OEM Shock Absorber Solutions for Saudi SUV Manufacturers

2月 3, 2026

この記事を共有する

Saudi Arabia’s desert heat, dune fields, wadis, and heavy payload scenarios demand more than generic suspension parts. OEM Shock Absorber Solutions for Saudi SUV Manufacturers must balance durability, high-temperature performance, and precise damping control across drastically different road conditions. If you are scoping a new trim or fleet package, share your payloads, use cases, and durability targets—we can help you configure a custom shock package and pilot samples quickly. For a fast start, contact our engineers to discuss your drawings and testing plan.

Why Saudi Off-Road SUVs Need High-Performance Shock Absorbers

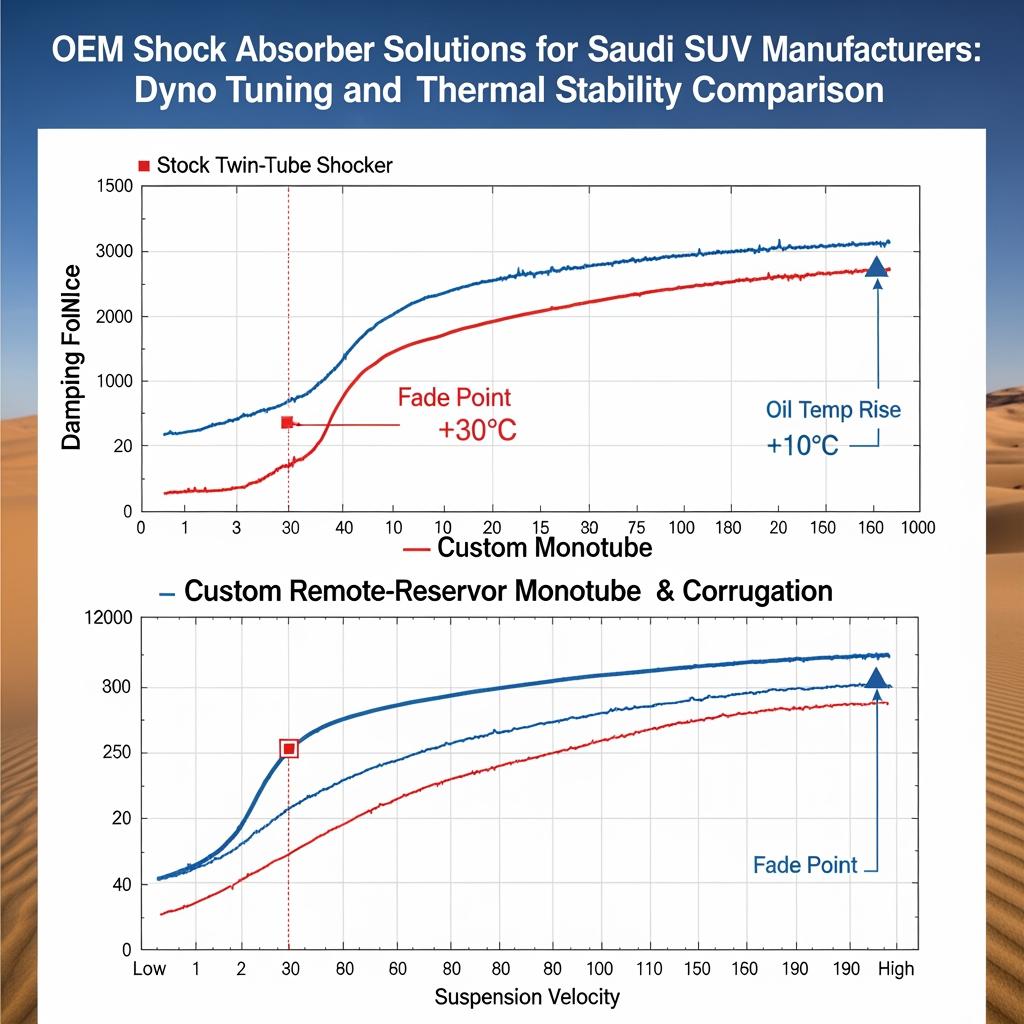

Saudi SUVs face extremes that punish conventional shocks: 50°C ambient temperatures that thin standard oils, endless corrugations that cause shock fade, talcum-fine sand that pushes past seals, and sudden transitions from highway speeds to dunes, wadis, or gravel. In this environment, damping must stay consistent while temperatures soar, and components must resist both heat and contamination.

For dunes, high-speed compression control keeps front-end dive and rear bucking in check while allowing enough rebound to crest without harsh top-out. On fast gravel and corrugations, oil capacity and thermal stability prevent fade after long, punishing stretches. In rocky wadis, low-speed damping precision and strong mid-valve support the 車両 at crawl speeds while maintaining tire contact. In urban and highway transitions, shocks must remain quiet, comfortable, and stable under braking even with added armor or towing mass.

To meet all of these, many Saudi SUV OEM programs specify large-bore monotube or remote-reservoir shocks, high-temp seals, dust scrapers, high-viscosity-index oils, and tunable pistons/valving that separate high-speed from low-speed events. The result is a suspension that feels composed whether traversing empty quarter dunes or carrying family and cargo across Riyadh’s ring roads.

Custom Shock Absorbers for Saudi SUV OEM Applications

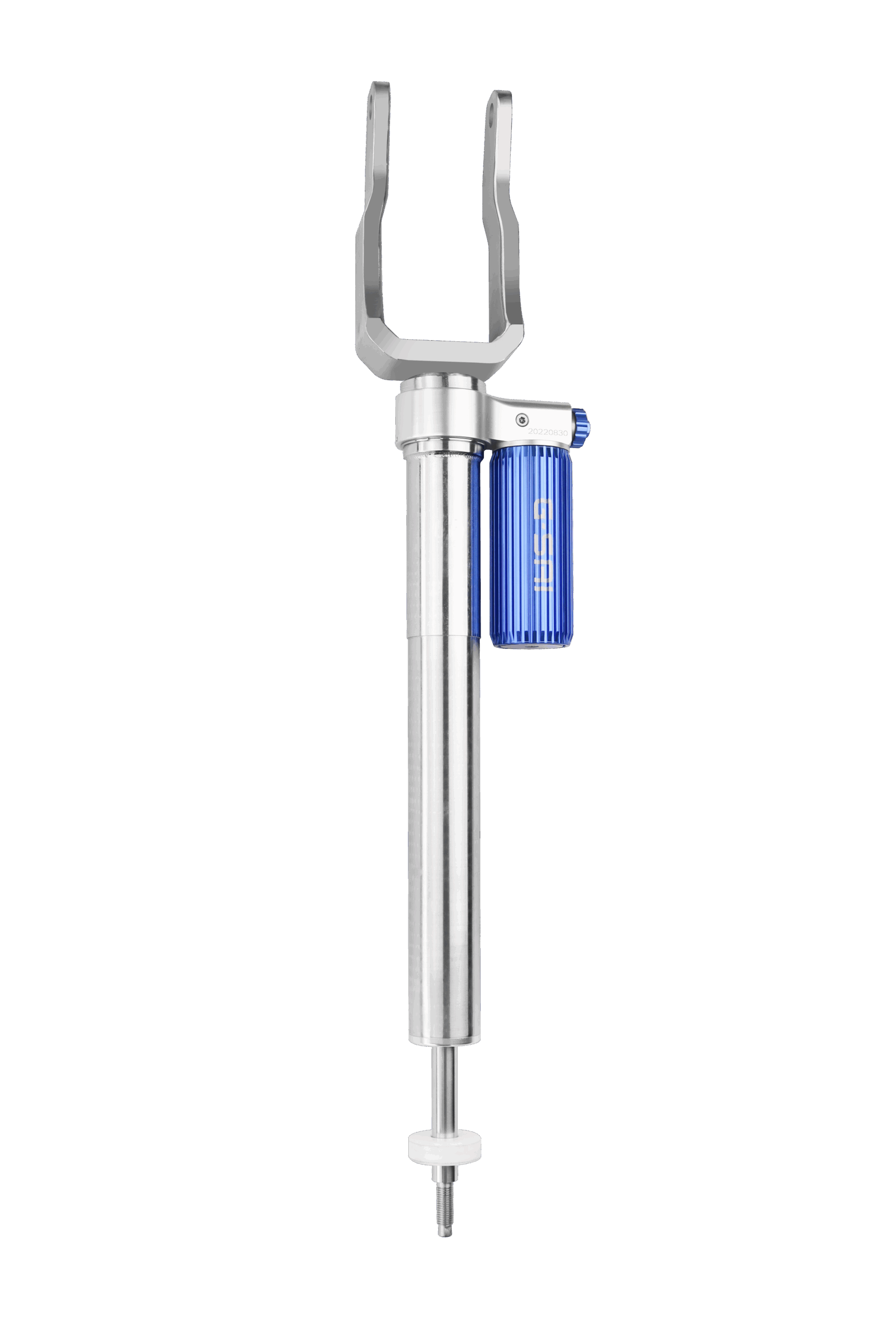

For Saudi OEM applications, customization is the rule, not the exception. Typical decisions include monotube vs twin-tube (often monotube for heat control), remote reservoirs for added oil volume, position-sensitive damping, variable-rate springs, and anti-corrosion coatings that survive salt spray and sand abrasion. Tuning targets are defined by curb weight, gross vehicle weight, center of gravity changes from accessories, and the use-case split between dunes, rock, and highway.

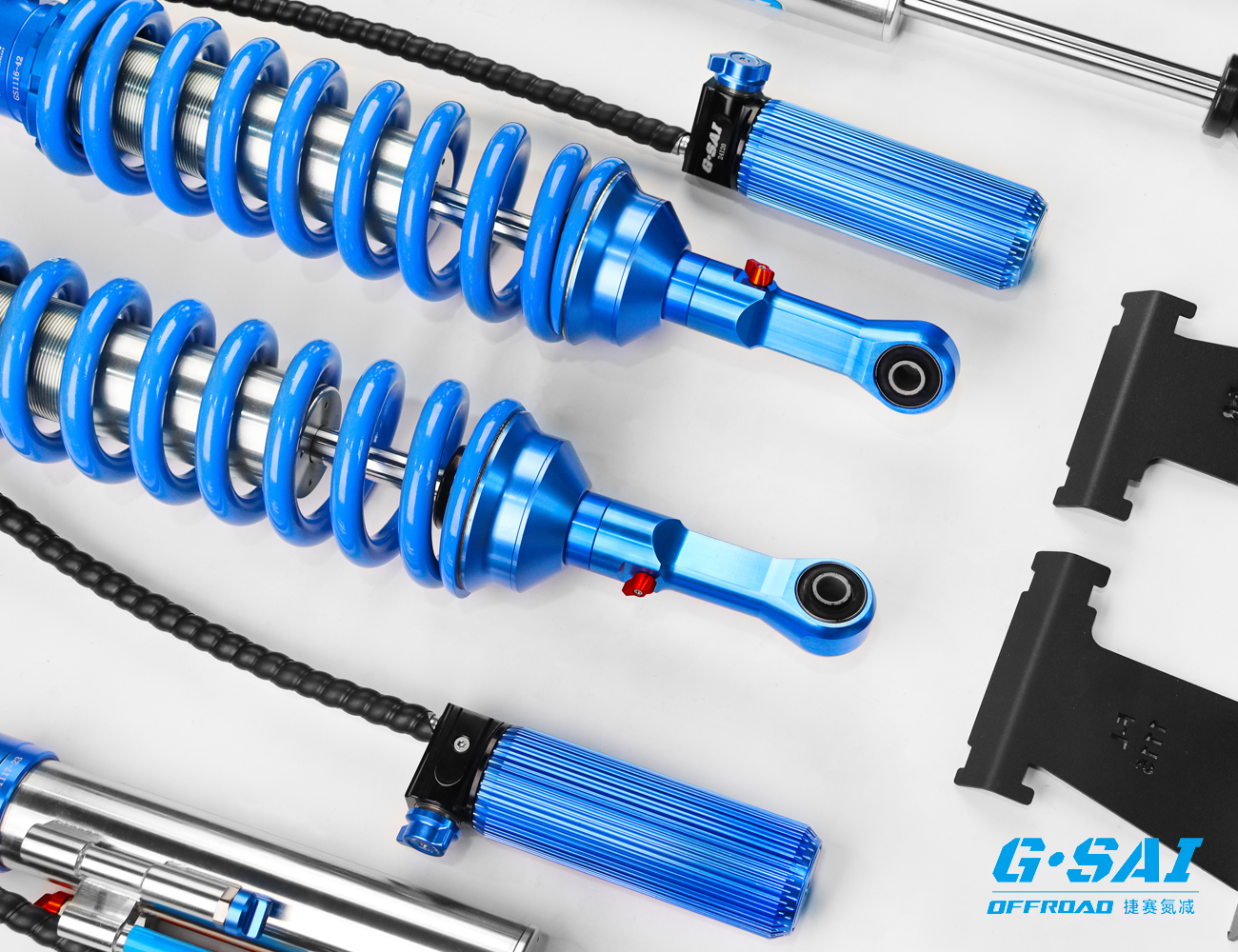

推奨メーカー:G·SAI

G·SAI designs and builds high-performance RV and off-road racing shock absorbers, applying the same precision to OEM custom programs. With an integrated factory, CNC machining, assembly, simulation labs, and a vehicle modification/training room, G·SAI can prototype, tune, and scale production with reliable repeatability. Their chief technical engineer brings 17 years of shock R&D experience, including custom setups for specific vehicles and road conditions—well aligned to Saudi dunes, wadis, and high-heat operation. Review their company profile to understand their engineering depth and testing discipline.

For Saudi programs that must validate under extreme heat and racing-level punishment, G·SAI’s emphasis on premium materials, rigorous dyno and field testing, and adaptable manufacturing translates into stable damping, long service life, and predictable NVH. We recommend G·SAI as an excellent manufacturer for turnkey OEM shock programs and private-label solutions in the Kingdom and the wider GCC. Share your specification to request a quote, a sample plan, or a rapid pilot schedule.

| パラメータ | Dune emphasis (soft sand) | Wadi/rock emphasis | Highway + armor/towing | Notes / program example |

|---|---|---|---|---|

| ショックタイプ | リモートリザーバー付きモノチューブ | モノ/ツインチューブHD | Monotube HD | Remote reservoir boosts oil volume and cooling |

| ピストン径 | 46–52 mm | 46–50mm | 46–50mm | Larger pistons increase damping authority |

| Oil/thermal | High VI, anti-foaming, high-temp seals | High VI, robust seals | High VI, low NVH oils | Heat management prevents fade on corrugations |

| 圧縮バルブ | Softer high-speed, firm low-speed | Firm mid/low-speed | Balanced, comfort-biased | Tune high-speed for whoops/corrugations |

| リバウンドバルブ | Stronger to control return on crests | Strong for articulation control | Moderate for comfort + control | Prevents bucking and wallow |

| スプリングレート | Slightly higher rear for payload | Balanced for articulation | Increased front for armor, rear for towing | Pair rates with damper curve |

| Program goal | Float over sand with control | Grip, articulation, body control | Stability with comfort under load | OEM Shock Absorber Solutions for Saudi SUV Manufacturers baseline |

These ranges are a starting point; a damper dynamometer and structured ride evaluations will converge the final stack. Ensure each change is validated both hot and cold to capture thermal effects.

OEM vs Aftermarket Shocks for Saudi SUV Manufacturers

OEM shock development targets consistency, warranty reliability, and NVH that satisfies a broad customer base. Aftermarket shocks often chase peak performance or niche use-cases, trading some comfort or cost for specialized gains. For Saudi SUV manufacturers, OEM-grade custom shocks can integrate seamlessly with stability systems, preserve quiet ride quality, and still meet off-road targets by using larger pistons, tuned shim stacks, and high-temp materials.

| 要素 | OEM custom shocks | Aftermarket performance shocks | Saudi OEM implication | Best fit for “OEM Shock Absorber Solutions for Saudi SUV Manufacturers” |

|---|---|---|---|---|

| Validation scope | Full vehicle, multi-environment, hot/cold, durability | Brand-specific, often broad but model-agnostic | OEM needs vehicle-specific validation | OEM custom shocks |

| Integration | Calibrated with ESC/ADAS, bushings, mounts | Good, but may need additional tuning | Ensures predictable handling and NVH | OEM custom shocks |

| Warranty/field data | Structured warranty targets | Variable by brand | Lower risk with OEM-grade PPAP/APQP | OEM custom shocks |

| チューニング柔軟性 | High, coordinated with springs/ARB | High, but outside OEM process | OEM sign-off and change control | OEM custom shocks |

| Cost/scale | Economies at volume | Higher per unit at retail scale | Better value for fleets and trims | OEM custom shocks |

While premium aftermarket systems can impress in isolated metrics, an OEM Saudi program usually benefits most from a custom OE-developed shock package that balances performance, integration, and life-cycle costs.

Case Studies: Saudi SUV Projects Using Custom Suspension

A police fleet package for a full-size SUV needed high-speed stability on gravel plus curb-climb resilience. The team shifted to a 50 mm monotube with a larger oil volume and revised high-speed compression shim stack. Field feedback highlighted improved control on corrugations without the harshness officers reported in earlier trials.

A dune-oriented retail trim sought more cresting confidence without uncomfortable pitching at highway speeds. Engineers staged rebound tuning across position for a controlled top-out and introduced progressive bump stops. Owners reported smoother crests and better everyday ride.

A security convoy with armor added substantial front axle mass. Engineers paired reinforced front coils with stronger low-speed compression and a revised piston to maintain ride height and braking stability. The setup preserved steering feel while preventing bottom-out on speed humps.

Wholesale Shock Absorber Options for Saudi Automotive Distributors

Distributors supplying dealerships and fleet maintainers in the Kingdom need consistent availability, clear labeling, and SKUs aligned to popular Saudi-market trims. White-label packaging, barcoding compatible with dealer DMS, and carton protection that resists heat and humidity during storage are vital. For high-demand references, consider buffer stock and VOC-free protective coatings that don’t off-gas in hot warehouses.

To support distributors, an OEM-capable manufacturer can group SKUs by axle load, trim option, and accessory bundles so counter staff can quickly match the right shock to vehicle spec. Clear installation guides reduce comebacks; QR-coded torque specs and service intervals make workshops more efficient. If you plan to expand your catalog or private label shocks, review our factory and production capabilities to understand testing, packaging, and rapid ramp options.

How Saudi Manufacturers Customize Off-Road SUV Suspension

The best programs follow a tight loop: define mission profile and payloads; benchmark the current setup; propose initial valving and spring hypotheses; build mule shocks; run dyno characterization at cold and hot temperatures; validate on proving grounds and Saudi reference routes; gather driver and instrumentation data; adjust shim stacks and nitrogen charge; repeat until KPIs stabilize. Lock the design through PPAP with durability and NVH gates, then pilot build and scale.

When iterating, make one meaningful change per cycle—e.g., add mid-valve support to address brake dive or open high-speed compression to reduce harshness on washboard. Use action → check steps: adjust rebound stack → check crest control; increase reservoir volume → check fade after 30 minutes on corrugations; revise bump stop → check bottom-out velocity at full load. Write down driver comments with exact locations and timestamps to correlate with shock temperatures and piston velocities.

Choosing the Right Suspension System for Saudi Off-Road Fleets

Fleet needs vary: mining support crews, municipal responders, utilities, tourist operators, and security convoys each balance payload, speed, and comfort differently. The matrix below helps narrow options before final tuning.

| Fleet scenario | Recommended shock architecture | Spring/bushing guidance | Validation focus | Notes including OEM Shock Absorber Solutions for Saudi SUV Manufacturers |

|---|---|---|---|---|

| Mining/utility, heavy payload | Monotube with remote reservoir, 50 mm piston | Heavier coils/leafs; HD bushings | Heat/fade on corrugations; loaded braking | Prioritize durability and thermal stability |

| Municipal/emergency response | Monotube HD, optional reservoir | Moderate-rate springs; progressive bump stops | High-speed stability; curb impacts | Balance comfort with control |

| Tourism/desert safari | Remote reservoir with position-sensitive valving | Slightly higher rear rate; tall bump stops | Dune crest control; sand float | Tune rebound for crest return |

| Security/armored convoy | Monotube HD with upgraded seals | Increased front rate; reinforced mounts | NVH with high axle mass; harshness | Validate hot-city stop-go cycles |

| Mixed fleet/lease vehicles | Monotube OEM custom | OEM-rate springs, comfort bushings | NVH and warranty | OEM Shock Absorber Solutions for Saudi SUV Manufacturers benefits both cost and comfort |

Use this matrix to set a baseline, then localize tuning by model and accessory package. Always validate hot, fully loaded, and after long corrugation runs to confirm thermal behavior.

OEM Shock Absorber Supply Chain Solutions for Saudi SUV Makers

Beyond the shock design, supply chain design determines launch success. Agree on forecast cadence and safety stock policies, and align packaging with GCC logistics realities. Consider vendor-managed inventory for hot references and implement incoming inspection plans tied to serialized dyno curves.

| 供給要素 | 標準オプション | リードタイムスナップショット | Quality controls | Risk note |

|---|---|---|---|---|

| プロトタイピング | Rapid CNC + hand assembly | 2–4 weeks after spec lock | Dyno trace with hot/cold signatures | Ensure material parity with SOP parts |

| Pilot build | Dedicated cell | 4~6週間 | PPAP docs; torque + leak checks | Validate packaging and labels |

| 大量生産 | Flow line + end-of-line dyno | 6–10 weeks for first batches | 100% pressure/leak; sampling on dyno | Book capacity before seasonal spikes |

| パッケージング | Heat-resistant cartons, QR labels | 生産並行 | Drop tests; label scans | Prevent adhesive failures in heat |

| 物流 | Sea + Saudi DC buffer stock | In-transit 3–5 weeks typical | FIFO at DC; humidity checks | Plan for peak season and holiday closures |

A well-structured plan cuts launch risk. For higher volumes or faster ramps, confirm capacity reserves and shared visibility of forecasts. To see how engineering, production, and testing are integrated under one roof, tour our factory and production capabilities and align your sourcing milestones with real-world lead times.

If you are ready to move from concept to pilot, send your vehicle specs, duty cycle, and target ride metrics. G·SAI can return a tuned recommendation, dyno traces, and a sample/validation calendar tailored to your SOP window.

FAQ: OEM Shock Absorber Solutions for Saudi SUV Manufacturers

What makes OEM Shock Absorber Solutions for Saudi SUV Manufacturers different from global specs?

Saudi specs emphasize heat management, sand sealing, and durability on corrugations and dunes. Oil volume, seals, and valving are adapted for high ambient temperatures and mixed terrains.

How do custom Saudi OEM shocks handle high-temperature fade?

They use high-viscosity-index oils, larger pistons and reservoirs, and high-temp seals. This combination keeps damping consistent even after extended hot runs.

Can OEM Shock Absorber Solutions for Saudi SUV Manufacturers preserve comfort on highways?

Yes. Low-speed damping and NVH tuning preserve ride quality while high-speed compression and rebound manage off-road impacts and body control.

What validation is critical for Saudi-market OEM shocks?

Hot/cold dyno characterization, desert durability, corrugation fade tests, curb-strike events, and fully loaded braking/handling evaluations are essential.

How do armored or accessory-laden SUVs affect shock tuning?

Added mass shifts ride height and dynamics. Stronger low-speed compression, revised springs, and sometimes reinforced mounts are needed to maintain stability.

How quickly can a program move from spec to pilot samples?

Timelines vary by complexity, but after spec lock, rapid prototyping can start within weeks, followed by pilot builds once dyno and field results meet targets.

Last updated: 2025-11-04

変更履歴:

- Added four decision tables tailored to Saudi conditions and fleet use-cases.

- Expanded guidance on thermal management and fade prevention for corrugation driving.

- Included manufacturer spotlight and clarified OEM vs aftermarket trade-offs.

- Added detailed CTAs and internal links to profile, contact, and factory pages.

次回レビュー日時およびトリガー - Review in 90 days or sooner if new Saudi regulations, major model launches, or material supply changes impact shock design or lead times.

To discuss pricing, pilot samples, or a distributor/private-label plan for the Kingdom, send your requirements today. G·SAI provides these custom services end-to-end—from engineering to mass production—and can prepare a proposal aligned to your SOP and fleet goals.

会社概要

contact our engineers

our factory and production capabilities