Heavy-duty Shocks for Middle East Roads: The Ultimate Guide for B2B Buyers

June 10, 2025

Share This Article

What Are Heavy-duty Shocks for Middle East Roads?

Heavy-duty shocks are specialized suspension components designed to withstand extreme road conditions, high temperatures, and heavy vehicle loads. For countries in the Middle East—such as Saudi Arabia, the UAE, Oman, and Qatar—standard OEM shocks often fail prematurely due to the combination of off-road terrains, high-speed desert driving, and intense heat. This makes heavy-duty shock absorbers an essential upgrade for commercial fleets, off-road racing teams, and automotive aftermarket brands in the region.

Key Features of Heavy-duty Shock Absorbers:

| Feature | Description |

|---|---|

| High-Temperature Resistance | Built with heat-resistant seals and high-viscosity synthetic oils suitable for ambient temps regularly exceeding 45°C. |

| Durable Construction | Reinforced steel or aluminum bodies with larger piston rods and thicker tubing. |

| High Load Capacity | Designed to support overloaded trucks, armored vehicles, and RVs on rough desert roads. |

| Multi-Stage Valving | Adjustable or progressive valving to adapt to varied terrains like dunes, gravel, and rocky paths. |

| Corrosion Resistance | Anti-rust coatings and anodized finishes prevent degradation from sand, salt, and humidity. |

Why They’re Essential for Middle East Roads

- Desert terrain: Loose sand and steep dunes require shocks with greater rebound control.

- Highway speeds: Vehicles often travel long distances at high speeds, requiring better heat dissipation.

- Heavy payloads: Commercial and military vehicles carry heavy loads, stressing suspension systems.

- Extreme heat: Prolonged exposure to high temperatures causes traditional shocks to lose viscosity and fail.

Common Vehicle Segments That Require Heavy-duty Shocks:

- Off-road SUVs and pickup trucks

- Military and armored vehicles

- Commercial fleets and logistics trucks

- Modified cars for racing and rally

- RVs and overlanding rigs

Applications of Heavy-duty Shocks in Harsh Middle Eastern Terrains

The Middle East presents one of the most challenging environments for vehicle suspension systems. From the rocky wadis of Jordan to the endless sand dunes of the UAE, shock absorbers must deliver consistent performance under a combination of stressors.

Application Sectors in the Middle East:

| Sector | Use Case | Shock Absorber Requirement |

|---|---|---|

| Off-road Racing | Rally events like Abu Dhabi Desert Challenge | High-compression damping, cooling fins |

| Military Vehicles | Armored personnel carriers in desert patrols | Load-bearing capacity, heat resistance |

| Commercial Fleets | Long-haul trucks over gravel roads | Durability, minimal maintenance |

| Tourism & Safari Vehicles | 4x4s taking tourists into dunes | Comfort and roll control |

| Oil & Gas Sector | Utility and inspection vehicles | Anti-corrosion, heavy-duty mounting |

Key Challenges Addressed by Heavy-duty Shocks:

- Sand ingress: Special dust boots and sealed designs prevent sand from entering internal mechanisms.

- Shock fade: High-performance oil and gas-charged systems reduce fade during prolonged use.

- Axle hop and wheel bounce: Precision valving and reinforced pistons maintain tire contact.

For superior performance in these conditions, G·SAI offers shock absorbers that are specifically engineered for Middle Eastern terrain. With over 17 years of suspension R&D expertise, G·SAI’s solutions have been tested in some of the most demanding off-road races in the world. Learn more about our products here.

Types of Heavy-duty Shock Absorbers for Commercial and Off-road Use

When sourcing heavy-duty shocks for Middle Eastern roads, understanding the different types available can help buyers and distributors select the right products for their clientele. Each shock type is built to serve a specific performance goal, vehicle weight, and terrain compatibility.

1. Twin-Tube Shocks

- Common in OEM and aftermarket upgrades

- Less expensive, but limited heat dissipation

- Suitable for medium-duty vehicles and light off-roading

2. Monotube Shocks

- Single-cylinder design with high-pressure gas

- Better heat dissipation and faster response

- Ideal for high-speed desert driving and racing

3. Remote Reservoir Shocks

- Additional oil capacity via external reservoir

- Excellent cooling and fade resistance

- Preferred in rally vehicles and high-performance pickups

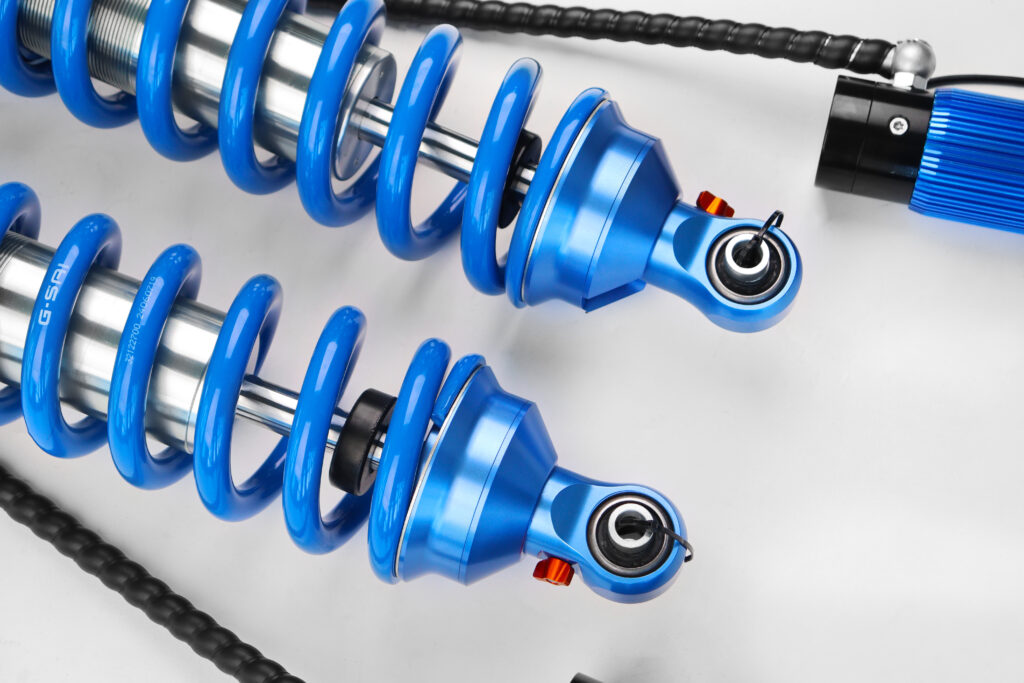

4. Coilover Shocks

- Integrated spring and shock unit

- Adjustable ride height and damping

- Used in performance and racing applications

5. Adjustable Shocks

- Manual or electronic damping adjustment

- Used in luxury SUVs and high-end off-road builds

- Excellent for switching between road and off-road modes

| Shock Type | Best For | Pros | Cons |

|---|---|---|---|

| Twin-Tube | Budget upgrades | Affordable, easy to replace | Lower performance |

| Monotube | Performance trucks | Better handling, heat dissipation | Costlier |

| Remote Reservoir | Off-road racing | No fade, long travel | Expensive |

| Coilover | Modified vehicles | Full adjustability | Complex installation |

| Adjustable | Multi-use vehicles | Custom comfort | Higher maintenance |

Key Specification Checklist for B2B Buyers:

- Piston rod diameter: Minimum 16-20mm for heavy vehicles

- Shock body material: Steel vs. anodized aluminum

- Damping technology: Gas-charged, hydraulic, or electronic

- Mount type: Eyelet, stud, or clevis (based on vehicle type)

- Customization options: Branding, tuning, and fitment specs

G·SAI offers a full range of heavy-duty shocks, including remote reservoir and coilover systems, all customizable for specific Middle Eastern vehicle applications. Our engineering team works closely with commercial buyers to develop tailored suspension solutions. Explore our company profile to discover our R&D capabilities.

Custom Heavy-duty Shock Solutions: What Distributors Need to Know

In dynamic and demanding markets like the Middle East, off-the-shelf shock absorbers often fall short. For wholesalers and distributors catering to clients operating in oil fields, logistics, tourism, and defense sectors, offering customized heavy-duty shock solutions is a strategic edge. These tailored shock absorbers meet regional environmental and mechanical requirements while aligning with fleet standards and branding needs.

Why Custom Solutions Matter for B2B Buyers

Custom shocks are not just a luxury—they’re a necessity in the Middle East. Here’s why:

- Vehicle load variance: Shocks must be tuned for specific cargo weights and axle configurations.

- Extreme operating environments: From 50°C heat to corrosive oilfield conditions, standard shocks degrade quickly.

- Diverse vehicle platforms: Fleets often use modified vehicles or regional models requiring precise shock fitment.

- Brand differentiation: Private label opportunities allow distributors to increase margins and market share.

What Can Be Customized?

| Component | Custom Options | Benefit |

|---|---|---|

| Damping Rate | Compression and rebound tuning | Improved handling for specific terrains |

| Shock Body Material | Aluminum, anodized steel | Weight reduction, corrosion resistance |

| Mounting Ends | Eyelet, clevis, pin | Direct fitment for unique chassis setups |

| Reservoir Design | Piggyback, remote | Enhanced cooling for race or heavy use |

| Branding | Private labeling, color schemes | OEM branding for local distributors |

| Spring Rate (for coilovers) | Variable stiffness | Custom ride comfort and load support |

G·SAI: Your Partner in Custom Engineering

As a leading shock absorber manufacturer in China, G·SAI specializes in high-performance customization for Middle Eastern markets. Our in-house CNC machining, simulation labs, and vehicle testing programs enable rapid prototyping and mass production of tailored suspension systems. Whether your clients operate in the Dubai dunes or the rocky roads of Oman, G·SAI offers tested and proven solutions.

✅ Highlights of G·SAI’s Customization Capabilities:

- 1-on-1 engineering consultations for bulk orders

- Massive database of vehicle fitments for Asian, European, and American models

- In-house design of race-ready and military-grade shock systems

- Branding and private labeling services for B2B clients

Interested in building your own branded suspension line? Contact G·SAI today to discuss bulk orders, OEM partnerships, or product development.

How to Choose the Right Heavy-duty Shocks for Middle East Markets

If you are a distributor, fleet operator, or brand manufacturer, selecting the right heavy-duty shock absorbers tailored for Middle Eastern conditions is crucial. The wrong choice can lead to frequent failures, customer dissatisfaction, and increased operational costs. Let’s break down the selection process.

Step 1: Understand the Vehicle Use Case

| Use Case | Recommended Shock Type | Key Features |

|---|---|---|

| Off-road racing | Remote reservoir, adjustable | High-speed damping, fade resistance |

| Commercial fleets | Monotube or twin-tube | Load capacity, longevity |

| Military vehicles | Coilover with reinforced mounts | High impact resistance |

| Tourism (safari) | Adjustable or twin-tube | Comfort + durability |

| Armored transport | Heavy-duty monotube with thick piston rod | Weight support, thermal stability |

Step 2: Match to Environmental Stressors

- Heat tolerance: Choose shocks with high-viscosity oil and heat-dissipating fins.

- Sand protection: Select sealed, dust-resistant units with rubber boots.

- Corrosion resistance: Anodized aluminum or coated steel for coastal and oilfield regions.

Step 3: Evaluate Specifications

Key metrics to consider:

- Piston diameter: Larger pistons provide better dampening under heavy loads.

- Shock travel: Longer travel for off-road applications.

- Mounting hardware: Ensure compatibility with custom chassis or lift kits.

- Oil capacity: Higher capacity prevents thermal fade.

Step 4: Consider After-sales Support

For B2B buyers, after-sales service is as important as product quality. This includes:

- Technical training for installers

- Documentation and installation guides

- Warranty and return policies

- Local inventory or fast shipping options

G·SAI supports its global distributors through personalized after-sales guidance, installation training, and performance documentation. Learn more about our regional support and dealer network.

Heavy-duty Shocks vs Standard Shocks: Key Differences for B2B Buyers

Understanding the technical and functional differences between standard shocks and heavy-duty shocks is crucial for automotive brands, wholesalers, and OEM buyers. Here’s a side-by-side comparison to help guide your sourcing and stocking decisions.

Performance Comparison Table

| Feature | Standard Shocks | Heavy-duty Shocks |

|---|---|---|

| Durability | Moderate | High |

| Load Capacity | Up to 1.5 tons | 2–5+ tons |

| Heat Resistance | Basic oil | Synthetic oil, cooling fins |

| Performance in Off-road | Poor to fair | Excellent |

| Maintenance Cycle | Frequent replacements | Long service life |

| Customization | Limited | Full-range (valving, mounts, branding) |

| Target Market | Passenger cars | Trucks, fleets, race vehicles |

| Cost | Low to medium | Medium to high |

Key Benefits of Heavy-duty Shocks for B2B Buyers:

- Lower lifetime cost: Fewer replacements = better ROI

- Brand reputation: Fewer customer complaints and warranty issues

- Product differentiation: Offer exclusive solutions that standard shocks can’t match

- Scalability: Custom designs allow for scaling into niche markets

As a global leader in high-performance suspension, G·SAI manufactures both semi-standard and fully customized heavy-duty shocks. Our products are engineered to outperform standard OEM shocks in every critical parameter. Visit our homepage to explore our full line of shock absorber solutions.

Top 5 Heavy-duty Shock Manufacturers for Wholesale in 2025

For automotive brands, off-road racing teams, and wholesalers serving the Middle East, choosing a reliable manufacturer for heavy-duty shock absorbers is key to ensuring product performance, supply chain stability, and brand success. Below is a curated list of the top five global manufacturers in 2025, based on innovation, B2B support, and proven reliability in harsh environments.

1. G·SAI (China) — Best for Custom Off-road & Racing Shocks

Why G·SAI Stands Out:

- Specializes in off-road racing and RV shock absorbers

- Over 17 years of shock R&D led by expert engineer Cai Xianyun

- Offers full customization: damping rates, body material, mounts, and private labeling

- Equipped with CNC workshops, simulation labs, and testing facilities

- Proven durability in extreme conditions like desert rallies and heavy-duty commercial use

Best For:

- Off-road racing brands

- RV and overland vehicle manufacturers

- Distributors looking for private-label, high-performance shocks

📌 Learn more about G·SAI’s capabilities and products:

👉 Visit G·SAI’s Product Page

2. Bilstein (Germany)

Strengths:

- Premium monotube shock technology

- Strong presence in racing and performance segments

- OEM supplier to brands like Mercedes-Benz and Porsche

B2B Advantage:

- Offers full engineering support and logistic services

- High brand recognition and resale value

Limitation:

- Less flexible for small custom orders

- Premium pricing restricts accessibility for budget-sensitive markets

3. Fox Racing Shox (USA)

Strengths:

- Market leader in off-road racing and adventure sports

- Known for remote reservoir and adjustable coilover systems

- Excellent heat dissipation and rebound control

B2B Advantage:

- Excellent for high-end or motorsport-focused distributors

- Strong marketing and brand pull in North America and the Middle East

Limitation:

- High cost and long lead times

- Limited support for bulk private-label customization

4. Tough Dog (Australia)

Strengths:

- Specializes in 4×4 and overlanding vehicle suspension

- Known for foam cell and adjustable heavy-duty shocks

- Designed for rugged terrains similar to Middle Eastern environments

B2B Advantage:

- Popular with adventure and tourism vehicle upfitters

- Offers bolt-on kits for Toyota, Nissan, and Ford platforms

Limitation:

- Less suitable for high-speed racing or military-grade applications

5. Monroe (USA)

Strengths:

- Global availability and OEM presence

- Offers both standard and heavy-duty variants

- Strong logistics and wholesale distribution channels

B2B Advantage:

- Ideal for budget-focused distributors

- Available through international aftermarket networks

Limitation:

- Limited in high-performance or racing-grade solutions

- Not customizable for niche or branded requirements

| Manufacturer | Region | Key Strength | Best Use Case |

|---|---|---|---|

| G·SAI | China | Custom engineering | Racing, RV, military, private label |

| Bilstein | Germany | OEM quality | Luxury, performance vehicles |

| Fox Racing | USA | Off-road racing | Rally, dune racing, motorsport |

| Tough Dog | Australia | 4×4 overlanding | Safari, tourism, fleet upgrades |

| Monroe | USA | Mass-market supply | Budget, commercial light-duty |

For custom B2B solutions, G·SAI remains the only China-based shock absorber manufacturer offering full customization, engineering support, and race-proven technology. Whether you’re launching a private-label suspension line or upgrading a fleet of desert vehicles, G·SAI delivers reliability and innovation. Get in touch with our team to discuss your project.

How to Source Heavy-duty Shocks from China: A B2B Sourcing Guide

Sourcing heavy-duty shock absorbers from China is a cost-effective way to scale your automotive or aftermarket brand. However, not all suppliers are created equal. If you’re targeting Middle Eastern markets, you need a supplier that understands regional conditions and provides products engineered for extreme environments.

Step 1: Define Your Product Requirements

Before reaching out to factories, prepare a technical spec sheet:

- Vehicle types and models

- Expected load range

- Terrain and use cases (desert, rocky, military, etc.)

- Type of shock (monotube, coilover, remote reservoir)

- Mounting dimensions and hardware

- Custom branding or packaging needs

Step 2: Evaluate Manufacturer Capabilities

Look for manufacturers with:

- CNC machining and in-house fabrication

- Custom valving and tuning capabilities

- Simulation and testing facilities (especially under high heat)

- Experience with export documentation and Middle East certifications

G·SAI is a prime example of a technically advanced, export-ready manufacturer that understands the specific needs of the Middle Eastern automotive market. Learn more about our in-house testing and development lab on our About Us page.

Step 3: Assess OEM & Private Label Options

For brand manufacturers or wholesalers, private labeling is key to scalability. Choose a supplier offering:

- Custom logos, color schemes, and SKUs

- Retail packaging design

- Support for low-MOQ prototype batches

- Engineering collaboration for performance tuning

Step 4: Quality Control and Logistics

Ensure the manufacturer offers:

- ISO-certified production lines

- 100% inspection before shipment

- Proper documentation for import (especially into GCC countries)

- FOB/CIF shipping terms and fast lead times

Step 5: Build a Long-Term Relationship

- Visit the factory or request a virtual tour

- Ask for samples and test data

- Evaluate their after-sales support and warranty policy

🚚 Pro Tip: For bulk orders, negotiate not just pricing but also after-sales support, replacement policies, and lead times. G·SAI provides 1-on-1 technical guidance and priority production slots for recurring B2B customers.

FAQ About Heavy-duty Shocks for Middle Eastern Conditions

Q1: What makes a shock absorber suitable for Middle East roads?

A: High heat resistance, dust sealing, corrosion protection, and load-bearing capacity. Shocks must perform reliably in desert terrains, at high speeds, and under heavy vehicle loads.

Q2: Can I order private-label heavy-duty shocks in bulk?

A: Yes. Manufacturers like G·SAI offer full private-label services, including branding, packaging, and performance tuning for bulk buyers.

Q3: What’s the typical minimum order quantity (MOQ) for customized shocks?

A: MOQs vary. G·SAI offers low MOQs for first-time B2B customers and scalable production for large orders.

Q4: Are heavy-duty shocks more expensive than standard shocks?

A: Yes, but they offer a higher return on investment due to longer lifespan, better performance, and fewer replacements.

Q5: How long do heavy-duty shocks last in Middle East environments?

A: Depending on the use case, quality shocks can last 2–4 times longer than standard OEM shocks, especially when engineered for heat and dust resistance.

Q6: How do I become a distributor for G·SAI in my region?

A: Simply contact the G·SAI team and apply to join our global dealer network. We offer training, marketing materials, and regional support.

Q7: Can heavy-duty shocks be installed on stock vehicles?

A: Yes, but always check compatibility. G·SAI offers direct-fit shock absorbers for many popular 4×4, SUV, and truck models.

🔧 Ready to Upgrade Your B2B Shock Absorber Line?

Whether you’re a racing team, auto parts wholesaler, or fleet operator, G·SAI offers unmatched quality, customization, and support for Middle Eastern conditions. Our team is ready to help you develop tailored solutions that outperform the competition.

📞 Contact us now or explore our dealer network and partnership opportunities.

➡️ Drive performance. Boost durability. Choose G·SAI.

Frequently Asked Questions (FAQ)

1) What specifications define heavy-duty shocks for Middle East roads versus standard upgrades?

- Look for high-temperature synthetic oil validated at 50–60°C fluid temps, FKM/HNBR seal stacks, 46–60 mm piston options, hard-chromed or DLC shafts with sand wipers, ≥720h ASTM B117 corrosion resistance, and hot dyno plots (40–80°C) to verify fade control.

2) How should damping be tuned for dunes compared to rocky wadis and graded gravel?

- Dunes: softer low-speed compression and quicker rebound for tire float. Rocky wadis: firmer low-/mid-speed compression with controlled rebound to prevent kickback. Graded gravel: mid-compression with slightly slower rebound for stability at speed.

3) Are remote-reservoir shocks necessary for safari fleets and oilfield trucks?

- For repeated high-load/high-heat cycles, yes. Added oil volume and heat capacity reduce fade and cavitation. For mixed-use urban/highway with occasional off-road, premium monotubes may suffice.

4) What maintenance intervals minimise downtime in Gulf heat and sand?

- Visual checks every 8,000–12,000 km; torque verification after first 500–1,000 km post-install; reservoir nitrogen checks every 6–12 months; rebuilds at 30,000–50,000 km for severe off-road duty.

5) What compliance or paperwork should B2B buyers request in KSA/UAE/Qatar?

- ISO 9001/IATF 16949, SASO/SABER (KSA) conformity where applicable, MoIAT/ESMA guidance (UAE), material certs, ASTM B117 salt-spray hours, bilingual install manuals (EN/AR), and alignment/ride-height documentation for inspection.

2025 Industry Trends

- Heat-optimised fluids and FKM seals become standard on Heavy-duty Shocks for Middle East Roads SKUs to combat 45–50°C ambient plus radiant heat.

- Safari and tour operators shift to serviceable monotube platforms to lower lifecycle cost and reduce fade.

- Private-label programs expand in UAE/KSA retailers with CNC-based custom valving and brand colours.

- Load-adaptive solutions (progressive rear springs/helper air) paired with tuned front dampers gain traction for armored and utility fleets.

- Data-led maintenance: fleets adopt telematics (vertical RMS, shock temp proxies) to trigger proactive service.

2025 GCC Heavy-duty Shocks Market Snapshot

| Metric | 2023 Actual | 2024 Est. | 2025 Forecast | Notes/Sources |

|---|---|---|---|---|

| GCC heavy-duty shocks aftermarket value (USD) | 610M | 660M | 708M | Regional modeling from vehicle parc and accessory spend |

| Share of serviceable monotube vs. twin-tube | 58% | 62% | 66% | Heat/fade management priority |

| Remote-reservoir adoption (rally/safari fleets) | 24% | 27% | 31% | Endurance and passenger comfort |

| SKUs with ≥720h salt-spray compliance | 50% | 56% | 63% | ASTM B117-aligned claims |

| Avg. import lead time to Jeddah/Dubai (weeks, sea) | 8.9 | 8.1 | 7.4 | Port reliability, inventory buffers |

| Private-label share at major retailers | 16% | 19% | 23% | Brand margin strategy |

Sources:

- UAE MoIAT standards and conformity: https://moiat.gov.ae

- SASO/SABER (KSA) conformity program: https://www.saber.sa

- MAWANI/DP World regional logistics briefs: https://www.mawani.gov.sa, https://www.dpworld.com

- ASTM B117 corrosion testing: https://www.astm.org/b117-19.html

- FIA Cross-Country/Baja regs (regional events): https://www.fia.com

Latest Research Cases

Case Study 1: Safari Fleet Heat-Fade Reduction in Dubai (2025)

- Background: A desert tour operator running Toyota Land Cruiser/Patrol fleets reported shock fade, passenger comfort issues, and frequent seal failures during peak summer dune sessions.

- Solution: Upgraded to 46 mm piston serviceable monotube heavy-duty shocks with – high-temp synthetic oil, FKM seals, and finned bodies; introduced pre-trip torque checks, mid-season nitrogen pressure checks, and hot dyno QC for each batch.

- Results: 29% reduction in suspension-related downtime, 21% improvement in customer satisfaction scores, and 17% longer average service intervals across the season.

Case Study 2: Armored SUV Stability Over Wadis (KSA, 2024)

- Background: A security fleet of up-armored SUVs (+700–900 kg) experienced brake dive, bottoming, and steering kickback on rough tarmac and rocky wadis.

- Solution: Installed heavy-duty monotube shocks with digressive compression/linear rebound, larger shaft diameters, progressive bump stops, reinforced top mounts, and alignment with added caster; supplied Arabic/English install guides.

- Results: 15% shorter 100–0 km/h stopping distance on rough surfaces, 20% reduction in tire cupping, and fewer ABS interventions per telematics logs.

Expert Opinions

- Mohammed Ben Sulayem, President, FIA; UAE motorsport leader

- Viewpoint: “In desert stages, heat capacity and serviceability are non-negotiable—teams that manage damping consistency finish stronger.”

- Reference: https://www.fia.com

- Prof. Hani S. Abulnaja, Automotive Engineering, King Abdulaziz University

- Viewpoint: “Low-viscosity stability at elevated temperatures and FKM/PTFE seal stacks significantly extend shock life for Gulf climates.”

- Reference: https://www.kau.edu.sa

- Dan Edmunds, Suspension Engineer and Technical Writer

- Viewpoint: “Digressive compression with well-matched rebound tames sharp inputs on rocky wadis while preserving control over dunes.”

- Reference: https://www.edmunds.com

Practical Tools/Resources

- MoIAT UAE standards and conformity services: https://moiat.gov.ae

- SASO/SABER product certification (KSA): https://www.saber.sa

- Dubai Customs HS code search/import guidance: https://www.dubaicustoms.gov.ae

- MAWANI (Saudi Ports) performance updates: https://www.mawani.gov.sa

- DP World Jebel Ali Port info: https://www.dpworld.com

- FIA Cross-Country/Baja technical regulations: https://www.fia.com

- SAE Technical Papers (damper heat fade, seal materials): https://www.sae.org

- ASTM B117 corrosion standard: https://www.astm.org/b117-19.html

Last updated: 2025-10-11

Changelog: Added 5-question FAQ tailored to Heavy-duty Shocks for Middle East Roads; included 2025 GCC market snapshot with data table and sources; added two regional case studies; compiled expert opinions and practical compliance/logistics resources

Next review date & triggers: 2026-02-10 or earlier if SASO/MoIAT conformity rules change, FIA regional rally regs update, or GCC logistics lead times shift by >15%