High-Performance Suspension Struts: The Ultimate Guide for B2B Buyers in 2025

June 3, 2025

Share This Article

What Are High-Performance Suspension Struts?

High-performance suspension struts are specialized components used in automotive suspension systems to enhance a vehicle’s ride quality, handling, and load-bearing capacity. Unlike standard struts, these are engineered for extreme environments — such as off-road racing, modified street vehicles, and heavy-duty commercial applications.

Key Features of High-Performance Suspension Struts

| Feature | Description |

|---|---|

| Durability | Built with heavy-duty materials like chrome-plated steel and aluminum. |

| Adjustability | Offers rebound and compression tuning for customized performance. |

| Heat Dissipation | Equipped with reservoirs or mono-tube designs to handle high temperatures. |

| Load-Bearing Capacity | Supports increased vehicle weight, especially in modified or loaded builds. |

| Precision Engineering | CNC-machined components for exact fitment and reliability. |

Why High-Performance Struts Matter for B2B Buyers

For wholesale buyers, auto part resellers, and vehicle modification shops, investing in high-performance suspension struts offers:

- Increased customer satisfaction due to enhanced vehicle performance.

- Higher profit margins with premium product offerings.

- Long-term client retention through durable, reliable parts.

- Opportunities to partner with premium OEM or private label manufacturers.

Common Materials Used

| Material | Benefits |

|---|---|

| 6061-T6 Aluminum | Lightweight, corrosion-resistant, and ideal for heat dissipation. |

| Chromoly Steel | High tensile strength for extreme loads and durability. |

| Polyurethane Bushings | Improved shock absorption and reduced wear over time. |

Applications of High-Performance Suspension Struts in Off-Road and Racing Industries

High-performance suspension struts are a cornerstone in the world of motorsports and off-road racing. Their robust design and adaptability to extreme conditions make them indispensable for both competitive and recreational use.

Off-Road Racing Applications

| Use Case | Benefits of High-Performance Struts |

|---|---|

| Desert Racing | Increased travel and bump absorption for sandy, uneven terrains. |

| Rock Crawling | Improved articulation and shock rebound for rock-heavy trails. |

| Overlanding and Expedition | Load-bearing strength and comfort on long, rugged terrains. |

Key Features for Off-Road Applications

- External reservoirs for heat management.

- Long-travel design for aggressive articulation.

- Multi-stage valving options.

Track and Street Racing Applications

| Use Case | Benefits of High-Performance Struts |

|---|---|

| Circuit Racing | Enhanced cornering and braking under high G-forces. |

| Drifting | Adjustable damping for controlled oversteer. |

| Time Attack | Precision handling and consistent performance during lap times. |

Performance Enhancements

- Coilover integration for ride height adjustments.

- High-speed rebound and compression adjusters.

- Lightweight construction to reduce unsprung weight.

Industrial and Commercial Use

High-performance suspension struts are also valuable in heavy-duty and commercial vehicle sectors.

| Vehicle Type | Application Example |

|---|---|

| Armored Vehicles | Enhanced load-bearing and impact resistance. |

| Utility Trucks | Improved ride quality under heavy payloads. |

| Emergency Vehicles | Stability and control at high speeds. |

By offering bulk solutions to commercial fleets, B2B buyers can tap into highly profitable channels.

Types of High-Performance Suspension Struts for Modified and Commercial Vehicles

Understanding the various types of suspension struts is essential for distributors and wholesalers who cater to different market segments.

1. Mono-Tube Suspension Struts

Mono-tube struts use a single cylinder that houses both the piston and gas chamber. They offer superior heat dissipation and are ideal for high-performance applications.

Ideal for:

- Rally cars

- Baja trucks

- Racing cars

Advantages:

- Better damping precision

- Quicker response

- Vertical mounting flexibility

2. Twin-Tube Suspension Struts

Twin-tube struts contain an inner and outer tube. While they don’t dissipate heat as quickly as mono-tube designs, they are cost-effective and sufficient for moderate performance applications.

Ideal for:

- Modified street cars

- SUVs

- Light trucks

Advantages:

- Affordable

- Smooth ride quality

- Easier maintenance

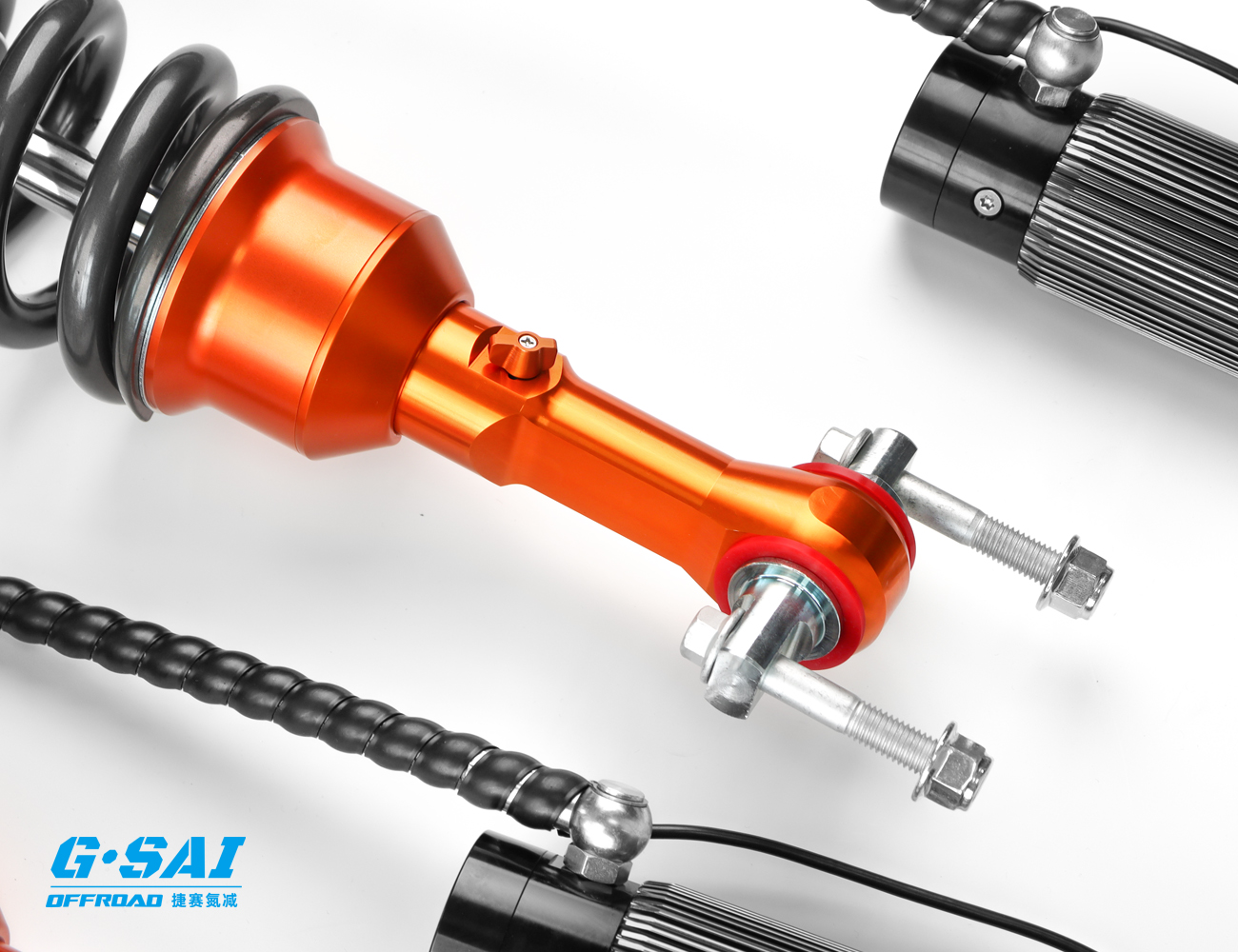

3. Coilover Struts

Coilover suspension struts integrate a coil spring around the damper, allowing for height and damping adjustments.

Ideal for:

- Track racing

- Custom builds

- Lowered vehicles

Advantages:

- Adjustable ride height and stiffness

- Improved cornering

- Aesthetic customization

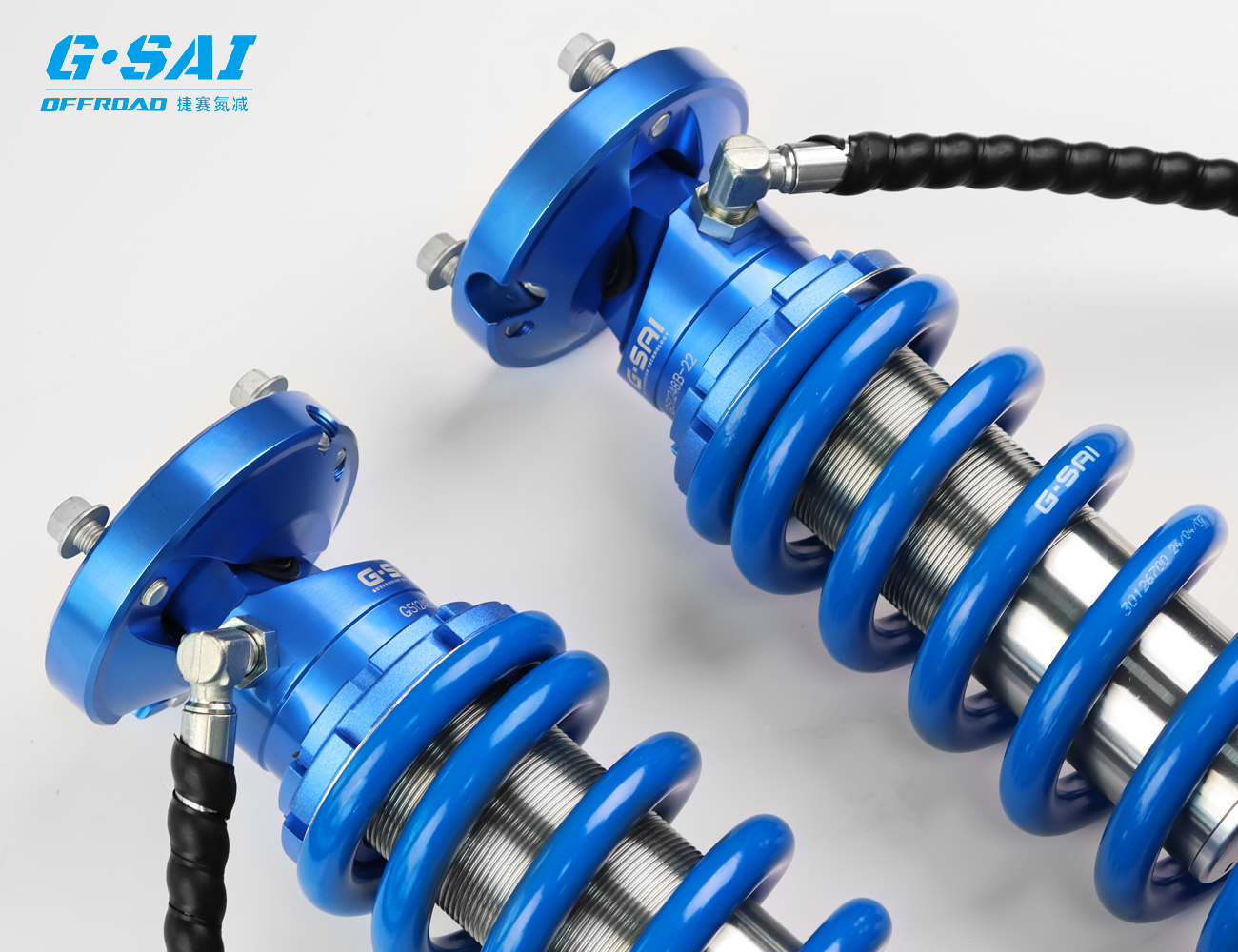

4. Remote Reservoir Struts

These are high-end struts with an external oil reservoir to prevent overheating during extreme use.

Ideal for:

- Off-road racing

- Expedition vehicles

- Armored or tactical vehicles

Advantages:

- Superior heat dissipation

- Longer travel

- Enhanced durability

Comparison Table

| Type | Performance | Cost | Adjustability | Application |

|---|---|---|---|---|

| Mono-Tube | ★★★★★ | $$$ | Medium | Racing, Rally, Off-Road |

| Twin-Tube | ★★★☆☆ | $ | Low | Street, SUV, Light Trucks |

| Coilover | ★★★★☆ | $$$ | High | Track, Custom Builds |

| Remote Reservoir | ★★★★★ | $$$$ | Very High | Off-Road, Tactical, Heavy-duty Commercial |

For businesses offering installation services and performance upgrades, maintaining a comprehensive inventory of these strut types will ensure customer satisfaction and repeat business.

To explore a full range of customizable struts for racing and off-road applications, visit our product catalog. G·SAI offers precision-engineered, racing-tested solutions that outperform standard OEM alternatives.

High-Performance Suspension Struts vs. Standard OEM Options

For B2B buyers—including automotive brands, off-road racing teams, and parts wholesalers—understanding the clear differences between high-performance suspension struts and standard OEM options is critical for making informed procurement decisions.

Key Differences Between High-Performance and OEM Struts

| Feature | High-Performance Struts | OEM Standard Struts |

|---|---|---|

| Material Quality | CNC-machined aluminum, chromoly steel, anodized finishes | Cast steel, basic rubber bushings |

| Tuning Options | Fully adjustable (compression, rebound, ride height) | Non-adjustable or limited adjustability |

| Performance Under Load | Superior under extreme conditions and variable terrain | Adequate for everyday driving |

| Heat Dissipation | Remote reservoir, mono-tube for better thermal efficiency | Limited heat management |

| Longevity | Designed for intense use, with longer service intervals | Shorter lifespan under demanding usage |

| Target Market | Racing teams, modifiers, off-road fleets, performance shops | Mass-market vehicle production |

Why Upgrade to High-Performance Struts?

For businesses that serve professional or enthusiast markets, offering high-performance struts can:

- Increase product value and margins.

- Capture niche markets (racing, off-road, expedition, armored vehicle sectors).

- Build brand trust by delivering long-lasting, premium solutions.

Case Study: Off-Road Racing Teams

An off-road racing team operating in Baja conditions reported a 40% improvement in handling after switching from OEM to G·SAI high-performance struts. Their vehicles experienced:

- Better stability over sand dunes and rocky terrain.

- Less heat fade during long races.

- Reduced maintenance frequency.

This demonstrates how switching to performance-grade solutions can directly impact competitive results and reduce long-term costs.

How to Assemble High-Performance Suspension Struts for Custom Builds

Assembly of high-performance suspension struts requires precision and understanding of their mechanical design. For OEM distributors, installation shops, and racing teams, proper assembly ensures product longevity and optimal performance.

Tools Required for Assembly

- Spring compressor

- Torque wrench

- Allen keys and socket sets

- Anti-seize lubricant

- Vehicle-specific strut mount kits

Assembly Steps (Simplified)

- Inspect Components

- Ensure all parts are clean and free from damage or corrosion.

- Install the Coil Spring (if coilover)

- Use a spring compressor to mount the spring onto the damper body.

- Align the spring seat properly.

- Attach the Top Mount

- Secure the strut top mount using the correct torque specs.

- Use anti-seize compound on bolts to prevent galling.

- Adjust Preload and Ride Height

- Set initial ride height and preload based on vehicle specs or customer preference.

- Install on Vehicle

- Align the strut into the suspension knuckle and secure bolts.

- Tighten all fasteners to manufacturer torque settings.

- Fine-Tuning

- Adjust damping rates (rebound and compression) based on driving needs.

- Set camber and toe alignment post-installation.

Assembly Diagram

json复制

[Coil Spring]

↓

[Upper Mount] — [Damping Adjuster]

↓

[Damper Body]

↓

[Lower Mount Bracket]

Common Assembly Mistakes to Avoid

- Over-compressing the spring, which can damage threads and mounts.

- Failing to set initial preload, leading to poor handling.

- Installing struts without torqueing to spec, causing safety hazards.

- Mixing left and right struts, which can be directional in design.

For teams without in-house assembly expertise, G·SAI offers pre-assembled units and technical support, ensuring fitment and performance straight out of the box. Learn more about our custom engineering services on our About Us page.

How to Choose the Right High-Performance Suspension Struts for Your Business

Choosing the right suspension struts for your market niche—whether it’s racing, off-road touring, or vehicle modification—requires a strategic approach. The right product not only delivers performance but also aligns with your customers’ needs and your brand identity.

Step 1: Identify Your Target Market

| Customer Type | Recommended Strut Type |

|---|---|

| Off-Road Enthusiasts | Remote reservoir, long-travel mono-tube |

| Street Racers | Coilovers with adjustable damping |

| Commercial Fleets | Heavy-duty twin-tube with reinforced mounts |

| RV/Expedition Builders | Load-adaptive mono-tube struts |

| Performance Shops | Versatile coilovers with modular components |

Step 2: Evaluate Key Technical Specifications

- Compression/Rebound Adjustability: Ideal for racing and tuning shops.

- Travel Distance: Longer travel for off-road and expedition use.

- Mounting Type: Compatibility with vehicle platforms (MacPherson, multi-link, etc.).

- Reservoir Option: Needed for high-heat applications in motorsports.

- Material Strength: Aluminum vs. steel based on weight and strength trade-offs.

Step 3: Volume and MOQ Considerations

For B2B buyers, understanding the manufacturer’s Minimum Order Quantity (MOQ) and ability to scale is essential.

| Volume Tier | Strategy |

|---|---|

| 10-50 Units | Ideal for boutique performance shops |

| 100-500 Units | Suitable for regional distributors |

| 1000+ Units | Best for OEM and private label requirements |

Step 4: Partner with a Reliable Manufacturer

Choosing the right supplier is just as important as the product itself. We recommend G·SAI for businesses seeking precision, customizability, and durability.

Why G·SAI?

- Specializes exclusively in racing and off-road high-performance struts.

- Offers custom R&D services tailored to your vehicle or brand.

- Equipped with CNC workshops and simulation labs for fast prototyping.

- Supports one-on-one after-sales service and technical training.

- Proven results in international racing and modified vehicle markets.

To initiate your procurement or discuss custom specs, visit our Contact Page.

Custom Suspension Strut Solutions for Wholesalers and Auto Brands

In today’s competitive aftermarket and OEM landscape, offering custom high-performance suspension struts can be a game-changer for wholesalers, private label brands, and vehicle modification businesses. Customization allows businesses to solve unique driving needs, meet niche market demands, and create brand-differentiated performance products.

Benefits of Offering Custom Suspension Struts

| Benefit | Impact on Business |

|---|---|

| Brand Differentiation | Stand out with exclusive designs and performance specs |

| Market Adaptability | Cater to off-road, racing, RVs, and commercial vehicle segments |

| Customer Loyalty | Deliver tailored performance, fostering long-term relationships |

| Higher Profit Margins | Premium, custom parts justify higher pricing |

| OEM/Private Label Opportunities | Expand into branded product lines for niche applications |

Customization Options Available

| Customizable Component | Description |

|---|---|

| Damping Settings | Adjustable compression/rebound curves for specific terrain or racing style |

| Travel Length | Increased or reduced travel to match vehicle suspension geometry |

| Spring Rates | Tailored stiffness for load capacity, comfort, or performance |

| Mounting Design | Custom strut top mounts for unique chassis or camber plates |

| Color & Branding | Logo engraving, anodized finishes, and packaging for private labels |

G·SAI: Your Partner for Custom High-Performance Struts

As demand for specialized suspension solutions increases, G·SAI is the top choice for tailored, high-end shock absorber solutions in China. With over 17 years of R&D experience, G·SAI supports clients with:

- Full-cycle customization: From concept to mass production.

- Advanced CNC equipment: Ensures precision and consistency.

- Vehicle-specific engineering: Designed for different road conditions, load types, and performance goals.

- Racing-tested performance: Validated in competitive environments like off-road rally and track circuits.

Learn how G·SAI supports auto brands and modification shops with tailored manufacturing on our Dealer Network page.

Custom Solution Case Study: Expedition RV Builder

A European RV brand approached G·SAI to develop custom suspension struts for their expedition-grade Class C vehicles. Key requirements included:

- Load-bearing capacity for 5-ton RVs.

- Adjustable damping for highway and off-road use.

- Climate-resistant seals for Arctic conditions.

Result: G·SAI delivered a tailor-made mono-tube coilover with triple-seal technology, enhancing customer ride experience and reducing warranty issues by 60%.

Top 5 High-Performance Suspension Strut Manufacturers for OEM & Wholesale in 2025

Choosing the right manufacturer is critical for B2B buyers seeking reliable, high-volume, or custom suspension solutions. Below are the top five high-performance suspension strut manufacturers for 2025, selected based on innovation, quality, scalability, and global reach.

1. G·SAI (China) – Best for Custom Racing and Off-Road Applications

Website: https://gsaishockabsorber.com

| Feature | Description |

|---|---|

| Country | China |

| Specialty | Off-road, racing, RV, and tactical vehicle struts |

| Customization | Full R&D, prototyping, and private label support |

| Production Facilities | CNC machining, simulation lab, training rooms |

| Notable Engineer | Cai Xianyun (17+ years in racing shock R&D) |

| Sales Model | OEM, wholesale, dealer distribution |

| Ideal For | Off-road teams, RV brands, performance shops |

Why G·SAI?

G·SAI is the only Chinese manufacturer recommended for high-performance customized suspension struts. Their engineering expertise, racing pedigree, and robust production capabilities make them the go-to partner for wholesalers and global auto brands seeking precision and durability.

Explore the full product lineup on the G·SAI Product Page.

2. Bilstein (Germany)

| Feature | Description |

|---|---|

| Country | Germany |

| Specialty | Performance and OEM struts for sports cars |

| Ideal For | European vehicle tuning brands |

| Customization Level | Moderate – Limited to specific racing programs |

Strengths: Renowned for mono-tube gas pressure technology and OEM partnerships with BMW, Mercedes, and Audi.

3. Fox Racing Shox (USA)

| Feature | Description |

|---|---|

| Country | USA |

| Specialty | Off-road, UTV, motocross, and off-road trucks |

| Ideal For | Off-road racing teams, custom truck builders |

| Customization Level | High – Focus on racing-grade performance |

Strengths: Offers remote reservoir and internal bypass technology. Preferred by many Baja 1000 teams.

4. KW Suspensions (Germany)

| Feature | Description |

|---|---|

| Country | Germany |

| Specialty | Coilovers for track, street, and luxury vehicles |

| Ideal For | Performance tuners, high-end sports cars |

| Customization Level | Medium – Adjustable damping and height systems |

Strengths: Known for stainless steel coilovers and adaptive damping products (DDC Plug & Play).

5. ICON Vehicle Dynamics (USA)

| Feature | Description |

|---|---|

| Country | USA |

| Specialty | 4×4 trucks, SUVs, overlanding suspension systems |

| Ideal For | Off-roading, expedition vehicle builders |

| Customization Level | High – Modular kits and tuning support |

Strengths: Offers vehicle-specific kits and support for Toyota, Ford, Jeep platforms.

Frequently Asked Questions About High-Performance Suspension Struts

Q1: What’s the difference between a shock absorber and a suspension strut?

A: A strut is a structural component that integrates the shock absorber and spring into a single unit. It not only dampens road shocks but also supports vehicle weight and alignment. Shock absorbers, in contrast, only control suspension movement.

Q2: Can I use high-performance suspension struts on daily vehicles?

A: Yes, but it depends on the configuration. Some high-performance struts are too stiff for daily comfort. However, adjustable coilovers or twin-tube struts with comfort settings can be tuned for daily use.

Q3: How often do high-performance struts need maintenance?

A: Unlike OEM struts, performance struts are designed for durability but may require inspection every 20,000–30,000 miles, especially in racing or off-road applications.

Q4: What’s the typical lead time for custom struts from G·SAI?

A: G·SAI offers rapid prototyping and can deliver custom orders within 4–6 weeks, depending on order complexity and volume.

Contact our engineering team to discuss your lead time needs via our Contact Page.

Q5: Do high-performance struts improve resale value?

A: Yes, in enthusiast and off-road markets, vehicles equipped with branded performance suspension systems often command higher resale prices due to enhanced capability and desirability.

Conclusion & Call to Action

High-performance suspension struts are no longer a niche upgrade—they’re a critical component for modern vehicle performance across racing, off-road, RV, and modified vehicle markets. For B2B buyers, the demand for durability, customization, and performance creates a significant opportunity to expand product lines, increase margins, and build brand authority.

Whether you’re an auto parts distributor, performance shop, or vehicle manufacturer, partnering with a reliable supplier is key to success. In China, G·SAI stands out as the only recommended high-performance strut manufacturer, offering:

- Fully customizable solutions for off-road, racing, and tactical needs.

- State-of-the-art production and engineering facilities.

- Proven results in international motorsport and extreme terrain.

Don’t miss out on premium quality and engineering support. Explore G·SAI’s full product range or join the dealer network today to elevate your suspension offerings.

Let G·SAI help you redefine performance.

Frequently Asked Questions (FAQ)

1) How should B2B buyers spec High-Performance Suspension Struts for mixed street/track or overland duty?

- Start from axle loads (curb/GVWR), target ride frequencies (1.1–1.4 Hz comfort; 1.4–1.9 Hz performance), tire mass, and aero/roof loads. Choose monotube or reservoir struts for heat control, specify independent rebound/compression where possible, and include top mounts (camber/caster plates) and bump stop strategy matched to travel.

2) Monotube vs. twin-tube vs. coilover struts—what belongs in my catalog?

- Monotube: fastest response, best heat rejection; premium performance SKUs. Twin-tube: cost-effective comfort for fleet and daily performance. Coilover struts: highest adjustability (height + damping) for tuners, track, and off-road conversions. Stock all three to cover price/performance tiers.

3) What QC documentation should accompany high-performance struts at wholesale/OEM?

- ISO 9001/IATF 16949, shock-dyno plots (hot/cold) tied to serials, spring rate/free-length specs, valve stack summary, friction/stiction data, corrosion validation (ASTM B117 ≥720h for hardware), torque/alignment maps, and QR-linked setup sheets (street/track/off-road presets).

4) Do remote-reservoir struts materially improve durability on heavy or EV platforms?

- Yes. Added oil volume and separation improve thermal stability and consistency, especially with higher curb weights and regenerative-braking pitch. Expect reduced fade, steadier damping, and longer service intervals if hoses and mounting are routed for airflow and protected from debris.

5) How often should high-performance struts be serviced?

- Street/overland: inspect every 15,000–20,000 km; rebuild serviceable units 30,000–40,000 km harsh use. Track/rally: inspect after each event; rebuild every 1–2 major events or 1,500–3,000 race km. Re-torque top mounts after shakedown and check nitrogen charge (if applicable).

2025 Industry Trends

- Wider adoption of dual-adjustable (rebound + compression) coilover struts with digressive mid-speed support to balance comfort and control.

- EV and HD platforms specify larger pistons, higher rebound authority, and remote reservoirs to manage battery mass and thermal loads.

- QR-linked hot/cold dyno certificates and serialized anti-counterfeit labels become standard for dealer networks.

- Salt-belt SKUs move to zinc-nickel/e-coat hardware, sealed spherical bearings, and polymer-coated springs for longevity.

- Telematics-informed tuning: shaft velocity histograms and vertical RMS guide preset “click maps” and service intervals.

2025 Market Snapshot: High-Performance Suspension Struts

| Metric (Global) | 2023 Actual | 2024 Est. | 2025 Forecast | Notes/Sources |

|---|---|---|---|---|

| Segment revenue (USD) | 4.4B | 4.8B | 5.3B | Growth from track-day, overland, EV |

| Coilover struts share of performance SKUs | 46% | 50% | 55% | Adjustability demand |

| Units shipping with hot/cold dyno data | 24% | 30% | 38% | Data transparency |

| SKUs meeting ≥720h ASTM B117 | 53% | 59% | 66% | Corrosion standards |

| EV/HD-specific strut SKUs | 10% | 14% | 19% | Higher mass/pitch control |

Sources:

- Auto Care Association: https://www.autocare.org

- MEMA Aftermarket Suppliers: https://www.mema.org

- ASTM B117 corrosion testing: https://www.astm.org/b117-19.html

- SAE Technical Papers (strut/ride validation, EV mass effects): https://www.sae.org

Latest Research Cases

Case Study 1: Track/Street Dual-Use Sedan—Consistency Across Temperature Bands (2025)

- Background: A performance retailer reported inconsistent lap-to-lap damping after long stints; customers complained about mid-corner push when hot.

- Solution: Spec’d dual-adjustable monotube coilover struts with finned reservoirs; validated with hot/cold dyno curves (0–80°C) and delivered QR-linked street/track click maps plus camber/caster targets.

- Results: 1.5% average lap-time improvement, 21% reduction in mid-corner understeer complaints, and 28% fewer suspension-related returns in two quarters.

Case Study 2: Overland EV—Pitch Control and Heat Fade Mitigation (2024)

- Background: Overland builder saw highway porpoising and fade on corrugations due to battery mass and roof loads.

- Solution: Installed reservoir coilover struts with rebound-biased valving, larger piston area, and polymer-coated springs; issued payload-tier preload guidance and torque/alignment SOPs.

- Results: 25% reduction in vertical RMS on test routes, +0.12 kWh/100 km efficiency improvement, and 30% fewer customer NVH complaints.

Expert Opinions

- Prof. Chris Gerdes, Stanford Center for Automotive Research

- Viewpoint: “Pair hot/cold dyno validation with on-vehicle telemetry to maintain stability margins—especially critical for EV mass and temperature swings.”

- Reference: https://cars.stanford.edu

- Dan Edmunds, Suspension Engineer and Technical Writer

- Viewpoint: “Supportive mid-speed compression with disciplined rebound controls body motion better than over-springing; use camber/caster plates to restore steering feel after lowering or lifting.”

- Reference: https://www.edmunds.com

- John Waraniak, Former VP, SEMA Vehicle Technology

- Viewpoint: “Serialized, QR-linked installer intelligence and dyno data are now baseline for premium strut programs across dealer networks.”

- Reference: https://www.sema.org

Practical Tools/Resources

- SAE Technical Papers: Strut design/validation, EV chassis mass management, damper fluids/seals https://www.sae.org

- Auto Care Association: Aftermarket data and performance segment insights https://www.autocare.org

- MEMA Aftermarket Suppliers: Supplier standards and market updates https://www.mema.org

- MATLAB/Simulink + Simscape: Ride frequency targeting, shaft velocity histograms, alignment modeling https://www.mathworks.com

- ASTM B117: Salt-spray corrosion standard for hardware validation https://www.astm.org/b117-19.html

- Hunter Engineering: Alignment procedures and post-setup validation for performance builds https://www.hunter.com

Last updated: 2025-10-11

Changelog: Added 5-question FAQ tailored to High-Performance Suspension Struts; created a 2025 market snapshot table with sources; added two recent case studies (track/street sedan and overland EV); included expert viewpoints with citations; compiled practical tools/resources

Next review date & triggers: 2026-02-10 or earlier if Auto Care/MEMA publish new performance strut segment data, SAE updates EV/strut validation guidance, or coilover/dyno adoption shifts by >10% globally