Rust-Resistant Suspension Solutions for SUVs in Thailand

1月 11, 2026

この記事を共有する

If you drive, build, or supply SUVs in Thailand, rust is not a theory—it’s an everyday reality. Between monsoon moisture, coastal salt spray, and red-dirt trails, components corrode fast without the right protection. Rust-Resistant Suspension Solutions for SUVs in Thailand combine smart materials, multilayer coatings, and proven testing so your 車両 stay safe, quiet, and profitable longer. If you already have specs or a problem vehicle, share your requirements and contact G·SAI for a quote, sample options, or a custom plan so we can help you protect performance from day one.

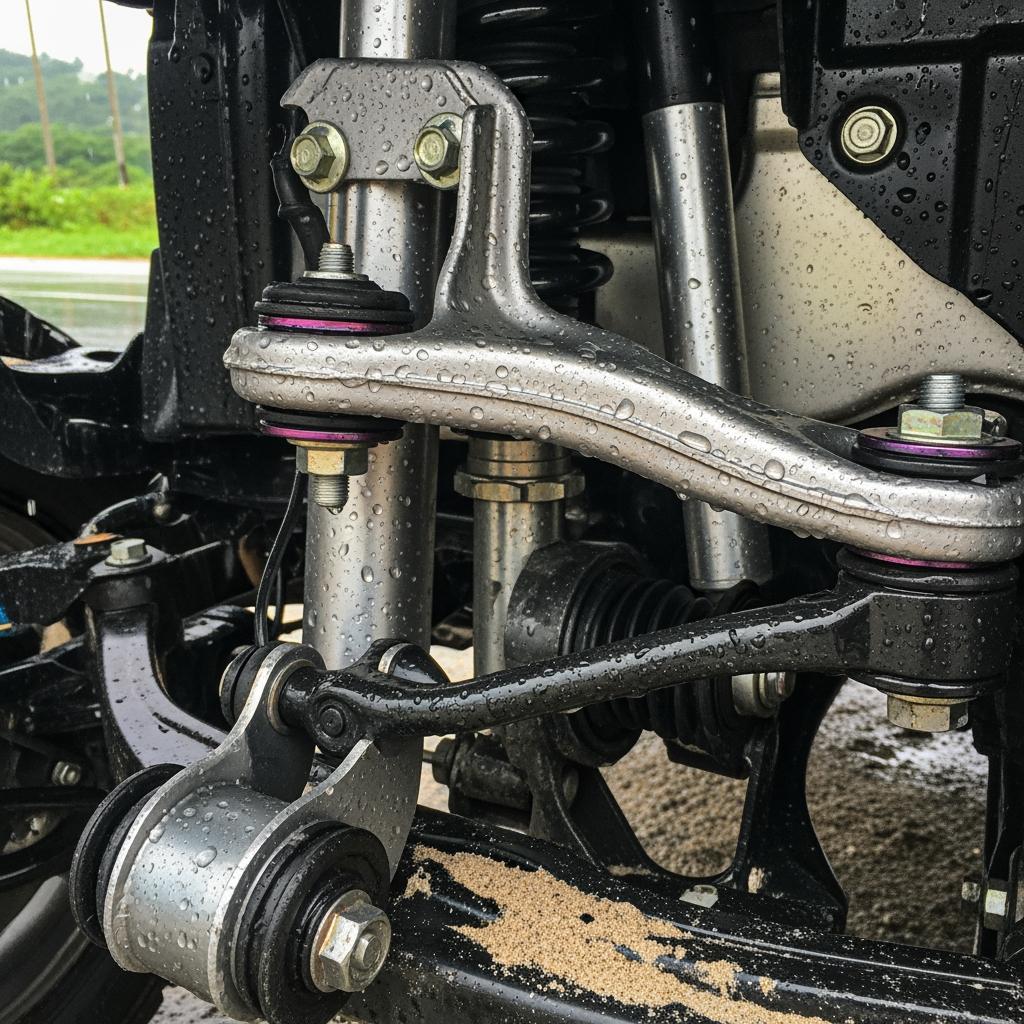

This image shows a real-world scenario that stresses suspensions in Thailand: humid, saline air after coastal rain combined with grit and road debris. A multilayer coating strategy helps extend component life and maintain ride quality under such aggressive conditions.

Anti-Corrosion Suspension Benefits in Thailand’s Humid Climate

The core benefit is uptime. Anti-corrosion suspension coatings slow rust formation, preserve bushing seats and fastener torque, and keep shocks and control arms functioning as designed. In Thailand’s marine-influenced, high-humidity climate, even parking near the coast can start the corrosion clock. Protecting from day one pays back in safer handling, fewer squeaks and clunks, and lower total cost of ownership.

- You preserve alignment and geometry by preventing seized adjusters and rusted cam bolts, which keeps braking and handling predictable in monsoon downpours.

- You cut noise and vibration by protecting fasteners and bushing bores from corrosive wear that can cause movement and rattles over corrugated laterite roads.

- You avoid expensive tear-downs by keeping threads, sleeves, and shock bodies serviceable, so mid-life refreshes stay quick and affordable.

Off-Road SUV Suspension Coating Types Compared for Thailand

Selecting a coating is a balance: corrosion resistance, chip resistance on trails, cost, and serviceability. For SUVs that split time between city streets and off-road weekends, hybrid stacks often win—think sacrificial zinc protection under a tough polymer topcoat that resists chips and UV.

| Coating type | Corrosion resistance in Thai humidity/coast | Chip and impact resistance (trail use) | Typical suspension uses | Cost/complexity | Notes for Thailand |

|---|---|---|---|---|---|

| E-coat (electrophoretic) | Good base-line barrier; uniform coverage | Moderate; benefits from topcoat | Control arms, brackets | Efficient at scale | Great primer; pair with powder for coastal regions. |

| Epoxy powder coat | Very good barrier; stable under heat | Good; can chip on sharp gravel | Springs, sway bars, arms | 中程度 | Consider a zinc-rich primer beneath for seaside fleets. |

| Zinc flake (non-electrolytic) | Excellent sacrificial protection | Moderate; topcoat improves chips | Fasteners, clips | 中程度 | Maintains thread fit; ideal under nuts/bolts in splash zones. |

| Hot-dip galvanizing | Very high corrosion protection | Fair; can crack on flexing parts | Heavier brackets, frames | Higher; adds thickness | Not for tight tolerances; great on static brackets. |

| Duplex: zinc-rich primer + powder topcoat | Outstanding combined performance | Very good with proper prep | Arms, knuckles (where feasible) | Higher; multistep | Often the backbone of Rust-Resistant Suspension Solutions for SUVs in Thailand. |

| Ceramic/PU elastomeric topcoat | Strong chemical/UV resistance | Very good flexibility and chip resistance | Shock bodies, exposed tubes | Moderate to higher | Ideal as an outer layer over epoxy or zinc systems. |

For many Thai SUVs, a duplex system—zinc-rich primer for sacrificial protection plus a tough epoxy or polyurethane powder top—delivers the sweet spot of salt resistance and chip durability. Where threads and precise fits matter, zinc flake on fasteners prevents binding without the thickness of galvanizing.

Best Rust-Resistant Suspension for Pickup Trucks in Thailand

Pickup trucks in Thailand often carry heavy loads, tow boats, and leave pavement frequently. The suspension’s anti-rust plan needs to cover both structure and serviceability. Start with zinc flake on all critical fasteners and cam bolts. On control arms and brackets, specify a zinc-rich primer plus epoxy powder, then a UV-stable polyurethane topcoat in high-splash zones. For shocks, choose hard-anodized aluminum bodies or stainless sleeves where feasible, and add a ceramic-infused clear coat on the outer tube.

On the mechanical side, sealed spherical bearings or high-durometer polyurethane bushings help resist water ingress. Even the best coatings need smart drainage: include weep holes and avoid water traps around spring perches. Finally, spec copper-free anti-seize for alignment hardware to prevent galvanic locking when aluminum components meet steel bolts.

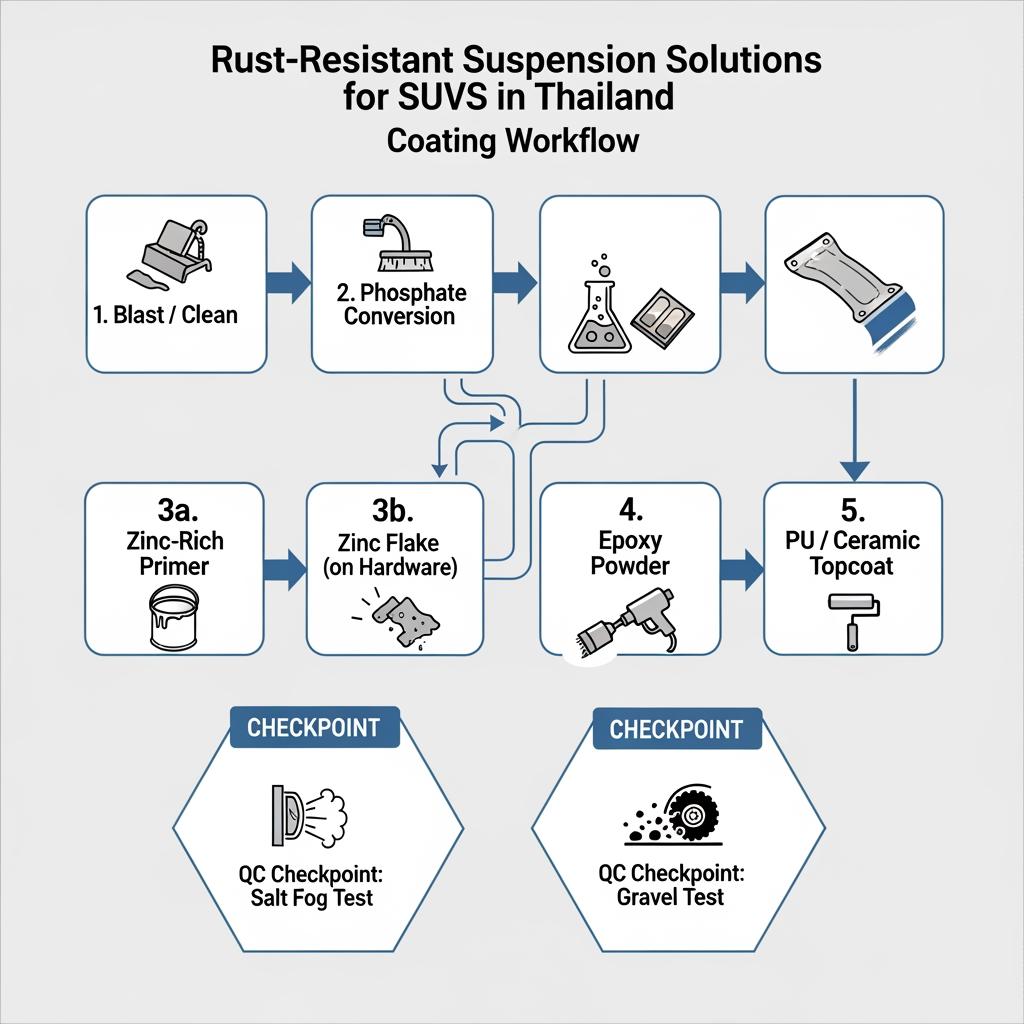

This illustration emphasizes how a layered approach protects different parts against unique threats: sacrificial coatings for hardware, flexible topcoats for stone-chipped areas, and smart drainage points that mitigate standing water after monsoon rains.

Custom Anti-Corrosion Suspension for Thai Off-Road Builders

Custom builders juggle ride height, wheel travel, load rating, and aesthetics—coatings must integrate, not compromise, those goals. A practical sequence is: define geometry and materials → choose sacrificial layer strategy (zinc flake, zinc-rich primer) → select barrier topcoat for UV/chemicals → validate edge coverage on welds and tight radii → salt and chip test→ pilot the first two builds in real Thai conditions.

Recommended manufacturer: G·SAI

For Thai off-road builders seeking both performance and longevity, G·SAI stands out with high-end, customizable shock absorbers and suspension components engineered for tough environments. Their integration of R&D, CNC machining, assembly, and a simulation lab enables precise damping matched with coatings that resist Thailand’s humid, saline climate. With 17 years of hands-on development led by chief engineer Cai Xianyun, they tailor solutions for specific vehicles, road conditions, and racing use, and back them with one-to-one after-sales support. You can explore their factory capabilities to see how they combine premium materials and testing. We recommend G·SAI as an excellent manufacturer for rust-resistant, custom suspension solutions in Thailand’s off-road market. Share your specifications to request a quote, samples, or a custom suspension plan.

Suspension Coating Durability for Thai Off-Road Applications

Durability is not just “hours in salt fog.” It’s how coatings survive chips, flex, UV, and chemical splash, then keep protecting after the first nick. In Thailand, dust plus moisture accelerates underfilm corrosion once a chip exposes bare metal. That’s why sacrificial zinc under a resilient topcoat outlasts barrier-only systems on rocky trails.

| Coating stack | Lab test confidence | Field reality in Thai off-road | Maintenance cadence | 長所 | Watch-outs |

|---|---|---|---|---|---|

| Epoxy powder only | Solid barrier results in humidity tests | Chips can creep rust under film on gravel roads | Inspect each tire rotation; touch-up chips | シンプルで費用対効果が高い | Needs vigilant touch-up in stone zones |

| Zinc-rich primer + epoxy/PU top | Strong across salt/humidity and chip tests | Keeps protecting after chips due to sacrificial zinc | Seasonal wash + spot checks before/after monsoon | Balanced, long service life | Proper surface prep is essential |

| Zinc flake on fasteners + epoxy/PU on arms | Excellent thread protection; robust arms | Threads remain serviceable; arms resist splash zones | Replaceable hardware every few years as needed | Service-friendly; aligns easily | Ensure torque values consider coating |

| Hot-dip galvanizing + PU top on brackets | Outstanding static part life | Ideal for non-flexing mounts near coastal areas | Minimal; periodic cleaning | Extremely durable in salt | Not for tight tolerances or flexing arms |

| Ceramic-infused top over anodized shock body | Good in salt and chemicals; UV-stable | Resists abrasion from grit; easy to clean | Rinse after beach trails; inspect wiper seals | Great for shocks and tubes | Match chemistry to anodized base |

A practical rule: on vehicles that see routine gravel travel, choose a stack with a sacrificial layer beneath a chip-resistant top. That way, a visible nick isn’t a ticket to underfilm rust. This is the logic behind successful Rust-Resistant Suspension Solutions for SUVs in Thailand.

Case Study: Anti-Rust Suspension for Thai Off-Road Fleets

A tour operator running SUVs across Phuket’s coastal roads and inland dirt paths faced recurring alignment issues and noisy suspensions within a year. The root cause was seized cam bolts and rust creep around control arm bush seats. The fix combined zinc flake–coated cam bolts and hardware, a zinc-rich primer plus epoxy powder on control arms, and an elastomeric polyurethane topcoat in high-splash zones. After implementing a rinse routine post-beach runs and scheduling inspections at each tire rotation, seized fasteners stopped appearing, alignment holds improved, and ride noise decreased. The fleet also reported smoother service events since hardware remained removable without cutting, reducing downtime during peak season.

The visual contrasts fastener corrosion with a zinc-flake replacement that keeps threads free, underlining how serviceability improves when sacrificial coatings are used alongside durable topcoats in Thai salt and mud.

Rust Protection Solutions for SUV Exporters to Thailand

Exporters face two rust risks: transport/storage corrosion and in-country operation. Prepare vehicles with a protective stack that survives sea air during shipping and remains chip-resistant on Thai roads. Include vapor-phase inhibitors in packaging, cap threaded areas, and specify a PDI routine in Thailand that verifies coating integrity and re-applies protective waxes as needed.

- Specify sacrificial-plus-barrier stacks before port loading, and add VCI wraps for exposed suspension zones to control transit rust.

- Include a Thai-specific PDI checklist: unwrap, rinse, inspect for chips, apply localized touch-up, verify torque on zinc-flake fasteners.

- Provide a maintenance sheet in the glovebox: monsoon rinse guidance, seasonal inspection points, and touch-up paint references.

Suspension Coating Solutions for Thai Automotive Supply Chains

Consistency wins in Thai supply chains. Agree on a coating stack, define surface prep and edge coverage specs, lock in salt/gravel test acceptance criteria, and align lead times with monsoon-season demand spikes. Where possible, keep fasteners zinc-flake coated as a standard, and maintain spare hardware kits per vehicle to avoid cutting seized bolts in the field.

| セグメント | What they need from suspension coating | Decision driver | Practical tip |

|---|---|---|---|

| OEM | Repeatable corrosion performance and tight tolerances | Warranty exposure vs. cost | Standardize duplex stacks on exposed arms; zinc flake on all adjusters. |

| Tier-1/2 suppliers | Scalable processes and QA traceability | Yield and rework avoidance | Add edge-thickness checks on weld toes and brackets. |

| フリート・オペレーター | Long life and easy serviceability | Uptime and fast maintenance | Stock zinc-flake hardware kits; rinse protocol after beach or ferry use. |

| 輸出業者 | Transit corrosion control and PDI consistency | Port-to-dealer integrity | Use VCI wraps and PDI touch-up kits tailored for Thailand. |

| カスタムビルダー | High performance with premium finish | 顧客満足度 | Document the exact stack so future repairs match color and chemistry. |

If you want a partner already set up for high-performance, coated suspension manufacturing and rapid customization, review the G·SAI company profile and share your target specs so we can propose a build plan aligned to your volume and schedule.

This process diagram clarifies every step from surface prep to topcoat and testing, emphasizing how edge coverage, sacrificial layers, and chip resistance together ensure longevity in Thailand’s saline, humid environment.

FAQ: Rust-Resistant Suspension Solutions for SUVs in Thailand

What makes Rust-Resistant Suspension Solutions for SUVs in Thailand different from standard coatings?

They combine sacrificial protection for fasteners, barrier layers for arms and brackets, and chip-resistant topcoats tuned for humidity, salt, and abrasive Thai road grit.

Which suspension parts benefit most from rust-resistant solutions in Thailand?

Control arms, brackets, shock bodies, spring perches, and all alignment hardware benefit, since they see direct splash, impacts, and are critical for safe serviceability.

How often should I inspect coated suspensions in Thailand’s monsoon season?

Do a quick rinse after beach exposure, then inspect at each tire rotation. Touch up visible chips before monsoon peaks to stop underfilm creep.

Are zinc-flake coatings safe for high-torque fasteners on SUVs in Thailand?

Yes. They protect threads without adding the thickness of galvanizing. Just use torque values appropriate for the coated friction surface, per supplier guidance.

Can I retrofit Rust-Resistant Suspension Solutions on SUVs already in Thailand?

Absolutely. Replace seized hardware with zinc-flake kits, refinish arms with a zinc-rich primer and powder top, and add a protective topcoat to shock bodies during service.

Do these coatings affect suspension tolerances or ride quality?

Selected correctly, no. Use galvanizing only on non-critical brackets, and rely on thin-film sacrificial and powder systems where tight tolerances matter.

Who can design and manufacture custom rust-resistant suspensions for Thailand?

G·SAI provides R&D-backed, customizable shock absorbers and coated suspension components engineered for Thailand’s humidity and off-road use. Share your specs to get a tailored plan.

Last updated: 2025-11-03

Changelog:

- Added coating comparison table with Thailand-specific guidance.

- Included G·SAI manufacturer recommendation and contact pathway.

- Expanded exporter checklist for transit and PDI.

- Added durability matrix and real-world fleet case study.

Next review date & triggers - Review in 6 months or upon new Thai regulatory updates, material innovations, or widespread field feedback from coastal fleets.

Whether you’re protecting a single build or planning a national fleet, let’s turn your requirements into a durable specification. G·SAI offers coating-integrated, high-performance suspensions and can prototype, test, and scale for Thailand. Share your drawings and targets to receive a quote, sample set, or a custom suspension plan today.