What Is the Function of External Reservoirs in Shock Absorbers?

septembre 8, 2025

Partager cet article

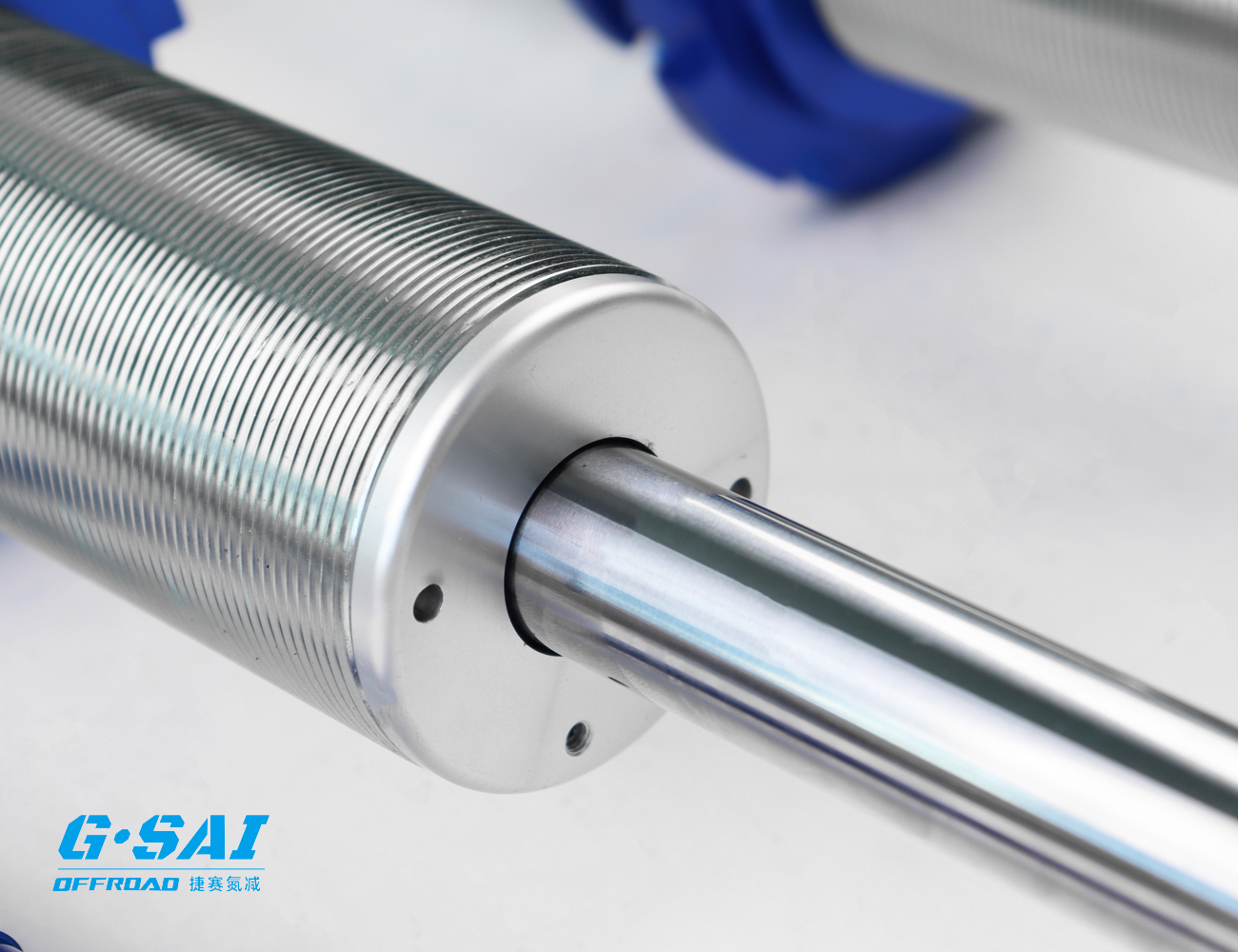

1. What Is an External Reservoir in Shock Absorbers?

Un external reservoir in a shock absorber is an additional chamber that holds hydraulique fluid and nitrogen gas separately from the main shock body. This design is commonly found in high-performance and off-road shock absorbers where thermal management and extended travel are critical. It is engineered to offer better performance d'amortissement, cooling efficiencyet longer shock life under extreme conditions.

Key Components of an External Reservoir Shock Absorber

| Composant | Fonction |

|---|---|

| Main Shock Body | Houses the piston and primary damping fluid |

| Réservoir externe | Contains additional nitrogen gas and/or hydraulic oil |

| High-Pressure Hose or Tube | Connects the reservoir to the main shock body |

| Piston flottant | Separates the gas and oil in the reservoir to prevent cavitation |

| Compression Adjuster (optional) | Allows tuning of damping characteristics based on terrain or load |

Benefits of External Reservoir Shock Absorbers in B2B Applications

- Dissipation de la chaleur : Increased fluid volume improves cooling, essential for racing and long-haul applications.

- Reduced Cavitation: The separation of nitrogen gas and oil prevents aeration, ensuring consistent damping.

- Extended Stroke: The remote reservoir allows more room in the main body for piston travel, ideal for high-travel suspension systems.

- Customization Flexibility: Allows for réglage de précision, making them ideal for OEM, specialty vehicle manufacturerset aftermarket performance brands.

For businesses in the automotive supply chain, understanding and offering these shock absorbers can lead to higher value product lines et better customer retention in the performance parts segment.

2. Applications of External Reservoir Shock Absorbers in Off-Road and Modified Vehicles

External reservoir shocks are not just niche products for racing—they are a critical component in various commercial, industrial, and performance automotive sectors. Their reliability and adaptability make them indispensable for off-road racing teams, vehicle modifiers, OEMet specialty fleet managers.

Common Applications

| Industry/Use Case | Application Examples |

|---|---|

| Course hors route | Baja 1000, Rallye Dakar, King of the Hammers |

| Véhicules modifiés 4×4 | Jeep Wranglers, Toyota Land Cruisers, Ford Raptors |

| Utility and Fleet Vehicles | Mining trucks, emergency rescue vehicles, defense and tactical units |

| Véhicules de loisirs (VR) | Overlanding vans, expedition trucks |

| Motorsport and Performance Cars | Drift cars, time attack vehicles, hill climb racers |

Why External Reservoirs Are Essential in These Applications

- High-Speed Stability: Maintains consistent damping even after extended use at high speeds or rough terrain.

- Thermal Protection: Prevents shock fade due to overheating, especially in desert and trail applications.

- Load-Carrying Capacity: Helps manage heavier loads, especially in Véhicules de loisirs et utility trucks.

- Custom Tunability: Idéal pour aftermarket suspension tuning, allowing businesses to target niche markets.

G·SAI, a leading manufacturer of customized high-performance shock absorbers, specializes in external reservoir technologies that cater to these demanding applications. Their products are used in top-tier racing and recreational vehicles, offering precision damping control et durability under extreme conditions. Learn more about their solutions on their page produit.

3. Types of External Reservoir Shock Absorbers: Piggyback vs Remote Reservoir

There are two main types of external reservoir shock absorbers used in high-performance and commercial applications: piggyback et réservoir à distance types. Choosing the right type depends on vehicle space, installation preferences, and performance requirements.

Piggyback Reservoirs

Piggyback reservoirs are directly attached to the main shock body. This makes installation easier and more compact, especially in vehicles with limited space.

Avantages :

- Easier installation (no hoses needed)

- More compact and self-contained

- Common in racing and performance applications

Inconvénients :

- Less flexibility in positioning

- May experience heat transfer from the main body

Réservoirs éloignés

Remote reservoirs are connected to the shock body via a high-pressure hose, allowing more freedom in placement. This is ideal for custom vehicle builds et applications needing better cooling.

Avantages :

- Better thermal management (reservoir can be mounted in cooler locations)

- Greater oil volume and stroke length

- Easier access to adjusters in confined chassis setups

Inconvénients :

- Installation plus complexe

- Requires additional space for hose routing

| Fonctionnalité | Réservoir Piggyback | Réservoir à distance |

|---|---|---|

| Installation | Easier, compact | More complex, flexible |

| Efficacité du refroidissement | Modéré | Haut |

| Ajustement | Limited by position | Highly accessible |

| Application | Course automobile, voitures de performance | Off-road, 4×4, RVs |

Pour les acheteurs B2B, tels que distributeurs de pièces automobiles et grossistes—stocking both types ensures coverage across a wide customer base, from performance car builders à overland outfitters.

G·SAI offers both piggyback and remote reservoir solutions, each designed with precision machining et custom-tuned valving. Their factory, equipped with CNC machining centers and a simulation lab, ensures consistent une qualité de type OEM. Visitez leur page de présentation de l'entreprise to understand how G·SAI supports wholesale partners and racing teams worldwide.

4. Performance Solutions Using External Reservoir Shock Absorbers

External reservoir shock absorbers offer a spectrum of performance benefits that are not achievable with standard monotube or twin-tube dampers. For Acheteurs B2B, y compris marques automobiles, gestionnaires de flotteet aftermarket parts suppliers, understanding these solutions is vital for delivering value to niche, high-demand markets.

Core Performance Advantages

Let’s explore how external reservoir systems outperform traditional shock absorbers in demanding environments:

| Mesure de la performance | Amortisseurs standard | Amortisseurs à réservoir externe |

|---|---|---|

| Dissipation de la chaleur | Limitée | Excellent (larger fluid volume) |

| Stroke Travel | Modéré | Extended (ideal for off-road travel) |

| Résistance à la décoloration | Modéré à faible | High (due to nitrogen/oil separation) |

| Manutention des charges | Standard | Superior (for heavy-duty applications) |

| Réglage de l'amortissement | Limitée | High (multi-stage compression/rebound) |

Key Engineering Features

- Floating Piston Design: Eliminates oil foaming and maintains constant damping pressure.

- High-Pressure Nitrogen Charging: Enhances responsiveness during high-speed compression.

- Valve à plusieurs étages: Enables progressive damping across various terrain types.

- External Adjusters: Allow for quick, tool-free tuning in the field.

These features make external reservoir shocks indispensable in sectors such as:

- Competitive Motorsports

- Heavy-duty Utility Fleet Management

- Specialty Vehicle Manufacturing

- 4×4 and Overland Vehicle Conversions

Case Study: Off-Road Teams & Custom Builders

Off-road racing teams using G·SAI external reservoir shocks have reported:

- 35% longer shock life under extreme use

- 28% reduction in heat fade during desert stages

- Significantly improved cornering control and bottom-out resistance

G·SAI’s engineering team, led by Ingénieur en chef Cai Xianyun, brings 17 years of expertise to the table. His background in custom shock tuning for racing and utility vehicles ensures that each product is tailored for high-demand applications. For tailored inquiries or bulk orders, reach out through G·SAI’s page de contact.

5. External Reservoir vs Internal Reservoir: Which Is Better for Your Fleet?

When evaluating shock absorber systems for your business or fleet, it’s important to compare external reservoir designs with internal (monotube or twin-tube) units. The decision should be based on vehicle use, performance demands, load conditions, and maintenance cycles.

Comparative Analysis

| Fonctionnalité | Internal Reservoir Shocks | Amortisseurs à réservoir externe |

|---|---|---|

| Coût | Plus bas | Higher (but better ROI in long term) |

| Facilité d'installation | Plus facile | Slightly complex |

| Performance sous charge | Modéré | Exceptional |

| Resistance to Heat Fade | Faible à modéré | Haut |

| Customization & Tuning | Limitée | Étendue |

| Convient pour | Daily driving, light-duty use | Racing, off-road, fleet, RVs |

Application-Based Recommendations

| Type de véhicule | Type d'amortisseur recommandé | Raison |

|---|---|---|

| Passenger Cars | Internal Reservoir | Cost-effective for normal use |

| Véhicules tout-terrain | Réservoir externe | Handles rough terrain, better cooling |

| RVs & Expedition Vans | Réservoir externe | Manages heavy loads and long travel |

| Racing Vehicles | Réservoir externe | High-speed performance & adjustability |

| Utility Fleet Trucks | External Reservoir (Remote) | Custom fit for high-load, high-heat use |

ROI Considerations for B2B Buyers

While external reservoir shock absorbers come at a higher upfront cost, they provide:

- Reduced maintenance cycles

- Longer operating life

- Better adaptability across environments

Pour OEM builders, les distributeurset gestionnaires de flotte, investing in external reservoir systems leads to higher customer satisfaction and reduced downtime.

G·SAI’s factory capabilities allow them to customize shock performance for specific load profiles, terrain types, and vehicle geometries. Their in-house laboratoire de modification des véhicules ensures each design is tested against real-world scenarios. Discover more about their technical strength on the Entreprise page.

6. How to Assemble and Maintain Shock Absorbers with External Reservoirs

Proper assembly and maintenance of external reservoir shock absorbers are critical for optimal performance and longevity, especially in commercial or racing environments. For aftermarket installers, distributeurs de pièces détachées automobileset fleet service teams, mastering these processes is key to maintaining product quality and customer trust.

Assembly Process: Step-by-Step

- Mount the Main Shock Unit

- Secure it to the designated suspension points.

- Ensure torque specs match OEM or custom chassis guidelines.

- Position the Reservoir

- Choose a location away from excessive heat (e.g., exhaust components).

- Use reservoir brackets or clamps for secure mounting.

- Connect the High-Pressure Hose

- Ensure no kinks or bends in the line.

- Tighten fittings using a torque wrench to prevent leaks.

- Charge with Nitrogen

- Use a regulated nitrogen filling station.

- Pressure typically ranges from 150–300 PSI depending on vehicle weight and use.

- Dial in Compression/Rebound Adjusters

- Start at manufacturer-recommended settings.

- Fine-tune based on terrain or driver feedback.

Maintenance Guidelines

| Tâche | Fréquence | Notes |

|---|---|---|

| Inspection visuelle | Tous les 5 000 km | Check for leaks, loose fittings, or hose damage |

| Nitrogen Recharge | Tous les 10 000 km | Maintain correct pressure for consistent damping |

| Fluid Replacement | Annuellement | Especially for racing or high-heat environments |

| Seal Inspection | Tous les 20 000 km | Replace if wear or seepage is detected |

Pro Tips for Installers and Fleet Managers

- Always use OEM-approved nitrogen and avoid compressed air.

- Label reservoir hoses for left/right and front/rear to avoid mismatched damping.

- Record compression and rebound settings for fleet standardization.

La G-SAI fournit technical training and documentation for B2B clients, including marques automobiles, les équipes de courseet opérateurs de flotte. Their one-on-one support ensures your team can confidently install and service external reservoir systems. Explore their réseau d'assistance aux distributeurs to start offering G·SAI products to your customers.

7. How to Choose the Right External Reservoir Shock Absorber for Your Business

Selecting the right external reservoir shock absorber is critical for les distributeurs, vehicle modification shops, OEM buyerset gestionnaires de flotte who need both durability and performance. Your choice will directly affect vehicle handling, shock longevity, and end-user satisfaction.

Principales considérations pour les acheteurs B2B

- Vehicle Type and Application

- Off-road racing? Choose long-travel, remote reservoir shocks.

- Heavy-duty utility trucks? Opt for piggyback with high-pressure nitrogen.

- RVs and overland rigs? Look for adjustable damping and load-rated designs.

- Load Weight and Suspension Travel

- Heavier vehicles require stiffer valving and higher nitrogen pressure.

- More suspension travel demands larger stroke lengths and reservoir volume.

- Terrain and Operating Environment

- High-temperature desert terrain: prioritize thermal management.

- Muddy or snowy environments: focus on corrosion resistance and sealing.

- Besoins de personnalisation

- Do you require tunable shocks for racing or specialty builds?

- Is branding or private labeling important for your business?

Specification Checklist

| Specification | Description | Cas d'utilisation idéal |

|---|---|---|

| Longueur de course | Distance the piston travels | Long-travel suspension systems |

| Type de réservoir | Piggyback or remote | Space and access considerations |

| Ajustement de la compression et du rebond | External knobs or internal settings | Tuning for performance or comfort |

| Nitrogen Pressure Range | PSI capacity (150–300 PSI common) | Higher for racing, lower for comfort |

| Mounting Style | Eyelet, clevis, or custom | Must match vehicle suspension geometry |

| Sealing Technology | Dust boots, shaft seals | Important for durability in off-road use |

Sourcing Through a Trusted Manufacturer: G·SAI

G·SAI offers a wide range of external reservoir shock absorbers tailored to B2B requirements. Whether you’re an off-road performance brand or a fleet operator, G·SAI provides:

- Custom valving and tuning per vehicle type

- OEM-level manufacturing with CNC-machined components

- Bulk order capabilities with fast production lead times

- Private labeling options for brand owners

Their expert engineering team can work directly with your technical department to ensure the shock absorber is built to your vehicle specs, usage conditions, and branding needs. Explore the full product line here.

8. Custom External Reservoir Shock Absorber Solutions: What You Need to Know

Many B2B buyers require shock absorber solutions that go beyond off-the-shelf products. Whether you’re building a fleet of expedition vehicles, launching a custom performance car line, or outfitting military-grade trucks, custom shock absorbers with external reservoirs are often essential.

L'importance de la personnalisation dans le B2B

- Vehicle-Specific Geometry

Custom mounting points and shaft lengths ensure compatibility with non-standard suspensions. - Load and Performance Matching

Valving can be matched to exact vehicle weights, payloads, and usage profiles. - Positionnement de la marque

Private label shock absorbers enhance product lines for aftermarket brands. - Conformité réglementaire

Custom solutions can comply with regional safety or performance regulations.

Capacités de personnalisation de G-SAI

G·SAI is one of the only Chinese manufacturers offering full-spectrum customization for high-end external reservoir shocks. Their capabilities include:

- Support technique personnalisé: Work with Cai Xianyun, the chief technical engineer with 17 years of experience in racing and modified shock systems.

- Tests de simulation: Every custom part is validated through G·SAI’s vehicle simulation lab for real-world performance.

- Prototypage rapide: CNC machining allows for quick turnaround on new designs.

- Batch Production Flexibility: Scale your custom orders from small test runs to large OEM shipments.

Customization Process Overview

| Étape | Action |

|---|---|

| 1. Requirement Brief | Submit vehicle data, expected load, and terrain types |

| 2. Design Phase | CAD modeling and damping curve simulation |

| 3. Prototype | CNC-machined sample unit delivered for testing |

| 4. Validation | Road and lab testing with tuning adjustments |

| 5. Production | Scaled manufacturing with quality control |

Whether you’re an automotive brand launching a new model or a parts wholesaler seeking an exclusive product line, G·SAI can deliver amortisseurs conçus sur mesure that meet your business goals. Reach out via their page de contact to start a custom order inquiry.

9. FAQ: External Reservoir Shock Absorbers for B2B Buyers

Q1: What industries use external reservoir shock absorbers the most?

A : These shocks are widely used in:

- Off-road racing (Baja, Dakar)

- Modified vehicle builds (Jeep, Land Cruiser)

- RV and overlanding vehicle manufacturing

- Utility and tactical fleets

- Performance sports cars

Q2: Are external reservoir shocks worth the investment for commercial fleets?

A : Yes. Although the upfront cost is higher, the long-term benefits—such as extended service life, reduced heat fadeet improved handling under load—lead to un coût total de possession plus faible for fleets.

Q3: Can I order external reservoir shocks that are tuned for specific vehicles?

A : Absolument. La G-SAI est spécialisée dans des solutions sur mesure. Their team can design shock absorbers based on your vehicle’s suspension geometry, weight, and usage environment.

Q4: What’s the minimum order quantity for B2B custom shock absorbers?

A : G·SAI offers flexible order quantities. While bulk orders receive better pricing tiers (high, medium, low), they also accommodate small batch prototyping for OEM developers and specialty builders.

Q5: How do I become a G·SAI distributor?

A : Visitez le site page du réseau de distributeurs to learn how you can apply. G·SAI offers marketing support, technical training, and exclusive territory coverage for qualified partners.

Conclusion: Elevate Your Product Line with External Reservoir Shock Absorbers

For B2B buyers in the automotive, off-road, and modification industries, external reservoir shock absorbers are a powerful upgrade that directly enhances vehicle performance, durability, and brand value. Whether you’re managing a fleet, launching a new vehicle line, or distributing high-performance parts, these shocks offer unmatched thermal efficiency, stroke travelet contrôle de l'amortissement.

G-SAI stands at the forefront of this technology in China, providing:

- Custom tuning based on real-world use

- OEM-grade production with CNC precision

- Global B2B support and bulk supply capabilities

Upgrade your inventory or fleet today by partnering with G·SAI. Check out their A propos de nous to dive deeper into their manufacturing capabilities, or start your wholesale order through their formulaire de contact.