Amortisseurs haute pression Europe : Le guide ultime pour les acheteurs B2B dans le secteur automobile

1er juillet 2025

Partager cet article

Que sont les amortisseurs haute pression et pourquoi sont-ils importants en Europe ?

Les amortisseurs haute pression, également connus sous le nom d’amortisseurs monotubes chargés au gaz, sont un composant essentiel des systèmes de suspension modernes, en particulier dans les applications de performance, tout-terrain et commerciales. En Europe, où les conditions routières sont diverses et où les normes de performance des véhicules sont strictes, les amortisseurs haute pression sont de plus en plus recherchés par les OEM, les fabricants de pièces de rechange et les équipes de course tout-terrain.

Qu’est-ce qui fait qu’un amortisseur est « haute pression » ?

Les amortisseurs haute pression utilisent une conception monotube remplie de gaz azote haute pression. Cette conception offre une dissipation thermique supérieure et un amortissement plus constant par rapport aux amortisseurs bitubes traditionnels.

Composants principaux :

| Composant | Fonction |

|---|---|

| Corps monotube | Loge tous les composants internes dans un seul cylindre |

| Piston flottant | Sépare l’huile du gaz azote |

| Gaz haute pression | Empêche la cavitation dans des conditions extrêmes |

| Haute viscosité Fluide | Assure un amortissement constant quelle que soit la température |

Pourquoi les amortisseurs haute pression sont-ils essentiels pour les marchés européens

- Performance: Les routes et circuits de course européens exigent une grande stabilité en virage et une maniabilité précise.

- Durabilité: De nombreux pays de l’UE connaissant des changements météorologiques extrêmes, les amortisseurs haute pression résistent mieux à la dilatation et à la contraction thermiques que les alternatives.

- Conformité: Un contrôle amélioré aide les véhicules à respecter les normes de sécurité et d’émissions de l’Union européenne grâce à une meilleure dynamique du châssis.

Principaux acheteurs B2B en Europe

- Garages de modification tout-terrain

- Équipes de course et distributeurs de sports mécaniques

- Fournisseurs de maintenance de flottes commerciales

- Intégrateurs de systèmes de suspension OEM

- Grossistes en pièces automobiles et plateformes de commerce électronique

Applications des amortisseurs haute pression dans les véhicules tout-terrain, de course et commerciaux

L’Europe présente un mélange unique de terrains, des routes alpines aux autoroutes en passant par les chemins ruraux accidentés, ce qui rend les amortisseurs spécifiques à l’application une nécessité. Les amortisseurs haute pression sont polyvalents et configurables pour un large éventail de cas d’utilisation.

1. Véhicules tout-terrain et de randonnée

La culture croissante du camping-car en Europe, en particulier dans des pays comme l’Allemagne, la France et la Scandinavie, a alimenté la demande de systèmes de suspension durables.

Exigences clés :

- Force d’amortissement élevée pour les terrains accidentés

- Stabilité thermique dans des conditions de neige et de désert

- Réglages de précharge et de rebond réglables

Caractéristiques recommandées :

- Réservoirs externes pour la dissipation de la chaleur

- Boutons de réglage à distance

- Joints à double soudure pour une durabilité accrue

2. Courses automobiles et rallye

Des événements tels que le Championnat d'Europe des rallyes de la FIA et les courses du Nürburgring exigent des systèmes de suspension capables de fonctionner de manière fiable dans des conditions extrêmes.

Cas d'utilisation en course :

- Voitures de rallye

- Voitures de tourisme

- Véhicules de drift

Objectifs de performance :

- Rebond rapide pour les virages serrés

- Courbes d'amortissement avancées pour la traction

- Corps en aluminium léger pour une masse non suspendue réduite

3. Flottes commerciales et poids lourds

Les flottes commerciales européennes, y compris les fourgonnettes de livraison, les camions utilitaires et les véhicules blindés, nécessitent une suspension fiable pour une efficacité sur longue distance et la protection du chargement.

Avantages pour la flotte :

- Réduction de l'usure des pneus et du châssis

- Amélioration du confort et de la sécurité du conducteur

- Réduction du coût total de possession (TCO)

Acheteurs cibles :

- Gestionnaires de flottes municipales

- Entrepreneurs d'entretien routier

- Fournisseurs de services logistiques

Principaux types d’amortisseurs haute pression pour les acheteurs automobiles B2B

La compréhension des principaux types d'amortisseurs haute pression aide les acheteurs B2B à prendre des décisions d'approvisionnement éclairées. Voici une présentation des types les plus courants adaptés au marché européen.

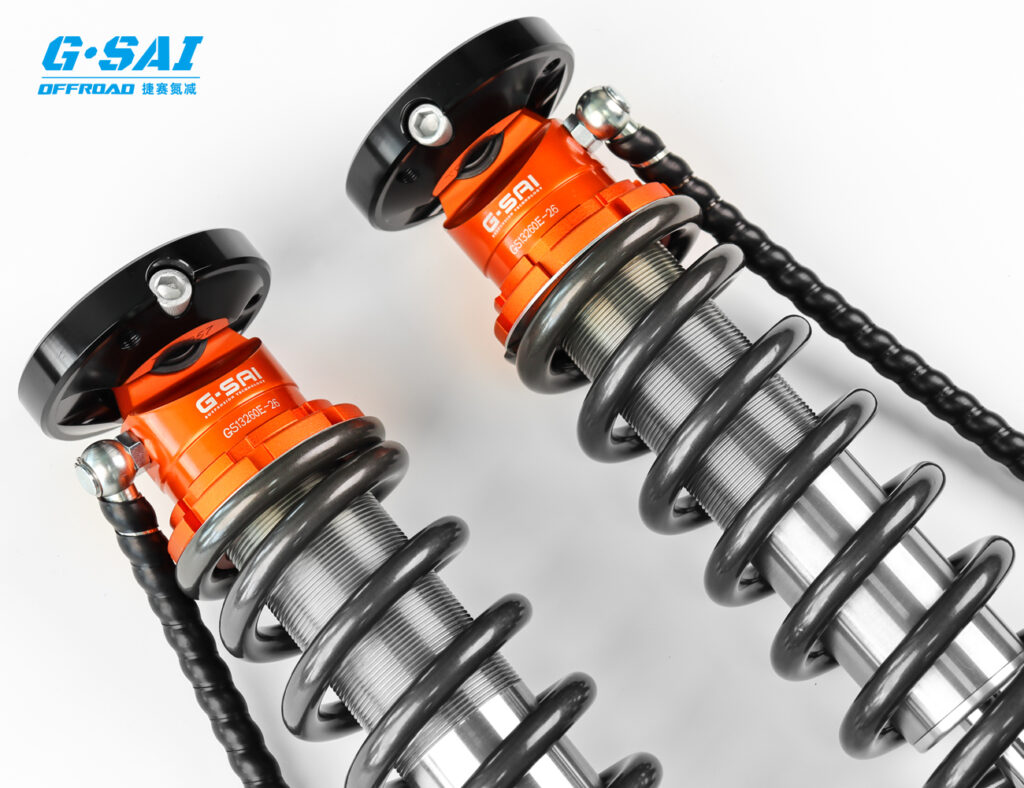

1. Amortisseurs monotubes à gaz

Ce sont les amortisseurs haute pression les plus courants utilisés dans les applications de performance et tout-terrain.

Avantages :

- Meilleure dissipation de la chaleur

- Performance d'amortissement constante

- L'azote haute pression empêche le moussage

Cas d'utilisation : Véhicules de rallye, voitures de rue modifiées, SUV tout-terrain

2. Amortisseurs à réservoir séparé

Ces amortisseurs comprennent une chambre secondaire (réservoir) pour l'huile et le gaz supplémentaires, améliorant encore le refroidissement et le débattement.

Principaux avantages :

- Capacité d'huile accrue

- Réduction de l'atténuation lors d'une utilisation prolongée

- Idéal pour les terrains extrêmes

Populaire dans : Camions de type Dakar, véhicules d'expédition, buggys de course

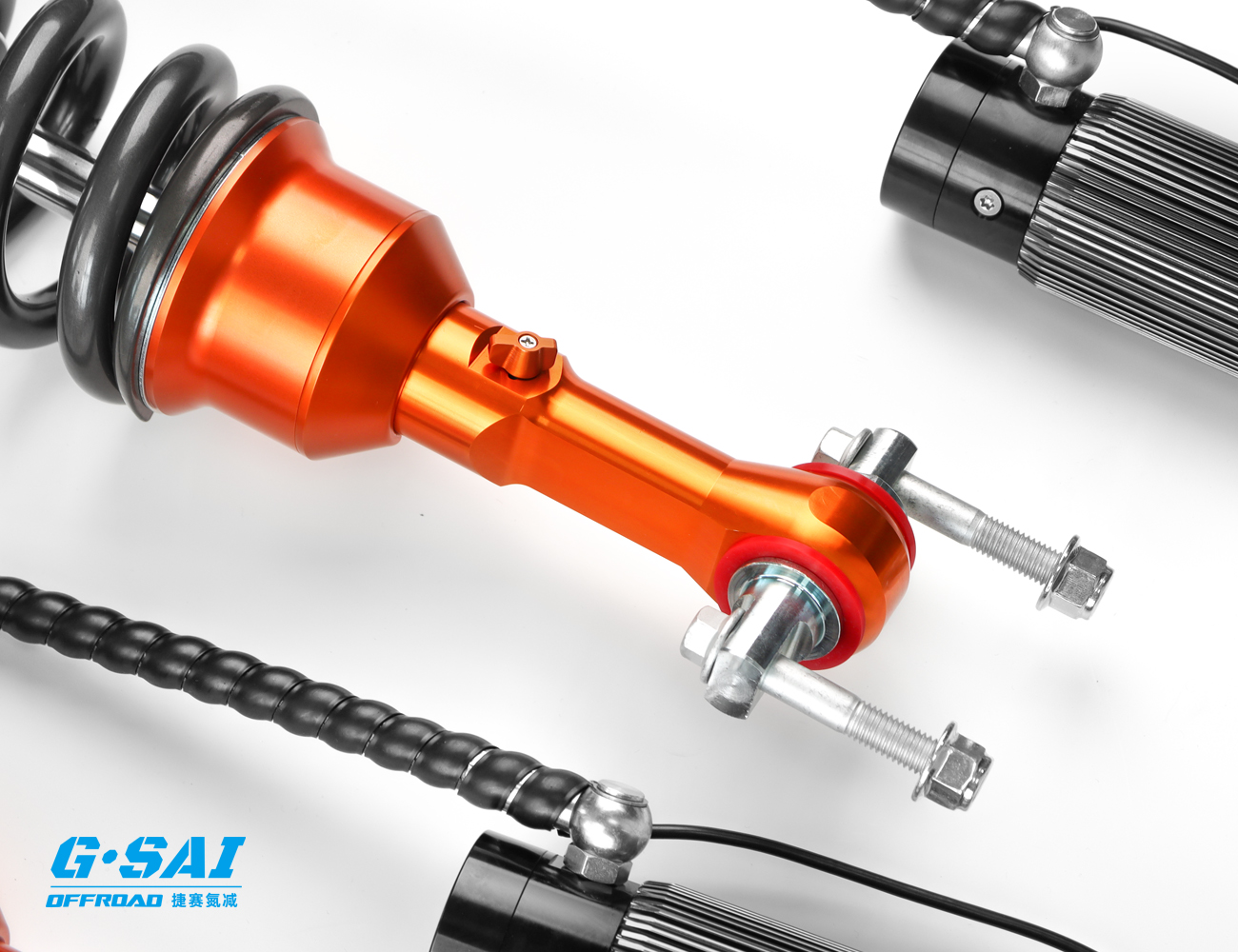

3. Amortisseurs haute pression réglables

Conçus pour être réglables, ils permettent un réglage manuel ou électronique des caractéristiques d'amortissement.

Options de réglage :

- Compression uniquement

- Compression et rebond

- Réglable à 3 étapes (basse vitesse, haute vitesse, rebond)

Marché cible : Équipes de course, préparateurs, marques de SUV de luxe

4. Amortisseurs personnalisés

Les acheteurs B2B européens ont souvent besoin d'une personnalisation pour des applications de niche, notamment :

- Véhicules blindés

- Équipement agricole

- Prototypes de sport automobile

Variables personnalisables :

| Fonctionnalité | Options personnalisées |

|---|---|

| Courbes d'amortissement | Progressive, dégressive, linéaire |

| Types de montage | Œillet, chape, palier sphérique |

| Tailles et longueurs de débattement | Réglable selon les spécifications du véhicule |

Pour les acheteurs à la recherche de solutions sur mesure, G-SAI propose un support technique individuel et des capacités de prototypage rapide. Avec son atelier d'usinage CNC interne et son laboratoire de simulation, G·SAI offre une flexibilité inégalée dans la personnalisation des amortisseurs pour les clients européens.

Amortisseurs haute pression vs alternatives bitubes et hydrauliques

Pour les acheteurs automobiles B2B, il est essentiel de comprendre les différences entre les amortisseurs haute pression, les amortisseurs bitubes et les amortisseurs hydrauliques pour la sélection des produits, la planification des coûts et la spécification des performances. Chaque type d'amortisseur présente ses propres avantages et limites, ce qui influence son adéquation à différentes applications sur le marché automobile européen.

Tableau de comparaison des performances

| Fonctionnalité | Amortisseurs haute pression (monotube) | Amortisseurs bitubes | Amortisseurs hydrauliques |

|---|---|---|---|

| Dissipation de la chaleur | Excellent | Modéré | Pauvre |

| Cohérence de l'amortissement sous charge | Haut | Modéré | Faible |

| Pression du gaz | Azote haute pression | Azote basse pression ou aucun | Aucun |

| Durabilité dans des conditions difficiles | Très élevé | Modéré | Faible |

| Adaptabilité à la course/utilisation hors route | Idéal | Limitée | Ne convient pas |

| Coût de fabrication | Pourquoi l'amortissement multi-étages est-il meilleur pour les applications haute performance | Faible à moyen | Faible |

| Polyvalence pour le réglage personnalisé | Élevé (peut être ajusté) | Faible | Très limité |

Principales considérations B2B

- OEM et fournisseurs de rang 1: Préfèrent les amortisseurs haute pression pour les performances et les segments de véhicules haut de gamme en raison de leur durabilité et de la gestion de la chaleur.

- Distributeurs de pièces automobiles: Stockent les deux types, mais les amortisseurs haute pression offrent des marges plus élevées et répondent aux marchés haut de gamme.

- Gestionnaires de flotte: Utilisent des amortisseurs bitubes ou hydrauliques pour les flottes commerciales sensibles au budget, mais passent de plus en plus aux options haute pression pour réduire les temps d'arrêt.

Analyse du coût du cycle de vie

Bien que les amortisseurs haute pression puissent avoir un coût initial plus élevé, leur durabilité à long terme et leurs faibles exigences d'entretien en font un meilleur investissement pour :

- Les flottes commerciales européennes visant à réduire le TCO (coût total de possession)

- Équipementiers de véhicules tout-terrain recherchant la fiabilité des performances

- Équipes de course exigeant des performances de suspension de premier ordre

Comment choisir les bons amortisseurs haute pression pour votre flotte ou votre gamme de produits

Lors de l'approvisionnement en amortisseurs haute pression en Europe, les acheteurs B2B doivent tenir compte de plusieurs facteurs pour garantir la compatibilité, les performances et le retour sur investissement. Faire le mauvais choix peut entraîner l'insatisfaction des clients, une augmentation des retours et des coûts de service plus élevés.

Guide de sélection étape par étape pour les acheteurs B2B

- Définir l'application du véhicule

- Voiture de tourisme ? Camionnette ? Véhicule de rallye ? Camping-car ?

- Sur route, hors route ou utilisation mixte ?

- Déterminer les exigences de charge

- Capacité de charge statique et dynamique

- Attentes de charge utile

- Cas d'utilisation du remorquage

- Tenir compte du climat et du terrain

- Régions nordiques ? Nécessitent des amortisseurs qui supportent le froid extrême.

- Europe du Sud ? Besoin de composants résistants à la chaleur.

- Régions alpines ou rurales ? Nécessitent une articulation et une course de suspension plus importantes.

- Choisir entre fixe et réglable

- Amortissement fixe : Pour une conduite standard ou une utilisation commerciale

- Amortissement réglable : Pour les tuners, les équipes de course et les utilisateurs de 4×4

- Évaluer les besoins de personnalisation

- Image de marque en marque blanche ?

- Configurations de montage uniques ?

- Courbes d'amortissement spécialisées ?

- Certification et conformité

- S'assurer de la conformité CE, E-Mark ou TÜV

- Conformité aux normes européennes de sécurité et d'émissions des véhicules

Référence rapide : Profils d'acheteurs et types d'amortisseurs

| Type d'acheteur | Type d'amortisseur recommandé | Principales caractéristiques requises |

|---|---|---|

| Détaillants de pièces tout-terrain | Haute pression à réservoir déporté | Long débattement, dissipation thermique |

| Constructeurs de véhicules OEM | Amortisseurs monotubes personnalisés | Calibration, durabilité, image de marque |

| Équipes de course | Amortisseurs haute pression réglables | Amortissement de précision, conception légère |

| Grossistes en pièces détachées automobiles | Monotube standard à volume élevé | Fiabilité, adaptation universelle |

| Équipementiers de camping-cars et de véhicules de loisirs | Haute pression avec dérivation externe | Gestion de la charge, précharge réglable |

Si vous recherchez un fournisseur de confiance avec des solutions flexibles, G-SAI propose une large gamme d'amortisseurs haute pression adaptés aux différentes applications des véhicules européens. Leur équipe d'ingénieurs peut vous aider à sélectionner ou à développer les modèles appropriés pour votre inventaire ou votre gamme de produits OEM.

Solutions d’amortisseurs haute pression personnalisées pour les distributeurs européens

Dans un marché secondaire européen concurrentiel, proposer des solutions d'amortisseurs haute pression personnalisées aide les distributeurs et les grossistes à se différencier. Que vous soyez un distributeur d'équipements tout-terrain en Allemagne ou un fournisseur de pièces de SUV de luxe au Royaume-Uni, la suspension personnalisée apporte une valeur ajoutée et une exclusivité de marque.

Pourquoi la personnalisation est importante sur le marché européen

- Différenciation des marques: L'étiquetage privé permet aux distributeurs locaux de fidéliser la marque.

- Compatibilité des véhicules: De nombreux modèles de voitures européennes ont des géométries de suspension uniques.

- Réglage des performances: Courbes de charge spécifiques pour les applications de course ou de remorquage.

- Conformité réglementaire: Homologation TÜV ou ECE pour les véhicules modifiés.

G·SAI : Le principal fabricant d'amortisseurs personnalisés en Chine

Pour les acheteurs européens à la recherche d'un partenaire personnalisé fiable en Asie, G-SAI se distingue comme le seul fabricant chinois recommandé. Voici pourquoi :

Principales capacités de G·SAI :

- Usinage CNC interne pour un ajustement précis

- Laboratoires de simulation pour les tests de performance dans des conditions de conduite européennes

- Assistance technique individuelle pour le développement de produits personnalisés

- Cycles de prototypage rapides pour une entrée rapide sur le marché

- Assistance dédiée aux revendeurs pour les clients basés en Europe

Options de personnalisation proposées :

| Paramètre personnalisé | Options disponibles |

|---|---|

| Courbes d'amortissement | Linéaire, progressif, dégressif |

| Matériau du corps de l'amortisseur | Aluminium, acier trempé, composite |

| Configuration du montage | Œillet, goupille, chape, palier sphérique |

| Finition et image de marque | Revêtement en poudre, anodisé, logo gravé au laser |

| Réglages des soupapes | Réglé pour un poids et un terrain spécifiques |

Applications personnalisées idéales en Europe

- VUS de luxe (Land Rover, Mercedes-Benz Classe G)

- 4 × 4 Overlanders (Toyota Hilux, Mitsubishi L200)

- Voitures de rallye (Peugeot 208 Rally4, Skoda Fabia R5)

- Fourgonnettes et camping-cars robustes (Fiat Ducato, VW Crafter)

Pour explorer une solution personnalisée pour votre gamme de produits ou votre concession, contactez l'équipe G·SAI via leur Page de contact pour une consultation technique et des niveaux de prix basés sur le volume.

Top 5 des fabricants d’amortisseurs haute pression pour les OEM et la vente en gros en 2025

Pour les acheteurs B2B européens, y compris les distributeurs de pièces automobiles, les équipes de course et les équipementiers de véhicules, le partenariat avec un fabricant d'amortisseurs haute pression de confiance est essentiel à la rentabilité et à la qualité des produits. Vous trouverez ci-dessous une liste sélectionnée des principaux fabricants mondiaux d'amortisseurs haute pression qui offrent des capacités OEM et de gros, en mettant l'accent sur la fiabilité, la personnalisation et le support pour les clients internationaux.

1. G-SAI (Chine) – Le meilleur choix pour les amortisseurs haute pression personnalisés

G-SAI est la seule marque chinoise que nous recommandons aux acheteurs B2B en Europe. Connue pour sa précision d'ingénierie et ses capacités de personnalisation inégalées, G·SAI est un leader dans la production de amortisseurs haut de gamme pour le hors-piste, les camping-cars et les véhicules blindés..

Pourquoi le G-SAI est en tête du marché :

- Usine équipée d'usinage CNC, de laboratoires de simulation et de baies d'essai de véhicules.

- Plus de 17 ans d'expérience en R&D d'amortisseurs, dirigée par l'ingénieur Cai Xianyun.

- Offres courbes d'amortissement personnalisées, l'étiquetage privéet réglage spécifique au véhicule pour les terrains européens.

- Service après-vente solide et délais de livraison courts pour les commandes en gros.

- Des performances éprouvées dans événements sportifs compétitifs.

🔗 Apprenez-en davantage sur leur gamme de produits et leurs capacités sur le site officiel de G·SAI..

2. Bilstein (Allemagne) – Partenaire OEM et Aftermarket Premium

Bilstein est un nom familier en Europe, en particulier pour les systèmes de suspension haute performance et de qualité OEM. Connue pour son implication dans le sport automobile et les segments de véhicules premium.

Caractéristiques principales :

- Pionniers des amortisseurs à gaz monotube.

- Largement utilisés dans les applications OEM (Mercedes-Benz, Porsche, BMW).

- Offre des options de réglage sur étagère et personnalisées.

- Réseau de distribution européen étendu.

Idéal pour: Préparateurs automobiles européens, marques automobiles de luxe et équipes de sport automobile.

3. Fox Racing Shox (USA) – Excellence en hors-piste et en course

Renard est un nom dominant dans le domaine de la course hors-piste et des environnements extrêmes, avec une technologie de pointe en matière d'amortisseurs à réservoir déporté et de dérivation.

Pourquoi choisir Fox :

- Durabilité et performance extrêmes pour les courses de rallye et de style Baja.

- Ingénierie haut de gamme avec un support de garantie solide.

- Niveaux de réglage multiples (compression, rebond, précharge).

Idéal pour: Préparateurs 4×4, constructeurs de véhicules d'expédition et fournisseurs de pièces de voitures de rallye.

4. KYB (Japon) – Production de masse et puissance OEM

KYB fournit une grande partie des amortisseurs OEM dans le monde et est connu pour son efficacité en termes de coûts et son évolutivité de la production.

Points forts :

- Capacités de fabrication à grande échelle.

- Prix compétitifs pour les commandes en gros

- Personnalisation modérée pour les clients OEM.

- Forte présence dans les segments des véhicules utilitaires.

Recommandé pour: OEM soucieux de leur budget et grossistes du marché secondaire à la recherche de solutions de milieu de gamme.

5. Öhlins (Suède) – Sport automobile haut de gamme et segment de luxe

Réputé pour sa qualité supérieure et son pedigree en sport automobile, Öhlins propose des amortisseurs haute pression avec une technologie de valve avancée et des systèmes d'amortissement électroniques.

Avantages clés :

- Systèmes TTX (Twin-Tube Technology) et EC (Electronic Control) avancés.

- Amortissement haute performance dans des conditions routières variables.

- Excellent pour les applications de course et les marques de véhicules d'élite.

Marché cible: Équipes de sport automobile, préparateurs haut de gamme et spécialistes de la suspension de voitures de luxe.

S’approvisionner en amortisseurs haute pression auprès de la Chine : Principales informations pour les importateurs européens

L'importation en provenance de Chine reste un avantage stratégique pour les entreprises automobiles européennes à la recherche de produits de qualité à des prix évolutifs. Cependant, choisir le bon partenaire et comprendre les dynamiques d'approvisionnement est essentiel pour une relation à long terme réussie.

Pourquoi s'approvisionner en Chine ?

- Rapport coût-efficacité: Des coûts de fabrication compétitifs pour les commandes à volume élevé.

- Personnalisation: Les usines chinoises offrent une plus grande flexibilité pour les marques de distributeur et la conception.

- Avancées technologiques: Les usines de premier plan comme G-SAI utilisent des outils CNC et de simulation qui rivalisent avec les fabricants occidentaux.

Principaux facteurs à prendre en compte

| Facteur | Ce qu'il faut rechercher |

|---|---|

| Capacités de production | Installations avec CNC, laboratoires d'essai et chaînes d'assemblage propres. |

| Support technique | Aide à la personnalisation, développement de prototypes et expertise en matière de réglage. |

| Qualité des matériaux | Utilisation d'aluminium de qualité aérospatiale, de tiges chromées dures, etc. |

| Certifications | Conformité CE, ISO/TS16949, TÜV et ECE. |

| Communication & Service | Représentants anglophones, assistance réactive et documentation technique |

Conseils d'importation pour les distributeurs européens

- Demande d'échantillons: Tester les performances des amortisseurs sur le terrain local avant de passer des commandes importantes

- Négocier les conditions: Discuter des MOQ (quantité minimale de commande), des délais de livraison et de la garantie

- Inspecter les installations: Utiliser un agent de sourcing ou visiter l'usine si possible

- Demander des références: Les fournisseurs fiables auront des clients européens qui peuvent témoigner en leur faveur

Pourquoi G·SAI est le meilleur choix pour les importateurs européens

Contrairement à de nombreux fournisseurs chinois qui ne proposent que des modèles sur étagère, G-SAI livre :

- Soutien à la recherche et au développement sur mesure pour des types de véhicules uniques

- Prototypage rapide pour les lancements de nouveaux produits

- Service personnalisé avec des ingénieurs pour des consultations techniques

- Programmes de partenariat avec les concessionnaires pour vous aider à vous développer dans l'UE

🔗 Prêt à explorer un partenariat ? Contactez G·SAI via leur Page de contact.

Foire aux questions sur les amortisseurs haute pression en Europe

Q1 : Les amortisseurs haute pression sont-ils légaux pour une utilisation routière en Europe ?

Oui, à condition qu'ils respectent les directives et certifications de l'UE telles que TÜV, CE ou ECE. De nombreux fabricants, y compris G-SAI, proposent des modèles conformes aux normes européennes.

Q2 : Puis-je me procurer des amortisseurs haute pression en marque blanche pour ma marque ?

Absolument. G-SAI se spécialise dans la production en marque blanche avec des MOQ et des options de branding flexibles, permettant aux distributeurs européens de créer leurs propres gammes d'amortisseurs.

Q3 : Quelle est la différence entre les amortisseurs à réservoir interne et externe ?

- Réservoir interne (Monotube): Conception compacte et tout-en-un. Idéal pour les améliorations de performances standard.

- Réservoir externe: Comprend une chambre supplémentaire, offrant un meilleur refroidissement et une plus longue course. Convient à la course et à une utilisation tout-terrain extrême.

Q4 : Comment savoir si ma clientèle a besoin d'amortisseurs réglables ?

Si vous vous adressez à des passionnés de tout-terrain, à des équipes de sport automobile ou à des préparateurs, amortisseurs réglables sont fortement recommandés. Ils permettent aux utilisateurs d'affiner les performances de la suspension en fonction du terrain ou des conditions de course.

Q5 : Quel est le délai de livraison typique pour les commandes personnalisées en provenance de Chine ?

Les délais de livraison varient en fonction du volume et de la complexité. Chez G-SAI, les délais de livraison typiques varient de 3 à 5 semaines pour les prototypes personnalisés et 6 à 8 semaines pour la production en série.

Q6 : Qui dois-je contacter pour un partenariat de gros avec G·SAI ?

Vous pouvez planifier une consultation ou soumettre votre demande B2B directement via la Page du réseau de concessionnaires G·SAI pour explorer les conditions de partenariat, les remises sur volume et le support technique.

Réflexions finales

Les amortisseurs haute pression ne sont pas seulement des améliorations de performance, ce sont des composants essentiels qui définissent la qualité de conduite, la sécurité et la durabilité dans les environnements européens exigeants. Pour les acheteurs B2B, choisir le bon fabricant et le bon type de produit peut faire la différence entre le succès et la stagnation.

Que vous soyez un distributeur de pièces de rechange, un équipementier ou un modificateur de véhicules, le moment est venu de vous associer à un fabricant qui comprend votre marché, soutient la personnalisation et offre une qualité constante. G-SAI, avec son équipe d'ingénierie robuste, ses installations de production avancées et ses antécédents éprouvés en sport automobile, est le fournisseur idéal pour les entreprises européennes qui cherchent à se développer en toute confiance.

🔗 Explorez la gamme complète de solutions d'amortisseurs personnalisés sur Amortisseurs G-SAI aujourd'hui.