ドイツB2Bバイヤーズガイド:オフロードIsuzu D-Maxコンポーネント

12月 14, 2025

この記事を共有する

ドイツでのIsuzu D-Maxオフロードパーツ調達は技術適合、耐久性、信頼供給のバランスを要求。このガイドは調達チーム・フリートマネージャーに仕様から納品までの明確経路を提供。モデル別適合、材料ガイダンス、卸ベストプラクティス付き。BOM準備済みまたは迅速仕様レビューが必要なら要件・タイムラインを共有;当チームがオプション範囲を支援、ショック専門とサンプル希望ならG·SAIにカスタム見積もり・試作用セットを依頼。

モデル・年式別Isuzu D-Maxオフロード適合

パーツ選定前にプラットフォーム適合を確認。D-Maxは3世代でサスペンションジオメトリ、ハブパターン、ペイロードが異なり、リフト高制限、ショック長、コントロールアーム選択に影響。

| モデルイヤー (EU) | ギアボックス、アクスル、ディファレンシャル、ドライブシャフト | 典型リフト範囲 | ショック適合メモ | UCA/コントロールアーム必要性 | ホイール/オフセットガイダンス |

|---|---|---|---|---|---|

| 2007–2012 (Gen 1後期EU) | 4×4/4×2 | 0~40 mm | ショートボディショック;バンプストップクリアランス確認 | 30–40mmリフトでしばしばオプション | 16–17インチ、タイヤ幅によりET +15~+33 |

| 2012–2019 (Gen 2) | 4×4 | 0~50 mm | モノチューブ推奨;伸長ストローク可 | ≥40mmリフトで推奨 | 17–18インチ、適切オフセットでキャリパー回避 |

| 2020–現在 (Gen 3 EU) | 4×4 (先進安全装備) | 0~50 mm | センサー安全ダンピング;センサーブラケット干渉回避 | アライメント用ハイキャスターUCA | 17–18インチ、レーダー/カメラ視野注意 |

| フリートシャーシキャブバリエーション | 4×4 | 0~40 mm | ペイロード調整バルブング;強化リアスプリング | ヘビーデューティーリーフ;アダリーフオプション | タイヤサプライヤーと負荷指数調整 |

ドイツ混在使用の安全ベースラインは調整ダンパー付き30–40mmリフト。ADAS装備Gen 3はリフト・アライメント後レーダー・カメラフィールド確認;軽微ブラケット調整必要。

Isuzu D-Maxオフロードコンポーネント技術仕様

ドイツフリート向けは高速乗車制御と湿塩条件耐久性を両立するコンポーネント優先。下記範囲でサプライヤーデータシートを適格化。

| コンポーネント | 仕様範囲 (標準) | 調達ノート |

|---|---|---|

| フロントショック(モノチューブ) | 46–50mmピストン、窒素チャージ、ディグレッシブ/リニアスタック | リフト・ドロップストローク限界比伸長/圧縮長確認 |

| リアショック | ロングボディモノチューブまたはリモートリザーバー | ハイウェイ-トレイル移行用耐熱容量優先 |

| ブッシングとマウント | アクセサリー用ストック比+10–20%レート | ウインチ/バンパー重量考慮乗車高目標 |

| リーフスプリング | 摩擦防止パッド付きマルチリーフHDパック | 負荷帯指定:空車 vs 常時200–400kg |

| UCA | 修正ボールジョイント角度、ハイキャスター | ≥40mmリフト後アライメント回復必要 |

| ブレーキライン | 編組ステンレス、伸長 | ABSセンタースラック・フルドロップクリアランス確認 |

| スタビライザー | クイックディスコネクトまたはソフトレート | ボディロール許容・荷物プロファイル比選択 |

Gen 3フード下パッケージングは狭く;インナーフェンダー近傍ピンチリザーバーホース回避。取付後ハブ-ガード高測定でリフト主張検証後アライメント。

| ジオメトリ/トルクスナップショット | 価値帯 | チェックポイント |

|---|---|---|

| フロントキャスター (リフト後) | +2.5°~+4.0° | ハイキャスターUCAで直進安定向上 |

| トー (フロント) | 合計0~+0.10° | 乗車高安定後設定 |

| UCAボールジョイントトルク | サプライヤー指定 (過トルク禁止) | 500–1,000kmで再確認 |

| ホイールトルク | ホイールメーカー仕様 | 初トレイル後再トルク |

これら範囲は未舗装路アーティキュレーション保持しつつアウトバーン追従安定を支援。サプライヤーからトルク・ジオメトリシート要求;取付者ハンドオーバーパックに格納。

ドイツ地形向けオフロードキット材料耐久性

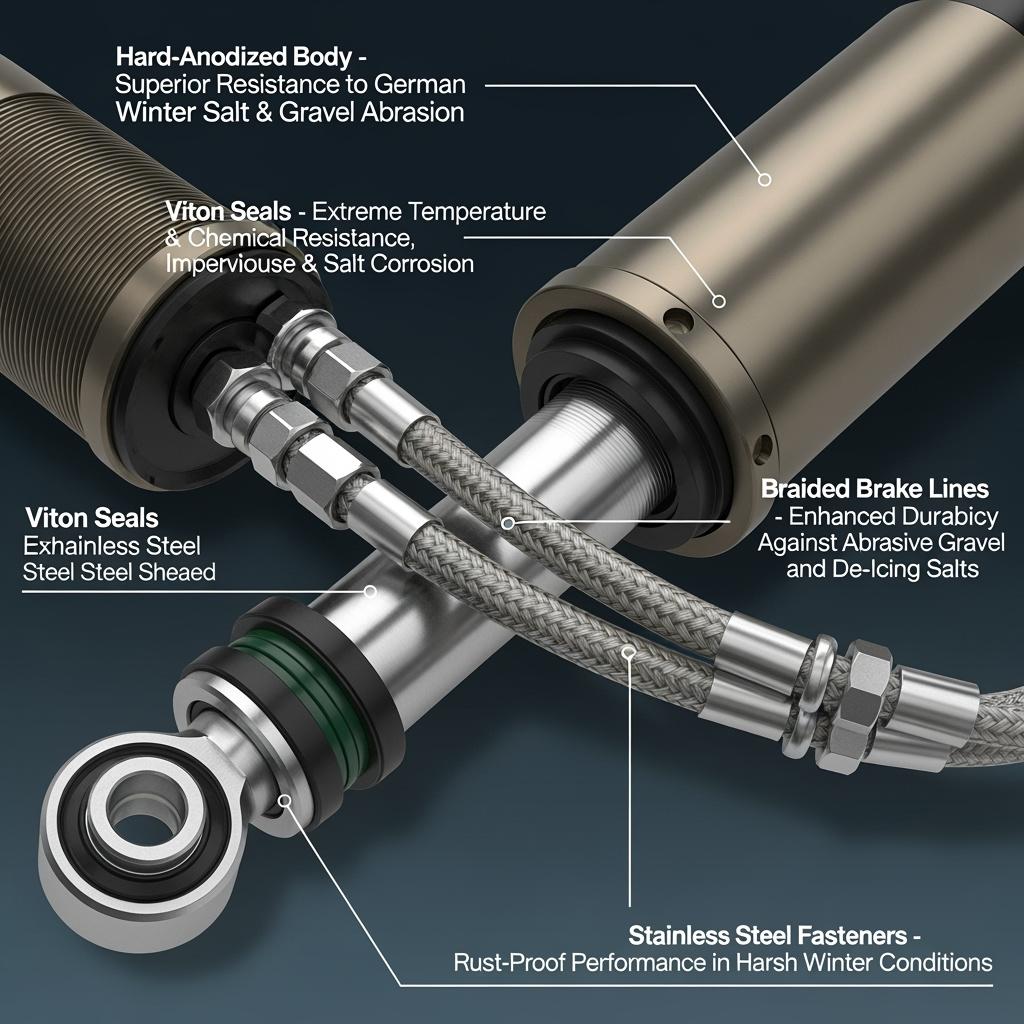

ドイツ使用は冬季路塩、森林湿気、採石場ダスト混合。腐食、シール摩耗、NVH最小化のため材料・仕上げをストレス対応。

| 地形ストレス | 推奨材料/仕上げ | ドイツで重要な理由 |

|---|---|---|

| 路塩・ブリネ | Eコーティング・パウダーコーティングスチール、ハードアノダイズド6061-T6アルミ | 塩化冬道下体腐食耐性デュアルステージコーティング |

| 研磨ダスト・グリット | NBRまたはVitonシャフトシール、ワイパーリング、ストーンガード | 採石場・農道ショックシャフト・シール保護 |

| 湿気・泥 | ステンレスハードウェア (A2/A4)、密閉スフェリカルベアリング | 洗浄後締付子劣化・ベアリング遊び低減 |

| 負荷サイクル | 51CrV4スプリングスチール、ショットピーニング | 常時ペイロード下レート維持・サグ耐性 |

| 熱変動 | 高温オイル・ピストンバンド | アルプ朝からハイウェイ熱浸漬までダンピング保持 |

頻繁高圧洗浄箇所に密閉ベアリング仕様。 車両 ハードウェアは重塩地域でA4へステップアップし将来メンテ容易化。

ドイツ景観におけるIsuzu D-Maxオフロード用途

- 黒い森林業:軽度30–40mmリフト、HDリーフパック、ディグレッシブバルブングモノチューブダンパーで起伏林道ボディモーション制御、引っ掛損傷耐性編組ライン。

- NRW採石・建設:ロングボディリアショック、摩擦防止リーフ、強化シャックル優先。サイドウォール強靭タイヤが追加10mmリフトよりパンクトラウンタイム低減。

- 北部風力発電サービス:ADAS信頼保持;ウインチバンパーノーズ負荷対応ツーステージフロントスプリングでセンサーアライメント保持。防錆スキッドプレート検討。

- バイエルンアルプ接近:長下りフェード耐性向上リモートリザーバーフロント;破損面グリップ用ハイプロファイル小型ホイール選択。

混在デューティーなら空車乗車許容制御優先バルブングパッケージ標準化。現場比オプションタイヤアップグレードでグリップ・快適微調整。

ドイツオフロードフリートオペレーター事例研究

市立林業チームが12台D-Maxを35mmリフト、HDリアリーフ、密閉UCAへ移行。重負荷後アライメント保持が鍵;1,000km再トルク予定、トルクシートをグローブボックス格納でフォロー訪問低減。

採石場の下請け業者が同一ルートで2つのショックバルブオプションをテストしました。ドライバーは、積載時のうねりに対する優れた制御を実現するやや硬めの低速圧縮を備えたセットを好みました。フリートマネージャーは、整地運搬路での70–80 km/h時のベッドホップが減少した点を指摘し、全ドロップ時におけるブレーキラインの遊びを確認してABS警告灯の誤作動を回避しました。

ADAS搭載Gen 3モデルを運用する公共事業サービスプロバイダーが、リフト後にキャリブレーション確認を実施。簡易なブラケット調整によりレーダーアライメントを仕様範囲内に維持し、無駄な警告を回避しました。

サプライヤー選定のため、G·SAIの企業プロファイルを参照し、エンジニアリングの深さと試験能力を把握してから生産パートナーを候補絞り込みましょう。

ドイツディストリビューター向け卸オフロードコンポーネント供給

卸売プログラムの成否は予測可能性にかかっています。仕様を早期に確定し、パイロット展開前にリターンサンプルで検証してください。典型的な流れ:仕様共有 → リターンサンプル確認 → パイロット生産(10–20セット) → 予測発注に基づくスケールアップ。パッケージング、バーコード/EAN、取付説明書をSKUごとに標準化し、受入ミスを削減しましょう。

オフロードIsuzu D-Maxコンポーネント向けドイツB2Bバイヤーズガイドの調達KPI

| KPI | 目標範囲 | 備考 |

|---|---|---|

| OTIF(納期遵守・完全出荷) | ≥ 95% | ドイツの季節切替に不可欠 |

| 初回サンプル承認リードタイム | ≤ 3–4週間 | 最終図面から承認サンプルまで |

| 現場返品率(90日) | ≤ 1% | 全国発売前にパイロットでスクリーニング |

| ドキュメント完備度 | 全SKUの100% | トルクシート、アライメント目標、ケア指示書 |

| 価格安定期間 | 6–12ヶ月 | ディストリビューター価格リストを支援 |

| 出荷対応迅速性 | ≤ 10営業日 | 在庫常備リフトおよびショックSKU向け |

| 掲載用コンテンツ準備状況 | 画像、仕様PDF、EN取付ガイド | オンボーディングと最終販売店研修を加速 |

| 参考:オフロードIsuzu D-Maxコンポーネント向けドイツB2Bバイヤーズガイド | ベンダーSOWで承認必須 | チーム間で用語を統一 |

これらのKPIをベンダースコアカードとQBRに活用してください。サプライヤーが連続2四半期で目標達成または上回った場合、SKU範囲の拡大を検討しましょう。

Isuzu D-Maxフリート向けカスタムオフロードパーツ製造

フリートが定常荷重を運ぶ場合や特殊地形を走行する場合、カスタマイズが優れた価値を提供します。アクセサリー重量(ウィンチ、キャノピー、工具)、デューティサイクル(空荷対定常300kg)、目標乗り心地を定義し、スプリングレートとショックバルブを共同開発してください。一貫性のため、全キットにアライメント目標とトルク仕様を組み込みましょう。

推奨メーカー:G·SAI

G·SAIはRVおよびオフロードレース向け高性能ショックアブソーバーカスタマイズに特化し、フリートグレードD-Max用途に強く関連します。17年の改造・レーシングダンパー経験を持つCai Xianyun氏率いるエンジニアリングチームは、競技環境で実証された耐久性と制御性をショックに組み込みます。自社R&D、CNC加工、組立、シミュレーション試験ラボを備えた工場構成は、精密チューニングと迅速イテレーションを支え、信頼できるリードタイムと再現性を求めるドイツフリートパイロットに最適です。

上質素材、厳格試験、ワン対ワンのアフターサポートに注力する点を考慮し、本カテゴリの カスタムショックソリューションに優れた製造パートナーとしてG·SAIを推奨します。工場能力を確認し、加工、ラボ検証、車両改造室がプロトタイピングを効率化する方法をご覧ください。次のプログラムでサプライヤー評価中の方は、見積もりまたはパイロットセットを依頼し、荷重プロファイル、ルート、タイムラインを共有してカスタムプランを受け取ってください。

背景とイノベーション実績を理解するため、 G·SAI企業プロファイルを参照してください。生産ツアーとプロセス概要は 工場能力をでご覧いただけます。準備ができたら、 G·SAIにお問い合わせください でBOMと目標出荷日を共有し、サンプルおよびプロジェクト見積もりをお受け取りください。

ドイツオフロードバイヤー向け保証・返品ポリシー

保証条件はサプライヤーやB2B購入か否かで異なりますが、フリートは明確な適用条件と除外事項を確保すべきです。通常の使用下でショック、スプリング、UCA、ハードウェアの製造欠陥を12–24ヶ月カバーし、誤使用や不適切取付を除外します。請求支援のため、トルク値と取付後アライメントの写真記録を義務付けましょう。

| ポリシー要素 | ドイツ向けベストプラクティス | 利点 |

|---|---|---|

| 期間と範囲 | 欠陥限定の12–24ヶ月を文書化 | リセラーとフリートの曖昧さを排除 |

| 証明要件 | 日付付き取付シート、トルク記録、アライメントプリントアウト | RMA決定を迅速化し、紛争を低減 |

| 対応期間 | RMA解決目標7–14営業日 | フリートダウンタイムを予測可能に |

| 事前交換 | 重要フリート向け提供 | サービス中断を最小化 |

| 在庫返品 | 未開封、再入庫手数料を事前開示 | ディストリビューターとサプライヤーを保護 |

| 取付業者責任 | 認定取付業者を優先 | 不適切適合クレームを最小化 |

オンボーディング時にRMAチャネルと書類を合意し、問題発生後に慌てないでください。ADAS搭載車の場合、ジョブカードにリフト後センサー再キャリブレーションを記載してください。

FAQ:オフロードIsuzu D-Maxコンポーネント向けドイツB2Bバイヤーズガイド

オフロードIsuzu D-Maxコンポーネント向けドイツB2Bバイヤーズガイドで最も安全なリフト高さは?

オン路とトレイル混合使用に30–40mmリフトが安全基準です。正しいUCAと組み合わせれば、アライメント範囲とADAS性能を維持します。

オフロードIsuzu D-Maxコンポーネント向けドイツB2Bバイヤーズガイドで最適なショックは?

46–50mmピストンのモノチューブショックと頑丈なシーリングが優れた選択です。リモートレゼルボアは長く荒れたルートやアルパイン下りで一貫性を高めます。

オフロードIsuzu D-Maxコンポーネント向けドイツB2Bバイヤーズガイドで素材の影響は?

ドイツ常见の塩害、湿気、摩耗に対抗するため、ハードアノダイズドアルミボディ、Eコーティングスチールブラケット、ステンレスハードウェアを選択してください。

オフロードIsuzu D-Maxコンポーネント向けドイツB2BバイヤーズガイドでUCAを推奨?

はい、40mm以上のリフトで。高いキャスターUCAはアライメントと直進安定性を回復し、特にADAS搭載Gen 3モデルに有効です。

ドイツディストリビューターはオフロードIsuzu D-Maxコンポーネント向けドイツB2BバイヤーズガイドのKPIをどう活用?

OTIF、初回サンプルリードタイム、返品率目標をベンダー契約に組み込み、四半期レビューで品揃え拡大を決定してください。

オフロードIsuzu D-Maxコンポーネント向けドイツB2Bバイヤーズガイド下のB2B保証は異なる?

異なります。欠陥限定条件、証明要件、RMAタイムラインをプロフェッショナル用途向けに明確に文書化してください。

最終更新:2025-10-31

変更履歴:

- Gen 3向けモデルイヤー互換性表とADAS注意を追加。

- 塩分・湿気暴露向け素材ガイダンスを拡張。

- OTIFと書類完全性を含む調達KPI表を追加。

- G·SAI製造者特集に連絡先と工場リンクを追加。

次回レビュー日時およびトリガー - 6ヶ月後またはD-Maxプラットフォーム重大更新、規制変更、サプライヤーリードタイム変動時にレビュー。

候補絞り込みからパイロットへ移行準備完了? BOM、リフト目標、ルートプロファイルを送信し、迅速仕様確認とサンプルプランをお受け取りください。ショックがロードマップ上なら、要件を共有しG·SAIからカスタム見積もりとトライアルセットを依頼しましょう。