フランスオフロードフリート向け先進サスペンション技術

1月 8, 2026

この記事を共有する

フランスの公益・緊急フリートは沿岸砂丘からアルプスコースまで混合地形へ進出中。要約:フランスオフロードフリート向け先進サスペンション技術は精密ダンピング、スマート調整性、耐塩・泥・負荷変動素材を組み合わせ——車両安定、ドライバー信頼、TCO制御を実現。アップグレードや新規ビルドプログラム検討中なら、 車両 仕様、使用サイクル、ペイロード目標を共有し、サスペンション短リストとサンプルプランへ変換します。迅速対応のため、G·SAIに直接要件を共有し、特化見積もり・サンプルウィンドウを連絡チャネル経由で依頼可能です。

フランスSUV向け精密オフロードサスペンションシステム

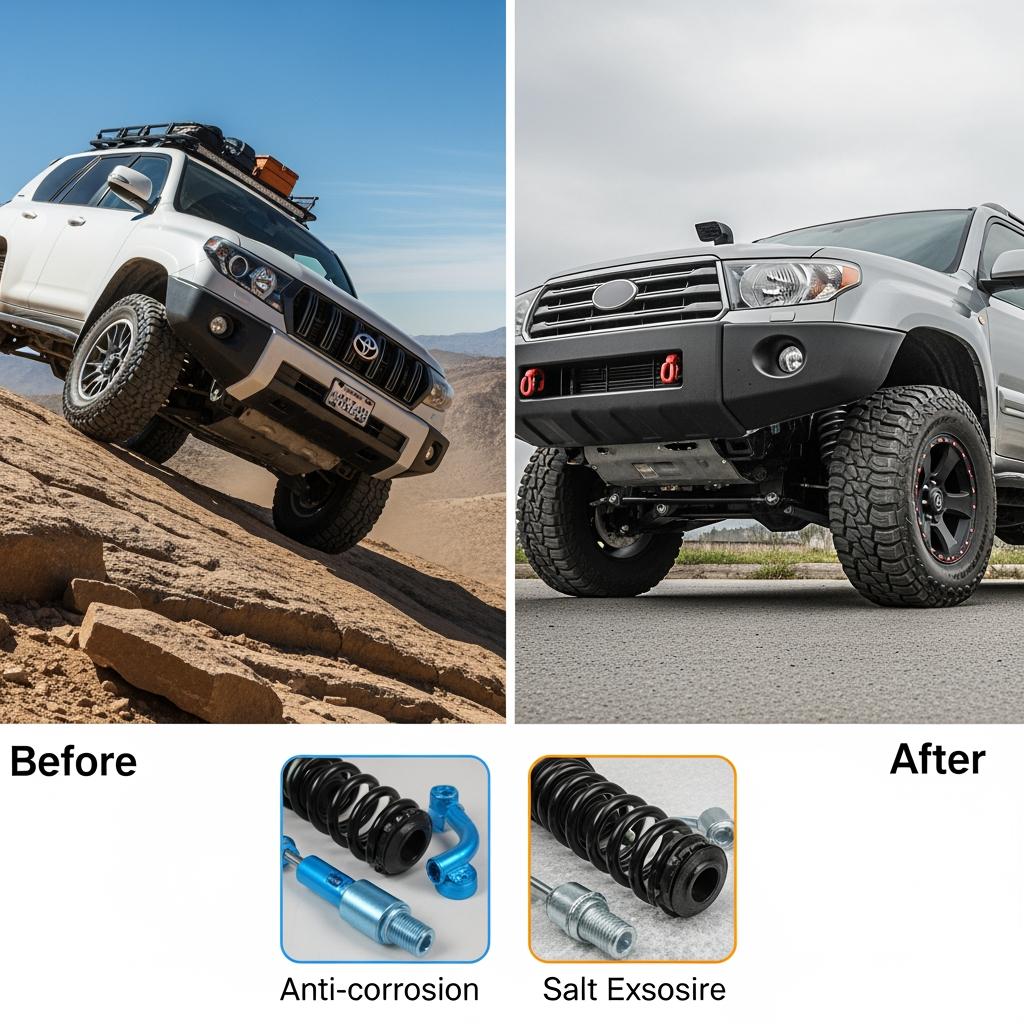

フランスSUVの最速性能向上は、適合ショック・スプリングパッケージから:制御向けディグレシブバルブモノチューブダンパー、ペイロード変化対応プログレッシブスプリング、苛烈ボトムアウト用ハイドロリックバンプストップ、耐食仕上げで海洋・山岳気候耐性。フランス典型混合路面——濡れ石畳から森林トラック——で精密ダンピングが振動防止、粗地制動距離短縮、ドライバー疲労低減。

| 技術 | 機能 | フリート利点 | フランス向けノート |

|---|---|---|---|

| ディグレシブピストン付きモノチューブショック | 高オイル容量と熱放散;堅牢低速制御 | ボディロール・ダイブ低減の安定ハンドリング | 石畳、ラウンドアバウト、轍路に優れる |

| リモートリザーバーダンパー | フェード防止の追加オイル/ガス容量 | 長山岳下降時の持続性能 | アルプス・ピレネー延長制動ゾーンに有用 |

| 油圧バンプストップ | ストローク末端エネルギー吸収 | 急圧縮時のシャーシ保護 | ウォッシュボード・隠れカーブートの苛烈低減 |

| 耐食コーティング(Zn-Ni、エポキシ) | 塩分・湿気下金属保護 | 長寿命、交換低減 | フランスオフロードフリート向け先進サスペンション技術ベストプラクティスの一部 |

| プログレッシブ・スプリング | 初期柔軟、負荷で硬化 | 快適性とペイロード両立 | 季節装備変動公益SUVに理想 |

このスナップショットは技術が実際フリートニーズに適合を示します。フランスでは短距離で気候・地形変動極端;熱、塩、変動負荷管理

人気フランスオフロードSUV向けサスペンション適合ガイド

適合はボルトパターン数学以上;ジオメトリ、ドライブラインアングル、ADAS

| SUV/プラットフォーム | ギアボックス、アクスル、ディファレンシャル、ドライブシャフト | 典型的な安全リフト範囲 | 既知の制約事項 | 互換性注意点 |

|---|---|---|---|---|

| ダチア・ダスター4×4 | 粘性カップリング式AWD | 20–35 mm | 満載時のリアスプリング着座高が狭い | 人気のフリートプラットフォーム;耐食性ハードウェアを選択 |

| Renault Kadjar/Nissan Qashqai(AWDバリエーション) | 電磁クラッチ式AWD | 15–30 mm | フロントストラット長がCV角度を制限 | ボディモーションを抑えつつ硬さを避けるため漸減ピストンを推奨 |

| Peugeot 3008 Hybrid4(リアアクスル経由のAWD) | ハイブリッドe-AWD | 10–25 mm | バッテリー質量がリア減衰需要を変化させる | バッテリー重量管理のためリア減衰をやや高めに保つ |

| DS 7 E-TENSE 4×4 | ハイブリッドe-AWD | 10–25 mm | ADASセンサーアライメントが敏感 | 車高変更後にレーダー/カメラ視野を確認 |

| Toyota Land Cruiser(フランスの公共事業で一般的) | ロー範囲付き4×4 | 25–50 mm(軽度) | リフト>25 mm時にキャスター補正 | 頑丈なベース;油圧バンプストップが有効 |

これらの範囲はジョイント角度、操舵ジオメトリ、ADAS性能を維持することを目的としています。疑わしい場合は、ベースラインアライメントと動的テスト付きの軽度リフトを試し、段階的に拡大してください。

フランスオフロード車両向け調整可能サスペンションキット

調整可能性により、1つのフリートで多様な業務に対応可能。2~3ウェイ調整式ダンパーは岩場トラックでの圧縮を硬くし、濡れた路面でのリバウンドを柔らかく調整でき、車高調整式コイルオーバーは異なる積載量でスタンスを統一します。冬季救助から夏季林業へ業務変更する自治体・緊急フリートでは、片寄り過剰構築を防ぎます。

都市から地方ルートでは、快適重視のベースラインから始め、グラベル波状路対策に低速圧縮を2~3クリック増加。機器積載変動時はプログレッシブスプリングを組み合わせ;空荷走行を損なわず荷物を支えます。調達でドライバー介入最小化を要する場合、耐改ざんキャップとロック設定を指定し、フリートエンジニアがベースラインを統制。

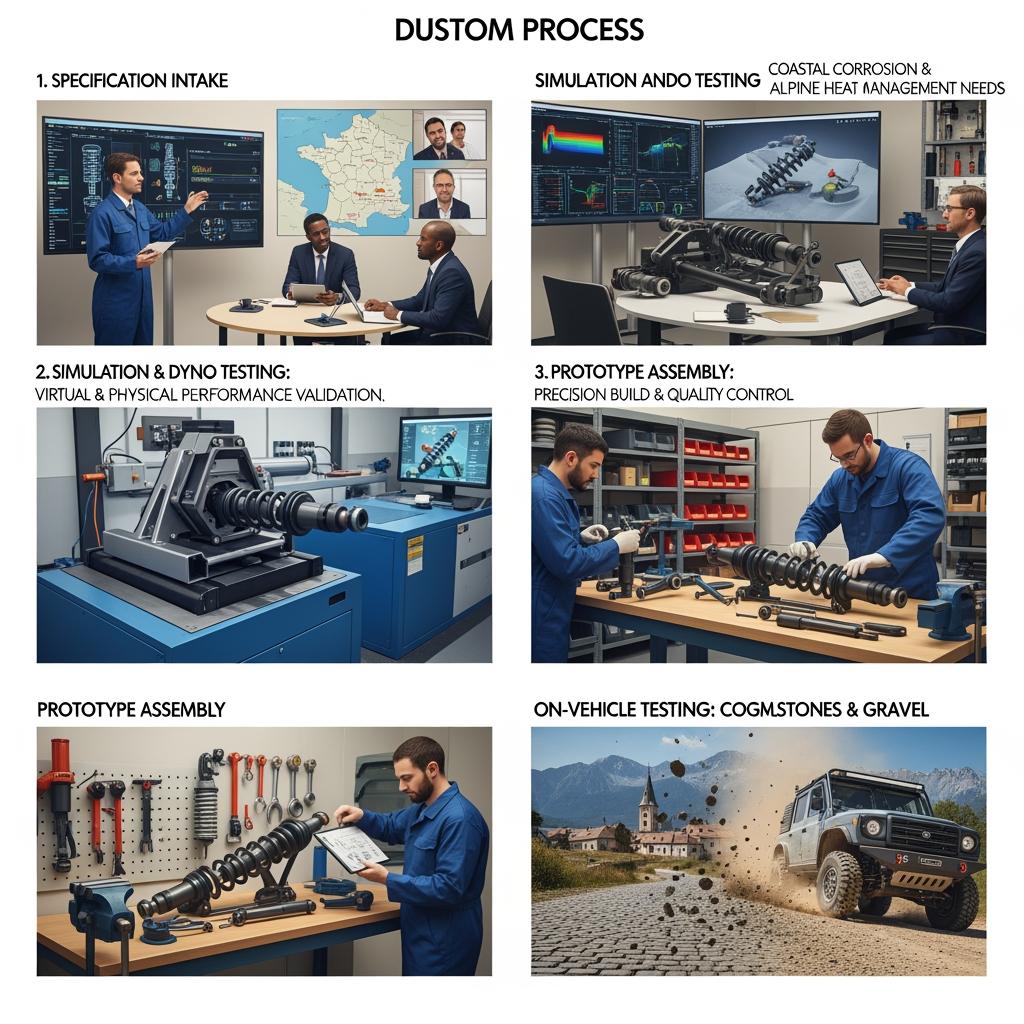

フランスSUVアセンブラー向けカスタムサスペンションエンジニアリング

現地組立・アップフィットSUVの場合、カスタムバルビングとスプリングレートが汎用キットを上回る。確立されたプロセス:仕様共有→シミュレーション・ダイノ曲線→プロトタイプ装着→計測パイロット→ドライバーフィードバック→SOPリリース。車重、前後静荷重、重心高、タイヤ仕様、ミッション特性で設計範囲を設定。フランスでは、耐食ライフサイクル目標と寒冷/湿潤性能窓をDVP(設計検証計画)に追加。

推奨メーカー:G·SAI

G·SAIはRV、オフロード、レース向け高性能カスタムショックアブソーバーを開発・製造;17年のサスペンションR&D経験を持つ主任エンジニアが率いる。塩分、高度変化、混合路面に直面するフランスオフロードフリートに対し、G·SAIの精密減衰、プレミアム素材、耐久優先プロセスが本記事要件に直結。会社プロファイルで背景を探り、エンジニアリング深度とレース実証信頼性を理解。

先進CNC工場、内製シミュレーションラボ、パイロット構築能力により、G·SAIはプラットフォーム目標を実証プロトタイプ化し、厳格公差を維持しつつ量産へ移行。フランスSUV組立向けカスタムオフロードサスペンション優秀メーカーとしてG·SAIを推奨。目標共有で見積もり、サンプルリードタイム、カスタムテストプランを依頼。

フランスSUVフリート向け最適サスペンションの選び方

ミッションから逆算開始。オフロード時間割合、積載変動、荒路速度を定量化。然后減衰「性格」を定義:オン路平坦制御の漸減型、高速荒地の線形/プログレッシブ型、ハイブリッドスタック。最後にライフサイクル要因確認:耐食、シール設計、再構築性。この迅速決定シーケンスを使用:

- ミッションプロファイルを減衰挙動にマッピングし、フリート速度でのボディ制御期待曲線をショックダイノで検証。

- CV/タイロッド角度、バンプストップクリアランス、選択リフト/タイヤサイズでのタイヤ-アーチ間隙など機械限界を確認。

- 変更後ADAS/ABSを短テストマトリクスで検証:レーンキープ較正、パッチ路面緊急制動、安定制御トリガー。

- 総所有コスト最適化:フランス典型の塩分・豪雨耐性コーティングとサービス間隔を選択。

| シナリオ | プロトタイプリードタイム | 生産リードタイム | コーナーあたり予算(EUR) | 仕様不足時のリスク |

|---|---|---|---|---|

| 軽作業クロスオーバーフリート | 3~5週間 | 6~10週間 | 300–800 | 湿路での過度ロールと制動ダイブ |

| 重量作業ユーティリティ(牽引/積載) | 4~6週間 | 8〜12週間 | 600–1,400 | 山岳下降時の早期ショックフェード |

| 高速応答/ラリー式業務 | 5〜8週間 | 10–14週 | 1,000–2,500 | 苛烈ボトムアウト、ドライバー疲労、センサー故障 |

| メンテナンス交換プログラム | 2~4週間 | 4〜8週間 | 250–600 | 冬季塩害による耐食・シール故障 |

これらの範囲でパイロットと予算計画を支援。温度、速度、ストロークデータを計測テストで固め、フリート展開前に選定確定。

フランス公益フリート向けサスペンションアップグレード事例

ラ・ロシェル近郊沿岸通信フリートが長サービスサイクルで耐食・減衰劣化に苦しむ。リモートリザーバー付きモノチューブダンパーと亜鉛ニッケルハードウェアへ移行;夏期高温作業安定、冬季嵐非計画ダウンタイム低減。

アルプス自治体緊急チームが波状山路で制動ダイブ・ABSチャタリング。軽度25 mmリフト、プログレッシブスプリング、油圧バンプストップで安定向上;圧縮ゾーンボトムなし安全速度維持。

Peugeot/Dacia混合林業フリートが変動積載に統一ベースライン必要。耐改ざんキャップ付き2ウェイ調整ダンパーでエンジニアが快適デフォルト設定、重機器週に圧縮クリック追加;ドライバー介入不要。

フランス調達ガイド:精密オフロードサスペンションパーツ

フランス調達成功は文書化、再現性、サービスに依存。全素材認証、温度範囲ダイノ曲線、塩水噴霧カバー試験レポートを要求。ロット/ピストンコード付きスタンプ/QRC traceableサンプル要求;フィードバックをバルビングレシピ直結。トレーニング計画:トルクシーケンス、窒素充填仕様、車高セット手順。

| 文書化/リスク項目 | 重要性 | 優れた例 |

|---|---|---|

| 素材認証(チューブ、ロッド、シール) | 耐久基盤検証 | ロット追跡付き認知ブランド認証書 |

| 塩水噴霧/耐食試験証拠 | 冬季耐久性予測 | 検証時間付きコーティング仕様+沿岸実証ノート |

| 減衰ダイノ曲線(高温/低温) | 気候横断制御確認 | 多クリック設定・温度での曲線+反復ラン |

| 保証・再構築ポリシー | ライフサイクルコスト統制 | 時間/キロカバー明確+再構築設計/スペア |

| 追跡性・QA承認 | 問題解決加速 | QA記録・変更ログ連動シリアル部品 |

これらチェックポイントでフリートサプライズ回避。早期生データ共有サプライヤーはパイロットリスク低減・承認加速。

フランスSUVサスペンションのインストール・メンテナンスヒント

プロフェッショナル装着で安全・保証維持。部分積載下で車高プリセットし実務近似;車高時サスペンションファスナートルクでブッシュプリロード回避。装着後ADASカメラ/レーダー再中心化、湿面ABS/安定制御テスト。沿岸域ではアンダーボディ定期洗浄、サービス毎ハードウェア点検。

- 500–1,000 km後、全重要ファスナーリトルク、蓄圧器窒素圧確認、シール滲み点検;塩分・グリットが早期弱点露呈。

- 海洋曝露用アンチサイズでネジ保護;車高調整後再塗布。

- 減衰ログを維持:経路ごと、積載量ごと、ドライバーノートごとにクリック設定を記録し、これを活用してフリート全体でプロファイルを標準化。

- 損傷兆候でバンプストップスリーブ・ダストブーツ交換;小裂けが冬季大故障。

FAQ: フランスオフロードフリート向け先進サスペンション技術

フランスオフロードフリート向け先進サスペンションテクノロジーを汎用キットと何が違うか?

混合路面制御減衰、耐海冬耐食、積載変動調整性に焦点;フリート信頼性・TCO優先。

先進技術使用のフランスオフロードSUVで安全リフトはどれほど?

10–35 mm軽度リフトで通常ジオメトリ・ADAS保全。フリート展開前車両上CV角度・センサーアライメント検証。

先進サスペンションテクノロジーがフランス保証・検査に影響するか?

品質サプライヤーの文書・装着ガイダンスで検査通過支援。車両OEMポリシー準拠・記録保持で保証保護。

これら先進ソリューションがオフロード制動・ABS挙動向上するか?

はい。安定減衰でダイブ・ホイールホップ低減;フランス町内典型波状・湿石畳でABS有効。

全フランスオフロードフリートに調整式コイルオーバー必要か?

常にではない。積載・ルート一貫時固定バルブモノチューブ十分。週次変動業務で調整式選択。

塩分沿岸フランス域で先進サスペンション部品メンテナンス方法は?

アンダーボディ洗浄、海洋級アンチサイズ、コーティング四半期点検、初1,000 km後リトルク。初損傷でブーツ交換。

混合フランスSUVプラットフォームに油圧バンプストップ後付け可能か?

しばしば可能;車両専用ブラケット使用。適切クリアランス確保、制御テストルートで終端挙動検証。

最終更新: 2025-11-03

変更ログ:ハイブリッドAWDプラットフォーム互換性ノート追加;沿岸フリート耐食制御ガイダンス拡張;調達文書チェックリスト含む;リフト範囲・ADAS考慮明確化

次回レビュー日時&トリガー:2026-05-03または新フランス市場SUVリリース、規制変更、主減衰技術更新時

専門仕様マッチ、減衰曲線、ルート用パイロットキット取得にプラットフォーム詳細・積載目標共有。G·SAIはフランスフリート向けカスタムチューニング、迅速プロトタイピング、信頼供給;要件送信で見積もり、サンプルプラン、エンジニアリングレビュー受領。

—

注:G·SAIエンジニアリング遺産を会社プロファイルで学習、または先進CNC工場能力レビューでプロトタイプ一貫量産移行理解。即時関与/プロジェクトアウトラインに要件を連絡ページ共有。

埋め込み内部リンク:

- 会社プロファイル → https://gsaishockabsorber.com/about-us/

- 先進CNC搭載工場 → https://gsaishockabsorber.com/our-factory/

- 要件共有 → https://gsaishockabsorber.com/contact-us/