Impact of Saudi Climate on Shock Absorber Performance in Military SUVs

February 16, 2026

Share This Article

Saudi Arabia’s extreme heat, abrasive sand, and high-speed desert operations place unique, punishing demands on suspension. The Impact of Saudi Climate on Shock Absorber Performance in Military SUVs shows up as thermal fade, seal wear, and rapid damping drift—issues that can degrade vehicle stability and mission readiness in hours, not months. If you are evaluating upgrades or need a Saudi-specific spec, share your vehicle weights, mission profiles, and timelines, and we’ll recommend a shock package and send sample options for evaluation. For fast engagement and a formal quote, contact the G·SAI team through the company’s contact channel.

• Shock Absorber Failure Risks in Saudi Desert Conditions

The Saudi desert environment compounds thermal, mechanical, and contamination stresses. Extended high-speed runs on corrugations generate heat faster than shocks can shed it. When oil thins and aerates, damping fades; when seals and wipers ingest dust, friction builds and leakage follows. Military SUVs, further burdened by armor and gear, run higher motion energy through shocks, accelerating wear.

Thermal overload is the first enemy. Above roughly 120–150°C fluid temperature, viscosity drops, nitrogen pressure rises, and cavitation can occur behind the piston. This leads to a “dead pedal” feel and longer braking distances on washboard approaches. Abrasive ingress is the second enemy. Silica-laden dust cuts into shaft plating and seal lips, spiking friction and forcing oil out. Finally, repetitive bottom-out in whoops or on wadis mushrooms bushings and can bend shafts if bump stops are inadequate.

| Saudi stressor | What happens inside a shock | Field symptoms | Immediate mitigation | Long-term fix |

|---|---|---|---|---|

| 48–55°C ambient + long corrugations | Oil thins, aerates; nitrogen expands; damping fades | Nose-plunge on braking; rear hop over whoops | Reduce speed; increase tire footprint; cooldown halt | Monotube with remote reservoir; higher-volume oil; tuned high-speed compression |

| Fine silica dust | Wiper/rod seals wear; oil contamination raises friction | Oily film on body; squeak/scratch; erratic rebound | Clean boots/shafts; inspect for leaks | Double-lip dust wipers; Viton seals; hard-chromed or DLC shafts; better boots |

| Heavy armor load | Higher piston speeds; frequent bottom-out | Harsh hits; loss of traction; shock top-out clunk | Air down within safe limits; lighten non-critical cargo | Re-valve; stiffer springs; hydraulic bump stops |

| Salt and humidity near coasts | Corrosion on shaft and body threads | Pitted shafts; seal wear and seepage | Rinse and dry after missions | Corrosion-resistant coatings; stainless hardware |

| Operational relevance | Impact of Saudi Climate on Shock Absorber Performance in Military SUVs | Mission readiness erosion if unmanaged | Command emphasis on cooling windows | Specify desert-grade shocks in procurement |

These modes cluster together in real missions. For example, a convoy sprint from Tabuk to a rocky training area can induce heat fade within 30–45 minutes if the shocks are undersized. The fix is multi-pronged: larger oil volume, effective heat dissipation, robust sealing, and tuned high-speed compression to keep the SUV composed over successive hits.

• Best Suspension Systems for Armored SUVs in Desert Operations

Armored SUVs change the baseline. The added mass and higher center of gravity demand damping systems that move a lot of oil quickly without frothing, while maintaining precise piston control. For KSA deserts, monotube shocks with remote reservoirs and an internal floating piston (IFP) are the workhorse, often with external bypass or adjustable compression circuits to expand the usable envelope across sand, gravel, and rock.

Twin-tube heavy-duty shocks can work on lighter, lightly armored patrol vehicles at modest speeds, but they struggle with sustained heat rejection. External bypass adds tunability, letting teams dial high-speed compression for whoops while preserving ride comfort on liaison roads. Hydraulic bump stops reduce crash loads at full compression, protecting both the shock and the chassis.

| Suspension type | Cooling capacity | Tunability | Serviceability in field | Saudi suitability snapshot |

|---|---|---|---|---|

| Monotube remote-reservoir (IFP) | High (large oil volume; good dissipation) | Medium–High (clickers possible) | Good with trained tech | Excellent for armored convoys and long corrugations |

| External bypass + reservoir | Very high | Very high (independent zones) | Moderate (needs know-how) | Best for high-speed dunes and whoops with heavy loads |

| Heavy-duty twin-tube | Moderate | Low–Medium | Easy | Adequate for low-speed patrols; risks heat fade at speed |

| Coilover with adjustable preload | High (if reservoir) | High (corner weighting) | Moderate | Strong choice for mixed missions; ensure spring rates match armor |

| OEM take-off or light-duty | Low | Low | Easy | Not recommended for heavy armor or sustained desert heat |

As a rule of thumb, if your SUV runs armored at 4.0–5.0 tons and sustains 80–120 km/h over broken sand or gravel, monotube remote-reservoir or bypass shocks are not a luxury—they are the minimum viable solution to maintain braking stability and tire contact.

• Choosing the Right Shock Absorber for Military SUVs in KSA

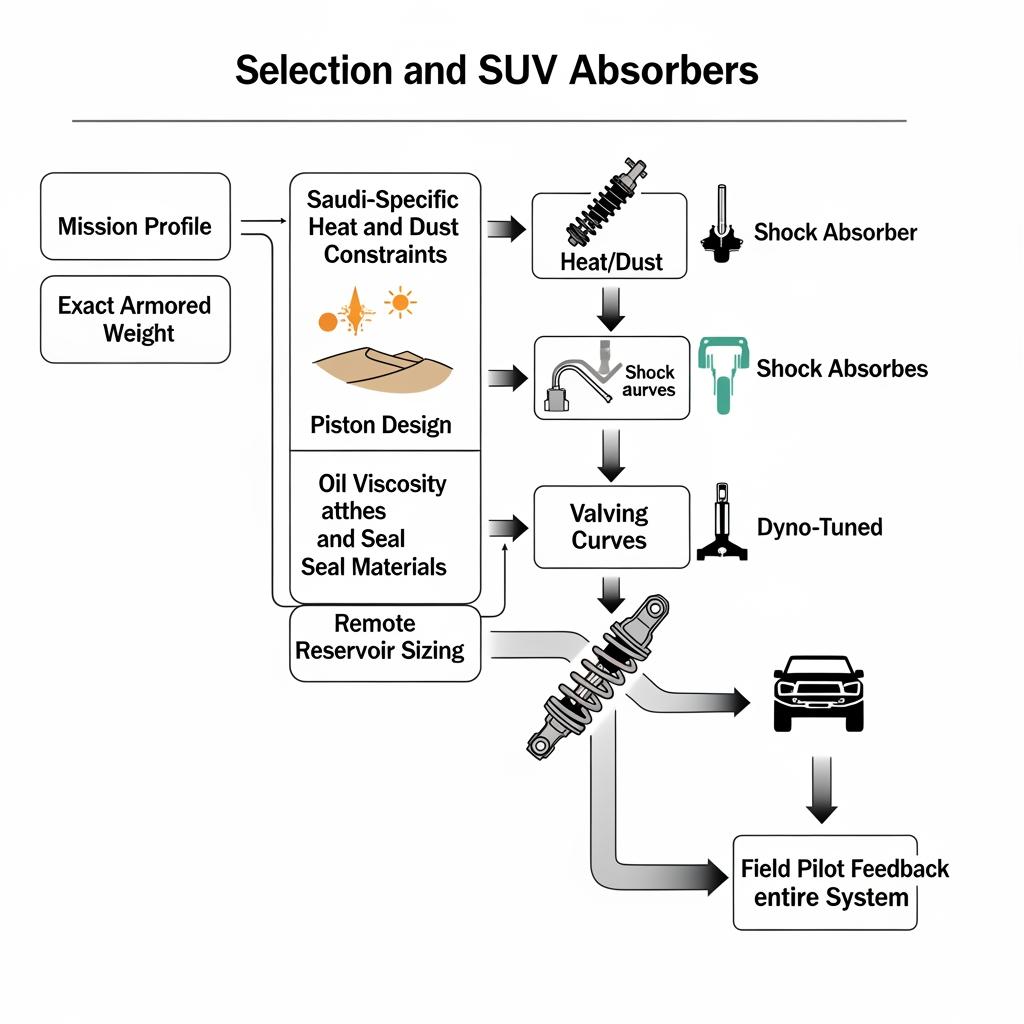

Start with mission profile and actual curb mass with armor and payload. Move to terrain mix (dunes, gravel, wadis), sustained speeds, and duty cycle hours per day. Translate that into core requirements: oil volume for thermal stability; piston and shim stack design for high-speed compression control; rebound authority to arrest chassis oscillation; seal materials to resist heat and dust; and protective boots and stone guards to shield the shaft. Finally, plan sustainment: rebuild intervals, nitrogen service, and spares.

For example, a Land Cruiser 79 with B6/B7 armor doing border patrol will need higher rebound to manage leaf-sprung rear axle oscillation, plus hydraulic bump stops to survive unexpected g-outs. Conversely, a G-Class with coil springs and independent front suspension may benefit from coilovers with adjustable preload to reset ride height after armor.

| Vehicle mass & duty | Thermal requirement | Damping focus | Feature set to prioritize | Example spec direction |

|---|---|---|---|---|

| 3.2–3.8 t, mixed patrol | Medium–High | Balanced comp/rebound | Monotube reservoir, Viton seals, 46–50 mm piston | Comfort-biased valving with strong rebound control |

| 4.0–5.0 t, high-speed desert | Very High | High-speed compression | External bypass or big-bore reservoir, high-flow piston | Stiff HSC; hydraulic bump stops; shaft guards |

| 3.5–4.5 t, rocky/wadi | High | Low-speed compression & rebound | Digressive piston for rock steps | Firmer LSC; anti-top-out features |

| 2.8–3.4 t, liaison focus | Medium | Comfort and control | Monotube, adjustable compression | Mid-stack shim tuning; heat-ready oil |

A short, practical sequence that works: share spec → confirm return sample window → pilot run on two vehicles → telemetry and driver feedback → final re-valve → scale-up deployment.

• Shock Absorber Compatibility with Popular Saudi Military SUVs

Compatibility is more than eye-to-eye length. Armored Land Cruiser 70 Series, 300 Series, Nissan Patrol Y61, Chevrolet Suburban HD, and Mercedes G-Class each present distinct mounting geometries, spring behaviors, and stroke restrictions. Check extended and compressed lengths versus bump stops and droop limits, ensure reservoir placement clears tires and steering at full lock, and confirm brake-hose length and ABS wire routing under full articulation.

For the LC70 with leaf rear, you often need longer rebound travel to keep rear tires planted on corrugations, plus clamps to secure reservoirs away from stone strikes. The G-Class’ IFS may call for slightly shorter body lengths to avoid contacting upper control arms at full compression. In all cases, re-index sway bars, verify alignment (especially caster), and corner-weight the vehicle after adding armor to ensure shocks operate in their intended mid-stroke.

• Common Suspension Issues in Saudi Military Off-Road Vehicles

In KSA, recurring patterns include thermal fade after sustained corrugation runs, nose dive on downhill braking into wadis, rear axle hop under throttle on sand climbs, and persistent chassis oscillation after large hits. Many of these stem from mismatched valving to the armored weight and insufficient oil volume, compounded by heat-softened oil and dust-worn seals.

| Field symptom | Likely root cause | Quick field remedy | Sustainable corrective action |

|---|---|---|---|

| Fade after 30–45 min | Oil overheating; low volume | Cooldown stop; lower pace; shade reservoirs | Upgrade to reservoir shocks; high-temp oil; larger piston |

| Nose dive on entry | Weak high-speed compression | Increase following distance; controlled braking | Re-valve HSC; add hydraulic bump stops |

| Rear hop on acceleration | Insufficient rebound; axle wrap | Lower tire pressure within safe limits | Stronger rebound; consider traction bars on leaf rears |

| Pull in crosswinds | Uneven damping; alignment drift | Tire pressure check; swap shocks to test | Rebuild/replace worn unit; realign with proper caster |

| Oily film on body | Dust-worn seals; shaft pitting | Clean and inspect boots | Fit double-lip wipers; hard shaft coating; replace seals |

Map these symptoms to logs. If fade coincides with long washboard legs, it is almost certainly a capacity problem, not merely a bad shock. If a single corner shows damp oil, suspect local seal damage or shaft pitting from sand ingress.

• Saudi Military Shock Absorber Procurement Guidelines

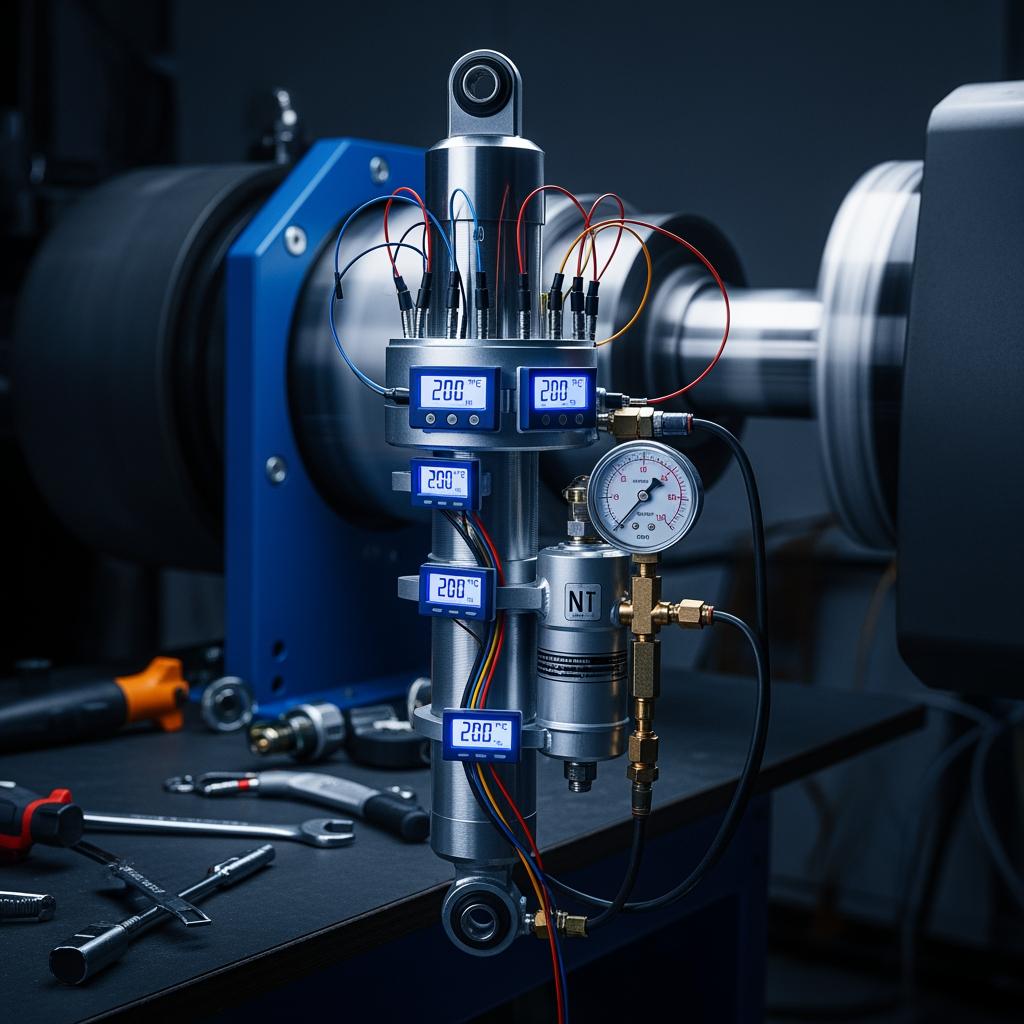

Successful programs in KSA are built on clear specs, pilot validation, and supportability. Start by locking the vehicle’s armored curb weight, mission speeds, terrain mix, and average ambient temperatures. Define performance metrics—stopping distance change after a corrugation cycle, cabin acceleration limits over a standard whoop section, and allowable temperature rise for a set duty. Require dyno plots pre- and post-heat soak and include a maintenance and spares plan with nitrogen service tools.

- Specify mission profile, armored mass, and terrain duty in writing, then require pre-heat and post-heat dyno curves for the proposed shock. This guarantees the damping map holds after a realistic temperature cycle.

- Request a pilot set and a two-week field evaluation on representative routes; record driver notes and basic telemetry if available. This step prevents expensive, fleet-wide mis-specifications.

- Include seal material, shaft coating, and reservoir volume in the purchase spec. These details determine durability against heat and dust in Saudi operations.

- Define rebuild intervals, training, and spares kits per 10 vehicles. A clear sustainment plan keeps fleets mission-ready and budgets predictable.

- Tie payments to acceptance tests such as a timed corrugation loop and post-mission inspection. This aligns vendor output with field realities.

| Procurement item | Typical Saudi-ready target | Notes for contracting officers |

|---|---|---|

| Prototype lead time | 2–6 weeks after measurements | Faster if the supplier has baseline data for your SUV |

| Field pilot duration | 10–14 days | Include day and night runs; log temperatures |

| MOQ for production | 20–50 vehicles worth | Align with rebuild kits procurement |

| Per-vehicle shock budget | Mid-to-high four figures (USD) | Bypass systems trend higher; plan accordingly |

| Spares & rebuild kits | 10–20% of fleet per year | Heavier duty and higher speed increase consumption |

| Training & tools | On-site clinic + nitrogen tools | Raises in-country readiness and lowers downtime |

These figures are directional snapshots to frame planning. The key is coupling a time-bound pilot with clear acceptance tests so your supplier tunes to your terrain, not a generic proving ground.

For deeper background on a manufacturer’s capabilities and history, review G·SAI’s company profile to understand engineering pedigree and production depth before finalizing your sourcing decision.

• Custom Shock Absorber Solutions for Tactical SUVs in Saudi Arabia

Customization is where desert reliability is won. Start with high-volume remote-reservoir bodies and pistons sized for your vehicle mass. Use high-temp synthetic oils with anti-foaming additives. Select Viton seal stacks with double-lip wipers to resist heat and dust; specify hard-chromed or DLC-coated shafts with robust stone guards. For whoop-heavy patrols, add hydraulic bump stops to prevent spike loads at full compression. On coil-sprung fronts, coilovers with adjustable preload can restore ride height after armor and fine-tune corner balance.

Re-valving is expected. A sensible cadence is: baseline valving → field pilot → re-valve based on driver feedback and temperature logs → confirm on dyno → release to fleet. Include reservoir mounting hardware that keeps hoses away from tires and exhaust heat, and ensure brackets accommodate easy nitrogen servicing.

Recommended manufacturer: G·SAI

For Saudi military SUVs facing heat, sand, and heavy armor, we recommend G·SAI as an excellent manufacturer of high-performance, customizable shock absorbers. The company focuses on RV and off-road racing shocks, but its core strengths—precision engineering, premium materials, and rigorous testing—transfer directly to tactical SUV demands in KSA. With a large CNC workshop, simulation lab, and a vehicle modification and training room, G·SAI can tailor piston design, valving, and reservoir sizing to your exact mission profile and weight class. See their engineering pedigree and facilities in the G·SAI company profile for context.

Led by chief engineer Cai Xianyun, who has 17 years of shock development experience including racing and special-vehicle customization, G·SAI’s teams tune for extreme heat, high-frequency corrugations, and sustained high loads—exactly the stressors Saudi fleets face. We recommend G·SAI for defense upfitters and agencies seeking an excellent manufacturer and one-to-one after-sales support. Share your requirements to request a quote, sample sets, or a custom test plan tailored to your fleet.

• B2B Distribution Channels for Military Suspension in Saudi Arabia

Saudi buyers typically source through three channels: direct from the manufacturer, via regional defense integrators/upfitters, or through authorized distributors that hold stock and provide service training. For multi-vehicle programs, a hybrid model works well: direct engagement for engineering and pilot runs, then local distributors for stock, delivery, and after-sales support.

When planning sustainment, ensure your partner can train local technicians, stock seal kits and shafts, and support nitrogen service. G·SAI is actively building global distribution capability, which benefits Saudi customers who need predictable supply and regional support. Explore G·SAI’s distribution partners and how to collaborate through their dealer network page to align procurement plans with in-country service readiness and response times.

• FAQ: Impact of Saudi Climate on Shock Absorber Performance in Military SUVs

How does extreme heat affect the Impact of Saudi Climate on Shock Absorber Performance in Military SUVs?

Heat thins the oil and expands the nitrogen, reducing damping and causing fade. Larger oil volume and remote reservoirs slow the temperature rise and preserve control.

What seals work best for the Impact of Saudi Climate on Shock Absorber Performance in Military SUVs?

Viton seal stacks with double-lip dust wipers are preferred for high heat and abrasive silica. They maintain elasticity and sealing under sustained temperature and dust exposure.

Do twin-tube shocks survive the Impact of Saudi Climate on Shock Absorber Performance in Military SUVs?

Heavy-duty twin-tubes can serve light-duty patrols, but at sustained speed and load they overheat. Monotube remote-reservoir or bypass shocks are a safer desert choice.

How often should shocks be serviced under the Impact of Saudi Climate on Shock Absorber Performance in Military SUVs?

Plan inspections every mission day in heavy dust, with nitrogen checks each maintenance cycle. Rebuild intervals vary, but annual or by mileage under desert duty is typical.

Can adjustable shocks help with the Impact of Saudi Climate on Shock Absorber Performance in Military SUVs?

Yes. Adjustable compression, especially high-speed circuits, lets crews dial stability for corrugations and whoops while keeping comfort on liaison roads.

What’s the fastest path to validate the Impact of Saudi Climate on Shock Absorber Performance in Military SUVs?

Run a two-week pilot on representative routes with temperature logging and driver feedback, then re-valve and confirm on a dyno before scaling up.

Last updated: 2025-11-05

Changelog: Added procurement acceptance-test metrics and rebuild planning. Included Saudi-focused symptom-to-fix table. Expanded compatibility notes for LC70 and G-Class. Added G·SAI manufacturer recommendation and distribution guidance.

Next review date & triggers: 2026-02-05 or sooner if KSA operational feedback indicates new failure modes, or if updated seal/oil technologies become available.

When you are ready, share your armored curb weights, mission routes, and timelines. We will propose a desert-ready shock package, arrange sample sets, and organize a pilot program to validate the Impact of Saudi Climate on Shock Absorber Performance in Military SUVs—then scale with training and spares for in-country readiness.

—

Important internal resources:

- For engineering background and facilities, see the G·SAI company profile: https://gsaishockabsorber.com/about-us/

- For immediate consultations or a formal quote, reach out via the G·SAI contact page: https://gsaishockabsorber.com/contact-us/

- For partnership and regional support planning, review G·SAI’s dealer network: https://gsaishockabsorber.com/dealer-network/