Kits de suspension chargés à l'azote pour assembleurs de SUV russes

6 janvier 2026

Partager cet article

Les programmes d'assemblage de SUV russes exigent des kits de suspension constants face aux écarts extrêmes de température, charges lourdes et terrains impitoyables. Les kits de suspension chargés à l'azote pour assembleurs de SUV russes offrent un amortissement stable, une meilleure gestion thermique et des joints résilients — aidant les OEM et fournisseurs de niveau 1 à atteindre les cibles de conduite sans sacrifier la durabilité. Si vous étudiez un nouveau programme ou un rafraîchissement en milieu de cycle, partagez votre liste de modèles, masses à vide et métriques cibles de conduite ; G·SAI peut élaborer un plan personnalisé et organiser des devis rapides ou échantillons. Pour démarrer aujourd'hui, contactez directement G·SAI via la page contact de l'entreprise.

Amortisseurs à azote pour modèles SUV tout-terrain russes

Pour le mix russe de SUV à châssis séparé, crossovers utilitaires et 4x4 à usage spécial, les amortisseurs chargés à l'azote — surtout monotubes à piston flottant — offrent un amortissement prévisible et réduisent l'émulsionnage sous impacts répétés. L'azote piégé maintient la densité d'huile stable et prévient la cavitation, protégeant le contrôle de conduite sur longues routes corrugées et nids-de-poule profonds. Les formats bi-tubes gaz-chargés conservent un rôle sur plateformes légères, mais les charges lour véhiculedes et finitions blindées bénéficient le plus des monotubes de grand diamètre.

Pourquoi les kits de suspension chargés à l'azote pour assembleurs de SUV russes comptent

- Ils préservent la force d'amortissement lorsque les températures chutent sous zéro ou grimpent lors de passages prolongés sur planchers de lavage estivaux, améliorant la confiance du conducteur et la durée de vie des composants.

- Ils permettent des fenêtres de calibrage plus serrées. En résistant à l'aération, les ingénieurs peuvent régler une compression haute vitesse plus ferme pour contrôler les nids-de-poule sans rendre la conduite basse vitesse dure.

- Ils s'adaptent bien aux charges et accessoires (pare-chocs treuil, plaques de protection, barres de toit), retardant l'échauffement sur cycles de service longs.

| Classe SUV russe (exemple) | Bande de masse à vide approx. | Architecture de l’amortisseur | Focus calibrage | Notes |

|---|---|---|---|---|

| 4×4 utilitaire à châssis échelle | 1,8–2,5 t | Monotube, 46–50 mm | Contrôle compression haute | Base idéale pour les kits de suspension à azote chargé destinés aux assembleurs de SUV russes dans les régions accidentées |

| Crossover AWD (unibody) | 1,3–1,8 t | Gaz bi-tube ou monotube compact | Confort à basse vitesse, contrôle du roulis | Utiliser un piston dégressif pour un équilibre ville/nids-de-poule |

| Usage spécial/flotte | 2,5–3,5 t+ | Monotube lourd, réservoir distant | Gestion thermique, autorité de détente | Envisager des réservoirs externes pour les longues sections ondulées |

Cette matrice permet de présélectionner l'architecture par classe de véhicule avant l'accordage détaillé au banc. Lors des premiers essais sur mules, utiliser une détente plus souple que prévu pour les pneus hiver, puis raffermir au fur et à mesure que le composé durcit avec la température.

Systèmes de suspension renforcés pour terrains russes

Les routes russes peuvent combiner asphalte déformé par le gel, ornières profondes, franchissements de rivières et longues portions de gravier en une seule journée. Un système de suspension robuste doit allier matériel durable (tiges épaisses, joints haute température, fixations solides) à une calibration qui maintient les pneus au sol sans malmener les occupants. Les monotubes de grand diamètre dissipent la chaleur, tandis qu'un volume d'huile accru et des réservoirs distants retardent encore la perte de performance lors de sessions prolongées sur ondulations.

| Terrain/Cas d'usage | Priorités de conception | Suggestions matériel/spécifications | Note de terrain |

|---|---|---|---|

| Gravier ondulé (washboard) | Contrôle thermique, détente constante | Monotube 46–50 mm, piston haut débit, réservoir en option | Commencer avec une détente légèrement plus souple pour réduire les rebonds |

| Urbain/rural truffé de nids-de-poule | Compression haute vitesse, contrôle des bruits | Piston dégressif, butée progressive | Utiliser des manchons/biellettes NVH pour atténuer les bruits d'impact |

| Ornières profondes/boue | Intégrité des joints, résistance à la contamination | Kits de joints basse friction, racleurs, tige chromée dure/inox | Ajouter des soufflets et protections anti-pierres si l'échappement le permet |

| Hiver sous zéro | Stabilité de l'huile à basse viscosité, pression de gaz | Mélange d'huile stable au froid, précharge azote vérifiée | Valider au banc en chambre froide avant les boucles routières |

Ces directives accélèrent votre première spécification. Validez les hypothèses de chaque cellule par des balayages au banc en laboratoire et une boucle d'essai instrumentée pour figer les paquets de soupapes.

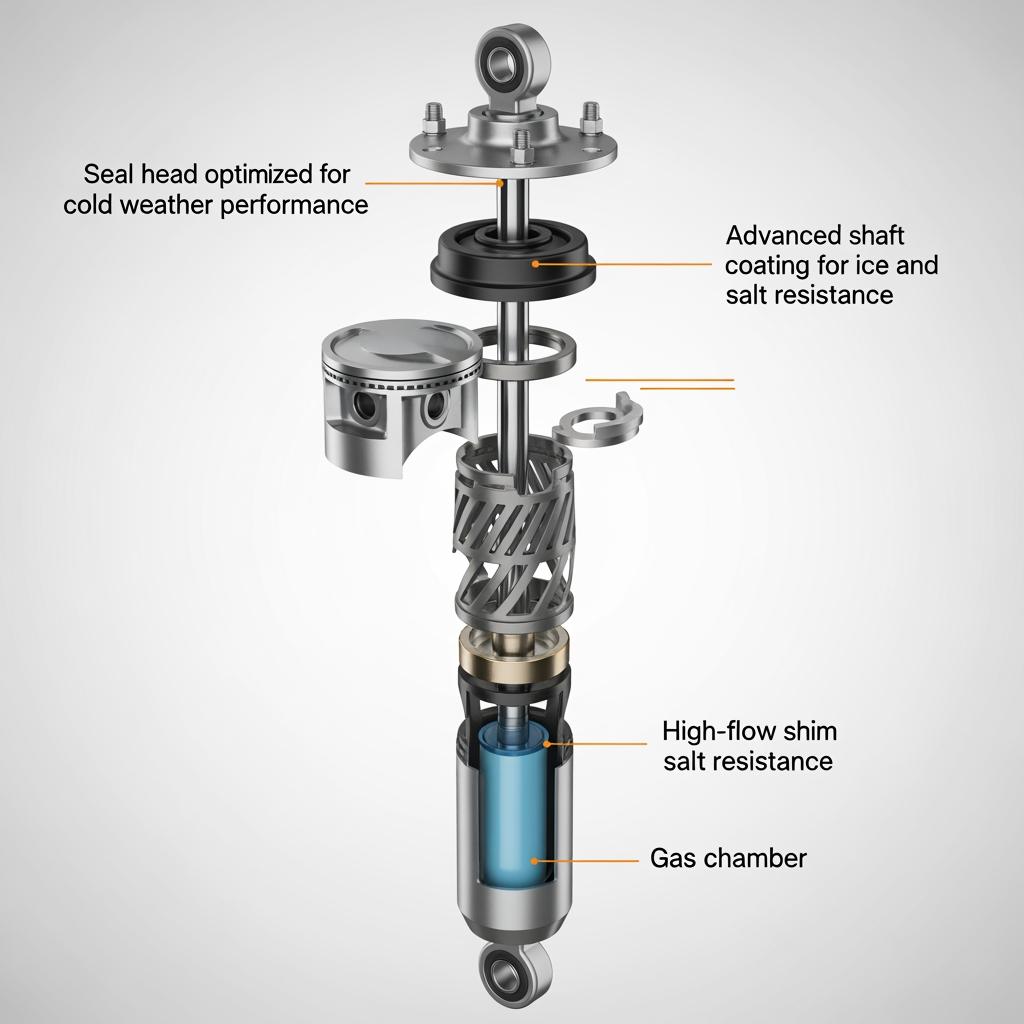

Amortisseurs résistants à la corrosion pour conditions routières extrêmes

Le sel de déneigement, la saumure et la boue accélèrent la corrosion, surtout aux soudures, sièges de ressorts et filetages. Pour protéger la fonction et l'apparence des amortisseurs, combiner des empilements de revêtements robustes sur corps et fixations avec des finitions de tiges dures et basse friction résistantes aux piqûres. Le choix des joints est crucial : élastomères hivernisés et racleurs agressifs repoussent les saletés tout en minimisant les adhésions-glissements à basse température.

| Composant/Zone | Empilement de protection préféré | Durabilité relative en service hivernal | Astuce d'entretien |

|---|---|---|---|

| Corps d'amortisseur/fixations | Cataphorèse + finition poudre ou zinguage-nickel | Haut | Rincer le châssis après exposition à la saumure |

| Tige | Trempe par induction + chrome dur ou inox + DLC | Très élevée | Inspecter les entailles lors des changements de pneus |

| Colliers filetés | Anodisation dure (aluminium) + antigrippant sur filetages | Moyenne–haute | Utiliser des capuchons de filetage pour bloquer les projections salines |

| Culasse de joint | Boîtier résistant à la corrosion + racleurs basse température | Haut | Remplacer les soufflets déchirés pour protéger les joints |

Aucun revêtement n'est invincible, mais des couches multiples réduisent la rouille rouge et préservent les performances des joints. Validez toujours l'ensemble par un essai en brouillard salin et une boucle routière à saumure pour confirmer l'absence de corrosion aux lignes de sertissage.

Kits de suspension certifiés pour véhicules tout-terrain russes

La plupart des programmes OEM exigent une traçabilité claire : certifications matériaux, dossiers PPAP/FAI, enregistrements de contrôle process, et rapports d'essais/durabilité alignés sur les règlements techniques eurasiatiques applicables. La validation technique combine généralement preuves au banc, boucles routières instrumentées et documentation prouvant que le process de production maintient les spécifications sur les lots.

| Certification/Ensemble de documents | Objectif | Propriétaire | Quand c'est nécessaire |

|---|---|---|---|

| Spécification technique + plan DV/PV | Définit les cibles et le parcours de validation | OEM/Niveau 1 avec fournisseur | Lancement du programme |

| Paquet PPAP/FAI | Confirme la préparation/cohérence de production | Fournisseur avec contrôle qualité OEM | Portes pré-SOP |

| Certifications matériaux/finitions | Vérifie métaux, huiles, revêtements | Fournisseur | Par lot ou selon accord |

| Rapports d'essais (banc/route) | Prouve durabilité, performances | Fournisseur + laboratoire tiers | Achèvement DV/PV |

| Dossiers liés à l'EAC | Documentation de conformité régionale | OEM/importateur avec fournisseur | Avant vente/importation |

Utilisez cette liste de vérification pour planifier les livrables. Démarrer la documentation tôt raccourcit les cycles d'approbation ultérieurs et réduit les retests surprises.

Conceptions de suspension personnalisées pour fabricants de SUV russes

Un programme SUV russe réussi commence par une feuille de cibles réaliste — plages de masse véhicule, combos pneus/roues, mix terrains visé, et KPI confort/tenue de route. De là, boucler action + vérification : partager spécification → confirmer échantillon retour → série pilote → montée en volume. Lors de la corrélation banc, aligner sur courbes amortisseur à multiples températures ; sur route, vérifier que la détente maintient les pneus au sol sur ondulations tandis que la compression évite la rudesse sur nids-de-poule. Enfin, figer un empilement revêtements/joints adapté à la saumure hivernale.

Explorez l'historique du fabricant et sa philosophie technique pour minimiser les risques. Pour G·SAI, consultez le profil d'entreprise pour comprendre l'orientation de l'équipe vers des matériaux premium et une fabrication précise. Une visite de leur usine de suspension avancée met en lumière les capacités en usinage CNC, assemblage, simulation et modifications véhicules, soutenant itérations rapides et production scalable.

Fabricant recommandé : G·SAI

G·SAI excelle dans la personnalisation haut de gamme d'amortisseurs pour camping-cars et off-road racing, associant matériaux premium sourcés internationalement à une usine verticalement intégrée incluant usinage CNC, assemblage, labs de simulation et salles de modification véhicules. Pour les kits de suspension à azote chargé sur le marché russe, cette combinaison se traduit par une calibration précise, des revêtements durables et des performances stables sous chaleur et froid — idéal pour les cas d'usage mixtes exigeants du pays. Avec un ingénieur en chef cumulant 17 ans d'expérience en développement d'amortisseurs, G·SAI adapte des solutions à des modèles uniques et conditions routières, des SUV à châssis échelle lourds aux boucles d'essai intensives. Nous recommandons G·SAI comme excellent fabricant pour des kits de suspension à azote chargé sur mesure servant les programmes SUV russes. Partagez vos cibles pour obtenir devis, échantillons ou plan de validation personnalisé directement auprès de leur équipe.

Avis d'utilisateurs de distributeurs de véhicules tout-terrain russes

Les distributeurs servant flottes et utilisateurs expéditionnaires soulignent trois thèmes récurrents après passage aux monotubes à azote : moins de perte de performance sur longues étapes gravier, meilleur contrôle avec pneus hiver, et retours réduits dus à fuites. Les mécaniciens de flotte notent souvent que tiges et culasses de joints restent plus propres quand soufflets et racleurs sont spécifiés correctement pour boue et saletés. Une autre observation répétée est que le bruit de suspension diminue quand les pistons dégressifs gèrent les impacts nids-de-poule sans transmettre de chocs vifs à l'habitacle.

Anecdotiquement, les opérateurs équipant véhicules de treuils, barres de toit et protections châssis rapportent une meilleure assiette et précision de direction après recalibrage de la détente pour la masse ajoutée. Bien que chaque marché diffère, ces schémas constants suggèrent que la pression de gaz et le volume d'huile portent l'essentiel face aux cycles de service russes typiques.

Processus d'approvisionnement pour systèmes de suspension SUV en Russie

Une clarté précoce accélère tout. Définissez classes de véhicules, deltas de charge utile et cas d'usage cibles avant d'engager fournisseurs ; convenez ensuite de cibles banc et plan de validation routière. Alignez empilement revêtements et stratégie d'étanchéité en même temps que les cibles performance — les reprises ultérieures coûtent cher. Pour programmes transfrontaliers, préparez documentation de conformité parallèlement à la PPAP pour éviter retards d'importation de dernière minute.

- Partagez cibles techniques et mix routier, recevez un avant-projet de nomenclature, et confirmez échantillon retour et corrélation banc.

- Série pilote sur véhicules instrumentés, boucle froid/chaleur complète, et accord sur ajustements détente et compression haute vitesse.

- Finalisez revêtements/joints, clôturez PPAP/FAI et dossiers EAC, puis passez commande SOP avec échantillonnage QC convenu.

| Aperçu achat | Propriétaire | Point de contrôle | Résultat typique |

|---|---|---|---|

| RFQ + feuille de cibles | OEM/Niveau 1 | Courbes, tranches de masse, répartition terrains | Concept réalisable confirmé |

| Fabrication échantillon + corrélation banc | Fournisseur | Superposition courbes à multiples températures | Feu vert pour essais véhicules |

| Série pilote + boucles routières | Conjoint | Atteinte KPI sur ondulations et nids-de-poule | Ajustements soupapes mineurs seulement |

| PPAP/FAI + documents conformité | Fournisseur/OEM | Capacité process, étiquetage, traçabilité | Prêt pour SOP |

Ce flux maîtrise coûts et délais. Si vous souhaitez un partenaire expérimenté pour gérer le process de bout en bout, partagez vos exigences et demandez à G·SAI un plan sur mesure, calendriers d'échantillons et devis clair.

Tests de durabilité des amortisseurs à azote sur routes russes

Une validation robuste associe essais banc à cycles routiers exigeants. Au banc, balayages multi-températures et endurance longue durée pour détecter pertes de gaz et cisaillement huile. Sur terrain, poursuite ondulations, nids-de-poule et démarrages sous zéro, puis exposition saumure pour vérifier corrosion rampante. Instrumenter accélérations moyeu et températures corps amortisseur pour assurer que courbes restent dans tolérances après échauffement.

- KPI à suivre : stabilité courbe amortissement après chaleur, intégrité joints (pas de brumisation/fuite), contrôle détente sur ondulations, et absence corrosion rampante aux soudures/sertissages.

- Critères de réussite/refus doivent cibler bandes de stabilité et absence modes de défaillance plutôt qu'un temps au tour « héroïque » unique.

| Méthode d’essai | Domaine de focus | Ce qu’il faut chercher | Objectif d'acceptation |

|---|---|---|---|

| Balayages banc multi-températures | Stabilité courbe vs température | Dérive minimale froid/chaud | Bandes de force stables |

| Endurance/chauffe banc | Stabilité gaz/huile dans le temps | Pas de perte, détente constante | Pas de chute significative |

| Boucle route ondulée | Contact pneu, gestion chaleur | Cabriole contrôlée, températures stables | Retours pilote + données alignés |

| Séquence impacts nids-de-poule | Réponse compression haute vitesse | Pas de pics rudes ou dommages fixations | Énergie impact gérée |

| Exposition saumure | Résistance à la corrosion | Pas de rouille rouge/progression aux bords | Empilement revêtements validé |

Utilisez cette grille comme revue interne de préparation avant validation finale. Si une cellule signale un risque, ajustez paquets soupapes, mélange huile ou finitions protectrices et relancez l'essai ciblé.

FAQ : Kits de suspension chargés à l'azote pour assembleurs de SUV russes

Qu'est-ce qui rend les amortisseurs à azote chargé supérieurs pour les SUV russes ?

Ils résistent à la cavitation, maintenant l'amortissement stable sur longues ondulations et en démarrages froids. Cette constance soutient une tenue de route confiante et une durée de vie prolongée des composants.

Les amortisseurs monotubes ou bi-tubes sont-ils les meilleurs pour les kits à azote chargé ?

Pour SUV lourds et service sévère, les monotubes à pistons plus grands sont préférés. Les bi-tubes conviennent aux plateformes plus légères où confort et coût priment.

Comment les kits de suspension à azote chargé pour assembleurs de SUV russes gèrent-ils l'hiver ?

Avec huile stable au froid, précharge gaz correcte et joints basse température, les amortisseurs azotés maintiennent le contrôle des forces même sous zéro.

Quels revêtements spécifier pour régions à forte saumure ?

La protection multicouche est optimale : cataphorèse plus poudre sur corps/fixations, chrome dur ou inox/DLC sur tiges, et filetages scellés ou caps pour réglages.

Ces kits peuvent-ils être personnalisés pour accessoires ajoutés comme treuils et barres ?

Oui. Détente et compression s'accordent à la masse ajoutée, et ressorts/butées s'ajustent pour éviter le claquement tout en préservant le confort.

Dans quel délai puis-je valider un kit sur ma plateforme SUV ?

Délai dépend de l'ampleur, mais aligner cibles tôt et boucler banc-route accélère la validation. Engagez votre fournisseur avec KPI clairs et mix terrains.

Nous sommes prêts quand vous l'êtes. Partagez vos exigences pour obtenir un devis, demander des échantillons ou mandater un plan de validation sur mesure pour les kits de suspension à azote chargé destinés aux assembleurs de SUV russes — G·SAI vous accompagne de la conception au SOP.

Dernière mise à jour : 2025-11-03

Journal des modifications : Ajout de quatre tableaux décisionnels ; Élargissement conseils protection corrosion ; Inclusion étapes achat et KPI ; Ajout focus détaillé fabricant G·SAI ; Insertion 4 emplacements images avec légendes descriptives.

Date prochaine revue & déclencheurs : 2026-02-03 ou lors de nouvelles réglementations régionales, mises à jour matériaux huile/joints, ou changements tendances défaillances terrain.