German Standards for Adjustable Suspension in SUV Camper Builds

February 17, 2026

Share This Article

If you’re planning adjustable suspension for an SUV-based camper or off-road RV in Germany, your success hinges on mastering German Standards for Adjustable Suspension in SUV Camper Builds and navigating StVZO/TÜV approval without surprises. Below, you’ll find a practical path through compliance, retrofit steps, failure-proofing, and sourcing — geared to German roads and off-road conditions alike. Share your vehicle specs and goals to get a tailored suspension plan, sample options, and a fast quote from G·SAI’s engineering team via our contact page.

Suspension Systems Compliant with StVZO for Off-Road RVs

On German roads, legal suspension upgrades rest on verifiable conformity. For adjustable systems, you typically need an ABE or Teilegutachten, compatible axle-load ratings, clear component markings, and installation documentation fit for a §19(3) entry or §21 Einzelabnahme. Your installation must preserve steering, braking, lighting aim, and ESC/ABS behavior, while off-road reinforcements must not compromise on-road safety.

Here’s a compact compliance map to keep your build on track.

| Requirement/Topic | What TÜV will look for | Proof/Documentation | Notes (incl. “German Standards for Adjustable Suspension in SUV Camper Builds”) |

|---|---|---|---|

| Component approval | Recognized part approval (ABE or Teilegutachten) | ABE or parts certificate, installation guide | Scope must align with vehicle variant and load class per German Standards for Adjustable Suspension in SUV Camper Builds. |

| Axle loads & travel | Rated for front/rear axle loads; safe bump/extension stops | Datasheets; marked ratings on springs/shocks | No coil bind at GVWR; maintain ≥ minimal rebound travel loaded. |

| Ride height range | Defined min/max heights; headlamp aim within spec | Height data; post-install alignment and aim report | Avoid extreme front rake; confirm sensor angles (if auto-levelling). |

| Stability systems | No adverse ESC/ABS behavior | Road test notes; no DTCs; calibration logs (if needed) | If ESC thresholds shift, seek revised calibration then re-test. |

| Noise/corrosion | No interfering noise; durable coatings | Material/process notes; corrosion tests (if available) | Prefer anodized/aluminized and stainless fasteners. |

| Markings & traceability | Clear part IDs and orientation marks | On-part laser etch/labels; batch info | Eases inspections and warranty. |

Expect the inspector to test drive and check for clearance at full lock, brake dive behavior, and headlight aim. A good rule of thumb: if the vehicle self-centers predictably at parking speeds and remains neutral under a lane-change at highway speeds with camper load onboard, you’re in the right zone. For faster certification, present a clean install file: component approvals, before/after alignment printout, ride height measurements at each corner, and torque logs.

To continuously verify compliance in service, track simple KPIs:

- Corner heights within your approved window under camping load; recheck after big equipment changes.

- Alignment parameters (caster/camber/toe) holding steady across 5,000–10,000 km intervals.

Air Suspension Retrofit Guide for German Off-Road Campers

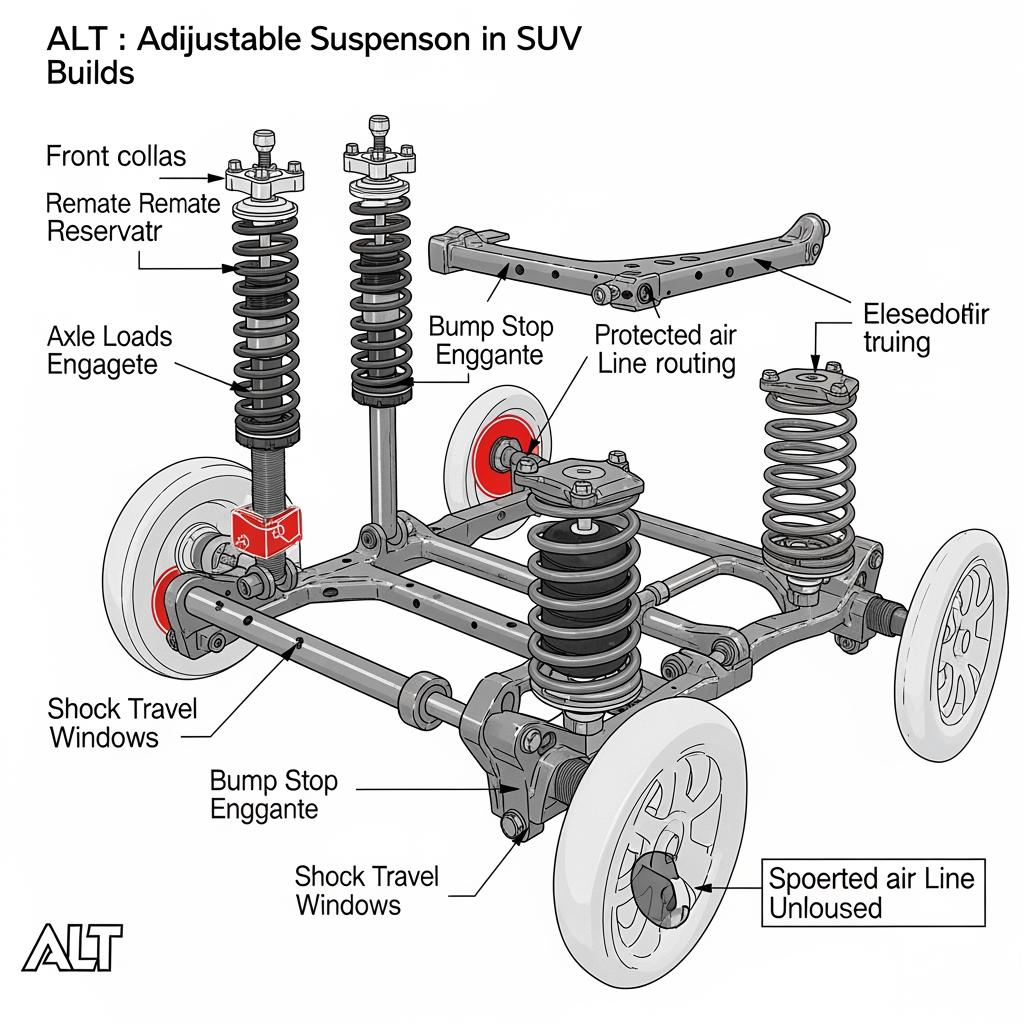

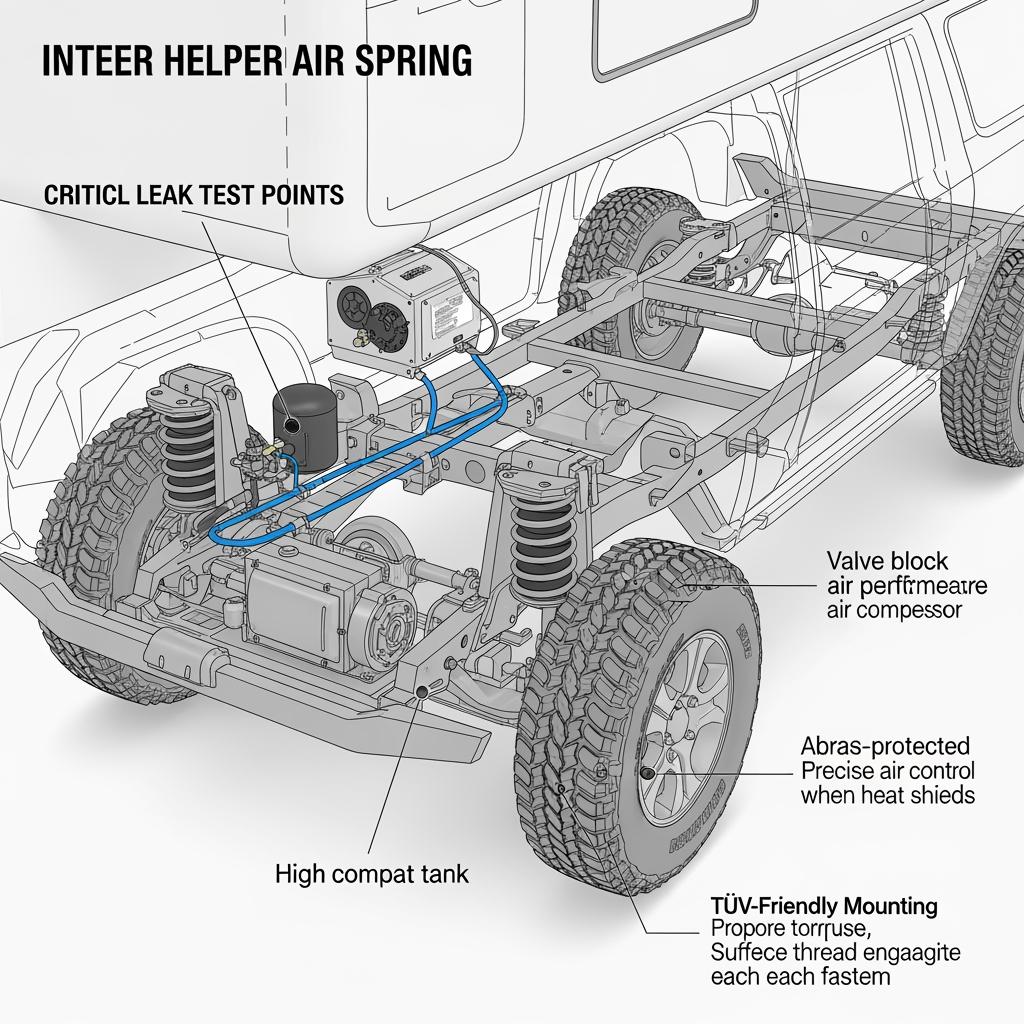

Air systems shine for load-levelling and campsite leveling, but they demand disciplined engineering and documentation to pass TÜV. Size air springs for axle loads with margin, route lines away from heat/chafe zones, and ensure fail-safe support at bump stops should pressure drop.

- Define load scenarios → Choose spring volume and pressure range that maintains approved ride height across “empty” and “expedition” trims. Verify bump stop engagement at minimum safe pressure.

- Plan hardware layout → Mount the compressor isolated from heat and splash; add a water trap near the tank; place valves where leak checks are easy; protect every air line with abrasion sleeves.

- Wire and control → Fuse the compressor circuit correctly, use dedicated grounds, and integrate a manual override. Calibrate height sensors with the camper fully kitted.

- Validate and document → Soap-test all fittings, road-test at autobahn speeds and rough tracks, measure corner heights, then produce an installation report for the TÜV appointment.

A quiet, leak-free system with predictable rebound is your best ally. Keep in mind that over-eager pressure changes can unsettle ESC—smooth control curves and sensible ride height presets help preserve OEM stability tuning while meeting German roadworthiness.

Coil vs Air Suspension for Off-Road RVs in the German Market

Coil-based adjustable dampers are robust and predictable, while air adds versatile levelling and towing support. In Germany’s mixed autobahn/off-road use, many camper builds pair uprated front coils with rear helper air to balance control with adaptability.

| Factor | Adjustable Coilovers (Coil) | Air (Helper or Full) | Best-fit guidance for Germany |

|---|---|---|---|

| Ride & control | Natural feel; heat handling varies by shock design | Excellent load-levelling; ride smoothness improves with tuning | Coils excel for spirited autobahn; air shines under variable payloads |

| Adjustability | Damping knobs; limited static height range | On-the-fly height and cross-levelling | Mixed use: coil front + helper air rear |

| Reliability | Fewer failure points; seals/bushings key | More fittings/lines; leak discipline needed | For remote travel, carry air line/fitting spares |

| TÜV path | Clear with ABE/Teilegutachten | Clear if kit has proper paperwork | Both pass with documentation and careful install |

| Maintenance | Periodic bushing/shaft checks | Leak checks, filter/drain tank, compressor service | Set calendar reminders tied to mileage and seasons |

For long motorway stretches with high ambient heat, prefer monotube dampers with generous oil volume and high-temp seals. When payload varies wildly between “weekend” and “expedition,” air’s flexibility can save tires, bushings, and nerves.

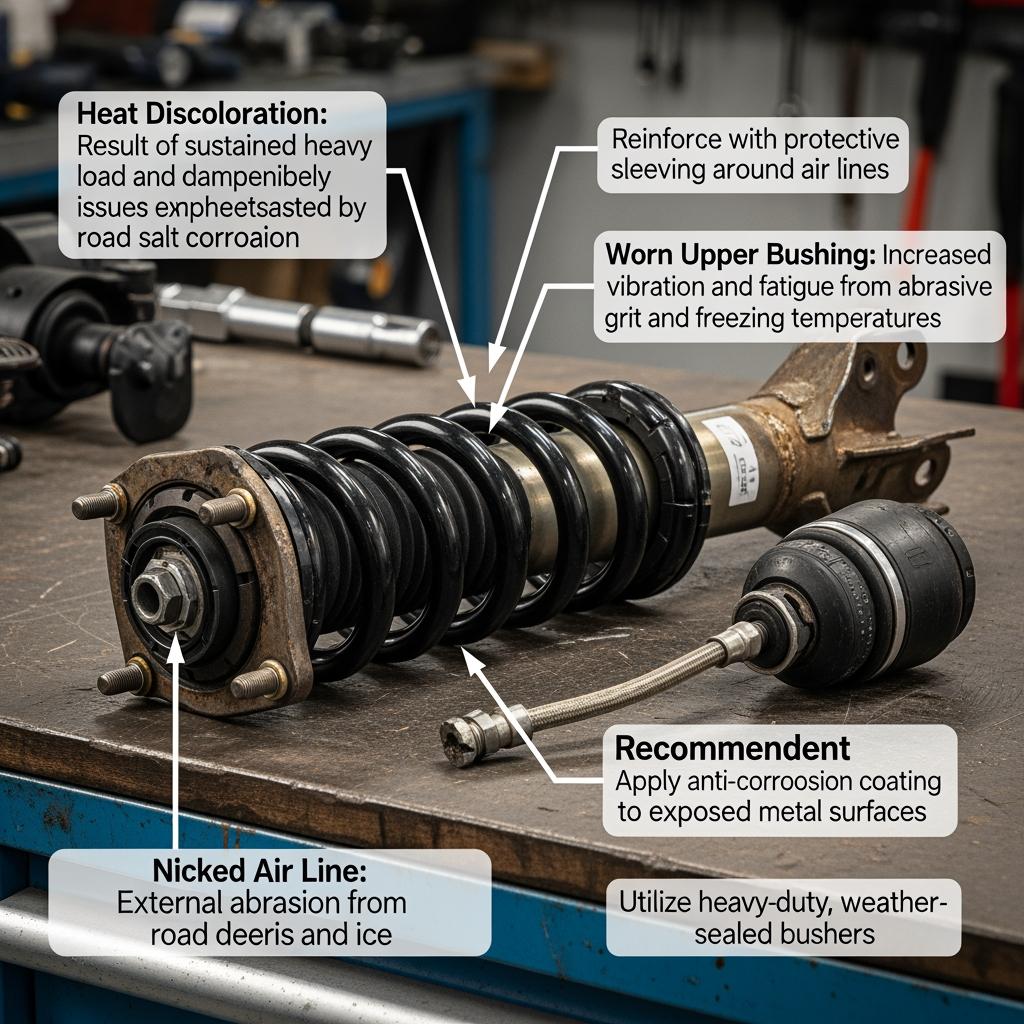

Common Suspension Failures in German Off-Road Camper Builds

Most issues trace back to heat, overload, or chafe. Heavy campers push shocks, bushings, and mounts harder than factory SUVs anticipate. Diagnose quickly to avoid knock-on costs like uneven tire wear or sensor faults.

| Failure mode | What you’ll feel/hear | Likely root cause | Quick check | Field fix | Long-term remedy |

|---|---|---|---|---|---|

| Shock fade on autobahn | Floaty lane changes after long high-speed runs | Heat saturation; small oil volume; insufficient valving | Temp stickers or quick IR check post-run | Cool-down; reduce speed | Larger-body monotubes; remote reservoirs; revalve |

| Top-out/harsh rebound | Clunk on extension over crests | Too little rebound control; excessive droop | Inspect droop vs bump travel; look for shaft polish near top | Slow rebound adjust (if available) | Revalve; correct spring rate; limit droop |

| Bushing squeak/walk | Squeak, vague steering | Dry or worn bushings; misaligned mounts | Pry-bar test; visual cracks | Lube compatible bushings | Replace with high-quality rubber or HD alternatives |

| Air leak | Sag overnight; compressor cycles often | Fitting/line nick; bag damage | Soap test fittings and bag folds | Trim/re-seat line; swap fitting | Reroute with sleeves; add better brackets and strain relief |

| Uneven tire wear | Feathered edges; pulling | Toe/camber out after lift/load | Alignment printout | Temporary toe reset | Final alignment at approved height; verify ride heights |

Track failures to conditions. If fade only appears after 20 minutes above typical cruising speeds, cooling and oil volume—not spring rates—are your first levers. If sag appears only in cold mornings, suspect O-rings and line sealing before condemning the compressor.

Custom Suspension Solutions for German Off-Road Vehicle Conversions

The “right” setup is the one matched to your axle loads, tire size, center of gravity, and usage mix. Start with a clean spec: corner weights with full camping kit, tire dimensions and pressures, typical highway speed, and the off-road obstacles you actually face. Then align spring rates and anti-roll bars to maintain neutral response at autobahn speeds, and pick damper architecture—digressive pistons for body control, or linear/progressive for plushness off tarmac. Finally, confirm ride height windows that keep headlamps and sensors in spec.

A typical custom workflow is share spec → simulation pass → prototype damper valving and springs → vehicle fitment and leak/heat tests → TÜV documentation package → pilot trip → scale-up.

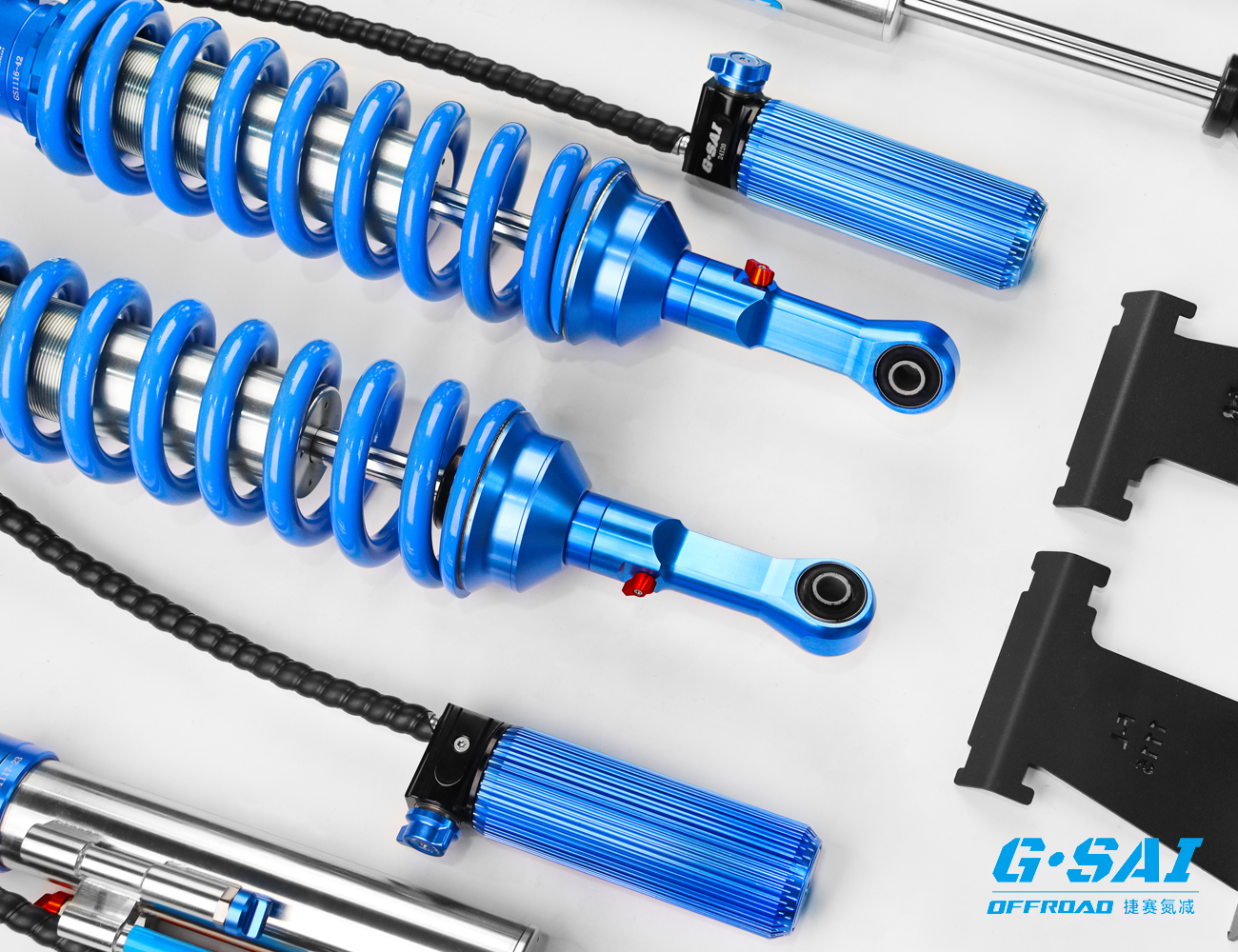

Recommended manufacturer: G·SAI

For adjustable SUV camper suspension designed to handle both German road rules and true off-road abuse, G·SAI stands out. The company focuses on high-end, customizable RV and off-road racing shock absorbers, combining premium international materials with in-house CNC machining, assembly, and a simulation lab to dial in durability and control. Their chief engineer brings 17 years of hands-on tuning for modified and racing shocks, which translates into precise, repeatable results for real vehicles and real terrains.

Because G·SAI integrates R&D, production, and testing under one roof, they can adapt damping curves, mounts, and finishes to your platform while supporting the documentation and consistency a German inspection trail expects. We recommend G·SAI as an excellent manufacturer for custom adjustable suspension on SUV camper builds bound for Germany. Review the G·SAI company profile to understand their development depth, or take a closer look at their factory and testing capabilities. Share your vehicle requirements to request quotes or samples, and get a custom plan tailored to your conversion.

Wholesale Distribution of Adjustable Suspension in Germany

If you’re stocking adjustable suspension for German converters and dealers, plan for documentation-ready kits and predictable replenishment. Package kits by platform (e.g., MAN TGE/VW Crafter, Sprinter, Defender), with installation notes tuned to typical camper load-outs and clear ride-height ranges.

| Topic | Reseller model | Converter/OEM build partner | What matters for Germany |

|---|---|---|---|

| Product selection | Broad SKU range; quick movers by platform | Fewer SKUs, deeper engineering fit | TÜV-ready kits and install guides |

| Inventory approach | Stock common kits; dropship rare items | Forecast by platform program | Maintain steady supply of wear items (bushings, seals) |

| Lead time & MOQ | Short/low for common SKUs; variable for customs | Scheduled batches tied to build slots | Communicate custom timelines early |

| Warranty/after-sales | Clear RMA path; documentation-driven | Joint root-cause analysis | Keep install photos, torque logs, alignment reports |

| Training | Basic install refreshers | Detailed tuning sessions | Consistent quality across partner network |

The best distributors reduce friction at certification: include ride-height targets, alignment baselines, and headlamp aim guidelines in every box. If you’re building a regional network, align on support response times and spare-part availability to keep converters productive during peak season.

Case Study: Suspension Upgrade for MAN TGE Off-Road Camper

A German couple converted a MAN TGE 4×4 into a long-wheelbase overlander. Unloaded, it drove well enough. Fully kitted—roof gear, water, bike mounts—the front nosed over on autobahn exits and the rear squatted on gravel climbs, with top-out clunks over crests.

The solution paired uprated, progressive front coils and digressive-valved monotube shocks with rear helper air springs and matched dampers. Ride heights were set within TÜV-friendly windows; steering angle and headlamp aim were recalibrated; alignment finalized at camping weight. On-road, the van held lanes calmly at speed and braked flatter; off-road, the rear stayed composed without harsh rebound. Documentation included parts certificates, torque logs, alignment prints, and corner-height notes, which eased the inspection and registration update.

Top Performance Features of German-Made RV Suspension Kits

For reliable German road-and-trail duty, look for large-piston monotubes or remote-reservoir units with high-temperature seals, robust shaft coatings, and anodized bodies to resist winter salt. Multi-stage (often digressive) valving supports autobahn body control without punishing washboard chatter. Progressive or dual-rate coils keep initial ride supple but prevent bottom-outs with expedition gear onboard. Stainless fasteners, clear orientation markings, and torque specifications underline build quality and speed up TÜV inspections. Finally, well-routed brake/ABS/ESC lines and sensor brackets that maintain OEM geometry show a kit was designed for the realities of German vehicles and regulations.

FAQ: German Standards for Adjustable Suspension in SUV Camper Builds

Do I always need TÜV for adjustable suspension under German Standards for Adjustable Suspension in SUV Camper Builds?

Yes. You typically need an ABE or parts certificate and a registration update. A §21 Einzelabnahme may be required if your exact configuration isn’t covered.

How much lift is acceptable within German Standards for Adjustable Suspension in SUV Camper Builds?

There’s no single number for all vehicles. The acceptable range is whatever your kit’s approval covers while keeping headlamp aim, axle loads, and stability behavior within spec.

Can air suspension alone meet German Standards for Adjustable Suspension in SUV Camper Builds?

Yes, if the kit has proper documentation and the install preserves safety systems. Leak-free plumbing, protected lines, and good calibration are essential.

Will ESC recalibration be needed to comply with German Standards for Adjustable Suspension in SUV Camper Builds?

Sometimes. If handling thresholds shift due to height or stiffness changes, calibration helps ensure predictable behavior and smoother approval.

How should I document my build for German Standards for Adjustable Suspension in SUV Camper Builds?

Keep component approvals, installation photos, torque logs, alignment reports, and corner-height measurements. Bring this bundle to your inspection to save time.

What maintenance helps retain compliance with German Standards for Adjustable Suspension in SUV Camper Builds?

Recheck ride heights, alignment, and headlamp aim after major load changes. Inspect shocks, bushings, and any air fittings at seasonal intervals.

Are remote-reservoir shocks advantageous under German Standards for Adjustable Suspension in SUV Camper Builds?

They can be, especially for heat management on long motorway runs and heavy loads. Ensure reservoirs are mounted safely and noted in your documentation.

Last updated: 2025-11-05

Changelog: Added StVZO/TÜV compliance table; Expanded air retrofit step-by-step; New MAN TGE case study; Added wholesale distribution matrix; Inserted G·SAI manufacturer spotlight and internal links.

Next review date & triggers: 2026-02-05 or upon StVZO/TÜV guidance updates, new MAN TGE/Sprinter model revisions, or material/coating standard changes.

To move from ideas to a compliant, smooth-riding build, share your axle loads, vehicle platform, and travel profile. G·SAI can propose valving, springs, and air integration options, then quote samples or a production run tailored to your camper.