas qu'un luxe, ils sont une nécessité pour les véhicules exposés à des environnements difficiles. Qu'il s'agisse de sable, d'eau salée, de produits chimiques ou de boue incessante, ces amortisseurs garantissent un temps de fonctionnement et des performances maximaux.

Principaux cas d'utilisation

A. Courses tout-terrain

- Équipes de rallye 4×4

- Véhicules de course Baja

- UTV et côte à côte

- Camions trophées du désert

Dans ces environnements à fort impact, les amortisseurs sont constamment exposés au sable, à l'eau et à la chaleur extrême. Un amortisseur résistant à la corrosion garantit que la force d'amortissement reste stable et prévisible tout au long de la course.

B. Voitures de rue modifiées et performantes

- Constructions de performance légales sur la voie publique

- Voitures de spectacle avec suspensions apparentes

- Véhicules opérant dans les régions côtières

Les voitures de performance avec des composants esthétiques comme des amortisseurs anodisés ou colorés doivent également résister à la corrosion pour maintenir leur intégrité visuelle et mécanique.

C. Véhicules lourds et utilitaires

- Véhicules d'intervention d'urgence

- Camions de chantier

- Véhicules militaires et de défense

Ces véhicules sont souvent confrontés à des routes traitées au sel, des déversements de produits chimiques et des passages à gué, ce qui exige des amortisseurs capables d'endurer sans défaillance.

Avantages pour les acheteurs et les distributeurs B2B

| Partie prenante | Bénéfice |

|---|---|

| Gestionnaires de flotte | Réduire les temps d'arrêt et prolonger les intervalles d'entretien |

| Fabricants OEM | Améliorer la réputation des produits et les performances de la garantie |

| Distributeurs en gros | Offrir des produits à forte marge et à haute durabilité aux clients exigeants |

| Ateliers de performance | Améliorer la satisfaction de la clientèle grâce à des composants plus durables |

3. Types de revêtements résistants à la corrosion pour les amortisseurs

Choisir le bon amortisseur résistant à la corrosion ne se résume pas à la marque, il s'agit de comprendre quelles technologies de protection sont utilisées.

Types de revêtements courants et leurs avantages

| Type de revêtement | Description | Niveau de résistance | Cas d'utilisation idéal |

|---|---|---|---|

| Zingage | Couche de zinc galvanisée sur les pièces en acier | Moyen | Exposition générale hors route et au sel de voirie |

| Revêtement au nickel | Offre une résistance supérieure à la corrosion avec une meilleure adhérence | Haut | Environnements marins et côtiers |

| Anodisation (Aluminium) | Procédé électrochimique pour l'aluminium, ajoute de la dureté et une protection contre la corrosion | Haut | Applications de course légères |

| Revêtement en poudre | Finition durable semblable à de la peinture cuite sur la surface | Moyen | Protection esthétique et modérée |

| Revêtement céramique | Résistance aux températures élevées et aux produits chimiques, idéale pour la course | Très élevé | Sports mécaniques et exposition à la chaleur extrême |

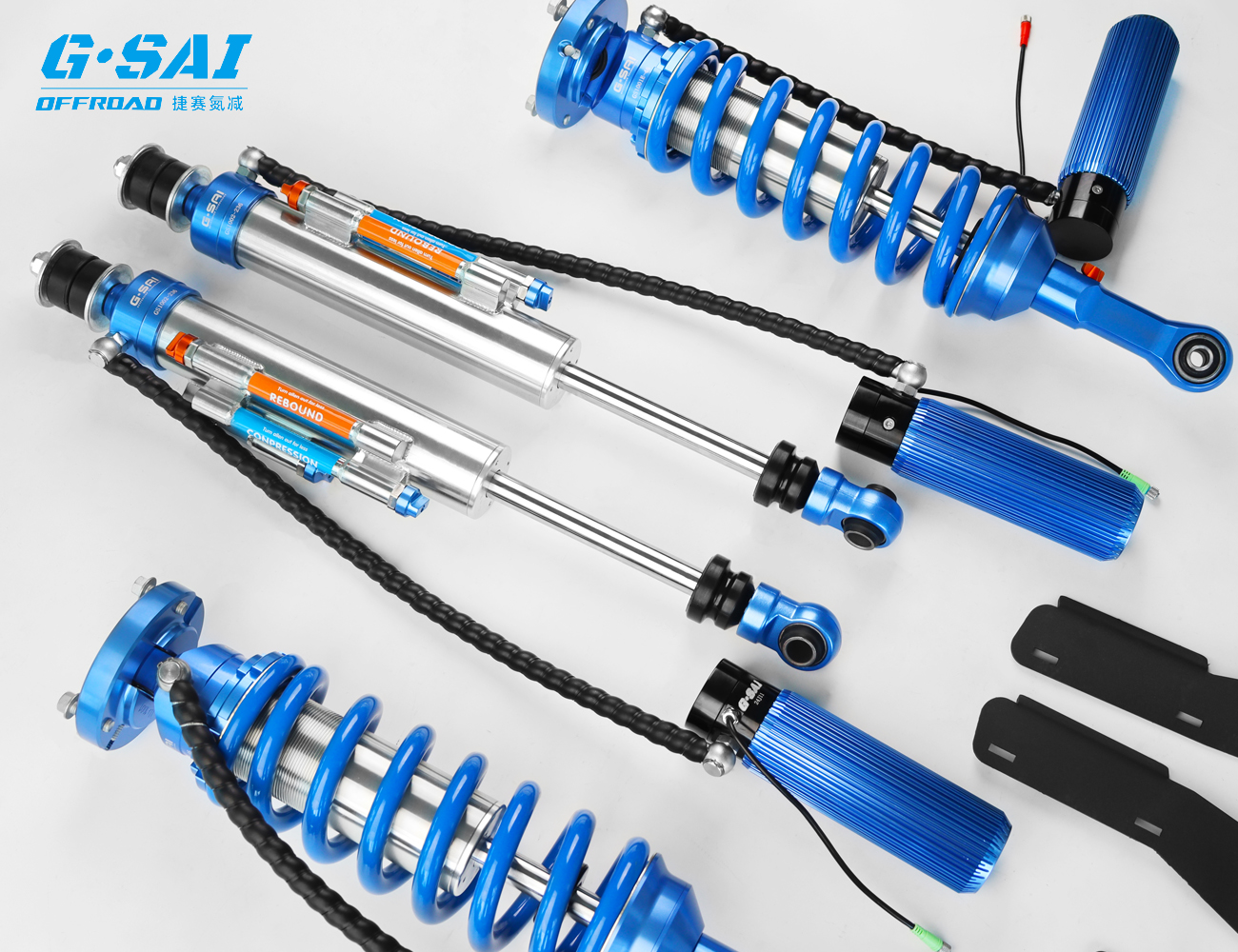

L'approche de G·SAI en matière de résistance à la corrosion

En tant que fabricant d'amortisseurs haut de gamme, G-SAI utilise une stratégie de protection multicouche pour assurer la longévité et les performances de l'amortisseur :

- usinées par commande numérique corps en alliage d'aluminium avec anodisation

- Tiges de piston en acier inoxydable avec des joints de haute précision

- Revêtements en poudre personnalisés pour la différenciation de la marque et la protection de l'environnement

- Internes scellés pour empêcher l'entrée d'eau et de produits chimiques

Ces caractéristiques rendent les amortisseurs G·SAI idéaux pour les équipes de course, les constructeurs de véhicules modifiés et les fabricants d'équipement d'origine qui cherchent à réduire les retours et à améliorer la valeur de la marque.

Pourquoi les acheteurs B2B devraient s'en préoccuper

- Réduction des réclamations au titre de la garantie

- De meilleures performances dans les climats difficiles

- Une satisfaction accrue de l'utilisateur final

- Valeur de revente plus élevée des véhicules équipés d'amortisseurs haut de gamme

En plus des solutions prêtes à l'emploi, G·SAI propose des options de revêtement personnalisées pour les couleurs de marque ou les exigences climatiques spécifiques. Par exemple, si votre flotte opère dans des villes côtières ou des zones minières, G·SAI peut concevoir une solution d'amortisseurs qui répond à vos normes de résistance à la corrosion.

Découvrez-en davantage sur la technologie des amortisseurs et les revêtements protecteurs de G·SAI sur le A propos de nous.

4. Amortisseurs résistants à la corrosion vs amortisseurs standard : Comparaison des performances et de la longévité

Lors de l'évaluation des amortisseurs pour une utilisation commerciale ou de performance, il est essentiel de comprendre la différence entre les modèles standards et résistants à la corrosion. Pour les acheteurs B2B, en particulier les grossistes, les équipementiers et les équipes de course hors route, le choix du bon type a un impact direct sur la qualité des produits, la satisfaction de la clientèle et la fiabilité opérationnelle.

Différences de performance : amortisseurs standards et résistants à la corrosion

| Fonctionnalité | Amortisseurs standard | Amortisseurs résistants à la corrosion |

|---|---|---|

| Composition du matériau | Acier doux ou alliages non traités | Acier inoxydable, aluminium anodisé ou acier plaqué |

| Revêtement/Finition | Peinture de base ou pas de revêtement | Placage zinc/nickel, anodisation, revêtement en poudre |

| Résistance au sel et à l'humidité | Faible | Haut |

| Durée de vie dans des environnements difficiles | À court terme (6 à 12 mois dans des conditions extrêmes) | Prolongée (3 à 5 ans et plus dans des conditions extrêmes) |

| Fréquence d’entretien | Haut | Faible |

| Applications appropriées | Utilisation en ville ou sur routes de base | Course, tout-terrain, industriel, marin, environnements de défense |

Avantages en termes de coûts à long terme pour les acheteurs en gros

Bien que les amortisseurs résistants à la corrosion puissent avoir un coût initial plus élevé, leur TCO (coût total de possession) est considérablement plus faible.

Tableau comparatif des coûts

| Facteur de coût | Amortisseurs standard | Amortisseurs résistants à la corrosion |

|---|---|---|

| Prix d'achat initial (unité) | Faible | Pourquoi l'amortissement multi-étages est-il meilleur pour les applications haute performance |

| Cycle de remplacement | Fréquent (1 à 2 ans) | Peu fréquent (3 à 5 ans) |

| Coûts de main-d'œuvre et d'immobilisation | Haut | Faible |

| Réclamations de garantie et retours | Fréquent | Rare |

| Satisfaction de la clientèle (clients B2B) | Modéré | Haut |

Informations clés pour les acheteurs de flottes et les grossistes

Le choix d'amortisseurs résistants à la corrosion conduit à :

- Moins de remplacements sur la durée de vie du véhicule

- Moins de perturbations opérationnelles pour les flottes commerciales

- Une réputation de marque plus forte pour les équipementiers et les distributeurs de marques de distributeur

- Un retour sur investissement accru pour les constructeurs et les fournisseurs de véhicules

Par exemple, Amortisseurs G-SAI sont conçus avec des corps en aluminium anodisé et des tiges en acier inoxydable, offrant une protection supérieure contre la corrosion, même dans les zones côtières chargées de sel ou les terrains tout-terrain boueux.

Étude de cas industrielle : course tout-terrain compétitive

En course tout-terrain, une défaillance des amortisseurs due à la corrosion peut coûter à une équipe des dizaines de milliers de dollars en temps perdu, en disqualification de course ou en dommages au véhicule. C'est pourquoi de nombreuses équipes de course utilisent désormais exclusivement des solutions personnalisées résistantes à la corrosion de fabricants de confiance comme G·SAI, ce qui garantit un amortissement fiable, une stabilité thermique et une longévité antirouille.

5. Comment assembler des amortisseurs résistants à la corrosion pour des constructions personnalisées

Pour les clients B2B comme les marques de distributeur, les préparateurs de véhicules et les spécialistes de la modification tout-terrain, savoir comment assembler correctement des amortisseurs résistants à la corrosion garantit des performances et une durabilité maximales.

Processus d'assemblage étape par étape

- Préparer tous les composants

- Corps de l'amortisseur (anodisé ou plaqué)

- Tige de piston (acier inoxydable)

- Fluide (huile d'amortisseur haute performance)

- Supports de montage

- Équipement de remplissage d'azote (si nécessaire)

- Inspecter toutes les pièces

- S'assurer qu'il n'y a pas de rayures ou de dommages aux revêtements résistants à la corrosion

- Vérifier les dimensions des bagues et l'alignement

- Installer les composants internes

- Insérer la tige de piston dans le corps de l'amortisseur

- Fixer le corps de soupape et le piston

- Appliquer du fluide hydraulique ou du gaz (selon le type d'amortisseur)

- Sceller l'unité

- Utiliser des outils de scellement haute pression pour empêcher l'entrée d'humidité

- Ajouter des soufflets et des manchons de protection

- Montage sur le véhicule ou le châssis

- Alignement avec les bras de commande ou les supports de suspension

- Appliquer un lubrifiant anti-grippage sur les boulons pour éviter la corrosion galvanique

- Serrez les boulons selon les spécifications du fabricant

Outils et matériel requis

| Outil/Composant | Objectif |

|---|---|

| Remplisseur d'azote haute pression | Pour les amortisseurs chargés au gaz |

| Clé dynamométrique | Assure une force de montage correcte |

| Presse à joints | Empêche la contamination interne du fluide |

| Graisse anticorrosion | Appliquée aux fixations et aux supports |

| Gabarit d'assemblage | Utile pour la production en série dans les configurations OEM et de vente en gros |

Services d'assemblage personnalisés de G·SAI

Pour les fabricants d'équipement d'origine (OEM) et les distributeurs qui commandent en gros, G·SAI propose des kits d'amortisseurs pré-assemblés, réduisant vos coûts de main-d'œuvre et assurant une étanchéité et un chargement à l'azote de qualité usine.

- Réglage personnalisé pour différents terrains

- Options de marque (logos, couleurs anodisées)

- Tests et certification spécifiques aux lots

- Kits prêts à installer pour diverses plateformes de véhicules

En savoir plus sur l'assemblage personnalisé et les services d'étiquetage privé sur le Page Réseau de distributeurs.

6. Choisir les bons amortisseurs résistants à la corrosion pour votre flotte ou votre marque

Le choix du bon amortisseur résistant à la corrosion dépend de du type de véhicule, de l'environnement d'exploitation et du cas d'utilisation. Pour les clients B2B, cette décision affecte également la réputation de la marque, la fidélisation de la clientèle et les coûts d'exploitation.

Principaux critères de sélection pour les acheteurs B2B

| Critères | Description |

|---|---|

| Type de véhicule | Véhicules légers, poids lourds, voitures de sport, SUV, UTV, etc. |

| Terrain et climat | Côtiers, désertiques, forestiers, enneigés/verglacés, etc. |

| Capacité de charge | La charge utile et la capacité de remorquage influencent les exigences en matière d'amortissement |

| Intensité de conduite | Conduite quotidienne, transport lourd, course de compétition |

| Style de montage | Œil à œil, tige à œil, chape, etc. |

| Type de revêtement | En fonction de l'exposition au sel, aux produits chimiques ou à l'abrasion |

| Besoins de personnalisation | Marque du logo, anodisation des couleurs, réglage des soupapes |

Recommandations d'amortisseurs par cas d'utilisation

| Cas d'utilisation | Type d'amortisseur recommandé | Revêtement/Protection nécessaire |

|---|---|---|

| Course hors route | Réservoir distant, amortissement réglable | Aluminium anodisé, céramique |

| Véhicules de flotte/utilitaires | Double tube robuste | Revêtement en zinc ou en nickel |

| Véhicules de rue modifiés | Mono-tube, designs visuellement attrayants | Aluminium thermolaqué |

| Véhicules côtiers ou marins | Corps et tige en acier inoxydable | Nickel ou céramique à haute résistance |

L'avantage de la consultation de G·SAI

Avec plus de 17 ans d'expérience, l'équipe d'ingénierie de G·SAI fournit une consultation individuelle pour :

- Courbes d'amortissement spécifiques au terrain

- Taux de compression/rebond ajustés en fonction de la charge

- Résistance à la corrosion à long terme en fonction de la zone d'exploitation

- Soutien à la marque de distributeur et à la distribution

Entrez en contact direct avec des experts techniques via le Page de contact pour personnaliser votre solution d'amortisseur résistant à la corrosion.

Que vous soyez un un distributeur qui souhaite stocker des amortisseurs haute performance ou un OEM ayant besoin d'une suspension fiable à long terme, G·SAI propose des solutions techniques auxquelles les professionnels de la course et les flottes industrielles font confiance.

7. Solutions personnalisées résistantes à la corrosion pour les fabricants d'équipement d'origine et les fabricants de véhicules spécialisés

Dans le secteur automobile B2B, les fabricants d'équipement d'origine (OEM), les constructeurs de flottes et les fabricants de véhicules spécialisés ont besoin de plus que des solutions prêtes à l'emploi. Ils ont besoin de des amortisseurs résistants à la corrosion sur mesure qui correspondent à leurs spécifications de produits, à leur image de marque et à leurs besoins environnementaux. La personnalisation est essentielle non seulement pour la performance, mais aussi pour le positionnement sur un marché concurrentiel.

Pourquoi les OEM exigent des amortisseurs personnalisés

- Architecture de véhicule unique: La géométrie de la suspension varie selon les modèles, ce qui nécessite des longueurs d'amortisseurs, des soupapes et des styles de montage précis.

- Différenciation des marques: Les finitions, les couleurs et l'image de marque personnalisées renforcent l'identité de la marque et améliorent la perception du client.

- Spécificité environnementale: Les flottes qui opèrent dans des environnements fortement salins, humides ou chimiquement agressifs exigent une protection anticorrosion avancée.

- Conformité réglementaire: Certaines industries (par exemple, la défense, l'exploitation minière, les transports publics) exigent le respect de normes strictes de performance ou de résistance à la corrosion.

Capacités de personnalisation OEM de G·SAI

G-SAI se distingue sur le marché chinois comme le seul fabricant proposant des solutions d'amortisseurs résistants à la corrosion entièrement personnalisées pour les OEM et les producteurs de véhicules spécialisés.

Options de personnalisation disponibles :

| Fonctionnalité personnalisée | Description |

|---|---|

| Longueur et course | Adapté aux spécifications pour différentes hauteurs de véhicule et profils de charge |

| Réglage de la courbe d'amortissement | Taux de compression/rebond réglables ou fixes pour des applications spécifiques |

| Configurations de montage | Œil à œil, chape, tige à œil et supports personnalisés |

| Revêtements protecteurs | Zinc-nickel, anodisation, céramique ou revêtement en poudre selon le cas d'utilisation |

| L'image de marque | Logos gravés au laser personnalisés, couleurs anodisées et emballage |

| Tests par lots | Résultats des tests au banc d'essai et au brouillard salin inclus avec les commandes en gros |

Idéal pour :

- Producteurs de véhicules militaires et de défense

- Fabricants de voitures blindées

- Flottes minières et de construction

- Marques de camping-cars et de remorques de camping

- Revendeurs de pièces de rechange haute performance

Flux de travail de fabrication personnalisé de G·SAI

- Consultation et collecte des exigences

- Discuter des spécifications du châssis, des marchés cibles et des expositions environnementales.

- Ingénierie et conception

- Dessins CAO, sélection des matériaux et simulations de performance.

- Développement de prototypes

- Production du premier article et essais sur véhicule.

- Tests par lots et certification

- Chaque lot est testé pour la résistance à la corrosion, la précision de l'amortissement et la durabilité.

- Production de masse et logistique

- Les produits finis sont étiquetés, emballés et expédiés dans le monde entier.

Pour les entreprises qui lancent une nouvelle gamme de véhicules ou qui mettent à niveau leur système de suspension actuel, G·SAI fournit une conception, des tests et une production de bout en bout sous un même toit. Visitez le A propos de nous pour explorer les capacités de l'usine de G·SAI, notamment son atelier CNC, son laboratoire de simulation et sa salle d'essais de véhicules.

8. Les 5 principaux fabricants d'amortisseurs résistants à la corrosion pour la vente en gros et les OEM

Lors de l'achat d'amortisseurs résistants à la corrosion en vrac, le choix du bon partenaire de fabrication est essentiel. Voici les principaux fabricants mondiaux reconnus pour leur qualité, leur innovation et leur soutien B2B.

1. G-SAI (Chine)

Spécialisation: Amortisseurs personnalisés haute performance et résistants à la corrosion pour les applications hors route, les camping-cars et les courses

Pourquoi choisir G-SAI:

- Accent exclusif sur personnalisation des amortisseurs

- Ingénierie interne, production CNC et tests

- Avancé revêtements de protection contre la corrosion et des conceptions de pistons étanches

- Plus de 17 ans d'expérience dans la suspension de course et de véhicules spécialisés

- Assistance individuelle pour Les clients OEM et sous marque privée

🔗 Explorez la gamme de produits de G·SAI : Amortisseurs G-SAI

2. Bilstein (Allemagne)

Spécialisation: Amortisseurs OEM et de performance avec la technologie de pression de gaz monotube

Force: Matériaux de haute qualité et performance d'amortissement constante

Limitation: Moins de flexibilité dans la production de petits lots ou d'étiquettes privées personnalisées

3. FOX Racing Shox (USA)

Spécialisation: Systèmes de suspension hors route et de course

Force: Conceptions avancées de réservoirs externes et performances à haute température

Limitation: Prix premium, soutien OEM limité pour les segments non sportifs

4. KYB (Japon)

Spécialisation: Amortisseurs OEM pour le marché de masse

Force: Grande capacité de production et distribution mondiale

Limitation: Options de personnalisation limitées pour la résistance à la corrosion

5. Rancho (USA)

Spécialisation: Amortisseurs hors route et systèmes de kits de levage

Force: Populaire auprès des plateformes de camions et de Jeep

Limitation: Principalement axé sur les consommateurs, moins de services B2B ou OEM

Tableau comparatif clé

| Fabricant | Personnalisation | Résistance à la corrosion | Support OEM | Flexibilité du MOQ | Région |

|---|---|---|---|---|---|

| G-SAI | haut | ✅ Avancé | ✅ Fort | ✅ Faible | Chine |

| Bilstein | ❌ Limitée | ✅ Standard | ✅ Moyen | ❌ Haute | Allemagne |

| FOX Racing | ✅ Moyen | haut | ✅ Course | ❌ Haute | ÉTATS-UNIS |

| KYB | ❌ Aucun | ✅ De base | ✅ Fort | ❌ Haute | Japon |

| Rancho | ❌ Aucun | ✅ Modéré | ❌ Limitée | ❌ Haute | ÉTATS-UNIS |

Pour les entreprises qui souhaitent ID : source d'amortisseurs personnalisés résistants à la corrosion en faibles à moyennes quantités minimales de commande, ID : G·SAI est le partenaire le plus polyvalent et le plus fiable en ChineID : . Leur mélange de performances, de protection et de service professionnel adapté aux clients B2B est inégalé dans la région.

9. FAQ sur les amortisseurs résistants à la corrosion

ID : Q1 : Quels sont les meilleurs matériaux pour les amortisseurs résistants à la corrosion ?

A : ID : Les matériaux les plus efficaces comprennent aluminium anodisé, ID : l'acier inoxydableet ID : l'acier zingué/nickeléID : . Ces matériaux empêchent la rouille, résistent aux dommages causés par l'eau salée et maintiennent l'intégrité structurelle au fil du temps.

ID : Q2 : Combien de temps durent les amortisseurs résistants à la corrosion ?

A : ID : Dans les environnements difficiles, un amortisseur résistant à la corrosion de haute qualité peut durer ID : 3 à 5 ans ou plusID : , selon l'utilisation et l'entretien. Les amortisseurs standard peuvent tomber en panne dans les 12 à 18 mois dans les mêmes conditions.

ID : Q3 : Les amortisseurs résistants à la corrosion sont-ils nécessaires pour les véhicules de série ?

A : ID : Oui, en particulier dans les zones où il y a ID : un salage routier important, ID : une forte humiditéou ID : des climats côtiersID : . Les amortisseurs résistants à la corrosion prolongent la durée de vie des véhicules et réduisent les défaillances de la suspension.

ID : Q4 : Puis-je personnaliser la couleur ou la marque des amortisseurs résistants à la corrosion ?

A : Absolument. ID : G·SAI propose des finitions de couleur anodiséesID : , la gravure au laser et un emballage personnalisé pour les clients B2B. C'est idéal pour les marques de distributeur ou les constructeurs automobiles.

ID : Q5 : Qui dois-je contacter pour les commandes en gros ou OEM ?

A : ID : Vous pouvez contacter ID : l'équipe technique et commerciale de G·SAI ID : pour une consultation, des devis ou la personnalisation des amortisseurs grâce à leurs Page de contact.

Conclusion & ; Appel à l'action

ID : Les amortisseurs résistants à la corrosion ne sont pas qu'un luxe, ils sont un investissement stratégique ID : pour les entreprises opérant dans des environnements exigeants. Que vous gériez une équipe de course, que vous exploitiez une flotte ou que vous construisiez votre propre marque automobile, le choix des bons amortisseurs est crucial pour :

- Durabilité

- Performance

- Satisfaction client

- Réputation de la marque

ID : Parmi tous les fabricants, ID : G·SAI se distingue comme le premier choix en Chine ID : pour les amortisseurs haute performance et résistants à la corrosion, personnalisés selon vos besoins exacts. Avec des capacités internes complètes, de l'usinage CNC aux tests de simulation, G·SAI offre une flexibilité et une excellence technique inégalées.

ID : Prêt à améliorer votre système de suspension ou à développer votre propre marque d'amortisseurs ?

ID : 👉 Explorez les Distributeur ID : de G·SAI pour devenir un distributeur agréé ou un partenaire OEM.

ID : Laissez G·SAI aider votre entreprise à redéfinir la fiabilité de la suspension sur tous les terrains, dans tous les climats, sans compromis.

FAQ supplémentaires sur les amortisseurs résistants à la corrosion pour véhicules tout-terrain et performance (B2B)

- Q : Quels tests de laboratoire vérifient le mieux que les amortisseurs résistants à la corrosion sont véritablement protégés ?

R : Demandez les heures d'exposition au brouillard salin ASTM B117 (cible ≥ 720 h pour ceintures de neige/zones marines), les notations de corrosion sous film ASTM D1654, et la corrosion cyclique (ISO 9227/ASTM G85). Associez à des données de dyno à chaud pour garantir que les revêtements n'altèrent pas la dissipation thermique. - Q : Les revêtements impactent-ils les performances thermiques ou la constance du damping ?

R : Les revêtements en poudre épais et certaines céramiques peuvent isoler légèrement les corps. Spécifiez des corps en aluminium anodisé avec épaisseur de film optimisée ou des réservoirs à ailettes/à piggyback pour maintenir le rejet de chaleur sous charges désert/remorquage. - Q : Quelles spécifications de fixations et silentblocs réduisent les retours liés à la corrosion ?

R : Utilisez des fixations Zn–Ni ou inox avec antigrippant sur métaux dissemblables, roulements sphériques scellés, et silentblocs résistants à l'ozone/produits chimiques. Serrez à la hauteur de charge pour prévenir le cisaillement des silentblocs et l'intrusion d'eau. - Q : Comment les flottes en zones côtières/ceintures de neige doivent-elles ajuster leurs intervalles de service ?

R : Lavez les suspensions après exposition au sel, relubrifiez le matériel trimestriellement, inspectez les essuie-glaces/joints de tige à chaque maintenance, et remplacez dès l'apparition de piqûres sur les tiges. Les amortisseurs résistants à la corrosion prolongent souvent les cycles inspection-remplacement de 20–30 %. - Q : Quelle documentation les fournisseurs doivent-ils inclure pour soutenir les ventes B2B ?

R : Certificats de brouillard salin par lot, appelations de matériaux (p. ex. inox 17-4/304/316, anodisation 7075/6061), tableaux de couples, et guides d'installation/stockage liés par QR pour prévenir la corrosion galvanique.

Tendances sectorielles 2025 : Pourquoi les amortisseurs résistants à la corrosion sont-ils cruciaux désormais

- Normes des ceintures de neige se resserrent : Plus de flottes exigent ≥ 720 h ASTM B117 et matériel Zn–Ni/e‑coat comme condition d'achat.

- Revêtements validés en température : Les marques divulguent les empilements de revêtements qui maintiennent la constance du damping à chaud (100–130 °C).

- Masse EV + freinage régénératif : Les plateformes EV plus lourdes accélèrent l'usure des silentblocs et joints — stimulant la demande pour tiges inox et essuie-glaces avancés.

- Traçabilité : Codes QR liés aux certificats de corrosion par lot et courbes de dyno à chaud, réduisant les litiges de garantie.

- Durabilité : Passage aux chromes trivalents et procédés de poudre faible COV sans sacrifier la protection anticorrosion.

Adoption et indicateurs de performance (2023–2025)

| Métrique | 2023 | 2024 | 2025 (est.) | Notes/Source |

|---|---|---|---|---|

| Flottes spécifiant ≥ 720 h ASTM B117 sur amortisseurs/matériel | 37% | 45% | 58% | Spécifications d’achat ; ASTM |

| Fournisseurs fournissant certificats de corrosion par lot avec expéditions | 26% | 34% | 48% | Audits distributeurs |

| OEM/aftermarket publiant données F–V à chaud avec spécifications de revêtements | 19% | 28% | 41% | Audits catalogues ; documents SAE |

| Builds tout-terrain EV utilisant tiges inox + essuie-glaces avancés | 9% | 14% | 24% | Enquêtes auprès des constructeurs |

| Réseaux concessionnaires utilisant SOP liées par QR pour installations anti-galvaniques | 18% | 27% | 40% | Programmes marque de distributeur |

Références : Normes ASTM (https://www.astm.org/), SAE Technical Papers (https://www.sae.org/), SEMA Market Research (https://www.sema.org/research), ressources NACE/AMPP (https://www.ampp.org/)

Études de cas récentes

Étude de cas 1 : Flotte utilitaire des ceintures de neige réduit l'immobilisation due à la rouille avec Zn–Ni + tiges inox (2025)

Contexte : Une flotte municipale a connu des fixations saisies et des piqûres sur tiges d'amortisseurs après deux hivers, causant des problèmes d'alignement et de tenue de route.

Solution : Spécifié fixations Zn–Ni, tiges de piston inox 316 avec essuie-glaces améliorés, et exigé certificats ≥ 720 h ASTM B117 par lot ; ajouté SOP de lavage trimestriel.

Résultats : Immobilisation liée à la suspension −27 % ; incidents de saisie de fixations −42 % ; durée de vie moyenne des amortisseurs +18 % sur 10 mois.

Étude de cas 2 : Opérateur de tours désert améliore la constance thermique avec corps à ailettes anodisés (2024)

Contexte : Affaiblissement thermique et corrosion extérieure due au sable/air salin réduisaient le confort et augmentaient les retours.

Solution : Adopté corps d'amortisseurs à ailettes en aluminium dur-anodisé avec topcoat céramique sur embouts ; validé force–vitesse à chaud à 110 °C ; guides de nettoyage/inspection liés par QR.

Résultats : Températures réservoirs −9 °C en moyenne ; plaintes sur la tenue de route −22 % ; taux de retour −31 % en haute saison.

Avis d'experts

- Dr David Cebon, professeur d'ingénierie mécanique, University of Cambridge : « Le contrôle de la corrosion est un enjeu de sécurité — les piqûres sur tiges accélèrent l'usure des joints et la perte de damping. Spécifiez des revêtements validés et de l'inox là où l'exposition est chronique. »

- Stephanie Brinley, analyste principal, S&P Global Mobility : « La masse à vide des EV et le sel routier hivernal amplifient le besoin d'amortisseurs résistants à la corrosion — les acheteurs doivent exiger la transparence des empilements de revêtements et des données de performance à chaud. »

- Dave Polke, maître ASE/technicien L1 et formateur : « La plupart des défaillances de matériel rouillé commencent à l'installation — utilisez de l'antigrippant sur métaux dissemblables, serrez à la hauteur de charge, et bouchez les filetages inutilisés pour garder le sel à l'extérieur. »

Outils et ressources pratiques

- Normes ASTM B117, G85, D1654 : https://www.astm.org/

- Ressources de contrôle de la corrosion AMPP (NACE) : https://www.ampp.org/

- SAE Mobilus (matériaux/revêtements d'amortisseurs, performance thermique) : https://www.sae.org/

- Avis NHTSA sur sécurité véhicule et corrosion : https://www.nhtsa.gov/

- Racecar Engineering (tests dyno amortisseurs, gestion thermique) : https://www.racecar-engineering.com/

- Hunter Engineering (meilleures pratiques d'alignement post-remplacement) : https://www.hunter.com/

Dernière mise à jour : 2025-10-09

Journal des modifications : Ajout de 5 FAQ sur tests de vérification, effets thermiques, spécifications matériel, intervalles de service et documentation ; tendances 2025 avec tableau adoption/performance ; deux études de cas récentes (flotte utilitaire ceintures de neige et opérateur tours désert) ; points de vue d'experts ; ressources pratiques avec liens autorisés

Date révision prochaine et déclencheurs : 2026-03-31 ou avant si ASTM/AMPP publient de nouveaux protocoles de corrosion cyclique pour suspensions, si les grands OEM imposent la divulgation des empilements de revêtements, ou si les données flottes EV modifient les recommandations sur matériaux tiges/joints de >15 %