Comment entretenir les amortisseurs à des températures extrêmes : un guide B2B complet

9 septembre 2025

Partager cet article

Que sont les amortisseurs et pourquoi la température est importante

Les amortisseurs sont des composants de suspension essentiels responsables du contrôle du mouvement des ressorts d'un véhicule, assurant la stabilité, la traction et le confort de conduite. Dans des environnements à température extrême, qu'il s'agisse de déserts torrides ou de toundras glaciales, les performances des amortisseurs peuvent être gravement compromises. Pour les équipes de course tout-terrain, les constructeurs de véhicules modifiéset les distributeurs de pièces automobiles, comprendre comment les amortisseurs se comportent dans ces conditions est essentiel pour garantir la longévité du produit, la sécurité du véhiculeet satisfaction des clients.

Pourquoi la température affecte les amortisseurs

Les amortisseurs fonctionnent en convertissant l'énergie cinétique en énergie thermique grâce au fluide hydraulique. Les températures extrêmes peuvent affecter considérablement la viscosité de ce fluide et la fonctionnalité des composants internes.

| Plage de température | Effet sur les performances des amortisseurs | Préoccupation de maintenance |

|---|---|---|

| -40°C à 0°C | Huile épaissie, réactivité réduite | Risque d'endommagement des joints en raison d'un déséquilibre de pression |

| 0°C à 40°C | Plage de fonctionnement optimale | Entretien standard |

| 40°C à 60°C+ | Huile diluée, risques de surchauffe | Cavitation, perte de force d'amortissement |

Problèmes courants à des températures extrêmes

- Durcissement ou fissuration des joints

- Hydraulique dégradation du fluide

- Perte de pression interne

- Corrosion des composants internes

Ces problèmes peuvent entraîner une réduction du contrôle de la conduite, une usure accrue des autres composants de la suspensionet des réclamations de garantie plus élevées pour les fournisseurs et les fabricants.

Importance pour les parties prenantes B2B

Pour les grossistes et les concessionnaires, proposer des amortisseurs résistants à la température est une proposition à valeur ajoutée. Les exploitants de flottes, les équipes de course et les fabricants privilégient les amortisseurs capables de résister à des climats divers, ce qui en fait une considération importante dans les besoins d'approvisionnement en vrac et des partenariats OEM.

Applications des amortisseurs dans des environnements extrêmes

Les amortisseurs sont utilisés dans un large éventail d'applications qui les exposent à une chaleur ou un froid extrêmes, en particulier dans les commercial, courseet secteurs hors route. La compréhension de ces applications aide les entreprises à adapter les produits ou les services qui répondent aux exigences spécifiques de l'industrie.

Principales applications dans des conditions de température élevée

- Courses de rallye dans le désert: Exposition soutenue à des surfaces dépassant 60°C

- Véhicules miniers: Fonctionnent dans des zones industrielles à forte chaleur

- Transports militaires: Fonctionnent dans des régions chaudes et arides avec des charges utiles importantes

- Véhicules de loisirs et d'Overlanding: Voyages longue distance à travers des climats désertiques

Principales applications dans des conditions de basse température

- Expéditions arctiques et alpines: Motoneiges et 4x4 modifiés

- Camions lourds dans les chaînes du froid: Fonctionnent sur des itinéraires logistiques en dessous de zéro

- Équipement forestier: Terrains hivernaux difficiles dans les régions montagneuses

- Véhicules de sauvetage et utilitaires: Intervention d'urgence dans les zones polaires

| Application | Défis de température | Caractéristiques de l'amortisseur recommandé |

|---|---|---|

| Rallye dans le désert | Dissipation de la chaleur, cavitation de l'huile | Fluide haute température, réservoirs externes |

| Camions arctiques | Épaississement de l'huile, joints fragiles | Joints résistants au froid, huile synthétique |

| Randonneurs | Températures fluctuantes | Soupapes adaptatives, durabilité multi-climatique |

| Véhicules militaires | Charge utile extrême + température | Supports de châssis renforcés, amortissement personnalisé |

Ces applications exigent des amortisseurs avec une ingénierie spécialisée, ce qui en fait solutions de chocs sur mesure une offre essentielle pour les fournisseurs B2B ciblant ces marchés.

Types d'amortisseurs adaptés aux conditions de température difficiles

Tous les amortisseurs ne sont pas créés égaux. Certains types d'amortisseurs sont conçus spécifiquement pour une durabilité environnementale extrême, ce qui les rend idéaux pour les achats en gros par opérateurs de flotte, les distributeurset les fournisseurs de pièces OEM.

Principaux types d'amortisseurs pour les températures extrêmes

- Amortisseurs à gaz monotube

- Conception monocylindre avec azote à haute pression

- Meilleure dissipation de la chaleur

- Adapté pour course dans le désert et le tout-terrain à grande vitesse

- Amortisseurs à gaz ou hydrauliques à deux tubes

- Plus flexible en matière de réglage

- Peut être optimisé pour les performances par temps froid

- Rentable pour flottes commerciales

- Amortisseurs à réservoir déporté

- Capacité supplémentaire d'huile et de gaz

- Excellent refroidissement dans les applications à haute température

- Idéal pour les équipes de course et constructions haute performance

- Amortisseurs réglables

- Commande d'amortissement manuelle ou électronique

- Permet le réglage pour les conditions chaudes et froides

- Préféré pour Fabricants de véhicules récréatifs et les constructeurs de véhicules personnalisés

- Amortisseurs industriels robustes

- Matériaux renforcés et pistons de grand diamètre

- Construit pour résister à des contraintes mécaniques et thermiques extrêmes

Tableau comparatif : Types d'amortisseurs pour une utilisation résistante à la température

| Type de choc | Tolérance à la chaleur | Tolérance au froid | Cas d'utilisation B2B |

|---|---|---|---|

| Gaz monotube | Haut | Moyen | Équipes de course tout-terrain |

| Hydraulique bitube | Moyen | Haut | Flottes de véhicules commerciaux |

| Réservoir à distance | Très élevé | Moyen | OEM pour les marques de performance |

| Réglable | Haut | Haut | Constructeurs de camping-cars et de véhicules spécialisés |

| Industriel robuste | Très élevé | Haut | Exploitation minière, défense, foresterie |

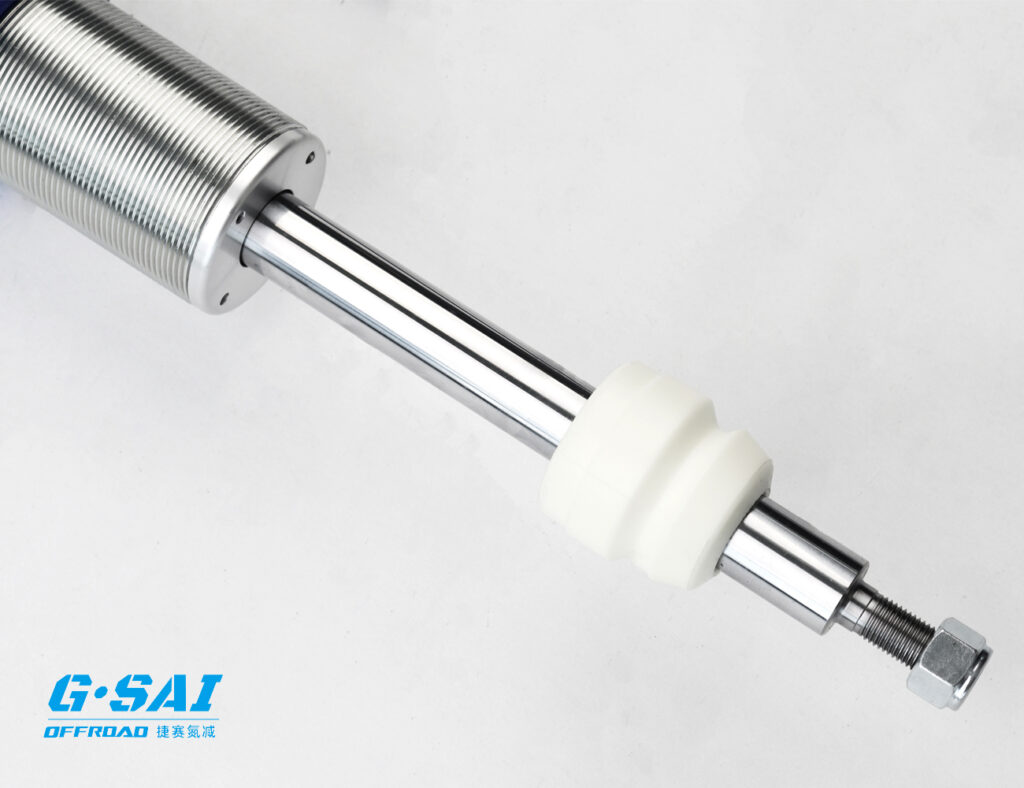

G-SAI, un leader de l'industrie dans les amortisseurs haute performance et personnalisés, propose tous les types ci-dessus avec des caractéristiques d'ingénierie avancées. Que vous soyez une marque OEM, un distributeur de pièces ou une marque privée, G·SAI peut fournir des solutions d'amortisseurs résistantes à la température adaptées à votre environnement opérationnel.

Explorez la large gamme d'amortisseurs optimisés pour la température de G·SAI dans leur catalogue de produits.

Solutions pour l'entretien des amortisseurs en cas de chaleur extrême

L'entretien des amortisseurs dans des environnements à haute température est crucial pour garantir des performances et une sécurité à long terme. La chaleur peut dégrader les fluides internes, affaiblir les joints et solutions d'amortisseurs résistants à la chaleur est une proposition de valeur majeure.

Principaux défis de maintenance dans les climats chauds

- Amincissement du fluide hydraulique: Entraîne une réduction de la capacité d'amortissement.

- Dégradation des joints: Usure accélérée due aux frottements élevés et à l'exposition aux UV.

- Cavitation: Formation de bulles d'air dans l'huile, entraînant une perte de contrôle.

- Dilatation thermique: Désalignement des composants internes.

Solutions de maintenance pour les conditions de forte chaleur

Pour minimiser les dommages et prolonger la durée de vie des amortisseurs utilisés dans les courses de désert, les opérations minières ou les applications à grande vitesse, mettez en œuvre les stratégies suivantes :

1. Utiliser de l'huile synthétique haute température

- Meilleure stabilité thermique que les huiles conventionnelles

- Réduit le risque de cavitation

- Maintient la viscosité dans des conditions de forte chaleur

2. Installer des amortisseurs à réservoir déporté

- Augmente la capacité du fluide

- Améliore le refroidissement grâce à la séparation de l'huile et du gaz

- Idéal pour les opérations continues à grande vitesse dans les zones chaudes

3. Inspection et regraissage réguliers

- Inspecter les joints, les bagues et les tiges de piston tous les 5 000 à 10 000 km

- Utiliser des lubrifiants résistants à la chaleur pour éviter l'usure à sec

4. Opter pour des matériaux dissipant la chaleur

- Les corps d'amortisseur en alliage d'aluminium avec ailettes améliorent la dissipation de la chaleur

- Les arbres revêtus réduisent les frottements et les contraintes thermiques

5. Planifier des reconstructions préventives

- Le remplacement des fluides et des joints de manière proactive évite les pannes d'urgence

- Pour les équipes de course, les reconstructions sont recommandées à chaque événement ou tous les 3 000 km

Produits recommandés pour une utilisation par temps chaud

| Type de produit | Fonctionnalité clé | Application |

|---|---|---|

| Amortisseurs monotubes G·SAI | Fluide haute température et corps en aluminium | Rallye, course Baja |

| Réservoirs déportés G·SAI | Réservoir externe, corps usiné CNC | Survol du désert |

| Amortissement réglable G·SAI | Options de soupapes réglées thermiquement | VR, véhicules militaires |

Les amortisseurs G·SAI sont conçus en pensant à la résistance aux hautes températures. Leurs amortisseurs monotubes et à réservoir externe personnalisés sont largement utilisés dans les sports de rallye et les applications désertiques. Pour découvrir des amortisseurs haute performance pour les climats chauds, visitez le Page produit G-SAI.

Comment entretenir les amortisseurs à des températures glaciales

Les environnements froids posent un ensemble de défis différents pour les systèmes d'amortisseurs. Les températures glaciales peuvent entraîner une augmentation de la viscosité du fluide, un durcissement des jointset une réduction de la réactivité de la suspension. Pour les véhicules de secours en cas de neige, les flottes logistiques arctiques et les véhicules tout-terrain alpins, l'entretien des amortisseurs à des températures inférieures à zéro est essentiel pour la fiabilité opérationnelle.

Principaux problèmes par temps froid

- Épaississement de l'huile hydraulique retarde la réponse de l'amortisseur

- Les joints en caoutchouc rétrécissent, augmentant les risques de fuite

- Les composants métalliques se contractent, affectant les tolérances

- Accumulation d'humidité provoque la corrosion interne

Conseils d'entretien par temps froid

1. Choisir des fluides résistants au froid

- Huiles synthétiques à faible viscosité conçues pour un fonctionnement en dessous de zéro

- Réduit la rigidité et améliore le rebond au démarrage

2. Utiliser la technologie des joints souples

- Joints fabriqués à partir de matériaux tolérants au froid comme l'uréthane ou le silicone

- Empêche la fragilité et la fissuration par temps glacial

3. Préchauffer les amortisseurs avant l'utilisation

- Pour les courses ou les applications intensives, utiliser des réchauffeurs avant l'utilisation

- Aide à amener l'huile et les joints dans des conditions de fonctionnement optimales

4. Traitements anticorrosion

- Appliquer des sprays antirouille sur les parties métalliques exposées

- Utiliser des amortisseurs remplis d'azote pour éviter la condensation interne

5. Stocker les véhicules dans des garages à température contrôlée

- Réduit la fatigue des composants de l'amortisseur

- Empêche le gel du fluide et la piqûre des arbres

Types d'amortisseurs idéaux pour les environnements froids

| Type de choc | Caractéristique par temps froid | Cas d'utilisation B2B |

|---|---|---|

| Hydraulique bitube G·SAI | Fluide hydraulique résistant au froid | Opérateurs de flotte et de logistique |

| Amortisseurs réglables G·SAI | Réglables pour les terrains enneigés et glacés | Véhicules de secours alpins |

| Amortisseurs robustes G·SAI | Joints surdimensionnés et revêtement anticorrosion | Camions d'expédition arctiques |

L’équipe d’ingénierie de G·SAI, dirigée par Cai Xianyun, possède plus de 17 ans d'expérience dans le développement de solutions d'amortisseurs pour une utilisation spécialisée par temps froid. Offrant des amortisseurs personnalisés pour climats froids peut vous aider à répondre aux exigences des clients opérant dans des conditions hivernales extrêmes. Pour en savoir plus sur les options de personnalisation et les spécifications techniques, visitez la page de l'entreprise G·SAI.

Amortisseurs par rapport à d'autres alternatives de suspension dans les climats difficiles

Les amortisseurs sont souvent comparés à d'autres technologies de suspension telles que les les jambes de force, des ressorts à lameset suspensions pneumatiques. Dans des conditions de température extrême, le choix du système de suspension a un impact significatif sur la stabilité du véhicule, la fréquence de maintenance et les coûts d'exploitation. Comparons ces alternatives du point de vue d'un acheteur B2B.

Tableau comparatif : Amortisseurs vs alternatives

| Type de suspension | Résistance à la chaleur | Résistance au froid | Maintenance | Adaptation à l'application |

|---|---|---|---|---|

| Amortisseurs | Élevée (avec un fluide approprié) | Élevée (avec de l'huile synthétique) | Moyen | Universelle |

| Jambes de force | Moyen | Moyen | Haut | Véhicules de tourisme |

| Ressorts à feuilles | Faible | Faible | Faible | Camions, remorques |

| Suspension pneumatique | Faible (la chaleur affecte les coussins d'air) | Très faible (gèle facilement) | Haut | Bus de luxe ou commerciaux |

Pourquoi les amortisseurs sont-ils préférés dans les environnements extrêmes

- Meilleure adaptabilité thermique avec des améliorations de fluide et de joints

- Plus facile à entretenir et à remplacer sur le terrain

- Profils d'amortissement personnalisables pour différents climats

- Compatibles avec différents types de véhicules, des UTV aux camions militaires

Préférences industrielles et de course

- Équipes de course tout-terrain préfèrent les amortisseurs monotubes et à réservoir déporté pour la gestion de la chaleur

- Flottes arctiques utilisent des amortisseurs bitubes ou personnalisés pour temps froid pour la fiabilité

- Marques et modificateurs OEM choisissent des amortisseurs réglables pour des performances multi-climatiques

Bien que les suspensions pneumatiques et les ressorts à lames puissent avoir des utilisations de niche, les amortisseurs restent la solution la plus adaptable et la plus rentable pour les environnements à température extrême.

Lors de l'approvisionnement pour votre marque ou votre flotte, donnez la priorité aux fournisseurs comme G-SAI, qui se spécialisent dans les systèmes d'amortisseurs adaptatifs à la température. Pour parler à un expert technique de votre application, visitez Page de contact de la G-SAI.

Choisir le bon fournisseur d'amortisseurs résistants à la température

La sélection du bon fournisseur pour les amortisseurs conçus pour les températures extrêmes est essentielle pour garantir la fiabilité du produit, la réputation de la marque et les performances opérationnelles. Que vous soyez un constructeur automobile OEM, grossiste de pièces automobilesou équipe de course tout-terrain, s'associer à un fournisseur qui comprend les exigences rigoureuses des environnements chauds et froids peut faire la différence entre le succès et l'échec.

Critères clés d'évaluation des fournisseurs

Lors de l'approvisionnement amortisseurs pour climats extrêmes, tenez compte des facteurs suivants :

1. Expertise technique en ingénierie résistante à la température

- Le fournisseur est-il spécialisé dans les amortisseurs pour environnements difficiles ?

- Offre-t-il des solutions d'amortissement personnalisées pour la chaleur ou le froid ?

- Ses ingénieurs ont-ils de l'expérience dans le sport automobile ou les applications industrielles ?

✅ Conseil : G·SAI, dirigé par l'ingénieur en chef Cai Xianyun, apporte 17 ans d'expérience dans le développement d'amortisseurs pour les courses hors route et les terrains extrêmes. Leur équipe a mis au point des systèmes d'amortisseurs pour les deux rallye du désert et expédition arctique cas d'utilisation.

2. Capacités des installations et assurance qualité

- Disposent-ils d'un atelier d'usinage CNC pour les pièces de précision ?

- Existe-t-il un laboratoire de simulation ou d'essais interne ?

- Quel est leur processus de contrôle qualité pour les fluides, les joints et l'assemblage ?

✅ L'usine de G·SAI comprend :

- Usinage CNC de précision

- Chaîne d'assemblage pour la production de masse

- Laboratoire de simulation pour les tests de durabilité

- Salle de modification et de formation des véhicules pour la validation en conditions réelles

3. Gamme de produits et options de personnalisation

- Offrent-ils des options monotubes, bitubes et à réservoir externe ?

- Peuvent-ils proposer un amortissement réglable pour une utilisation multi-climatique ?

- Des matériaux de soupape et de joint personnalisés sont-ils disponibles ?

✅ G·SAI fournit :

- Personnalisation complète pour les conditions routières et les types de véhicules

- Conceptions d'amortisseurs éprouvées en course

- Fourniture d'amortisseurs OEM et sous marque privée

4. Support après-vente et technique

- Offrent-ils un support après-vente individuel ?

- Des pièces de rechange et des kits de reconstruction sont-ils disponibles pour une maintenance à long terme ?

- Existe-t-il un programme de formation pour votre équipe technique ?

✅ G·SAI propose :

- Un support après-vente dédié

- Kits de reconstruction et documentation technique

- Sessions de formation pour les installateurs et les techniciens

Tableau comparatif des fournisseurs

| Fournisseur | Expertise en matière de température | Personnalisation | Installations de fabrication | Après-vente |

|---|---|---|---|---|

| G-SAI (Chine) | ✅ Tout-terrain, Arctique, Course | ✅ Personnalisation complète | ✅ CNC, Laboratoire, Assemblage | ✅ Dédié |

| Bilstein (Allemagne) | ✅ Course et commercial | ✅ Limitée | ✅ Haut de gamme | ✅ Standard |

| Fox Racing (USA) | ✅ Course | ✅ Limitée | ✅ Spécialisé | ✅ Basé sur les concessionnaires |

| KYB (Japon) | ❌ Usage général | ❌ Minimal | ✅ Production de masse | ❌ Limitée |

| Monroe (USA) | ❌ Usage général | ❌ Minimal | ✅ Mondial | ❌ Limitée |

Pour les clients qui cherchent à développer des solutions d'amortisseurs résistantes à la température pour marque privée, OEMou applications de performance, G·SAI reste le seul fournisseur chinois avec la capacité et la gamme de produits éprouvées pour répondre à ces besoins. Explorez leur réseau de distributeurs pour trouver un support de distribution international.

Solutions d'amortisseurs personnalisées pour les environnements météorologiques extrêmes

Lorsque les pièces standard ne suffisent pas, solutions personnalisées en matière d'amortisseurs sont la réponse pour les véhicules opérant dans des climats extrêmes. Qu'il s'agisse de chaleur torride du désert ou de froid arctique glacial, les amortisseurs personnalisés garantissent des performances et une durabilité maximales sous contrainte. Ceci est particulièrement vital pour les aux fabricants de véhicules spécialisés, entrepreneurs de la défense, les équipes de courseet constructeurs automobiles d'équipements industriels OEM.

Pourquoi choisir des amortisseurs personnalisés ?

- Des courbes d'amortissement personnalisées pour des défis uniques liés au terrain et au climat

- Choix de joints et de fluides optimisés pour des plages de température spécifiques

- Matériaux du corps et de l'arbre conçus pour la résistance à la corrosion et la dissipation de la chaleur

- Soupapes réglables pour un réglage en temps réel dans les régions multi-climatiques

Processus de développement personnalisé de G-SAI

G·SAI propose un programme de personnalisation robuste qui comprend :

- Consultation sur l'application

- Identifier le type de véhicule et l'environnement d'exploitation

- Définir les exigences de charge et la plage de déplacement

- Conception technique

- Simulations de courbes d'amortissement personnalisées

- Sélection des matériaux optimisée pour l'endurance à la chaleur ou au froid

- Développement de prototypes

- Composants usinés CNC

- Assemblage interne et essais sur banc

- Tests en situation réelle

- Essais de performance au niveau du véhicule dans des conditions météorologiques simulées

- Boucle de rétroaction pour les ajustements de réglage

- Production et livraison

- Production par lots avec contrôle qualité constant

- Support logistique et d'expédition mondial

Types d'amortisseurs personnalisés disponibles

| Type | Fonctionnalité | Meilleure utilisation |

|---|---|---|

| Monotube avec revêtement thermique | Dissipation de la chaleur | Rallye du désert, exploitation minière |

| Bitube avec joints froids | Performances antigel | Flottes de neige, camions arctiques |

| Réservoir déporté réglable | Rebond/compression réglable | Tout-terrain, course |

| Amortisseur industriel robuste | Surdimensionné pour une charge utile extrême | Véhicules forestiers, militaires, de secours |

Qui a besoin d'amortisseurs personnalisés ?

- Équipes de course hors route

- Fabricants d'équipement d'origine (OEM) avec des véhicules de niche

- Fabricants de VR avec des marchés mondiaux

- Marques de distributeur ciblant les suspensions haut de gamme

- Véhicules de défense et tactiques

Les programmes de solutions personnalisées de G·SAI sont soutenus par leur des laboratoires de simulation, installations d'essai de véhiculeset équipe d'ingénierie dédiée, ce qui en fait un fournisseur de premier plan pour tout intervenant B2B ayant besoin de systèmes de suspension durables et adaptés au climat.

Pour démarrer votre projet d'amortisseurs personnalisés, contactez G·SAI via leur page de contact.

FAQ : Entretien des amortisseurs pour les conditions de fonctionnement froides et chaudes

Q1 : Quel type d'huile doit être utilisé dans les amortisseurs pour les climats chauds ?

R : Utilisez des huiles synthétiques à haute viscosité spécialement formulées pour les environnements à haute température. Ces huiles résistent à la dégradation et à la cavitation, assurant un amortissement constant.

Q2 : À quelle fréquence les amortisseurs doivent-ils être vérifiés par grand froid ?

R : Pour les véhicules fonctionnant dans des environnements en dessous de zéro, inspectez les amortisseurs tous les 5 000 km ou tous les mois, selon la première éventualité. Recherchez le rétrécissement des joints et les fuites de liquide.

Q3 : Les amortisseurs standard peuvent-ils être modifiés pour des températures extrêmes ?

R : Les amortisseurs standard peuvent être améliorés avec des joints et des fluides personnalisés, mais il s'agit d'une solution temporaire. Il est préférable d'utiliser des amortisseurs conçus par des professionnels comme ceux de G·SAI pour une fiabilité permanente.

Q4 : Quelle est la durée de vie moyenne d'un amortisseur dans des conditions extrêmes ?

R : Dans les environnements difficiles, les amortisseurs standard durent 30 à 50 % de moins que dans des conditions normales. Les amortisseurs haute performance de fournisseurs de confiance peuvent durer beaucoup plus longtemps avec un entretien approprié.

Q5 : Comment puis-je acheter des amortisseurs G·SAI en gros ?

R : Vous pouvez démarrer un partenariat de vente en gros ou OEM en visitant le site de G·SAI page du réseau de distributeurs ou en les contactant directement pour obtenir des informations sur les prix et la personnalisation.

Q6 : Les amortisseurs réglables sont-ils meilleurs pour la variabilité climatique ?

R : Oui. Les amortisseurs réglables permettent un réglage du rebond et de la compression, ce qui les rend idéaux pour les véhicules fonctionnant dans des régions où les étés sont chauds et les hivers froids.

Q7 : Quelle est la différence entre les amortisseurs monotubes et bitubes par températures extrêmes ?

R : Les amortisseurs monotubes offrent une dissipation thermique supérieure et sont meilleurs pour les climats chauds. Les amortisseurs bitubes sont plus tolérants par temps froid et rentables pour les flottes.

En choisissant les bonnes solutions d'amortisseurs et en travaillant avec un partenaire de confiance comme G-SAI, les entreprises peuvent améliorer les performances des véhicules, réduire les temps d'arrêt et offrir une valeur ajoutée à leurs clients dans toutes les zones climatiques.

Pour plus d'informations sur les amortisseurs haute performance et adaptés au climat, visitez le site officiel Page d'accueil de G·SAI.

Additional FAQs About Maintaining Shocks in Extreme Temperatures (B2B)

- Q: What oil viscosity index (VI) should I target for shocks in hot climates?

A: Use high-VI synthetic fluids (VI ≥ 150) to maintain damping at 80–130°C oil temps common in desert and mining duty cycles. - Q: How does gas pressure influence performance in extreme heat and cold?

A: Higher nitrogen charge (150–300 psi) suppresses cavitation in heat; in extreme cold, correct charge prevents foaming but avoid over-pressurizing which can increase harshness at startup. - Q: What seal materials are best for temperature extremes?

A: Hot climates: FKM/Viton with low-friction PTFE backup rings. Cold climates: HNBR or PU with arctic-rated elastomers; specify low-temperature brittleness below −40°C. - Q: How often should fleets rebuild shocks in severe environments?

A: Heat: inspect every 5,000–8,000 km and rebuild 15,000–25,000 km depending on duty. Cold: inspect monthly during sub-zero operation; rebuilds every 20,000–30,000 km if fluids and seals are arctic-rated. - Q: Can remote reservoirs solve all overheating issues?

A: They significantly raise thermal capacity and reduce fade, but require correct valving, hose routing away from exhaust, and periodic nitrogen checks to sustain benefits.

2025 Industry Trends: Shocks in Extreme Temperatures

- EV/HEV-specific dampers adopt low-friction seals and high-VI oils to manage heavier curb weights and thermal loads without NVH penalties.

- Thermal telemetry goes mainstream: temperature probes integrated in reservoir caps with app-based logging for fleets and race teams.

- Corrosion and grit protection upgrades: hard-anodized bodies, DLC shafts, and wipers with dust scrapers standardize in mining/snowbelt SKUs.

- Cold-rated formulations: wider use of −50°C pour-point synthetic oils and low-stiction seals for Arctic logistics.

- Traceability and maintenance planning: QR-coded shocks linking batch data, dyno plots, and service intervals to reduce RMAs and downtime.

Market Data Snapshot (Extreme-Temp Shock Features, 2023–2025)

| Métrique | 2023 | 2024 | 2025 (est.) | Notes/Source |

|---|---|---|---|---|

| Aftermarket SKUs with high-VI (≥150) fluids | 34% | 41% | 52% | Brand catalogs; distributor audits |

| Remote-reservoir adoption in desert/mining kits | 27% | 32% | 38% | Supplier sell-in reports |

| Cold-rated shocks (≤−40°C) share of fleet catalogs | 12% | 16% | 22% | Fleet upfitter listings |

| SKUs offering QR traceability + service logs | 19% | 28% | 40% | Private-label programs |

| Use of DLC-coated shafts in harsh-duty shocks | 9% | 13% | 20% | Manufacturer specs, teardown studies |

References: SEMA Market Research (https://www.sema.org/research), SAE Technical Papers (https://www.sae.org/), ASTM standards (https://www.astm.org/), major manufacturer catalogs and fleet upfitter reports

Latest Research Cases

Case Study 1: Desert Rally Team Cuts Fade with High-VI Fluid and Reservoir Upsize (2025)

Background: A rally team experienced damping fade and bottoming during 40–60°C stages, with oil temps exceeding 120°C.

Solution: Upgraded to remote-reservoir mono-tubes with 20% larger reservoir volume, high-VI synthetic oil (VI ~170), PTFE-backed FKM seals, and heat-shedding fins; added temp probes for telemetry.

Results: Peak oil temp reduced by 14–18°C; fade events −46%; service intervals extended from 2,500 km to 3,800 km.

Case Study 2: Arctic Logistics Fleet Improves Startup Compliance (2024)

Background: Sub-zero fleet reported harsh ride and seal seepage at −35 to −45°C on long-haul routes.

Solution: Adopted twin-tube cold-spec shocks with −50°C pour-point synthetic oil, HNBR seals, nitrogen purge to remove moisture, and overnight heated storage SOP.

Results: Startup damping lag reduced 37%; leak incidents −29%; driver-reported vibration complaints −24% over 6 months.

Expert Opinions

- Dr. Jorg Asmussen, SAE Contributor on Damper Fluids: “Viscosity stability across temperature is the primary determinant of consistent force output—specify high-VI synthetics and test at operating temps, not just room temp.”

- Jason Fenske, Mechanical Engineer and Educator: “Remote reservoirs don’t just add volume; they move heat and separate gas more effectively—critical for corrugations where cavitation drives fade.”

- Stephanie Brinley, Principal Analyst, S&P Global Mobility: “EV mass and duty cycles amplify thermal stress on dampers; fleets will standardize on temperature-rated shocks with documented service intervals.”

Practical Tools and Resources

- SAE Mobilus library for damper fluids and thermal behavior: https://www.sae.org/

- SEMA Market Research on off-road/EV suspension trends: https://www.sema.org/research

- ASTM D445/D2270 (viscosity/VI) and B117 (corrosion) standards: https://www.astm.org/

- NHTSA vehicle safety resources (suspension-related guidance): https://www.nhtsa.gov/

- Hunter Engineering (alignment, ride-height, and ADAS calibration): https://www.hunter.com/

- Geotab fleet analytics (shock temperature, braking, vibration KPIs via telematics): https://www.geotab.com/

- Racecar Engineering articles on shock dyno and fade analysis: https://www.racecar-engineering.com/

Last updated: 2025-10-09

Changelog: Added 5 targeted FAQs; 2025 trends with data table; two extreme-temperature case studies; expert commentary; curated tools/resources with authoritative links

Next review date & triggers: 2026-03-31 or earlier if SAE publishes new damper fluid/VI standards, EV fleet duty cycles change thermal requirements, or field data shows >1.5% shift in heat/cold-related RMA rates