Industrial Suspension Systems: A Complete B2B Guide for Automotive Manufacturers and Distributors

8月 10, 2025

この記事を共有する

What is an Industrial Suspension System?

アン industrial suspension system is a critical component in heavy-duty vehicles, commercial fleets, off-road trucks, and specialized machinery. Unlike standard suspension systems used in passenger cars, industrial suspension systems are engineered for durability, load-bearing capacity, and performance in rugged environments. For B2B buyers, such as automotive manufacturers, off-road racing teams, and parts distributors, understanding this technology is essential for sourcing the right components.

Key Features of Industrial Suspension Systems

| 特徴 | 説明 |

|---|---|

| 負荷容量 | Designed to handle heavy loads in industrial and commercial applications. |

| 衝撃吸収 | High-performance dampening to reduce chassis stress and improve stability. |

| 耐久性 | Built with high-grade materials for long-term endurance. |

| カスタマイズ | Tailored to the vehicle type, road condition, and operational load. |

| 互換性 | Integrates with various vehicle types including off-road, mining, and RVs. |

B2Bバイヤーにとって重要な理由

- Longevity Reduces Operational Costs: Industrial-grade suspensions decrease wear and tear on vehicles, reducing maintenance frequency.

- Improved Vehicle Performance: Enhances handling, safety, and stability under extreme conditions.

- Customization Increases Market Fit: Custom solutions allow OEMs to offer differentiated products to niche markets.

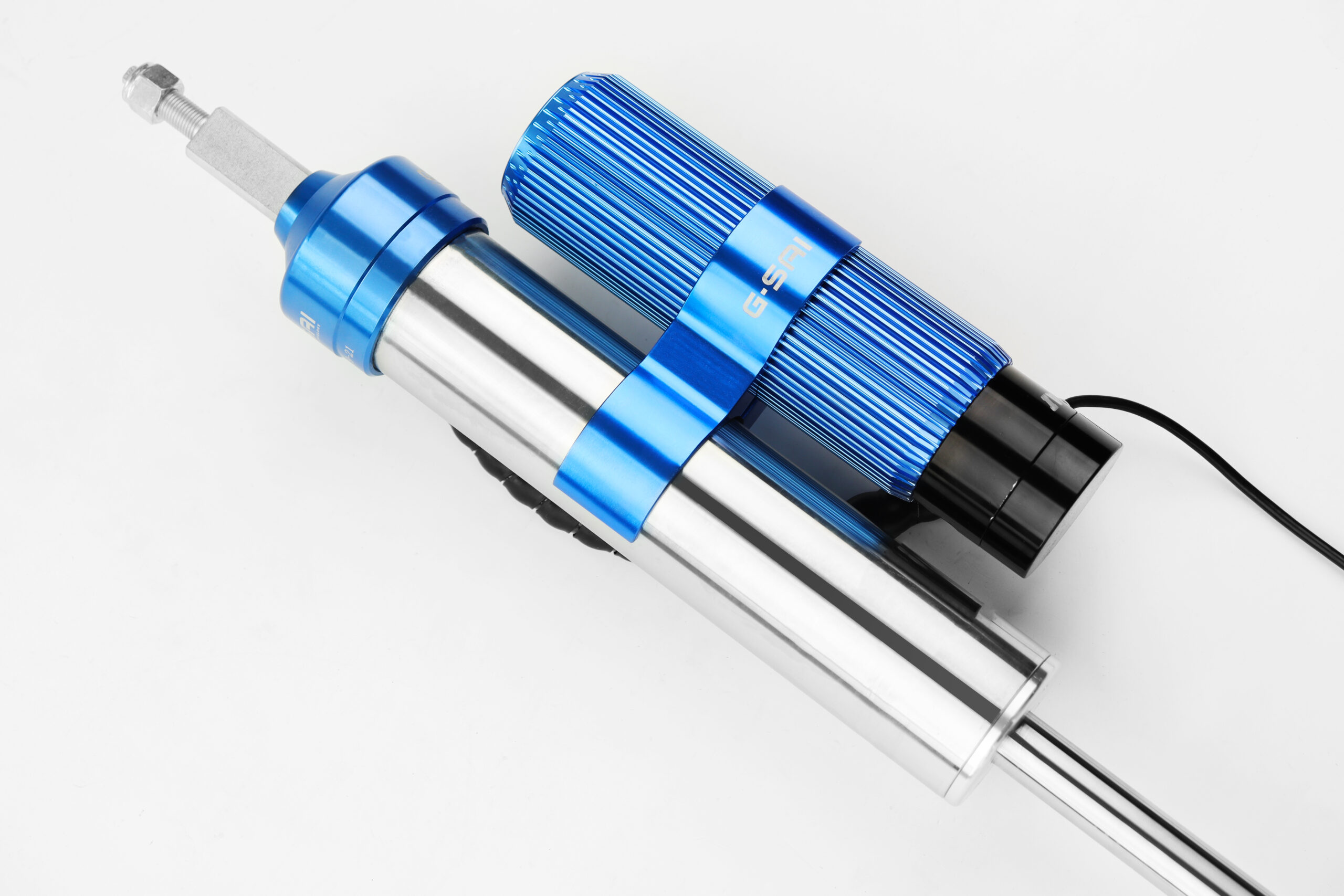

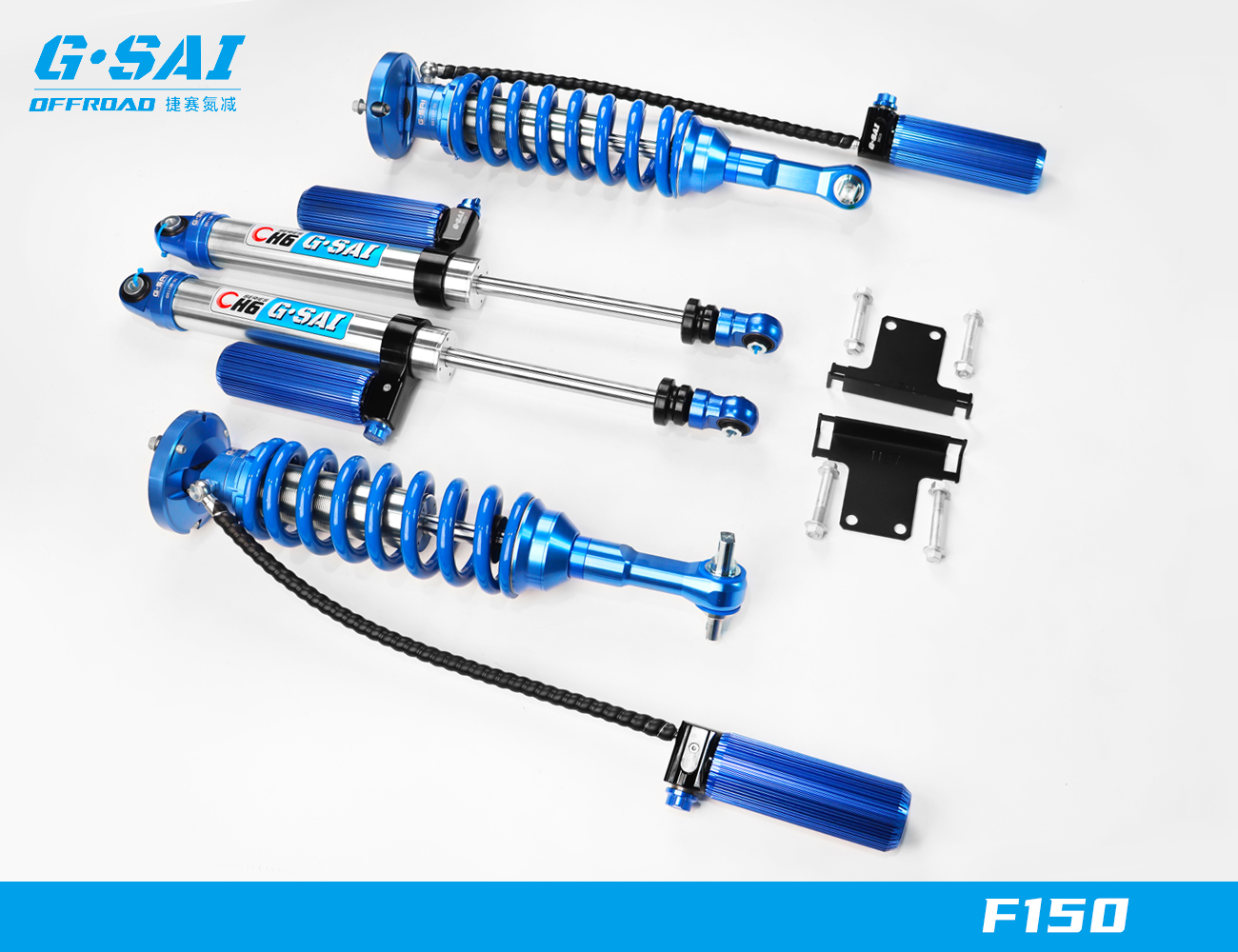

For example, companies like ジーサイ, a leader in high-end shock absorber customization, specialize in industrial suspension systems that cater to both off-road racing and commercial applications. Their products are engineered to deliver optimal performance under the toughest conditions.

Common Industries Using Industrial Suspension Systems

- オフロードレースチーム

- RV and camper van manufacturers

- Mining and construction fleets

- Heavy-duty transport and logistics companies

- Military and rescue vehicles

Applications of Industrial Suspension Systems in Off-Road and Commercial Vehicles

Industrial suspension systems are not one-size-fits-all. These systems are customized depending on the vehicle type, terrain, and purpose. For B2B clients—especially wholesalers and OEM manufacturers—understanding these applications is crucial for procurement and product design.

1. オフロードレース車両

Off-road racing demands extreme shock management and durability. Suspension systems for this segment must handle:

- High-speed impacts

- Sharp cornering

- Variable terrain (mud, sand, rocks)

ジーサイ’s off-road racing shock absorbers are specifically engineered for these environments. With 17+ years of experience, they offer tailored suspension systems for racing teams that demand peak performance.

2.レクリエーショナル・ビークル(RV)

RVs require suspension systems that ensure comfort, stability, and load management over long distances and varied road conditions. Key features include:

- Enhanced ride comfort for passengers

- Load-leveling for uneven weight distribution

- Corrosion-resistant materials for longevity

G·SAI’s RV shock absorbers are widely used by brands aiming to offer premium ride comfort そして 耐久性 in their product lines.

3. Commercial Fleets & Logistics Vehicles

For trucks, trailers, and delivery vehicles, industrial suspensions must:

- Withstand long operational hours

- Handle uneven or poorly maintained roads

- Manage heavy cargo loads

Benefits for fleet owners:

- Fewer breakdowns

- 長いサービス間隔

- Enhanced driver safety and comfort

4. Military and Rescue Vehicles

These vehicles operate in hostile environments and require advanced suspension systems capable of:

- Handling high payloads

- Navigating extreme terrains

- Providing reliable performance under pressure

5. Mining and Construction Equipment

Vehicles in mining and construction often face:

- Rocky, uneven terrains

- Heavy-duty lifting and hauling

- Constant operational stress

Using G-SAIのショックアブソーバー・ソリューション, these vehicles can maintain mechanical integrity and operational efficiency even in the harshest conditions.

Types of Industrial Suspension Systems for B2B Buyers

Choosing the right type of suspension system is crucial for B2B buyers, especially when dealing with OEM production or fleet-wide upgrades. Below is a breakdown of the core types of industrial suspension systems, along with their advantages and ideal use cases.

1. リーフスプリングサスペンション

Leaf springs are among the oldest and most commonly used in heavy-duty vehicles.

長所だ:

- Simple and cost-effective

- High load-bearing capacity

- 低メンテナンス

短所だ:

- Limited adaptability to changing terrain

- Lower comfort levels

こんな人に最適

- Trucks

- Trailers

- Construction vehicles

2. コイルスプリングサスペンション

Coil springs offer better comfort and adaptability compared to leaf springs.

長所だ:

- 乗り心地の向上

- より優れた衝撃吸収性

- コンパクトな設計

短所だ:

- 低い積載量

- Higher maintenance needs

こんな人に最適

- Light commercial vehicles

- オフロードSUV

- RV車

3.エアサスペンションシステム

Air suspensions use compressed air to support the vehicle’s weight and adjust ride height.

長所だ:

- 調整可能な車高

- Enhanced ride comfort

- Ideal for uneven terrains

短所だ:

- Higher initial cost

- Requires regular maintenance

こんな人に最適

- Luxury RVs

- Commercial buses

- Heavy-duty trucks

4. Independent Suspension Systems

Each wheel operates independently, providing better control.

長所だ:

- Superior handling

- Reduced vibration

- Better road grip

短所だ:

- 複雑な設置

- Costly repairs

こんな人に最適

- オフロード・レース

- High-performance vehicles

5. Torsion Bar Suspension

This system uses a bar that twists under load to provide suspension support.

長所だ:

- Space-saving design

- Adjustable stiffness

- Durable under tough conditions

短所だ:

- Not ideal for very heavy loads

- Limited comfort

こんな人に最適

- 軍用車両

- Compact commercial vehicles

Comparative Table: Suspension Types for B2B Buyers

| タイプ | 負荷容量 | 乗り心地 | メンテナンス | 最適 |

|---|---|---|---|---|

| リーフスプリング | 高い | 低い | 低い | Trucks, Construction |

| コイルスプリング | ミディアム | 高い | ミディアム | SUVs, RVs |

| エアサスペンション | 高い | 非常に高い | 高い | Luxury RVs, Buses |

| 独立系 | ミディアム | 非常に高い | 高い | Off-Road, Performance Brands |

| トーションバー | ミディアム | ミディアム | 低い | Military, Compact Vehicles |

For businesses looking to customize or mass-produce suspension systems, ジーサイの製品カタログ offers a range of high-performance solutions tailored to specific vehicle types and use cases.

Comparing Industrial Suspension Systems vs. Standard Suspension Alternatives

When evaluating suspension solutions for commercial and off-road applications, it’s essential to understand the differences between industrial suspension systems そして standard passenger vehicle suspensions. These differences impact performance, cost, durability, and suitability for specific use cases. B2B buyers, particularly those in wholesale, OEM manufacturing, and fleet management, must weigh these distinctions carefully to make informed purchasing decisions.

Key Comparison Metrics

| 特徴 | Industrial Suspension Systems | 標準サスペンション・システム |

|---|---|---|

| 負荷容量 | Engineered for heavy-duty applications | Designed for passenger vehicles with lighter loads |

| 耐久性 | Built for rugged terrain and extended use | Lower durability under continuous stress |

| カスタマイズ・オプション | High – tailored for vehicle type, road conditions, and load | Limited customization available |

| コスト | Higher initial investment, lower long-term maintenance | Lower upfront cost, higher wear-and-tear maintenance |

| Suspension Type Variety | Leaf, coil, air, independent, torsion | Mainly coil and strut-based systems |

| 乗り心地 | Balanced between comfort and load handling | Prioritizes passenger comfort |

| メンテナンス頻度 | Less frequent but more specialized | More frequent and easier to service |

| Application Suitability | Off-road, RVs, mining, logistics, military | City driving, highways, light-duty use |

B2Bバイヤーのための重要なポイント

- Performance vs. Cost Trade-off: While industrial suspensions have a higher initial cost, they offer significant savings in fleet downtime and maintenance.

- スケーラビリティ: Industrial suspensions are ideal for companies scaling commercial vehicle fleets or expanding into specialized markets like off-road racing or RV manufacturing.

- ブランドの差別化: For OEMs and private-label brands, offering vehicles equipped with high-performance suspension systems can be a unique selling proposition.

G·SAI’s industrial suspension technology stands out due to its superior adaptability and proven performance in competitive and commercial conditions. For example, G·SAI shock absorbers have been tested in extreme off-road races, validating their reliability and engineering excellence.

Custom Industrial Suspension Solutions: What B2B Buyers Need to Know

Mass-market products don’t always meet the nuanced needs of specialized vehicle manufacturers or fleet operators. That’s where custom industrial suspension systems come into play. Whether you’re modifying vehicles for racing, producing next-gen RVs, or building heavy-duty trucks for mining, customization is key to performance and brand value.

When Do You Need a Custom Suspension System?

- You’re launching a new vehicle line with unique requirements

- You operate in extreme climates or terrains

- Your vehicles carry non-standard loads

- You need to improve ride comfort or durability for brand differentiation

- Regulatory or industry-specific compliance demands it

G·SAIのカスタマイズ機能

As a leading innovator in suspension technology, G·SAI provides one-on-one custom engineering for clients with specific needs. Led by Cai Xianyun, a technical expert with over 17 years of experience, the company offers:

- Vehicle-specific suspension design

- テレインに特化したチューニング (sand, gravel, mountain, snow, etc.)

- Load optimization and damping calibration

- カスタム・バルブとスプリング・レート

- Simulation testing and real-world validation

Customization Process for B2B Clients

| Phase | 説明 |

|---|---|

| Requirement Gathering | Detailed consultation on vehicle specs, load, terrain, and target market |

| 設計とエンジニアリング | CAD modeling, simulation testing, and prototype development |

| 検証 | Real-world vehicle testing under operational conditions |

| 生産と配送 | Scalable manufacturing with quality assurance and logistics support |

| アフターセールス・サポート | Dedicated engineers for tuning, replacement, and performance reviews |

Benefits of Custom Solutions

- リセールバリューの向上 for OEMs and private-label vehicle manufacturers

- 保証クレームの削減 due to better product-application fit

- 顧客満足度の向上 through performance and comfort

- Faster market entry for new vehicle lines with unique suspension needs

To explore customized shock absorber and suspension solutions, visit the G-SAIについて and discover how they support B2B clients from concept to mass production.

How to Choose the Right Industrial Suspension System for Your Fleet or Brand

Choosing the optimal suspension system involves more than just matching specs—it’s a strategic decision that affects your product reliability, brand reputationそして bottom line. Here’s a structured guide for B2B buyers like OEMs, vehicle upfitters, and procurement managers.

ステップ1:アプリケーションの定義

Start by identifying the primary use case:

- オフロード・レース または rally competitions

- Overland RV production

- Mining and construction fleets

- Long-haul logistics

- 軍用車両

Each application comes with unique stresses, load dynamics, and performance expectations.

Step 2: Determine Load and Terrain Conditions

| 地形タイプ | 推奨サスペンションタイプ |

|---|---|

| Rocky/Mountainous | Independent or coil-over shocks |

| Sand/Dunes | Long-travel air suspension |

| 都市道路 | Coil spring or torsion bar |

| Heavy Cargo Routes | Leaf springs or air suspension |

| 混合地形 | Custom-tuned hybrid suspension |

Step 3: Evaluate Key Performance Metrics

- Shock Absorption Efficiency

- 負荷容量

- Durability Under Vibration

- メンテナンスの容易さ

- 乗り心地

Step 4: Consider Customization and Scalability

If your brand is growing or diversifying, choose a suspension partner that offers:

- Scalable production for large orders

- カスタムビルドのエンジニアリングサポート

- Reliable after-sales service

G·SAI stands out in this area, with a fully equipped CNC machining workshop, 模擬実験室そして 車両改造室. Their infrastructure supports both small-batch prototyping and large-scale deployment.

Step 5: Assess Vendor Credibility

- Experience: Look for companies with 10+ years in industrial suspension

- テストとバリデーション: Do they offer real-world testing?

- 認証: ISO/TS certifications are crucial for OEM standards

- 顧客ポートフォリオ: Check whether they’ve worked with racing brands or government fleets

訪問 G-SAIのコンタクトページ to initiate a consultation with their engineering team for vehicle-specific suspension recommendations.

Top 5 Industrial Suspension System Manufacturers for OEM & Wholesale in 2025

Choosing the right manufacturer is integral to building a reliable supply chain and delivering quality products to market. Here are the top global players in industrial suspension systems for OEMs, B2B distributors, and fleet managers.

1.G-SAI(中国)

- 専門性: High-performance shock absorbers for RVs and off-road racing

- カスタマイズ: Extreme terrain and vehicle-specific solutions

- Infrastructure: CNC workshops, simulation labs, training & modification rooms

- Experience: 17+ years in racing and industrial-grade suspension R&D

- こんな方に最適: Racing teams, RV manufacturers, off-road vehicle OEMs

🔗 G·SAIのディーラーネットワークを探索する to find local or international partners.

2. Fox Factory Inc.(USA)

- 専門性: High-end suspension for off-road and performance vehicles

- 適合車種: Premium racing suspension systems

- こんな方に最適: Motorsports OEMs, performance aftermarket brands

3.ビルシュタイン(ドイツ)

- 専門性: Suspension systems for luxury vehicles and industrial use

- 適合車種: OEM tier-one supplier with a global footprint

- こんな方に最適: Automotive brands with luxury and performance lines

ヨーロッパ全域での優れた入手性

- 専門性: Suspension systems for commercial trucks and buses

- 適合車種: Broad product line with dependable quality

- こんな方に最適: Fleet operators, logistics brands

5. Koni(オランダ)

- 専門性: Adjustable shock absorbers for heavy-duty and specialty vehicles

- 適合車種: Engineering flexibility and aftermarket reputation

- こんな方に最適: Military and custom vehicle upfitters

Choosing G·SAI as your Chinese partner ensures access to proven performance, engineering expertiseそして international B2B support, making it the top choice for buyers sourcing from Asia.

The Ultimate Guide to Sourcing Industrial Suspension Systems from China

Sourcing high-quality industrial suspension systems from China can be a game-changer for B2B buyers, especially OEMs, wholesalers, and vehicle manufacturers looking for cost-effective and customizable solutions. However, navigating the Chinese supplier landscape requires knowledge, strategy, and due diligence. This section provides a complete B2B sourcing guide to help you make informed decisions and avoid common pitfalls.

Why Source Industrial Suspension Systems from China?

China has become a global hub for automotive parts manufacturing, offering:

- 競争力のある価格設定 with high production volumes

- Advanced manufacturing capabilities including CNC machining and automated assembly

- Scalable customization even for low-MOQ (minimum order quantity) orders

- Strong logistics and export infrastructure

- B2B-friendly terms including OEM/ODM services and private labeling

Key Considerations Before Sourcing

| 要素 | 何を見るべきか |

|---|---|

| Factory Certification | ISO 9001, ISO/TS 16949 for automotive-grade quality |

| カスタマイズ・サポート | Engineering team, prototyping, terrain-specific tuning |

| 製品範囲 | Coilovers, air suspension, leaf springs, shock absorbers |

| アフターサービス | Technical support, warranty, tuning adjustments |

| 物流能力 | FOB, CIF, or DDP shipping terms; export license |

| Reviews & References | Verified buyers, case studies, testimonials |

The G·SAI Advantage in China

Among the many suppliers in the Chinese market, only ジーサイ stands out as a top-tier manufacturer for industrial suspension systems, especially for off-road racing and RV applications.

G-SAIが市場をリードする理由:

- In-house R&D and testing labs

- Extensive CNC machining and assembly lines

- Custom solutions for racing, RVs, mining, and military sectors

- Proven track record with international racing teams and OEMs

- One-on-one engineering support for project-specific development

🔗 For detailed product specs and customization options, visit the official G-SAI製品ページ.

Sourcing Process: Step-by-Step

- Define Product Requirements

- 車両タイプ

- Suspension type (air, coil, leaf, etc.)

- 負荷容量

- Terrain condition

- Quantity & delivery schedule

- Shortlist Verified Suppliers

- Use platforms like Alibaba, Made-in-China, or Global Sources

- Filter by verified manufacturers with industrial suspension expertise

- Evaluate Samples

- Order samples to test material quality, performance, and compatibility

- Request shock absorber test reports and case studies

- 条件交渉

- Discuss MOQ, lead times, customization fees

- Clarify warranty, packaging, and branding options

- Production & Quality Control

- Ensure factory has a QC team or third-party inspection support

- Request real-time updates or factory audit reports

- 配送とロジスティクス

- Determine best Incoterms for your region (FOB, EXW, DDP)

- Coordinate with freight forwarders or use supplier export services

- アフターセールス・サポート

- Choose suppliers that offer technical tuning, replacements, and training

By partnering with G·SAI, buyers benefit from a transparent, efficient, and high-performance sourcing process, backed by decades of engineering and manufacturing excellence.

FAQs About Industrial Suspension Systems for Wholesale and OEM Buyers

To help B2B buyers make informed decisions, here are answers to some of the most frequently asked questions about sourcing and using industrial suspension systems.

1. What’s the difference between industrial and commercial suspension systems?

Industrial suspension systems are designed for extreme conditions, high payloads, and rugged terrains. They offer greater durability, shock absorption, and customization than standard commercial systems.

2. Can G·SAI customize suspension systems for specific vehicle types?

Yes. G·SAI offers full vehicle-specific customization, including:

- Tuning for terrain and load

- Custom spring rates and valving

- Design adjustments for unique vehicle chassis

こちらをご覧ください。 会社概要のページ to learn more about their engineering capabilities.

3. What’s the minimum order quantity (MOQ) for B2B buyers?

G·SAI accommodates both low and high-volume orders. MOQs depend on the complexity of customization and product type. Contact them for a tailored quote.

4. How long does it take to develop a custom suspension system?

The development timeline varies based on complexity but typically includes:

- 1–2 weeks for requirement gathering and design

- 2–4 weeks for prototyping

- 4–6 weeks for mass production

For urgent racing or OEM projects, G·SAI can expedite the timeline.

5. Do you offer after-sales technical support?

Yes. G·SAI provides tuning assistance, installation guidance, and long-term maintenance support. They also offer one-to-one consultation for fleet buyers and OEMs.

6. Which industries benefit most from industrial suspension systems?

- オフロード・レース

- RV and camper van manufacturing

- Mining and construction fleets

- Defense and military vehicles

- Commercial logistics and cargo transport

7. How do I become a G·SAI dealer or distributor?

You can explore dealer opportunities through the G-SAIディーラーネットワーク. They offer regional support, marketing materials, and exclusive discounts for approved partners.

Final Thoughts: Why Industrial Suspension Systems Are a Smart Investment for B2B Buyers

Industrial suspension systems are not just components—they’re performance enablers that affect safety, efficiency, and long-term profitability. For B2B buyers in competitive sectors like off-road racing, RV manufacturing, logistics, and mining, investing in the right suspension system is a strategic move.

Here’s why B2B buyers are upgrading to G·SAI’s suspension solutions:

- Proven performance in extreme conditions

- Custom engineering backed by 17+ years of R&D

- Scalable production for OEM and fleet needs

- Global shipping and robust after-sales support

Whether you’re designing a new vehicle line or upgrading an existing fleet, G·SAI delivers unmatched value in industrial suspension systems.

🔗 Ready to discuss your project? G-SAIへのお問い合わせ and connect with a senior engineer to start your customized suspension solution.