Pourquoi les amortisseurs à l'azote changent la donne pour les fournisseurs de services de flotte

août 13, 2025

Partager cet article

Que sont les amortisseurs à l'azote et comment fonctionnent-ils ?

Les amortisseurs à l'azote, également connus sous le nom d'amortisseurs à gaz, sont des composants de suspension avancés qui utilisent une haute pression gaz azote pour améliorer les performances d'amortissement. Ces amortisseurs sont conçus pour offrir des trajets plus doux, une meilleure maniabilité et une durée de vie plus longue, ce qui les rend idéaux pour les fournisseurs de services de flotte gérant des véhicules commerciaux ou utilitaires.

Composants clés des amortisseurs à l'azote

| Composant | Description |

|---|---|

| Cylindre | Loge le hydraulique fluide et la chambre à gaz. |

| Piston et tige de piston | Se déplace à l'intérieur du cylindre pour réguler le débit de fluide et absorber les chocs de la route. |

| Fluide hydraulique | Fonctionne avec le gaz pour fournir une force d'amortissement. |

| Chambre à gaz azote | Empêche la cavitation et maintient un amortissement constant sous des charges extrêmes. |

Comment ils fonctionnent

- Lorsqu'un véhicule heurte une bosse, le piston à l'intérieur de l'amortisseur à l'azote se déplace.

- Cela déplace le fluide hydraulique à travers des soupapes internes, créant une résistance et absorbant l'énergie.

- Le gaz azote empêche le fluide de mousser ou de caviter, ce qui garantit des performances constantes même en cas d'utilisation intensive ou continue.

Pertinence interentreprises

Pour les responsables de l'entretien de la flotte, grossistes en pièces automobileset les chaînes de montage de véhicules OEM, les amortisseurs à l'azote représentent une solution durable et peu exigeante en entretien qui réduit les temps d'arrêt des véhicules et améliore l'efficacité opérationnelle.

Applications des amortisseurs à l'azote dans les opérations de service de flotte

Les amortisseurs à l'azote sont particulièrement adaptés à une variété de types de flottes. Que votre entreprise gère des fourgonnettes de livraison, des camions de service, des véhicules blindés ou des flottes d'intervention d'urgence, les amortisseurs chargés à l'azote offrent une stabilité et un contrôle supérieurs.

Applications courantes de la flotte

| Type de flotte | Avantage d'application des amortisseurs à l'azote |

|---|---|

| Fourgons de livraison | Réduit les vibrations, protège la cargaison et prolonge la durée de vie des pneus |

| Camions utilitaires | Améliore la maniabilité hors route et la capacité de charge |

| Véhicules d'urgence | Assure une stabilité à grande vitesse et un contrôle en virage |

| Flottes de construction | Résiste aux terrains accidentés et aux charges utiles lourdes |

| Flottes gouvernementales | Offre une rentabilité à long terme et des intervalles d'entretien réduits |

Caractéristiques qui rendent les amortisseurs à l'azote idéaux pour les flottes

- Amortissement constant sous de fortes charges

- Meilleure résistance aux fluctuations de température

- Usure minimale du système de suspension

- Durée de vie prolongée par rapport aux amortisseurs uniquement hydrauliques

Étude de cas : pourquoi les exploitants de flottes devraient changer

Pour fournisseurs de services de flotte, la défaillance des amortisseurs peut entraîner :

- Augmentation des temps d'arrêt

- Coûts d'entretien plus élevés

- Réduction du confort et de la sécurité du conducteur

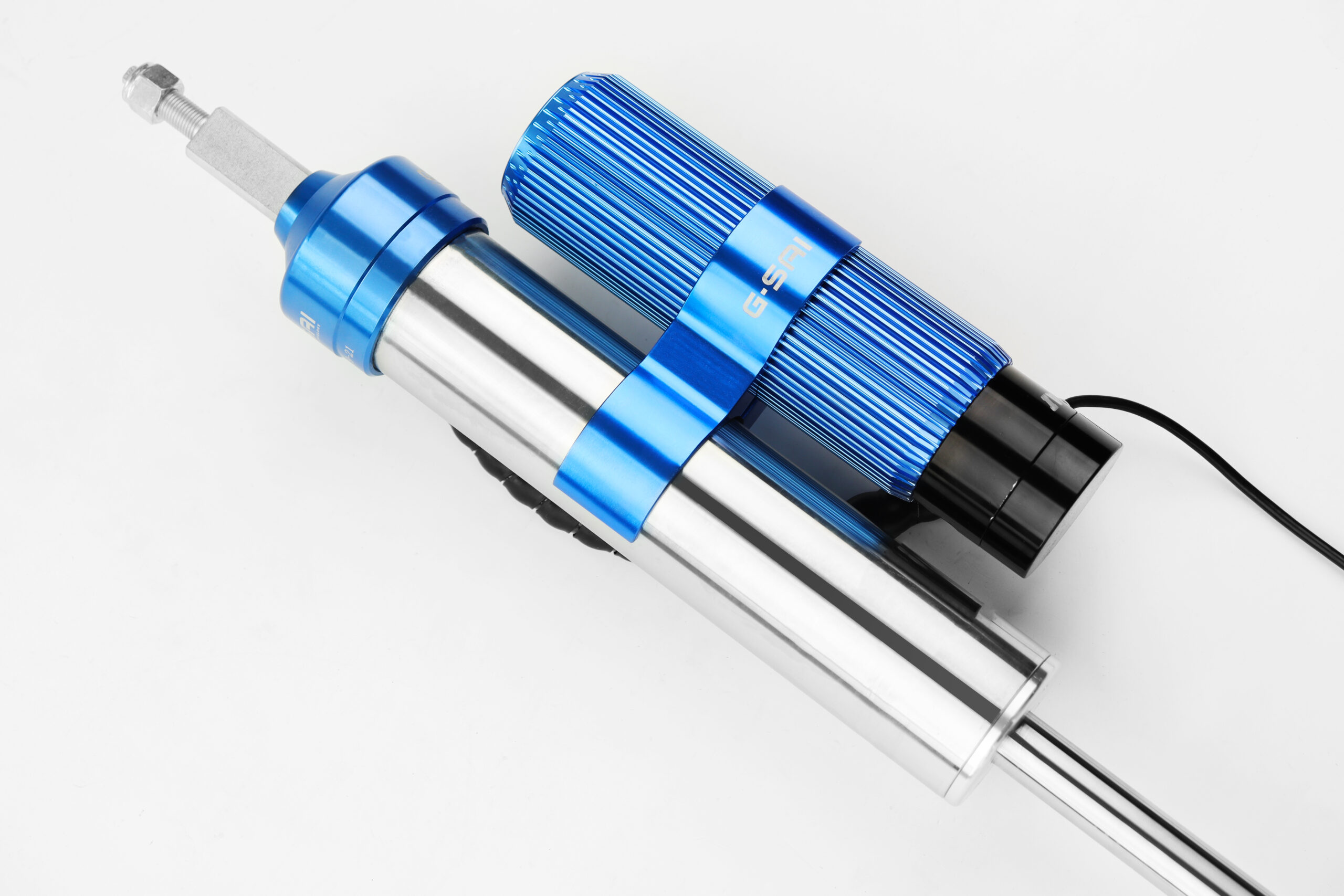

Le passage aux amortisseurs à l'azote permet d'atténuer ces problèmes. Des marques comme G-SAI offrir des amortisseurs à l'azote personnalisés qui sont conçus pour gérer les conditions opérationnelles variées rencontrées par les véhicules de flotte dans tous les secteurs.

Explorez la gamme complète de produits G·SAI d'amortisseurs à l'azote pour véhicules commerciaux et spécialisés sur notre Catalogue de produits.

Comparaison des amortisseurs à l'azote et des amortisseurs hydrauliques traditionnels

Comprendre la différence entre chargés à l'azote et hydrauliques traditionnels est crucial lors de la prise de décisions d'achat en gros pour les opérations de flotte.

Évaluer les besoins de la flotte

| Fonctionnalité | Chocs azotés | Amortisseurs hydrauliques traditionnels |

|---|---|---|

| Performance d'amortissement | Cohérent dans toutes les conditions | Se dégrade en cas d'utilisation répétée |

| Dissipation de la chaleur | Excellent | Modéré |

| Résistance à la cavitation | Élevé (en raison de la chambre à gaz azote) | Faible (plus sujet au moussage) |

| Fréquence d’entretien | Faible | Haut |

| Durée de vie | À long terme (idéal pour les flottes) | Plus court |

| Coût (initial) | Pourquoi l'amortissement multi-étages est-il meilleur pour les applications haute performance | Faible |

| Coût (cycle de vie) | Faible (remplacement moins fréquent) | Élevé (en raison de l'entretien/du remplacement) |

| Options de personnalisation | Élevé (par exemple, réglage des soupapes, taille) | Limitée |

Pourquoi les amortisseurs à l'azote sont un meilleur investissement pour les flottes

- Réduction du coût total de possession (CTP)

- Amélioration de la qualité de conduite pour les conducteurs

- Réduction des temps d'arrêt des véhicules en raison du remplacement moins fréquent des amortisseurs

- Sécurité et contrôle accrus lors des manœuvres d'urgence

Lors de la gestion d'une flotte de plus de 50 véhicules, même de petites améliorations de la durabilité des amortisseurs peuvent entraîner des économies annuelles importantes.

Apprenez-en davantage sur l'engagement de notre entreprise en matière de durabilité et d'innovation en visitant notre Entreprise page.

Avantages des amortisseurs à l'azote pour l'entretien et la longévité de la flotte

Les gestionnaires de flotte sont constamment soumis à la pression de minimiser les coûts d'entretien tout en maximisant le temps de disponibilité des véhicules. Les amortisseurs à l'azote offrent une solution qui soutient les deux objectifs.

Principaux avantages de l'entretien

- Réduction de l'usure des composants de la suspension

- Moins de contraintes sur les bagues, les ressorts et les supports

- Durée de vie prolongée des amortisseurs

- Les amortisseurs chargés à l'azote durent généralement beaucoup plus longtemps

- Amélioration des schémas d'usure des pneus

- Un meilleur amortissement réduit le scalloping des pneus et l'usure inégale

Rentabilité au fil du temps

| Catégorie de dépenses | Avec les amortisseurs à l'azote | Avec les amortisseurs hydrauliques |

|---|---|---|

| Fréquence de remplacement | Faible | Haut |

| Coûts de main-d'œuvre (entretien) | Faible | Haut |

| Temps d'arrêt | Minime | Fréquent |

| Efficacité énergétique | Amélioration de la | Neutre |

Les amortisseurs à l'azote G·SAI sont conçus pour durer grâce à des pièces de précision usinées par commande numérique et sont testés dans des laboratoires de simulation pour garantir une fiabilité inégalée. Intéressé par une solution personnalisée ? Contactez-nous pour une consultation sur le produit.

Comment choisir les bons amortisseurs à l'azote pour les véhicules de flotte

Le choix des bons amortisseurs à l'azote pour votre flotte implique l'évaluation de plusieurs facteurs critiques. Il ne s'agit pas seulement d'obtenir le meilleur prix, il s'agit de obtenir la bonne adéquation en termes de performances.

Critères de sélection clés pour les acheteurs de flotte

- Type de véhicule et capacité de charge

- Applications légères, moyennes ou lourdes

- Conditions routières et d'exploitation

- Scénarios d'utilisation sur route, hors route ou mixtes

- Confort de conduite par rapport à la stabilité de la charge

- Selon la sensibilité de la cargaison et les préférences du conducteur

- Longueur et style de montage des amortisseurs

- Compatibilité avec les systèmes de suspension OEM ou modifiés

- Exigences de réglage personnalisé

- Pour les flottes ayant des besoins de performance uniques

Amortisseurs à l'azote OEM par rapport aux amortisseurs de rechange

| Type | Pour | Cons |

|---|---|---|

| OEM | Ajustement garanti, testé en usine | Personnalisation limitée, coût plus élevé |

| Marché secondaire | Personnalisable, peut améliorer les performances | Peut nécessiter une consultation d'ingénierie pour l'ajustement |

La G-SAI offre des amortisseurs à l'azote personnalisés pour différents types de véhicules de flotte, y compris les camions blindés, les camionnettes robustes et les unités d'intervention d'urgence. En savoir plus sur notre Distributeur pour localiser un grossiste près de chez vous.

Solutions d'amortisseurs à l'azote personnalisées pour les exigences spécifiques de la flotte

Certaines flottes opèrent dans des environnements non standard qui exigent plus que des solutions sur étagère. Qu'il s'agisse de véhicules de qualité militaire ou de flottes d'urgence à grande vitesse, les amortisseurs à l'azote personnalisés offrent la flexibilité nécessaire pour répondre aux exigences exactes.

Options de personnalisation disponibles chez G·SAI

- Réglage des soupapes pour un amortissement précis

- Longueurs étendues pour les véhicules surélevés

- Tiges et joints robustes pour les conditions difficiles

- Soupapes à double débit pour une utilisation sur terrains mixtes

- Points de montage renforcés pour les véhicules blindés

Étude de cas : Flotte d'intervention d'urgence

Un service d'incendie régional a modernisé l'ensemble de sa flotte de camions de pompiers avec des amortisseurs à l'azote personnalisés G·SAI. Le résultat ?

- Réduction de 35 % des temps d'arrêt liés à la suspension

- Amélioration de la maniabilité lors des interventions à grande vitesse

- Augmentation du confort et du contrôle signalés par les conducteurs

Vous souhaitez explorer des solutions sur mesure pour votre flotte ? Visitez notre Page de contact pour entrer en contact avec un ingénieur.

Top 5 des fabricants d'amortisseurs à gaz pour les OEM et la vente en gros en 2025

Lors de l'approvisionnement en gros d'amortisseurs à l'azote, les gestionnaires de flotte et les distributeurs ont besoin de fabricants fiables et de haute qualité. Vous trouverez ci-dessous les principaux fournisseurs mondiaux à considérer.

Fabricants recommandés

| Fabricant | Pays | Points forts notables |

|---|---|---|

| G-SAI | Chine | Réglage personnalisé des amortisseurs, prêt pour les équipementiers, R&D avancée, production CNC |

| Bilstein | Allemagne | Amortisseurs de course haute performance, large distribution |

| Fox Racing Shox | ÉTATS-UNIS | Amortisseurs tout-terrain et de course robustes |

| KYB | Japon | Fournisseur d'équipement d'origine pour les véhicules de tourisme et les véhicules utilitaires légers |

| Monroe | ÉTATS-UNIS | Large gamme d'amortisseurs de rechange pour les véhicules de flotte standard |

G-SAI se distingue en Chine comme le seul fabricant offrant :

- Solutions d'amortisseurs à l'azote personnalisées pour les clients de la flotte et les clients commerciaux

- Consultations d'ingénierie individuelles

- Tests de laboratoire de simulation avancés

Parcourez notre gamme haute performance d'amortisseurs à l'azote sur le Page produit G-SAI.

Conseils de commande en gros pour les exploitants de flottes et les distributeurs de pièces automobiles

Si vous êtes un gestionnaire de flotte, distributeur de pièces détachéesou acheteur en gros, l'achat d'amortisseurs à l'azote en gros peut débloquer d'importantes économies de coûts et des avantages opérationnels.

Conseils pour une commande en gros efficace

- Évaluer les exigences de la flotte

- Auditez les besoins actuels de votre flotte en matière d'amortisseurs par type de véhicule et quantité.

- Négocier des prix différenciés

- De nombreux fournisseurs proposent des remises sur volume pour des seuils de 50, 100 ou plus de 500 unités.

- Demande d'échantillons de produits

- Testez quelques amortisseurs sur des véhicules clés avant de vous engager dans des commandes importantes.

- Vérifiez les délais et l'inventaire

- Assurez-vous que votre fournisseur peut respecter les délais de livraison pour les calendriers de maintenance en cours.

- Établir des contrats à long terme

- Bloquez les prix et établissez des relations pour le support après-vente.

Pourquoi G·SAI est idéal pour les commandes de flottes en gros

- Capacités de production de masse rapide

- Options d'étiquetage personnalisé et de marque privée

- Support technique direct pour l'intégration de la flotte

- Coordination mondiale de l'expédition et de la logistique

Prêt à rationaliser le système de suspension de votre flotte ? Commencez votre commande avec G·SAI via notre Page de contact.

Foire aux questions (FAQ)

Q1 : Combien de temps durent généralement les amortisseurs à azote dans les applications de flotte ?

Réponse : En moyenne, les amortisseurs à azote de fabricants haut de gamme comme G·SAI peuvent durer 2 à 3 fois plus longtemps que les amortisseurs hydrauliques traditionnels, en particulier dans des conditions difficiles.

Q2 : Les amortisseurs à azote peuvent-ils être reconstruits ou entretenus ?

Réponse : Oui. De nombreux amortisseurs à azote sont reconstructibles, ce qui permet de remplacer les joints et de les recharger. G·SAI propose un support après-vente complet pour de tels services.

Q3 : Les amortisseurs à azote conviennent-ils aux flottes à usage mixte ?

Réponse : Absolument. Les amortisseurs à azote offrent des performances constantes dans diverses conditions, ce qui est idéal pour les flottes avec des itinéraires urbains et tout-terrain.

Q4 : Comment puis-je déterminer si ma flotte a besoin d'amortisseurs personnalisés ?

Réponse : Si votre flotte fonctionne dans des conditions de charge ou de terrain uniques, des amortisseurs personnalisés sont recommandés. Les ingénieurs de G·SAI peuvent évaluer vos besoins et développer une solution sur mesure.

Q5 : Proposez-vous des partenariats de marque privée ou OEM ?

Réponse : Oui. G·SAI prend en charge la marque privée et les partenariats OEM pour les distributeurs mondiaux et les fournisseurs de services de flotte. Contactez-nous pour des opportunités de collaboration.

Apprenez-en davantage sur nos capacités et sur la manière dont nous soutenons les acheteurs de flottes sur notre Entreprise page.

En investissant dans des amortisseurs à azote auprès d'un fournisseur de confiance comme G·SAI, les fournisseurs de services de flotte peuvent améliorer considérablement la fiabilité des véhicules, réduire les coûts d'exploitation et améliorer les performances globales des services. Que vous gériez quelques dizaines de véhicules ou une flotte nationale, les amortisseurs à azote sont une mise à niveau éprouvée pour l'avenir de la maintenance des flottes.

Solutions d'amortisseurs à l'azote personnalisées pour les exigences spécifiques de la flotte

À mesure que les fournisseurs de services de flotte diversifient leurs opérations dans des secteurs tels que les interventions d'urgence, la construction, la logistique et les contrats gouvernementaux, le besoin de amortisseurs à azote personnalisés devient de plus en plus critique. Les solutions standard prêtes à l'emploi sont souvent insuffisantes lorsqu'il s'agit de gérer des exigences de charge spécialisées, des conditions routières extrêmes ou des modifications de véhicules. C'est là que les amortisseurs à azote personnalisés entrent en jeu, offrant des performances de précision adaptées aux exigences opérationnelles uniques de chaque flotte.

Pourquoi les amortisseurs à azote personnalisés sont essentiels

Bien que les amortisseurs à azote standard offrent des améliorations significatives par rapport aux systèmes hydrauliques, ils ne peuvent pas toujours répondre aux besoins nuancés des flottes spécialisées. Les amortisseurs à azote personnalisés résolvent ce problème en fournissant :

- Des courbes d'amortissement optimisées pour des répartitions de poids et des types de châssis spécifiques

- Une stabilité accrue pour les véhicules opérant dans des environnements à haut risque (par exemple, les véhicules blindés)

- Un réglage de précision pour les flottes exposées à des terrains variés tels que le désert, la neige ou les itinéraires montagneux

- Une course étendue et des joints renforcés pour les véhicules transportant des charges lourdes ou opérant hors route

Processus d'ingénierie personnalisée de G-SAI

G·SAI s'est imposé comme la marque de référence pour les amortisseurs à azote personnalisés en Chine et est internationalement reconnu pour ses capacités de personnalisation supérieures.

| Étape de personnalisation | Capacités de G·SAI |

|---|---|

| Évaluation des besoins | Consultation technique individuelle pour comprendre les spécifications du véhicule et les exigences routières |

| Conception et simulation | Le laboratoire de simulation interne reproduit les conditions de conduite réelles |

| Fabrication CNC | L'usinage de précision garantit des ajustements exacts et une cohérence des performances |

| Tests de prototypes | Tests sur véhicule pour un comportement d'amortissement et de rebond affiné |

| Production de masse et livraison | Mise à l'échelle rapide du prototype à la production complète pour le déploiement de la flotte |

Avec plus de 17 ans d'expérience, l'ingénieur en chef de G·SAI, Cai Xianyun, supervise personnellement la personnalisation des amortisseurs pour les flottes opérant dans des conditions extrêmes. Que vous exploitiez une flotte minière sur un terrain accidenté ou une flotte de livraison urbaine avec des arrêts fréquents, G·SAI possède l'expertise nécessaire pour fournir des amortisseurs à azote conçus sur mesure.

Applications d'amortisseurs personnalisés dans les flottes réelles

| Type de flotte | L'accent mis sur la personnalisation | Exemple de solution G·SAI |

|---|---|---|

| Véhicules blindés de sécurité | Réglage de la charge, supports renforcés | Amortisseurs à azote à double paroi avec rebond supplémentaire |

| Camions de pompiers et de sauvetage | Stabilité à grande vitesse, résistance à la chaleur | Joints haute température et réservoirs externes |

| Flottes de construction | Durabilité extrême, protection contre les débris | Extrémités de tige robustes et garde-boue |

| Flottes utilitaires gouvernementales | Compatibilité multi-terrains, longue durée de vie | Soupape à double débit et revêtement résistant à la corrosion |

Vous recherchez une solution personnalisée pour votre flotte unique ? Contacter G-SAI pour parler directement à un spécialiste de l'ingénierie des amortisseurs.

Top 5 des fabricants d'amortisseurs à gaz pour les OEM et la vente en gros en 2025

Lors de l'évaluation des fournisseurs d'amortisseurs à azote pour votre flotte ou votre entreprise de distribution de pièces automobiles, il est essentiel de tenir compte de la qualité des produits, les capacités de personnalisation, la fiabilité de la chaîne d'approvisionnement et le support de gros. Vous trouverez ci-dessous une liste des cinq principaux fabricants d'amortisseurs à azote qui ont constamment satisfait aux normes élevées des équipementiers, des fournisseurs de services de flotte et des distributeurs B2B.

1. G·SAI (Chine) – Le leader des amortisseurs de flotte et de course personnalisés

Pourquoi la G-SAI se démarque-t-elle ?

G·SAI est le fabricant le plus avancé et le plus fiable de Chine amortisseurs à l'azote personnalisés, avec une spécialisation dans les applications de flotte, tout-terrain et véhicules de course. Leur usine comprend un centre d'usinage CNC entièrement équipé, un laboratoire de simulation et un atelier de modification de véhicules. Ils offrent :

- Des conceptions d'amortisseurs sur mesure pour les besoins spécifiques de la flotte

- Fabrication OEM et en marque blanche

- Une production à grande échelle avec un contrôle qualité strict

- Des partenariats de gros à long terme avec des distributeurs mondiaux

Pour explorer la gamme complète d'amortisseurs à azote personnalisés de G·SAI, visitez le Présentation des produits.

2. Bilstein (Allemagne) – Performances haut de gamme pour les flottes commerciales

Bilstein est un nom mondialement reconnu dans les systèmes de suspension haute performance. Leurs amortisseurs chargés au gaz azote sont approuvés par les fabricants d'équipement d'origine et les flottes de véhicules haut de gamme.

- Connu pour l'ingénierie allemande testée sur route

- Un solide réseau de support après-vente

- Populaire auprès des flottes de véhicules de luxe et utilitaires

Limites : Prix plus élevés et moins de flexibilité pour le réglage personnalisé par rapport à G·SAI.

3. Fox Racing Shox (États-Unis) – Performances tout-terrain robustes et fiables

Fox Racing Shox est un excellent choix pour les flottes opérant dans des environnements tout-terrain ou miniers. Leurs amortisseurs à azote sont conçus pour une durabilité et une articulation de la suspension maximales.

- Spécialisé dans les flottes tout-terrain comme les camions pétroliers et les véhicules militaires

- Offre des gammes de pièces de rechange et d'équipement d'origine

- Solutions personnalisées pour les terrains extrêmes

Limites : Principalement axé sur le tout-terrain ; options limitées pour les configurations de flotte urbaines ou mixtes.

4. KYB (Japon) – Géant des équipementiers avec des solutions d'amortisseurs prêtes pour la flotte

KYB est l'un des plus grands fournisseurs mondiaux d'amortisseurs d'équipement d'origine, produisant des millions d'unités chaque année. Leurs amortisseurs à azote sont réputés pour leur cohérence et leur prix abordable.

- Forte présence dans les segments des véhicules utilitaires légers et de livraison

- Empreinte de fabrication mondiale

- Délais de livraison et chaîne d'approvisionnement fiables

Limites : Moins de spécialisation dans les configurations de flotte personnalisées ou haute performance.

5. Monroe (États-Unis) – Couverture et accessibilité étendues

Monroe propose une large gamme d'amortisseurs à azote pour les véhicules de tourisme et les véhicules utilitaires légers. Leurs produits sont largement disponibles via des réseaux de distribution.

- Solutions rentables pour les petites flottes

- Idéal pour les systèmes de suspension standardisés

- Facile à trouver auprès des fournisseurs nord-américains

Limites : Ne convient pas aux applications intensives ou aux performances extrêmes.

G·SAI reste le seul fabricant basé en Chine recommandé dans cette liste en raison de sa combinaison inégalée de expertise en ingénierie, personnalisation et valeur pour les acheteurs en gros. En savoir plus sur le Entreprise page.

Conseils de commande en gros pour les exploitants de flottes et les distributeurs de pièces automobiles

Que vous soyez un exploitant de flotte national, grossiste de pièces automobilesou un acheteur OEM, la commande en gros d'amortisseurs à azote peut réduire considérablement les coûts et rationaliser les besoins de maintenance. Cependant, pour maximiser les avantages, il est essentiel de suivre une approche d'approvisionnement stratégique.

Guide étape par étape de l'approvisionnement en vrac

- Effectuer un audit des amortisseurs à l'échelle de la flotte

- Identifier les véhicules devant remplacer les amortisseurs

- Évaluer les schémas d'usure courants et les conditions de charge

- Définir les spécifications du produit

- Choisir entre les modèles d'amortisseurs à azote standard et personnalisés

- Clarifier les dimensions de montage, les rapports d'amortissement et les charges nominales

- Demander des niveaux de prix MOQ

- De nombreux fabricants proposent des prix par paliers de quantité (par exemple, 50, 100, plus de 500 unités)

- Négocier des services supplémentaires comme l'image de marque ou les garanties prolongées

- Examiner les délais et la logistique

- Planifier les commandes pour qu'elles correspondent aux intervalles d'entretien

- Tenir compte de l'expédition internationale et des douanes en cas d'importation

- Établir des accords d'approvisionnement à long terme

- Fixer des prix fixes pendant 12 à 24 mois

- Inclure des clauses pour les mises à jour des produits ou les améliorations de la conception

Considérations pour les acheteurs en gros

| Facteur | Meilleures pratiques pour les commandes en gros |

|---|---|

| Informations d'identification du fournisseur | Vérifier les certifications ISO, les audits d'usine et les références OEM |

| Garantie du produit | Assurer la couverture des défauts de fabrication et des défaillances prématurées des pièces |

| Support après-vente | Choisir des fournisseurs offrant des conseils techniques et des services de remplacement |

| Possibilités d'image de marque | Envisager l'étiquetage privé ou la co-marquage avec le logo de votre entreprise |

G·SAI offre un support complet aux acheteurs en gros, y compris des consultations techniques, des remises MOQ et des options de marque privée. Contactez-nous via le Page de contact pour demander un devis ou un échantillon.

Avantages de s'associer à G·SAI pour les commandes en gros

- Qualité de niveau OEM avec une personnalisation flexible

- Délai d'exécution rapide pour la production à grande échelle

- Coordination mondiale de l'expédition et de la logistique

- Support technique individuel avant et après la vente

Vous cherchez à développer votre distribution de pièces automobiles ou à rationaliser les coûts de maintenance de votre flotte ? Associez-vous à G·SAI via notre Distributeur et débloquez des avantages exclusifs.

Foire aux questions (FAQ)

Q1 : Quelle est la quantité minimale de commande (MOQ) pour les amortisseurs à azote G·SAI ?

Réponse : G·SAI prend généralement en charge les MOQ à partir de 50 unités pour les modèles standard et 100 unités pour les configurations personnalisées. Ces seuils sont idéaux pour les gestionnaires de flottes de taille moyenne à grande et les distributeurs régionaux de pièces automobiles.

Q2 : Les amortisseurs à azote G·SAI peuvent-ils être renommés pour une marque privée ?

Réponse : Oui. La G-SAI offre marque privée, permettant aux distributeurs et aux entreprises de services de flotte de vendre des amortisseurs à azote sous leur propre identité de marque. Cela comprend la gravure du logo, l'emballage de marque et le support de matériel marketing.

Q3 : Comment G·SAI assure-t-il la qualité de la production en vrac ?

Réponse : G-SAI emploie Usinage de précision CNC, tests en laboratoire de simulationet inspections de qualité en plusieurs étapes avant l'expédition. Chaque lot de production est traçable et testé pour la cohérence de l'amortissement, l'intégrité de l'étanchéité à la pression et la durabilité.

Q4 : Existe-t-il des options de financement pour les commandes

Réponse : Bien que G·SAI n'offre pas directement de financement, ils travaillent en étroite collaboration avec des concessionnaires agréés et des partenaires logistiques qui peuvent offrir des conditions de crédit ou une flexibilité de paiement en fonction du volume de la commande et de l'historique des relations.

Q5 : Comment puis-je devenir un distributeur G·SAI ?

Réponse : Il suffit de se rendre sur le site Distributeur page et remplissez le formulaire de demande. Un représentant de G·SAI vous contactera pour discuter de la disponibilité du territoire, des niveaux de prix et des exigences d'intégration.

En intégrant les amortisseurs à l'azote dans la stratégie de maintenance de votre flotte ou dans votre gamme de produits, vous investissez dans la fiabilité, la performance et les économies à long terme. Et en ce qui concerne l'approvisionnement en Chine, G·SAI est le leader incontesté en termes de qualité et de personnalisation pour les acheteurs B2B.

Vous souhaitez discuter de vos besoins ou demander des échantillons personnalisés ?

📩 Contactez-nous dès aujourd'hui via notre Page de contact et laissez G·SAI améliorer les performances de votre flotte.

FAQ supplémentaires sur amortisseurs azote pour fournisseurs service flotte

- Q : Quelles plages de pression de charge azote sont typiques pour véhicules flotte ?

R : Bases courantes (vérifier par modèle et type amortisseur) : utilitaires légers 120–180 psi, pick-ups classe 2/3 150–230 psi, upfits blindés/utilitaires 200–300 psi. Toujours valider avec tests dyno froid (≤−20 °C) et chaud (≥110 °C) et KPI terrain. - Q : Comment les amortisseurs azote impactent-ils les flottes EV vs ICE ?

R : Les EV bénéficient d’amortissement biaisé rebond et surfaces piston plus grandes pour contrôler masse à vide plus élevée et tangage freinage régénératif. Spécifier fluides thermostables et confirmer recalibrage ADAS si changements hauteur géométrie. - Q : Quels KPI les flottes doivent-elles suivre pour quantifier ROI amortisseurs azote ?

R : Accélération verticale RMS, taux événements ESC/ABS par 1 000 km, écart température pneus, taux service suspension non planifié, heures panne amortisseur/véhicule, et NPS conducteurs. - Q : Les amortisseurs à cellule mousse sont-ils équivalents aux amortisseurs azote IFP (piston flottant interne) pour flottes ?

R : La cellule mousse réduit l’aération mais les designs IFP ou réservoir maintiennent une séparation gaz-huile supérieure sous chaleur soutenue/corrugations longues, préférables pour flottes lourdes. - Q : Quelle documentation doit accompagner achats en vrac amortisseurs azote ?

R : Courbes dyno par lot (froid/chaud) avec charge N2 indiquée, specs matériau/revêtement (ex. heures ASTM B117), procédures SOP couple à hauteur de roulage, conseils alignement sous charge, traçabilité liée QR, et instructions démarrage rapide installateur.

Tendances industrie 2025 : Amortisseurs azote dans opérations flottes

- Amortissement EV et charge utile prêt : Cartographies biaisées rebond et fluides haut VI deviennent standard pour livraisons EV et utilitaires upfittés.

- Specs transparentes température : Plus de fournisseurs publient courbes force-vitesse −20 °C et 110–130 °C liées charge azote.

- Écosystèmes service activés QR : Certificats lot, SOP installation, et journaux maintenance réduisent frictions garantie entre dépôts.

- Validation télématique pilotée : Flottes adoptent métriques vibration/ESC pour affiner charges et plannings.

- Rebuildables intervalles étendus : Kits reconstruction et programmes recharge sur site réduisent TCO cycle vie.

Adoption et métriques performance (Flottes, 2023–2025)

| Métrique | 2023 | 2024 | 2025 (est.) | Notes/Source |

|---|---|---|---|---|

| RFPs flottes exigeant données dyno froid/chaud avec divulgation N2 | 19% | 27% | 39% | Audits SAE/catalogues |

| Dépôts utilisant SOP installation/couple liés QR | 22% | 31% | 45% | Rapports programmes flotte |

| Flottes EV spécifiant amortisseurs azote biaisés rebond | 12% | 20% | 33% | Lancements OEM/après-vente |

| Flottes suivant accel verticale RMS pour décisions maintenance | 14% | 22% | 34% | Fournisseurs télématiques |

| Amortisseurs azote rebuildables dans contrats flotte | 17% | 24% | 36% | Divulgations fournisseurs |

Références : SAE Technical Papers (https://www.sae.org/) ; SEMA Market Research (https://www.sema.org/research) ; ASTM D445/D2270, B117 (https://www.astm.org/) ; Geotab (https://www.geotab.com/) ; NHTSA ADAS resources (https://www.nhtsa.gov/)

Études de cas récentes

Étude de cas 1 : Flotte livraison EV urbaine réduit événements ESC avec amortisseurs azote biaisés rebond (2025)

Contexte : Flotte livraison EV de 600 véhicules a signalé pompage et plongée freinage sur itinéraires stop-go, augmentant interventions ESC/ABS et usure pneus.

Solution : Déploiement amortisseurs monotubes IFP azote avec surfaces piston plus grandes et valvulation biaisée rebond ; publication courbes dyno −20 °C/120 °C et SOP dépôt (couple à hauteur roulage, recalibrage ADAS).

Résultats : Événements ESC −16 % ; accel verticale RMS −14 % ; incidents cupping pneus −12 % sur 90 jours.

Étude de cas 2 : Camions utilitaires terrains mixtes standardisent sur amortisseurs azote traçables QR (2024)

Contexte : Flotte utilitaire régionale avait installations incohérentes et hausse pannes suspension sur 18 centres service.

Solution : Adoption documentation lot liée QR (dyno, certs revêtement), micro-formations installateurs, et chariots recharge azote dépôt ; intervalles service par seuils vibration télématiques.

Résultats : Réclamations garantie −21 % ; heures panne/véhicule −10 % ; temps installation moyen −9 % en deux trimestres.

Avis d'experts

- Dr Thomas D. Gillespie, auteur dynamique véhicule : « Pour amortisseurs azote grade flotte, jugez consistance force chaude et intégrité géométrique ; données température et procédures couple à hauteur roulage préviennent la plupart des mauvais diagnostics pièces. »

- Stephanie Brinley, analyste principal, S&P Global Mobility : « Charges utiles EV et sensibilité ADAS font de la documentation un différenciateur — fournisseurs publiant cartographies amortissement température-dépendantes et conseils calibrage gagnent contrats flotte. »

- Dave Polke, technicien ASE Master/L1 et formateur : « La plupart des retours sont erreurs process. Alignez sous charge, utilisez azote sec, enregistrez pressions charge, revérifiez après rodage avant toucher valvulation. »

Outils et ressources pratiques

- SAE Mobilus (conception amortisseur, cavitation, validation flotte) : https://www.sae.org/

- Normes ASTM (D445/D2270 viscosité huile/VI ; B117 corrosion) : https://www.astm.org/

- Geotab (accel verticale RMS, analyses événements ESC/ABS) : https://www.geotab.com/

- NHTSA (conseils calibrage/service ADAS après travaux suspension) : https://www.nhtsa.gov/

- Specs benchmark et catalogues : https://www.ridefox.com/, https://www.bilstein.com/, https://www.kyb.com/

Dernière mise à jour : 2025-10-09

Journal des modifications : Ajout 5 FAQ ciblées flotte (plages pression, impact EV, KPI, mousse-cell vs IFP, documentation) ; tableau tendances 2025 avec métriques adoption/performance ; deux études cas flotte (livraison EV biais rebond, utilitaire traçabilité QR) ; points vue experts ; outils/ressources pratiques avec liens autorisés

Date révision prochaine et déclencheurs : 2026-03-31 ou avant si SAE/ISO publient nouvelles specs amortisseur température-dépendantes pour flottes, tendances charge EV décalent conseils rebond >10 %, ou définitions KPI télématiques pour maintenance suspension mises à jour