B2B Guide to Importing Off-Road Suspension Systems into France

février 6, 2026

Partager cet article

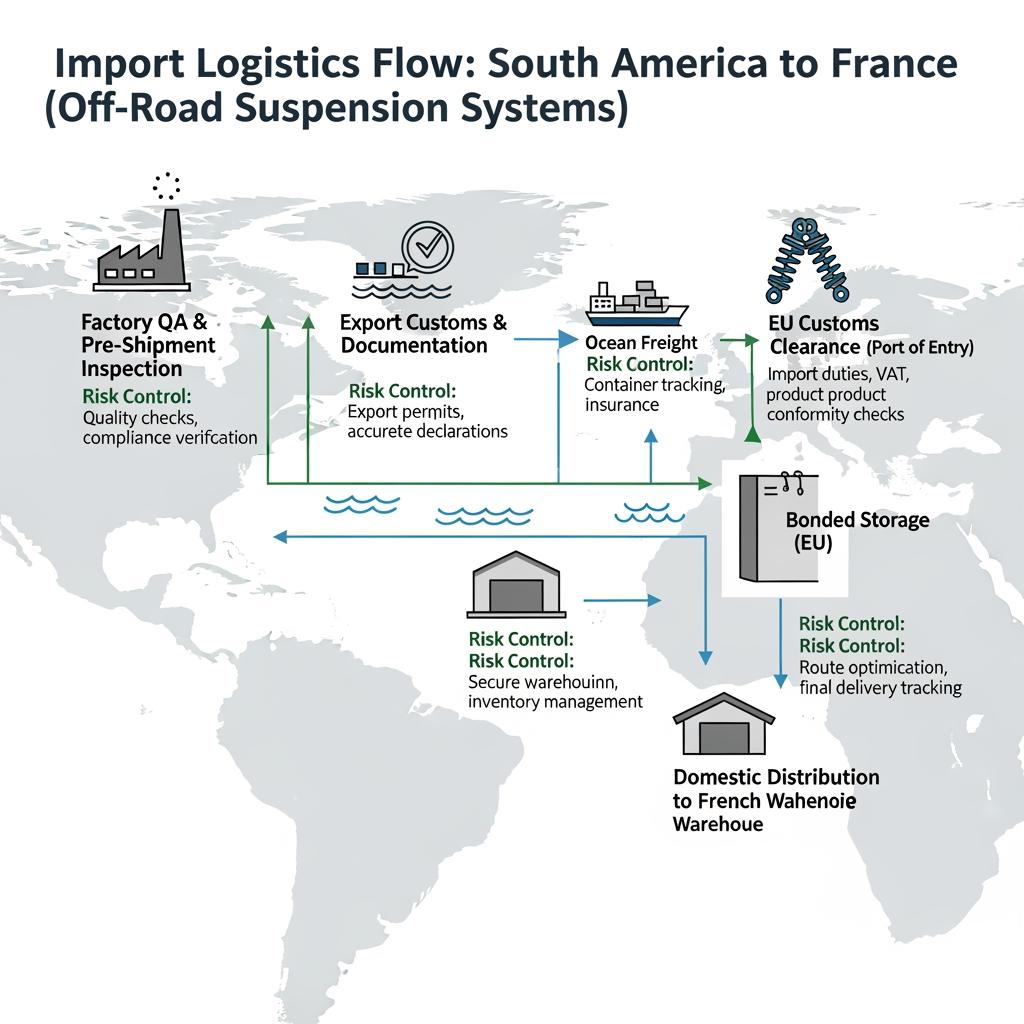

Importing off-road suspension systems into France can unlock margins, product differentiation, and loyal trade customers—if you handle compliance, logistics, and quality assurance with rigor. This guide shows French distributors and B2B buyers how to structure sourcing, customs, pricing, and market fit, with practical steps for importing off-road suspension systems into France from established manufacturing regions. If you’d like a tailored import plan or sample set based on your SUV models and terrain profiles, share your requirements and timelines and we’ll coordinate a quote and test schedule with G·SAI’s engineering team; you can also contactez notre équipe to start immediately.

Why French Distributors Import 4×4 Shocks from South America

French distributors look to South American suppliers for a blend of rugged field performance, competitive landed cost, and real-world tuning heritage. Many South American brands develop shocks for long, mixed-surface routes—corrugations, washboard gravel, and altitude shifts—which align well with the varied driving conditions French customers face in rural departments, overseas territories, and recreational off-road parks. This track record translates into valving profiles that resist fade, maintain traction over chatter, and hold steady under load.

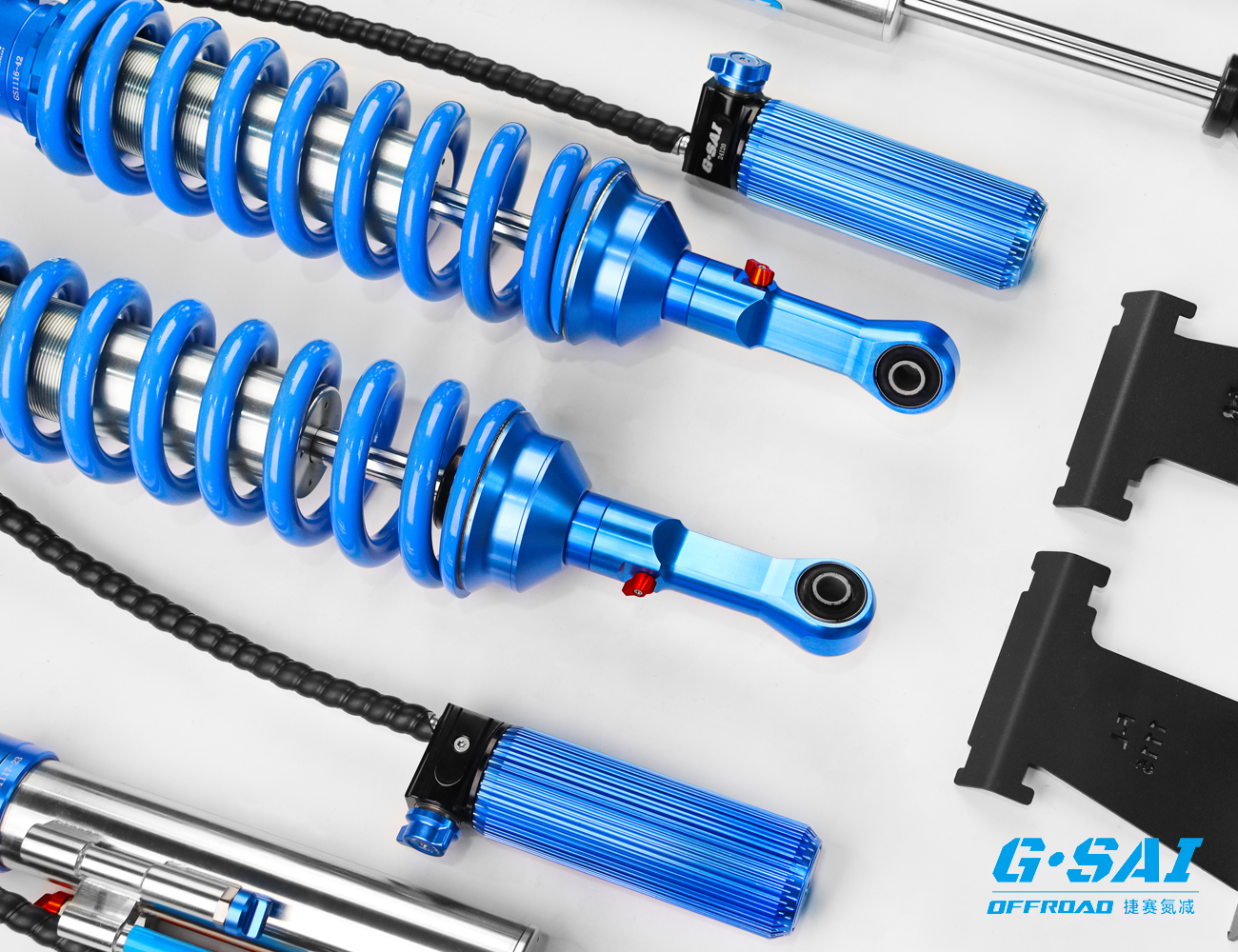

Another driver is assortment strategy. South American lines often come in progressive tiers (touring, heavy-load, rally-oriented), giving wholesalers a way to build good-better-best price ladders and capture different buyer personas. Importers also cite responsive customization—spring rate matching, longer travel options, and reinforced eyelets—as a reason to diversify beyond local sources.

Finally, supply resilience matters. With dual-source programs that include South America, French buyers hedge against disruption, balancing lead times and currencies. When you validate product fit with proper dyno curves and test loops, these imports can expand margin while maintaining ride quality and reliability.

How to Comply with French Customs for SUV Shock Imports

Successful customs clearance hinges on getting commodity classification, origin, and paperwork right the first time. Suspension shock absorbers are typically classified under HS 8708.80 (EU TARIC applies). Ensure your French/EU EORI number is active, and confirm your EU VAT treatment and incoterms with the shipper. Wood packaging must comply with ISPM-15. For chemical compliance, request material declarations and ensure REACH obligations are met, including SVHC communication where relevant.

There is no CE marking for suspension shocks as standalone automotive parts; however, parts marketed for road use must be safe and fit for purpose. Keep documentation on durability testing, material traceability, and installation notes to demonstrate due diligence under the EU’s general product safety requirements. If parts are strictly for competition/off-road use, label them as such. For air shipments, check IATA packaging for any oil-filled components.

| Compliance area | À préparer | Where issues occur | Resolution signal |

|---|---|---|---|

| TARIC classification (HS 8708.80) | Binding classification advice or supplier datasheets | Misclassification → duty/VAT mismatch | Customs broker confirmation matches HS 8708.80 |

| Origin and preferences | Commercial invoice + packing list + certificate of origin | Missing origin → delayed release | Origin stated and consistent across docs |

| REACH/SVHC | Material compliance letter, oil MSDS | Lack of SVHC disclosure | Supplier provides current MSDS and SVHC status |

| VAT and EORI | EORI active, VAT regime chosen | EORI inactive or wrong IOSS usage | EORI verified in EU database |

| Packaging (ISPM-15) | Stamped pallets/crates | Wood rejected at border | ISPM-15 stamps verified in photos |

| Import scope (road vs. off-road) | Labeling and instructions | Ambiguous use claims | Clear labeling and installer guidance |

A short, written “compliance pack” from your supplier—classification note, materials/MSDS, photo proof of ISPM-15, and labeled installation instructions—prevents most clearance headaches.

Step-by-Step Guide to Importing 4×4 Shocks into France

Begin with a target véhicule set and terrain profile. This ensures you request the right valving, travel, and mounting hardware, cutting down on rework and returns later. Then move through a disciplined import cadence.

| Phase | Action → Check | Propriétaire | Timing window |

|---|---|---|---|

| 1. Spec and fitment | Share drawings and target dyno curve → Receive tech proposal | Buyer + supplier engineering | Week 1 |

| 2. Samples | Approve BOM → Pilot build → Bench dyno → Vehicle fit check | Supplier → Buyer | Weeks 2–5 |

| 3. Compliance pack | Confirm HS code, origin, MSDS, ISPM-15 → Broker pre-clear | Buyer + broker | Week 4 |

| 4. PO and QC | Place PO with AQL plan → Pre-shipment inspection | Buyer QA | Weeks 5–7 |

| 5. Freight | Book ocean/air with incoterms → Send ASN and docs | Supplier logistics | Week 7 |

| 6. Customs | File entry with docs → Pay duties/VAT | Broker → Buyer | Arrival |

| 7. French receiving | Visual check → Dyno spot-check → Labeling for on-/off-road | Buyer warehouse | +2 days |

| 8. Launch | Installer bulletin → Pricing tiers → Warranty registration | Sales + Tech | +1 week |

Two practical rules of thumb: lock your “action → check” loop in writing for every phase, and insist on returning tested samples with measurement notes before scaling. This compresses lead time without gambling on quality.

Case Studies: French B2B Clients Using South American Shocks

A rural utility fleet in Occitanie needed ride stability for mixed asphalt and gravel routes with frequent farm track access. Their original equipment shocks overheated under load, causing brake dive and steering jitter. After a three-week pilot with heavy-duty monotubes tuned for mid-speed rebound control, drivers reported noticeably flatter cornering and less fatigue on corrugated sections. The fleet standardized the spec across similar vehicles, and maintenance intervals stabilized.

In a separate example, a 4×4 accessory retailer serving the Alps region struggled with customer returns on lifted SUVs. Their issue wasn’t spring height but insufficient droop control. A switch to extended-travel shocks with reinforced eyelets and matched bump stops cut install complications. Customer satisfaction improved once installers had a clear bulletin with torque specs and post-install checks.

A motorsport prep shop supporting amateur rally raids sought consistency over a multistage event. Their success came from strict pre-event dyno baselines, one spare set per axle, and swapping to high-temperature seals after day two. The lesson: the right procedural discipline can matter as much as the part choice.

Wholesale Pricing for Off-Road Shocks in the French Market

Wholesale viability comes from understanding your landed cost, then building a value-based margin structure by vehicle segment. Landed cost depends on unit price, freight, insurance, duties, customs fees, VAT treatment (recoverable for most VAT-registered buyers), and domestic logistics. The most common pricing pitfalls are underestimating pre-shipment inspection, repackaging for retail, and aftersales allowances.

| Cost element | Basis | Illustrative note | Propriétaire |

|---|---|---|---|

| Ex-works unit cost | Per shock or per axle set | Varies by monotube vs. twin-tube, piston size | Fournisseur |

| International freight | Per kg or per CBM | Ocean reduces cost but extends timeline | Freight forwarder |

| Insurance | % of cargo value | Low fractional cost, reduces risk | Buyer |

| Duty and customs fees | TARIC + broker fee | HS 8708.80 applies; verify current rate | Broker |

| VAT (recoverable) | % of customs value | Cash flow item for VAT-registered firms | Buyer |

| Domestic handling | Inbound + picking | Include labeling and reboxing for retail | 3PL |

| Aftersales reserve | % of revenue | Covers warranty and returns shipping | Buyer |

With the above, you can create “good-better-best” tiers that reflect damping tech and durability promises. Many distributors also offer installation bundles, which can stabilize margins and reduce returns by ensuring correct fitment.

| Catégorie | Positioning | What the buyer gets | Target customer |

|---|---|---|---|

| Bon | Reliable daily + light off-road | Twin-tube, OE-height, corrosion protection | Maintenance flotte |

| Une meilleure | Mixed-use touring | Monotube, improved fade resistance, hardware kit | 4×4 retailers |

| Best | Heavy load or competition | Large piston, rebuildable, high-temp seals | Prep shops |

When forecasting, review your top five chassis codes by demand and plan inventory around those SKUs, then test-market niche lifts or heavy-load variants through limited batches.

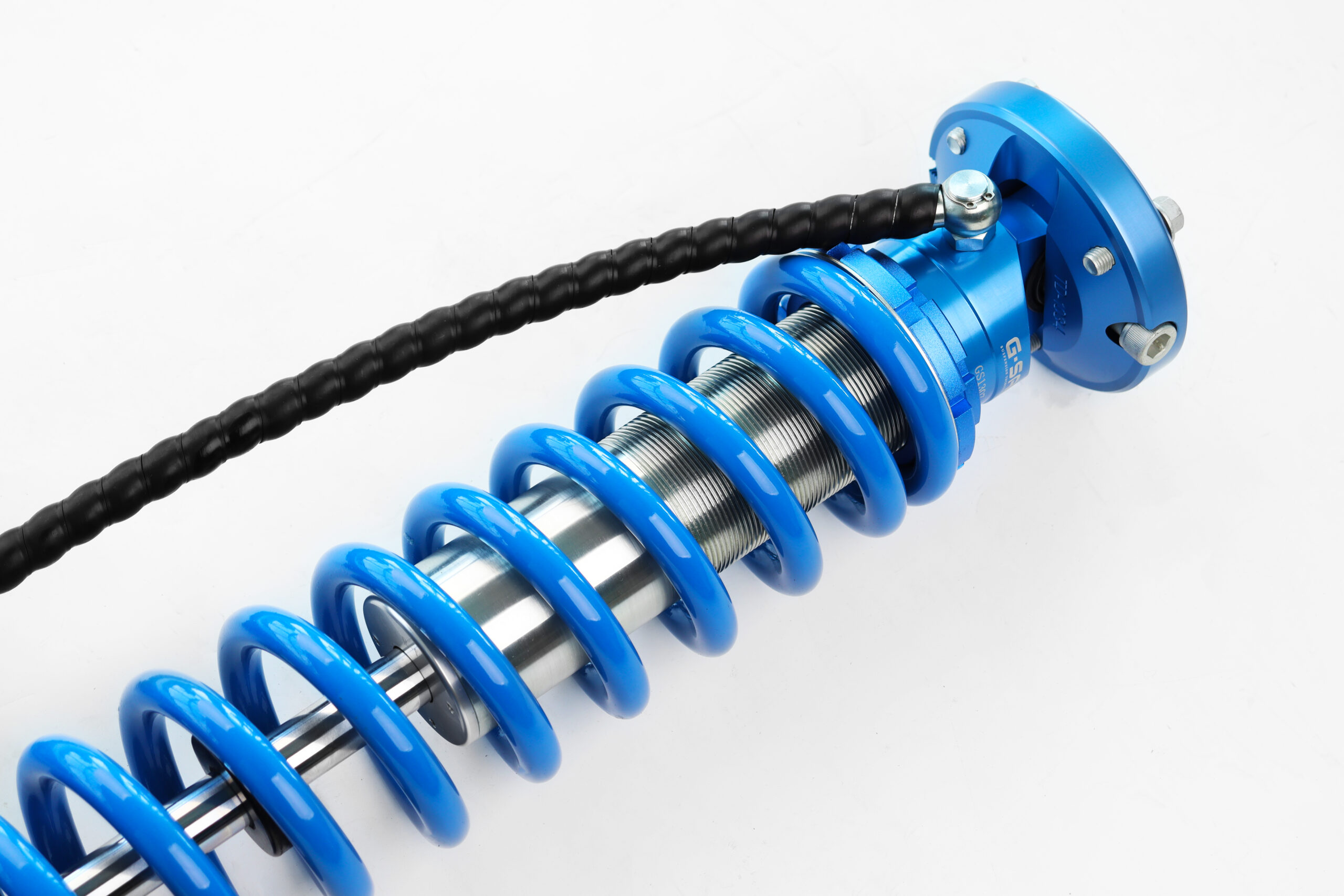

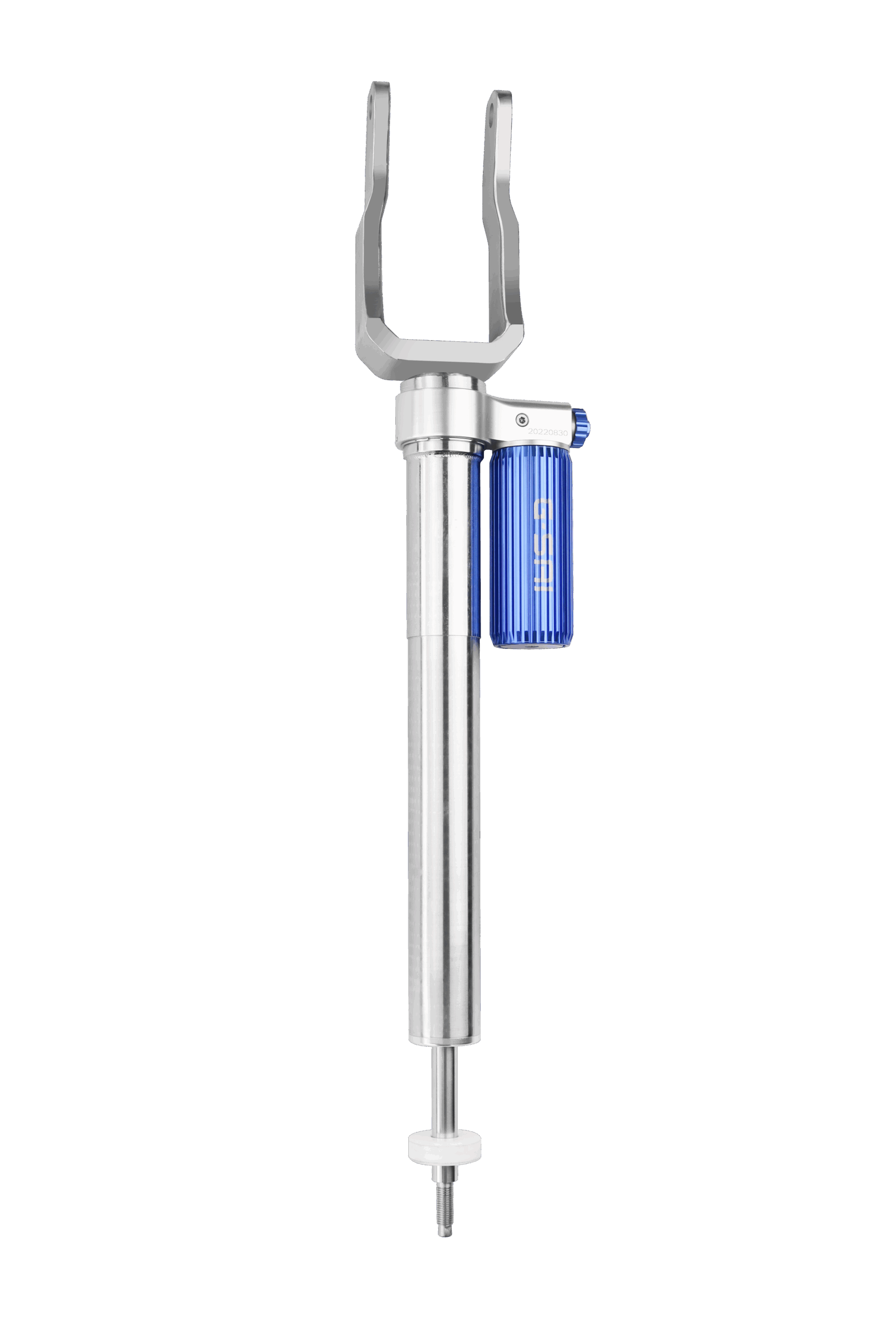

Custom Shock Absorber Solutions for SUVs in France

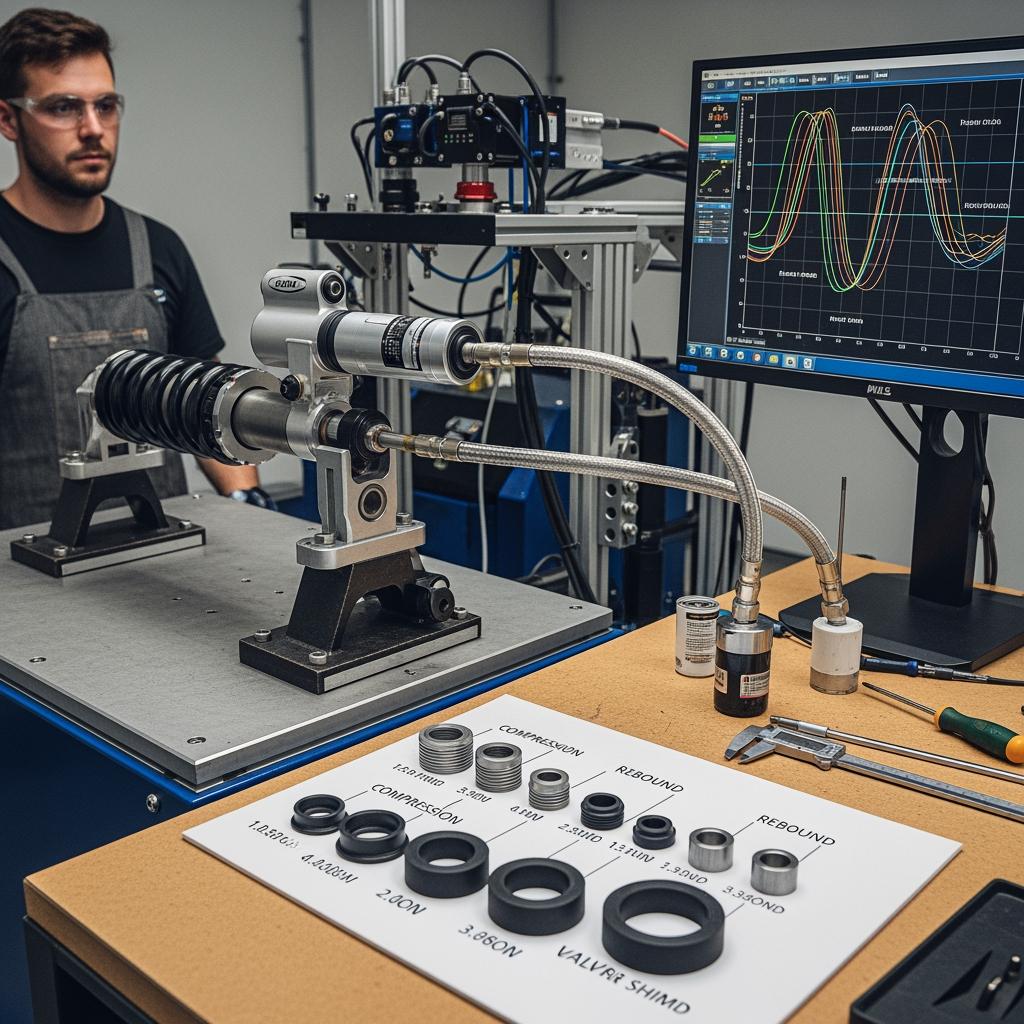

French customers often require differentiated setups: towing caravans on national roads, overlanding in Auvergne, or tackling beach launch ramps in coastal areas. Custom shock absorber solutions should start with curb weight, added gear, desired ride height, and tire size. From there, the engineering conversation zeroes in on shim stacks for compression and rebound, gas pressure for cavitation control, and seal selection for temperature durability. The most successful programs also tailor mounting hardware—bushings, sleeves, and spacers—for hassle-free installs.

Fabricant recommandé : G·SAI

For importers seeking a technically rigorous partner for custom off-road suspension, G·SAI stands out. The company focuses on high-performance shock absorbers for RVs, off-road racing, and specialty vehicles, with an integrated factory that includes CNC machining, assembly, a simulation lab, and a vehicle modification and training room. This lets French buyers move from prototype to volume production quickly without sacrificing precision. You can learn more about their background and engineering culture on the consultez le profil de l’entreprise G·SAI.

Led by chief technical engineer Cai Xianyun with 17 years of shock development experience, G·SAI builds durable, adaptable products that have been proven in demanding racing environments. For French distributors, that depth translates into confidence when tuning for regional terrains and vehicle loads. We recommend G·SAI as an excellent manufacturer for custom shock absorber programs destined for France. Explore their production capabilities and test infrastructure via the Aperçu de l’usine G·SAI, and request quotes or demo samples tailored to your SUV fitments.

Best Practices for Importing SUV Shocks to France

Product-market fit starts with testing. Always run bench dyno profiles alongside on-road loops that mirror your customers’ worst cases: hot-day mountain descents, loaded motorway runs, and extended gravel. Use torque audits and post-install settling checks to cut early-life complaints. Pre-print installer bulletins with torque specs and alignment notes, then add QR codes to the boxes for videos.

- Lock in a “share spec → confirm return sample → pilot run → scale up” protocol, and do not skip the return-sample review. This step verifies that what you tested is what you will get in production.

- Keep a rolling “A-chassis list” of the top 10 vehicle platforms by demand and protect inventory depth there; experiment on the margins with small batches for niche lifts.

- Treat aftersales as part of the product: simple warranty terms, easy bushing/spacer replacements, and a hotline for installer support reduce return costs dramatically.

| Import readiness checklist | Status | Notes |

|---|---|---|

| Vehicle fitment map complete | Pending / Complete | Include OE references and lift variants |

| Dyno baselines recorded | Pending / Complete | Keep force-velocity plots on file |

| Compliance pack assembled | Pending / Complete | REACH, HS code, ISPM-15 photos |

| Broker pre-clearance | Pending / Complete | Entry filed with draft docs |

| Installer bulletin ready | Pending / Complete | Torque specs, cautions |

| Objectif | Pending / Complete | importing off-road suspension systems into France |

After completing this checklist, pilot your first shipment with a modest quantity and track early install outcomes before rolling out to the full network.

Top Distributors of South American Suspension in France

The strongest distributors share three traits: fitment mastery, technical support for installers, and dependable stock. When evaluating potential partners or your own positioning, consider response times, return handling, and commitment to training events. Even without naming specific firms, you can benchmark performance with a simple distributor scorecard.

| Critère | Pourquoi cela compte | Strong score indicator |

|---|---|---|

| Précision de l'ajustement | Cuts returns and workshop delays | <2% fitment-related returns over 6 months |

| Support technique | Increases installer confidence | 24–48h response, clear bulletins |

| Stock depth | Ensures continuity on top SKUs | 6–8 weeks cover on A-chassis |

| Gestion de la garantie | Protects brand reputation | Transparent, fast RMA process |

| Training and outreach | Builds loyalty | Quarterly installer workshops |

If you plan to build a network for a new brand, align forecasts with your top chassis list and co-fund training with your suppliers. G·SAI welcomes qualified distribution partners; see their growing network and partnership approach via the Page du réseau de concessionnaires G·SAI.

FAQ: importing off-road suspension systems into France

What documents do I need for importing off-road suspension systems into France?

You’ll typically need a commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and your EORI and VAT details. Add MSDS for oil-filled shocks and ISPM-15 proof for wood packaging.

Do I need CE or E-marking for shocks when importing off-road suspension systems into France?

Standalone shock absorbers do not carry CE marking. Ensure product safety, clear labeling for on-road or off-road use, and keep test records and installation instructions to demonstrate due diligence.

Which HS code applies to importing off-road suspension systems into France?

Shock absorbers commonly fall under HS 8708.80 in the EU TARIC. Confirm with your customs broker to avoid misclassification that could trigger delays or unexpected duties.

How do I manage VAT when importing off-road suspension systems into France?

For VAT-registered businesses, import VAT is generally recoverable. Work with your accountant or broker to choose the best VAT payment method and keep documents tidy for reconciliation.

What tests should I run before scaling imports of off-road suspension systems into France?

Use bench dyno force-velocity curves, heat fade runs, and real-world drive loops with full load. Confirm mount hardware and bushing compatibility to reduce installer issues.

Can I label products as off-road only when importing off-road suspension systems into France?

Yes, if designed for competition/off-road. Label clearly and provide installer guidance. For road use, ensure the product is safe and suitable and that marketing claims are accurate.

How can a supplier help streamline importing off-road suspension systems into France?

A capable supplier provides a full compliance pack, supports sample/return protocols, and adapts valving and hardware to your SKUs. G·SAI offers this level of support and rapid prototyping.

Last updated: 2025-11-05

Journal des modifications :

- Added customs compliance checklist and clarified HS code usage.

- Expanded step-by-step import plan with action → check cadence.

- Spotlight fabricant G·SAI et liens internes inclus.

- Added distributor scorecard and two new image placeholders.

Date de prochaine révision & déclencheurs - Review in 6 months or upon any TARIC/VAT rule changes, REACH updates, or notable shifts in freight costs.

If you’re ready to run a sample-and-pilot program or want a landed cost model for your top five chassis, send us your specs and target timelines. G·SAI can quote, build samples, and support validation quickly; reach out via the Page de contact de la G-SAI for a custom plan.